| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: L6918D | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

1/35

L6918 L6918A

October 2002

s

OUTPUT CURRENT IN EXCESS OF 100A

s

ULTRA FAST LOAD TRANSIENT RESPONSE

s

REMOTE SENSE BUFFER

s

INTEGRATED 2A GATE DRIVERS

s

5 BIT VID VOLTAGE POSITIONING, VRM 9.0

s

0.6% INTERNAL REFERENCE ACCURACY

s

DIGITAL 2048 STEP SOFT-START

s

OVP & OCP PROTECTIONS

s

Rdson or Rsense CURRENT SENSING

s

1200KHz EFFECTIVE SWITCHING

FREQUENCY, EXTERNALLY ADJUSTABLE

s

POWER GOOD OUTPUT AND INHIBIT

s

PACKAGE: SO28

APPLICATIONS

s

HIGH DENSITY DC-DC FOR SERVERS AND

WORKSTATIONS

s

SUPPLY FOR HIGH CURRENT

MICROPROCESSORS

s

DISTRIBUTED POWER

DESCRIPTION

L6918A is a master device that it has to be combined

with the L6918,slave, realizing a 4-phases topology,

interleaved. The device kit is specifically designed to

provide a high performance/high density DC/DC con-

version for high current microprocessors and distrib-

uted power. Each device implements a dual-phase

step-down controller with a 180∞ phase-shift between

each phase.

A precise 5-bit DAC allows adjusting the output volt-

age from 1.100V to 1.850V with 25mV binary steps.

The high peak current gate drives affords to have

high system switching frequency, typically of

1200KHz, and higher by external adjustement.

The device kit assure a fast protection against OVP,

UVP and OCP. An internal crowbar, by turning on the

low side mosfets, eliminates the need of external pro-

tection. In case of over-current, the system works in

Constant Current mode.

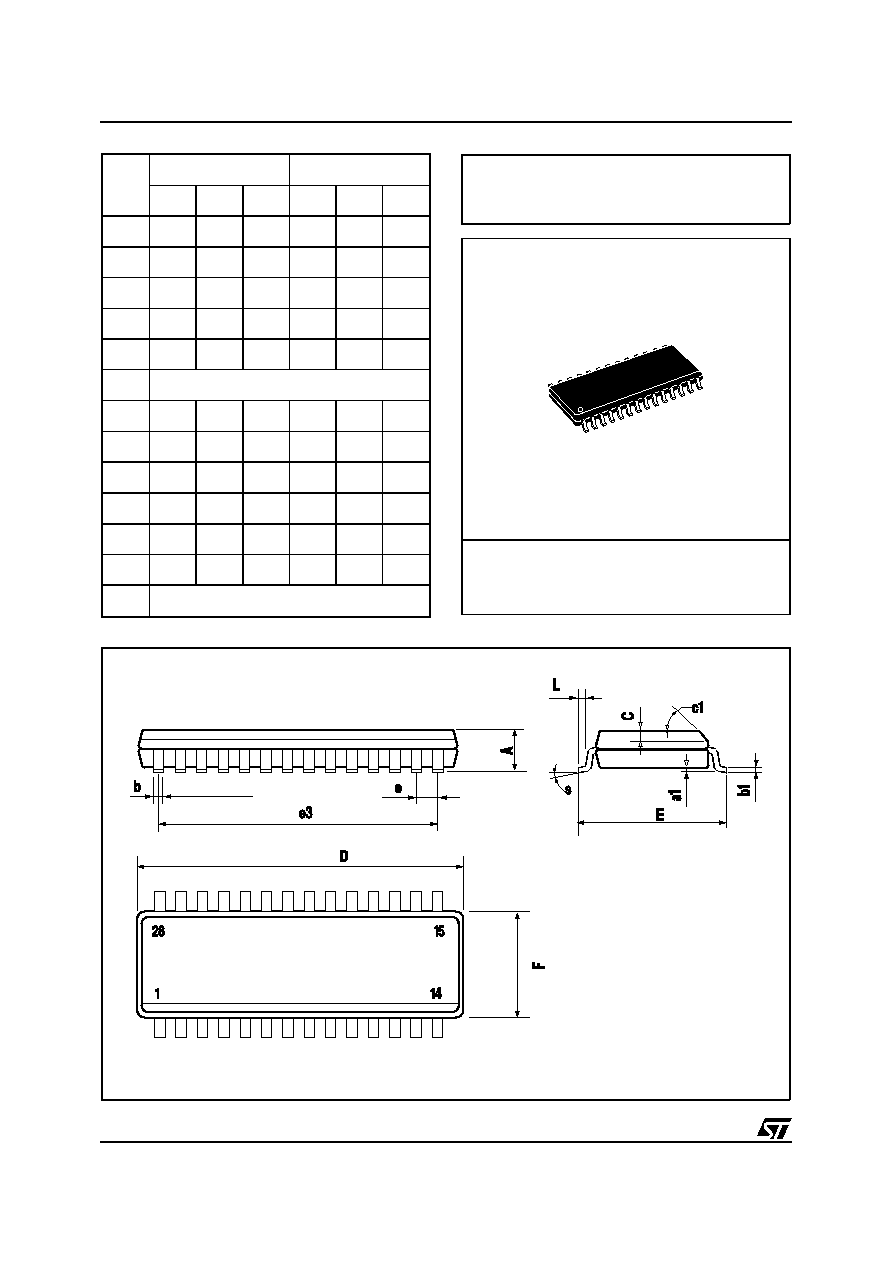

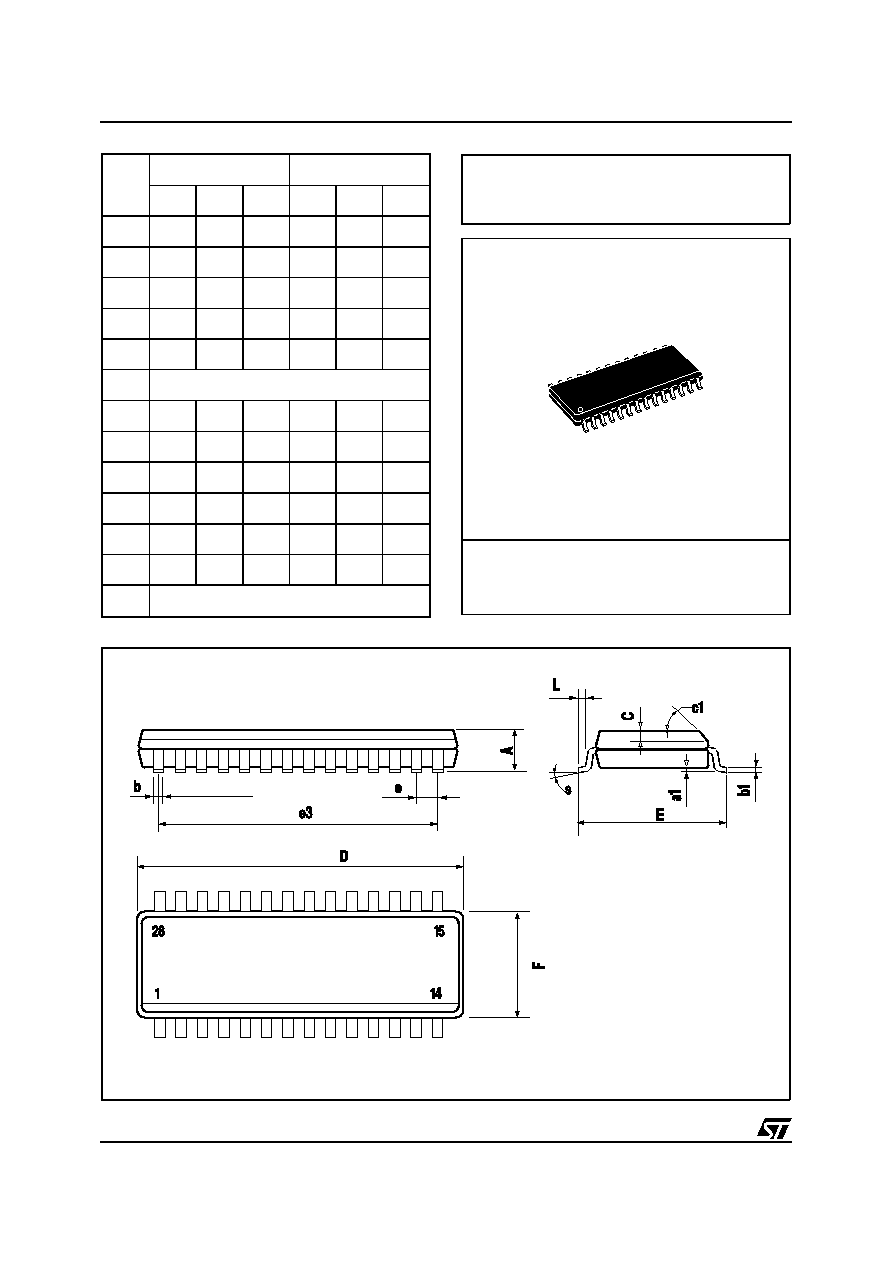

SO28

ORDERING NUMBERS: L6918D, L6918AD

L6918DTR, L6918ADTR

5 BIT PROGRAMMABLE MULTIPHASE CONTROLLER

PIN CONNECTIONS

1

3

2

4

5

6

7

8

9

18

17

16

15

19

20

10

11

12

13

14

24

23

22

21

25

26

27

28

LGATE1

VCCDR

PHASE1

FB

BOOT1

UGATE1

VSEN

VCC

SGND

COMP

ISEN1

PGNDS1

FBR

FBG

SYNC_IN

SLAVE_OK

SYNC / ADJ

VPROG_IN

BOOT2

PGOOD

UGATE2

PHASE2

LGATE2

PGND

OSC / INH / FAULT

ISEN2

PGNDS2

SYNC_OUT

L

6

918

(S

la

v

e

)

1

3

2

4

5

6

7

8

9

18

17

16

15

19

20

10

11

12

13

14

24

23

22

21

25

26

27

28

LGATE1

VCCDR

PHASE1

FB

BOOT1

UGATE1

VPROG_OUT

VCC

SGND

COMP

ISEN1

PGNDS1

SYNC_OUT

SLAVE_OK

VID3

VID2

VID1

VID4

BOOT2

PGOOD

UGATE2

PHASE2

LGATE2

PGND

OSC / INH / FAULT

ISEN2

PGNDS2

VID0

L

6

91

8A

(

Ma

s

t

e

r

)

L6918 L6918A

2/35

L6918A (MASTER) DEVICE BLOCK DIAGRAM

L6918 (SLAVE) DEVICE BLOCK DIAGRAM

UGATE1

CURRENT

READING

I

FB

TO TAL

CUR RENT

CUR

R

E

NT

AV

G

CH1

OCP

DAC

DIGITAL

SO FT- STAR T

LO

G

I

C

P

W

M

AD

AP

T

I

VE

AN

T

I

CR

O

S

S

C

O

ND

U

C

T

I

O

N

CH1 OCP

2

PH

A

SE

O

S

C

I

LLA

T

O

R

P WM1

CU

RRE

N

T

C

O

R

R

E

C

TIO

N

ERROR

AMPLIFIER

LS

LS

HS

Vc c

HS

BOOT1

PHAS E1

LGATE1

ISEN1

PGNDS1

PGND

PGNDS2

ISEN2

LGATE2

PHAS E2

UGATE2

BOOT2

Vcc

COMP

FB

VSEN

VID0

VID1

VID2

VID3

VID4

ROSC / INH

SGND

VCCDR

VCC DR

VCC

LO

G

I

C

A

N

D

P

R

OT

E

C

T

I

ON

S

CH2 OCP

P WM2

CU

RRE

N

T

C

O

R

R

E

C

TIO

N

CH2

OCP

CURRENT

READING

LO

G

I

C

P

W

M

A

D

AP

T

I

VE

AN

T

I

CR

O

S

S

C

O

ND

U

C

T

I

O

N

PGOOD

SYNCH.

CIRCUITRY

SYNC_ OUT

SLAVE_OK

UGATE1

CURRENT

READING

CURRENT

READING

I

FB

TO TAL

CUR RENT

CUR

R

E

NT

AV

G

CH1

OCP

DAC

DIGITAL

SO FT- STAR T

LO

G

I

C

P

W

M

AD

AP

T

I

VE

AN

T

I

CR

O

S

S

C

O

ND

U

C

T

I

O

N

LO

G

I

C

P

W

M

AD

AP

T

I

VE

AN

T

I

CR

O

S

S

C

O

ND

U

C

T

I

O

N

CH1 OCP

2

PH

A

SE

O

S

C

I

LLA

T

O

R

P WM1

CU

RRE

N

T

C

O

R

R

E

C

TIO

N

ERROR

AMPLIFIER

LS

LS

HS

Vc c

HS

BOOT1

PHAS E1

LGATE1

ISEN1

PGNDS1

PGND

PGNDS2

ISEN2

LGATE2

PHAS E2

UGATE2

BOOT2

Vcc

COMP

FB

VSEN

VID0

VID1

VID2

VID3

VID4

ROSC / INH

SGND

VCCDR

VCC DR

VCC

LO

G

I

C

A

N

D

P

R

OT

E

C

T

I

ON

S

CH2 OCP

P WM2

CU

RRE

N

T

C

O

R

R

E

C

TIO

N

CH2

OCP

CURRENT

READING

CURRENT

READING

LO

G

I

C

P

W

M

A

D

AP

T

I

VE

AN

T

I

CR

O

S

S

C

O

ND

U

C

T

I

O

N

LO

G

I

C

P

W

M

A

D

AP

T

I

VE

AN

T

I

CR

O

S

S

C

O

ND

U

C

T

I

O

N

PGOOD

SYNCH.

CIRCUITRY

SYNC_ OUT

SLAVE_OK

UGATE1

CURRENT

READING

I

FB

TO TAL

CUR RENT

CURR

E

N

T

AV

G

CH1

OCP

LO

G

I

C

P

W

M

AD

AP

T

I

V

E

AN

T

I

C

R

O

S

S

CO

N

DUC

T

I

O

N

CH1 OCP

2 P

H

A

S

E

O

S

C

I

LLA

T

O

R

P WM1

CU

RRE

N

T

CO

R

R

E

CTI

O

N

ERROR

AMPLIFIER

LS

LS

HS

Vc c

HS

BOOT1

PHAS E1

LGATE1

ISEN1

PGNDS1

PGND

PGNDS2

ISEN2

LGATE2

PHAS E2

UGATE2

BOOT2

Vcc

COMP

FB

V SEN

ROSC / INH

SGND

VCCDR

VCC DR

VCC

LO

G

I

C

A

N

D

PR

O

T

E

C

T

I

O

N

S

CH2 OCP

P WM2

CU

RRE

N

T

CO

R

R

E

CTI

O

N

CH2

OCP

CURRENT

READING

LO

G

I

C

P

W

M

A

D

AP

T

I

V

E

AN

T

I

C

R

O

S

S

CO

N

DUC

T

I

O

N

PGOOD

SYNC_OUT

SLAV E_OK

RE MOTE

BUFFER

10 k

10 k

1 0k

VSEN

FBG

FBR

1 0k

VPROG_IN

SYNC_I N

SLAVE / ADJ

SYNCH.

CIRCUITRY

UGATE1

CURRENT

READING

CURRENT

READING

I

FB

TO TAL

CUR RENT

CURR

E

N

T

AV

G

CH1

OCP

LO

G

I

C

P

W

M

AD

AP

T

I

V

E

AN

T

I

C

R

O

S

S

CO

N

DUC

T

I

O

N

LO

G

I

C

P

W

M

AD

AP

T

I

V

E

AN

T

I

C

R

O

S

S

CO

N

DUC

T

I

O

N

CH1 OCP

2 P

H

A

S

E

O

S

C

I

LLA

T

O

R

P WM1

CU

RRE

N

T

CO

R

R

E

CTI

O

N

ERROR

AMPLIFIER

LS

LS

HS

Vc c

HS

BOOT1

PHAS E1

LGATE1

ISEN1

PGNDS1

PGND

PGNDS2

ISEN2

LGATE2

PHAS E2

UGATE2

BOOT2

Vcc

COMP

FB

V SEN

ROSC / INH

SGND

VCCDR

VCC DR

VCC

LO

G

I

C

A

N

D

PR

O

T

E

C

T

I

O

N

S

CH2 OCP

P WM2

CU

RRE

N

T

CO

R

R

E

CTI

O

N

CH2

OCP

CURRENT

READING

CURRENT

READING

LO

G

I

C

P

W

M

A

D

AP

T

I

V

E

AN

T

I

C

R

O

S

S

CO

N

DUC

T

I

O

N

LO

G

I

C

P

W

M

A

D

AP

T

I

V

E

AN

T

I

C

R

O

S

S

CO

N

DUC

T

I

O

N

PGOOD

SYNC_OUT

SLAV E_OK

RE MOTE

BUFFER

10 k

10 k

1 0k

VSEN

FBG

FBR

1 0k

VPROG_IN

SYNC_I N

SLAVE / ADJ

SYNCH.

CIRCUITRY

3/35

L6918 L6918A

ABSOLUTE MAXIMUM RATINGS

THERMAL DATA

Symbol

Parameter

Value

Unit

Vcc, V

CCDR

To PGND

15

V

V

BOOT

-V

PHASE

Boot Voltage

15

V

V

UGATE1

-V

PHASE1

V

UGATE2

-V

PHASE2

15

V

LGATE1, PHASE1, LGATE2, PHASE2 to PGND

-0.3 to Vcc+0.3

V

VID0 to VID4

-0.3 to 5

V

All other pins to PGND

-0.3 to 7

V

V

PHASEx

Sustainable Peak Voltage t<20nS @ 600kHz

26

V

Symbol

Parameter

Value

Unit

R

th j-amb

Thermal Resistance Junction to Ambient

60

∞

C / W

T

max

Maximum junction temperature

150

∞

C

T

storage

Storage temperature range

-40 to 150

∞

C

T

j

Junction Temperature Range

0 to 125

∞

C

P

MAX

Max power dissipation at Tamb=25

∞

C

2

W

L6918A (MASTER) PIN FUNCTION

N. Name

Description

1

LGATE1

Channel 1 low side gate driver output.

2

VCCDR

LS Mosfet driver supply. 5V or 12V buses can be used.

3

PHASE1

This pin is connected to the Source of the upper mosfet and provides the return path for the

high side driver of channel 1.

4

UGATE1

Channel 1 high side gate driver output.

5

BOOT1

Channel 1 bootstrap capacitor pin. This pin supplies the high side driver. Connect through a

capacitor to the PHASE1 pin and through a diode to Vcc (cathode vs. boot).

6

VCC

Device supply voltage. The operative supply voltage is 12V.

7

GND

All the internal references are referred to this pin. Connect it to the PCB signal ground.

8

COMP

This pin is connected to the error amplifier output and is used to compensate the control

feedback loop.

9

FB

This pin is connected to the error amplifier inverting input and is used to compensate the

voltage control feedback loop.

A current proportional to the sum of the current sensed in both channel is sourced from this pin

(50

µ

A at full load, 70

µ

A at the Over Current threshold). Connecting a resistor R

FB

between

this pin and VSEN pin allows programming the droop effect.

10

VPROG_OUT Reference voltage output used for voltage regulation.

This pin must be connected together with the slave device VPROG_IN pin.

Filter to SGND with 1nF capacitor (a total 30nF distributed capacitance is allowed).

11

SYNC_OUT

Synchronization output signal. From this pin exits a square - 50% duty cycle - 5Vpp ≠90 deg

phase shifted wave clock signal that the Slave device PLL locks to.

Connect this pin to the Slave SYNC_IN pin.

12

SLAVE_OK

Open-drain input/output used for start-up and to manage protections as shown in the timing

diagram. Internally pulled-up. Connect together with other IC's SLAVE_OK pin. Filter with 1nF

capacitor vs. SGND.

L6918 L6918A

4/35

13

ISEN1

Channel 1 current sense pin. The output current may be sensed across a sense resistor or

across the low-side mosfet RdsON. This pin has to be connected to the low-side mosfet drain

or to the sense resistor through a resistor Rg in order to program the current intervention for

each phase at 140% as follow:

Where 35

µ

A is the current offset information relative to the Over Current condition (offset at

OC threshold minus offset at zero load).The net connecting the pin to the sense point must be

routed as close as possible to the PGNDS1 net in order to couple in common mode any

picked-up noise.

14

PGNDS1

Channel 1 Power Ground sense pin. The net connecting the pin to the sense point must be routed as

close as possible to the ISEN1 net in order to couple in common mode any picked-up noise.

15

PGNDS2

Channel 2 Power Ground sense pin. The net connecting the pin to the sense point must be

routed as close as possible to the ISEN2 net in order to couple in common mode any picked-

up noise.

16

ISEN2

Channel 2 current sense pin. The output current may be sensed across a sense resistor or

across the low-side mosfet Rds

ON.

This pin has to be connected to the low-side mosfet drain

or to the sense resistor through a resistor Rg in order to program the current intervention for

each phase at 140% as follow:

Where 35

µ

A is the current offset information relative to the Over Current condition (offset at

OC threshold minus offset at zero load).

The net connecting the pin to the sense point must be routed as close as possible to the

PGNDS2 net in order to couple in common mode any picked-up noise.

17

OSC/INH

FAULT

Oscillator switching frequency pin. Connecting an external resistor from this pin to GND, the

external frequency is increased according to the equation:

Connecting a resistor from this pin to Vcc (12V), the switching frequency is reduced according

to the equation:

If the pin is not connected, the switching frequency is 300KHz.

Forcing the pin to a voltage lower than 0.8V, the device stop operation and enter the inhibit

state; all mosfets are turned OFF.

18

to

22

VID0-4

Voltage Identification pins. These input are internally pulled-up and TTL compatible. They are

used to program the output voltage as specified in Table 1 and to set the over voltage and

power good thresholds.

Connect to GND to program a `0' while leave floating to program a `1'.

23

PGOOD

This pin is an open collector output and is pulled low if the output voltage is not within the

above specified thresholds. It must be connected with the Slave's PGOOD pin.

If not used may be left floating.

24

BOOT2

Channel 2 bootstrap capacitor pin. This pin supplies the high side driver. Connect through a

capacitor to the PHASE2 pin and through a diode to Vcc (cathode vs. boot).

25

UGATE2

Channel 2 high side gate driver output.

26

PHASE2

This pin is connected to the source of the upper mosfet and provides the return path for the

high side driver of channel 2.

27

LGATE2

Channel 2 low side gate driver output.

28

PGND

Power ground pin. This pin is common to both sections and it must be connected through the closest

path to the low side mosfets source pins in order to reduce the noise injection into the device.

L6918A (MASTER) PIN FUNCTION (continued)

N. Name

Description

I

O C Px

35

µ

A R

g

R

s ens e

--------------------------

=

I

O C Px

35

µ

A R

g

R

s ens e

--------------------------

=

f

S

300KHz

14.82 10

6

R

O SC

K

(

)

-----------------------------

+

=

f

S

300KHz

12.91 10

7

R

O SC

K

(

)

-----------------------------

+

=

5/35

L6918 L6918A

L6918 (SLAVE) PIN FUNCTION

N.

Name

Description

1

LGATE1

Channel 1 low side gate driver output.

2

VCCDR

LS Mosfet driver supply. 5V or 12V buses can be used.

3

PHASE1

This pin is connected to the Source of the upper mosfet and provides the return path for the

high side driver of channel 1.

4

UGATE1

Channel 1 high side gate driver output.

5

BOOT1

Channel 1 bootstrap capacitor pin. This pin supplies the high side driver. Connect through a

capacitor to the PHASE1 pin and through a diode to Vcc (cathode vs. boot).

6

VCC

Device supply voltage. The operative supply voltage is 12V.

7

GND

All the internal references are referred to this pin. Connect it to the PCB signal ground.

8

COMP

This pin is connected to the error amplifier output and is used to compensate the control

feedback loop.

9

FB

This pin is connected to the error amplifier inverting input and is used to compensate the

voltage control feedback loop.

A current proportional to the sum of the current sensed in both channel is sourced from this pin

(50

µ

A at full load, 70

µ

A at the Over Current threshold). Connecting a resistor R

FB

between this

pin and VSEN pin allows programming the droop effect.

10

VSEN

Connected to the output voltage it is able to manage Over & Under-voltage conditions and the

PGOOD signal. It is internally connected with the output of the Remote Sense Buffer for

Remote Sense of the regulated voltage.

If no Remote Sense is implemented, connect it directly to the regulated voltage in order to

manage OVP, UVP and PGOOD.

11

FBR

Remote sense buffer non-inverting input. It has to be connected to the positive side of the load

to perform a remote sense.

If no remote sense is implemented, connect directly to the output voltage (in this case connect

also the VSEN pin directly to the output regulated voltage).

12

FBG

Remote sense buffer inverting input. It has to be connected to the negative side of the load to

perform a remote sense.

Pull-down to ground if no remote sense is implemented.

13

ISEN1

Channel 1 current sense pin. The output current may be sensed across a sense resistor or

across the low-side mosfet Rds

ON.

This pin has to be connected to the low-side mosfet drain or

to the sense resistor through a resistor Rg in order to program the current intervention for each

phase at 140% as follow:

Where 35

µ

A is the current offset information relative to the Over Current condition (offset at

OC threshold minus offset at zero load).

The net connecting the pin to the sense point must be routed as close as possible to the

PGNDS1 net in order to couple in common mode any picked-up noise.

14

PGNDS1

Channel 1 Power Ground sense pin. The net connecting the pin to the sense point must be

routed as close as possible to the ISEN1 net in order to couple in common mode any picked-up

noise.

15

PGNDS2

Channel 2 Power Ground sense pin. The net connecting the pin to the sense point must be

routed as close as possible to the ISEN2 net in order to couple in common mode any picked-up

noise.

I

O C Px

35

µ

A R

g

R

s ens e

--------------------------

=

L6918 L6918A

6/35

16

ISEN2

Channel 2 current sense pin. The output current may be sensed across a sense resistor or

across the low-side mosfet Rds

ON.

This pin has to be connected to the low-side mosfet drain or

to the sense resistor through a resistor Rg in order to program the current intervention for each

phase at 140% as follow:

Where 35

µ

A is the current offset information relative to the Over Current condition (offset at

OC threshold minus offset at zero load).

The net connecting the pin to the sense point must be routed as close as possible to the

PGNDS2 net in order to couple in common mode any picked-up noise.

17

OSC/INH

FAULT

Oscillator switching frequency pin. Connecting an external resistor from this pin to GND, the

external frequency is increased according to the equation:

Connecting a resistor from this pin to Vcc (12V), the switching frequency is reduced according

to the equation:

If the pin is not connected, the switching frequency is 300KHz.

Forcing the pin to a voltage lower than 0.8V, the device stops operation and enters the inhibit

state; all mosfets are turned OFF.

The pin is forced high when an over voltage is detected. This condition is latched; to recover it

is necessary turn off and on VCC.

18

SYNC_OUT

Output synchronization signal. A 60

∞

phase shift signal exits when the device works as a Slave

while no signal exits when the device works as an adjustable.

19

SYNC / ADJ

Slave or Adjustable operation.

Connecting this pin to GND the device becomes an adjustable two-phase controller using an

external reference for its regulation. No soft start is implemented in this condition, so it must be

performed with external circuitry. The device switches using its internal oscillator according to

the frequency set by R

OSC

.

Leaving this pin floating, the device works as a Slave two-phase controller. It uses the

reference sourced from the master device and an internal PLL locks the synchronization signal

sourced from the master device.

20

SLAVE_OK

Open-drain output used for start-up and to manage protections as shown in the timing diagram. Internally

pulled-up. Connect together with other IC's SLAVE_OK pin. Filter with 1nF capacitor vs. SGND.

21

SYNC_IN

Synchronization input signal locked during the slave operation. Connect to the master SYNC_OUT pin.

22

VPROG_IN

Reference voltage input used for voltage regulation.

This pin must be connected together with the other's slave (if present) to the VPROG_OUT pin

of the master device.

Filter to SGND with 1nF capacitor (a total 30nF distributed capacitance is allowed).

If the device works as an Adjustable (SYNC/ADJ to GND), this is the reference used for the regulation.

23

PGOOD

This pin is an open collector output and is pulled low if the output voltage is not within the

above specified thresholds. It must be connected with the master's PGOOD pin.

If not used may be left floating.

L6918 (SLAVE) PIN FUNCTION (continued)

N.

Name

Description

I

O C Px

35

µ

A R

g

R

s ens e

--------------------------

=

f

S

300KHz

14.82 10

6

R

O SC

K

(

)

-----------------------------

+

=

f

S

300KHz

12.91 10

7

R

O SC

K

(

)

-----------------------------

+

=

7/35

L6918 L6918A

24

BOOT2

Channel 2 bootstrap capacitor pin. This pin supplies the high side driver. Connect through a

capacitor to the PHASE2 pin and through a diode to Vcc (cathode vs. boot).

25

UGATE2

Channel 2 high side gate driver output.

26

PHASE2

This pin is connected to the Source of the upper mosfet and provides the return path for the

high side driver of channel 2.

27

LGATE2

Channel 2 low side gate driver output.

28

PGND

Power ground pin. This pin is common to both sections and it must be connected through the closest

path to the low side mosfets source pins in order to reduce the noise injection into the device.

ELECTRICAL CHARACTERISTCS

(Vcc=12V±10%, TJ=0∞C to 70∞C unless otherwise specified)

Symbol

Parameter

Test Condition

Min.

Typ.

Max.

Unit

Vcc SUPPLY CURRENT

I

CC

Vcc supply current

HGATEx and LGATEx open

V

CCDR

=V

BOOT

=12V

7.5

10

12.5

mA

I

CCDR

V

CCDR

supply current

LGATEx open; V

CCDR

=12V

2

3

4

mA

I

BOOTx

Boot supply current

HGATEx open; PHASEx to

PGND

V

CC

=V

BOOT

=12V

0.5

1

1.5

mA

POWER-ON

Turn-On V

CC

threshold

V

CC

Rising; V

CCDR

=5V

7.8

9

10.2

V

Turn-Off V

CC

threshold

V

CC

Falling; V

CCDR

=5V

6.5

7.5

8.5

V

Turn-On V

CCDR

Threshold

V

CCDR

Rising; V

CC

=12V

4.2

4.4

4.6

V

Turn-Off V

CCDR

Threshold

V

CCDR

Falling; V

CC

=12V

4.0

4.2

4.4

V

OSCILLATOR AND INHIBIT

f

OSC

Initial Accuracy

OSC = OPEN

OSC = OPEN; Tj=0

∞

C to 125

∞

C

278

270

300

322

330

kHz

kHz

f

OSC,Rosc

Total Accuracy

R

T

to GND=74k

450

500

550

kHz

Vosc

Ramp Amplitude

2

V

d

MAX

Maximum duty cycle

OSC = OPEN

45

50

-

%

INH

Inhibit threshold

I

SINK

=5mA

0.8

0.85

0.9

V

REFERENCE AND DAC only for L6918A (MASTER)

V

PROG_OUT

Reference Voltage

Accuracy

VID0 to VID4 see Table1

-0.6

-

0.6

%

I

DAC

VID pull-up Current

VIDx = GND

4

5

6

µ

A

VID pull-up Voltage

VIDx = OPEN

3.1

-

3.4

V

ERROR AMPLIFIER

DC Gain

80

dB

SR

Slew-Rate

COMP=10pF

15

V/

µ

S

Offset

-7

7

mV

DIFFERENTIAL AMPLIFIER (REMOTE BUFFER) only for L6918 (SLAVE)

DC Gain

1

V/V

CMRR

Common Mode Rejection Ratio

40

dB

Input Offset

FBR=1.100V to1.850V;

FBG=GND

-12

12

mV

DIFFERENTIAL CURRENT SENSING

I

ISEN1

,

I

ISEN2

Bias Current

I

LOAD

= 0%

45

50

55

µ

A

L6918 (SLAVE) PIN FUNCTION (continued)

N.

Name

Description

L6918 L6918A

8/35

Table 1. VID Settings (only for L6918A)

I

PGNDSx

Bias Current

45

50

55

µ

A

I

ISEN1

,

I

ISEN2

Bias Current at

Over Current Threshold

80

85

90

µ

A

I

FB

Active Droop Current

I

LOAD

= 0

0

1

µ

A

I

LOAD

= 100%

47.5

50

52.5

µ

A

GATE DRIVERS

t

RISE HGATE

High Side

Rise Time

V

BOOTx

-V

PHASEx

=10V;

C

HGATEx

to PHASEx=3.3nF

15

30

nS

I

HGATEx

High Side

Source Current

V

BOOTx

-V

PHASEx

=10V 2

A

R

HGATEx

High Side

Sink Resistance

V

BOOTx

-V

PHASEx

=12V;

1.5

2

2.5

t

RISE LGATE

Low Side

Rise Time

V

CCDR

=10V;

C

LGATEx

to PGNDx=5.6nF

30

55

nS

I

LGATEx

Low Side

Source Current

V

CCDR

=10V

1.8

A

R

LGATEx

Low Side

Sink Resistance

V

CCDR

=12V

0.7

1.1

1.5

PROTECTIONS

PGOOD

Upper Threshold

(V

SEN

/ VPROG_IN)

V

SEN

Rising

109

112

115

%

PGOOD

Lower Threshold

(V

SEN

/ VPROG_IN)

V

SEN

Falling

87

90

93

%

OVP

Over Voltage Threshold

(V

SEN

/ VPROG_IN)

V

SEN

Rising

114

117

120

%

UVP

Under Voltage Trip

(V

SEN

/ VPROG_IN)

V

SEN

Falling

55

60

65

%

V

PGOOD

PGOOD Voltage Low

I

PGOOD

= -4mA

0.3

0.4

0.5

V

VID4 VID3

VID2

VID1

VID0

Output

Voltage (V)

VID4 VID3

VID2

VID1

VID0

Output

Voltage (V)

0

0

0

0

0

1.850

1

0

0

0

0

1.450

0

0

0

0

1

1.825

1

0

0

0

1

1.425

0

0

0

1

0

1.800

1

0

0

1

0

1.400

0

0

0

1

1

1.775

1

0

0

1

1

1.375

0

0

1

0

0

1.750

1

0

1

0

0

1.350

0

0

1

0

1

1.725

1

0

1

0

1

1.325

0

0

1

1

0

1.700

1

0

1

1

0

1.300

0

0

1

1

1

1.675

1

0

1

1

1

1.275

0

1

0

0

0

1.650

1

1

0

0

0

1.250

0

1

0

0

1

1.625

1

1

0

0

1

1.225

0

1

0

1

0

1.600

1

1

0

1

0

1.200

0

1

0

1

1

1.575

1

1

0

1

1

1.175

0

1

1

0

0

1.550

1

1

1

0

0

1.150

0

1

1

0

1

1.525

1

1

1

0

1

1.125

0

1

1

1

0

1.500

1

1

1

1

0

1.100

0

1

1

1

1

1.475

1

1

1

1

1

Shutdown

ELECTRICAL CHARACTERISTCS (continued)

(Vcc=12V±10%, TJ=0∞C to 70∞C unless otherwise specified)

Symbol

Parameter

Test Condition

Min.

Typ.

Max.

Unit

9/35

L6918 L6918A

FOUR PHASE REFERENCE SCHEMATICS

PGOOD

PGND

PGNDS2

ISEN2

LGATE2

PHASE2

UGATE2

BOOT2

VCC

SGND

OSC / INH

VID0

VID1

VID2

VID3

VID4

ISEN1

LGATE1

PHASE1

UGATE1

BOOT1

VCCDR

6

24

25

26

27

16

15

2

5

4

3

1

13

11

22

21

20

18

19

7

28

23

10

12

VPROG_OUT

SLAVE OK

17

Rg

Rg

LS2

HS2

L2

C

OUT

S1

S0

S3

S2

S4

Rg

Rg

LS1

L1

HS1

Vin

GNDin

PGOOD

Master

L6918A

C

IN

FBG

PGND

PGNDS2

ISEN2

LGATE2

PHASE2

UGATE2

BOOT2

VCC

PGOOD

SYNC_OUT

SYNC/ADJ

PGNDS1

ISEN1

LGATE1

PHASE1

UGATE1

BOOT1

VCCDR

6

24

25

26

27

16

15

2

5

4

3

1

13

14

22

21

20

18

19

28

23

11

12

VPROG_IN

SLAVE_OK

SGND

OSC / INH

7

17

Rg

Rg

LS4

HS4

L4

R2

Rg

Rg

LS3

L3

HS3

Slave

L6918

FB

COMP

9

8

R

F

C

F

PGNDS1

VSEN

FB

COMP

10

9

8

R

F

C

F

R

F

FBR

S

Y

NC_

O

U

T

S

Y

NC_

I

N

R

FB

14

To Slave's

PGOOD

CPU

L6918 L6918A

10/35

DEVICES DESCRIPTION

The devices are integrated circuit realized in BCD technology. They provide, in kit, a complete control logic and

protections sets for a high performance four-phases step-down DC-DC converter optimized for microprocessors

supply and High Density DC-DC converters. They are designed to drive N-Channel mosfets in an interleaved

four-phase synchronous-rectified buck topology. Each controller provides a 180 deg phase shift between its two

phases and a 90deg phase-shifted synchronization signal is passed from the master to the slave controller that

locks the signal through a PLL. The resulting four-phases converter synchronized together results in a 90 deg

phase shift on each phase, allowing a consistent reduction of the input capacitors ripple current, minimizing also

the size and the power losses. The output voltage of the converter can be precisely regulated, programming the

master's VID pins, from 1.100V to 1.850V with 25mV binary steps. The reference for the regulation is passed

from the master device to the slave device through apposite pin likewise the synchronization signal. Each device

provides an average current-mode control with fast transient response. They include a 300kHz free-running os-

cillator externally adjustable up to 600kHz, realized in order to multiply by 4 times the equivalent system fre-

quency. The error amplifier features a 15MHz gain-bandwidth product and 10V/

µ

s slew rate that permits high

converter bandwidth for fast transient performances. Current information is read in all the devices across the

lower mosfets R

DSON

or across a sense resistor in fully differential mode. The current information corrects the

PWM output in order to equalize the average current carried the two phases of each device. Current sharing

between the two phases of each device is then limited at ±10% over static and dynamic conditions. Current

sharing between devices is assured by the droop function. The device protects against over-current, with an

OCP threshold for each phase, entering in constant current mode. Since the current is read across the low side

mosfets, the constant current keeps constant the bottom of the inductors current triangular waveform. When an

under voltage is detected the Slave device latches. The Slave device also perform an over voltage protection

that disable immediately both devices turning ON the lower driver and driving high the FAULT pin. Over Load

condition are transmitted from the Slave device(s) to the master through the SLAVE_OK line.

MASTER - SLAVE INTERACTIONS

Figure 1. Four Phase connection with L6918 family

Master and slave devices are connected together in order to realize four-phase high performance step-down

DC/DC converter. Four-phase converter is implemented using L6918A master and one L6918 slave devices as

shown in figure 1.

A communication bus is implemented among all the controllers involved in the regulation. This bus consists in

the following lines:

≠ Reference (VPROG_IN / VPROG_OUT pins): Unidirectional line.

The devices share the reference for the regulation. The reference is programmed through the master

device VID pins. It exits from the master through the VPROG_OUT pin and enters the slave device

through the VPROG_IN pin(s). Filter externally with at least 1nF capacitor.

L

6

9

1

8

A

L

6

9

1

8

VID 9.0

S YNC_OUT

V PROG_OUT

S LAV E_OK

OS C

S YNC_IN

V PROG_IN

S LAV E_OK

OS C

S YNC_OUT

SL

A

VE C

O

N

T

R

O

L

L

E

R

M

A

ST

ER

C

O

N

T

R

O

L

L

E

R

P GOOD

P GOOD

11/35

L6918 L6918A

≠ Clock Signal (SYNC_IN / SYNC_OUT pins): Unidirectional line.

A synchronization signal exits from the Master device through the SYNC_OUT pin with 90 deg phase-

shift and enters the Slave device through the SYNC_IN pin. The Slave device locks that signal

through an internal PLL for its regulation. An auxiliary synchronization signal exits from the Slave

through the SYNC_OUT.

≠ SLAVE_OK Bus (SLAVE_OK pins): Bi-directional line.

While the supply voltages are increasing, this line is hold to GND by all the devices. The Slave device

sets this line free (internally 5V pulled-up) when it is ready for the Soft-Start. After that this line is

freed, the Master device starts the Soft Start (for further details about Soft-Start, see the relevant sec-

tion).

During normal operation, the line is pulled low by the Slave device if an Over / Under voltage is de-

tected (See relevant section).

≠ PGOOD pins:

PGOOD pins are connected together and pulled-up. During Soft-Start, the master device hold down

this line while during normal regulation the slave device de-assert the line if PGOOD has been lost.

Connections between the devices are shown in figure 1.

OSCILLATOR

The devices have been designed in order to operate on each phase at the same switching frequency of the in-

ternal oscillator. So, input and output resulting frequencies are four times bigger.

The oscillator is present in all the devices. Since the Master oscillator sets the main frequency for the regulation,

the Slave oscillator gives an offset to the Slave's PLL. In this way the PLL is able to lock the synchronization

signal that enters from its SYNC_IN pin; it is able to recover up to ±15% offset in the synchronization signal fre-

quency. It is then necessary to program the switching frequency for all the devices involved in the multi-phase

conversion as follow.

The switching frequency is internally fixed to 300kHz. The internal oscillator generates the triangular waveform

for the PWM charging and discharging with a constant current an internal capacitor. The current delivered to the

oscillator is typically 25

µ

A (Fsw = 300KHz) and may be varied using an external resistor (R

OSC

) connected be-

tween OSC pin and GND or Vcc. Since the OSC pin is maintained at fixed voltage (typ. 1.235V), the frequency

is varied proportionally to the current sunk (forced) from (into) the pin considering the internal gain of 12KHz/

µ

A.

In particular connecting it to GND the frequency is increased (current is sunk from the pin), while connecting

ROSC to Vcc=12V the frequency is reduced (current is forced into the pin), according to the following relation-

ships:

R

OSC

vs. GND:

R

OSC

vs. 12V:

Note that forcing a 25

µ

A current into this pin, the device stops switching because no current is delivered to the

oscillator.

Figure 2 shows the frequency variation vs. the oscillator resistor ROSC considering the above reported relation-

ships.

f

S

300kHz

1.237

R

O SC

K

(

)

-----------------------------

12

KHz

µ

A

------------

300KHz

14.82 10

6

R

OS C

K

(

)

-----------------------------

+

=

+

=

f

S

300kHz

12

1.237

≠

R

O SC

K

(

)

-----------------------------

12

KHz

µ

A

------------

300KHz

12.918 10

7

R

OSC

K

(

)

--------------------------------

≠

=

+

=

L6918 L6918A

12/35

Figure 2. R

OSC

vs. Switching Frequency

DIGITAL TO ANALOG CONVERTER (ONLY FOR MASTER DEVICE L6918A)

The built-in digital to analog converter allows the adjustment of the output voltage from 1.100V to 1.850V with

25mV as shown in the previous table 1. The internal reference is trimmed to ensure the precision of ±0.6% and

a zero temperature coefficient around the 70∞ C. The internal reference voltage for the regulation is programmed

by the voltage identification (VID) pins. These are TTL compatible inputs of an internal DAC that is realized by

means of a series of resistors providing a partition of the internal voltage reference. The VID code drives a mul-

tiplexer that selects a voltage on a precise point of the divider. The DAC output is delivered to an amplifier ob-

taining the VPROG voltage reference (i.e. the set-point of the error amplifier). Internal pull-ups are provided for

the VID pins (realized with a 5

µ

A current generator); in this way, to program a logic "1" it is enough to leave the

pin floating, while to program a logic "0" it is enough to short the pin to GND.

The voltage identification (VID) pin configuration also sets the power-good thresholds (PGOOD) and the Over/

Under voltage protection (OVP/UVP) thresholds.

The reference for the regulation is generated into the master device and delivered to the slave device through

the VPROG_OUT / VPROG_IN pins.

Programming the "11111" VID code, the device enters the NOCPU state: both devices keeps all mosfets OFF

and the condition is latched. Cycle the power supply to restart operation. Moreover, in this condition, the OVP

protection is still active into the slave device with a 0.8V threshold.

SOFT START AND INHIBIT

At start-up a ramp is generated from the master device increasing its loop reference from 0V to the final value

programmed by VID in 2048 clock periods. The same reference is present on the VPROG_OUT pin, producing

an increasing loop reference also into the slave device. In this way all the devices involved in the multi-phase

conversion start together with the same increasing reference (See Figure 3).

Before soft start, the lower power MOS are turned ON after that VCCDR reaches 2V (independently by Vcc val-

ue) to discharge the output capacitor and to protect the load from high side mosfet failures. Once soft start be-

gins, the reference is increased and also the upper MOS begins to switch: the output voltage starts to increase

with closed loop regulation. At the end of the digital soft start, the Power Good comparator is enabled and the

PGOOD signal is then driven high (See fig. 3). The Under Voltage comparator is enabled when the reference

voltage reaches 0.8V.

The Soft-Start will not take place, if both VCC and VCCDR pins are not above their own turn-on thresholds. The

soft-start takes place, and the Master device starts to increase the reference, only if the SLAVE_OK bus is at

high level. The Slave device keeps this line shorted to GND until it is ready for the start-up while the master

keeps this line free before soft-start; anyway, this line is shorted to GND if VCC and VCCDR are not above the

turn-ON threshold. During normal operation, if any under-voltage is detected on one of the two supplies, the

devices are shutdown.

0

1000

2000

3000

4000

5000

6000

7000

0

100

200

300

Frequency (KHz)

Rosc(K

) vs. 12V

0

100

200

300

400

500

600

700

800

900

1000

300

400

500

600

Frequency (KHz)

Rosc(K

) vs. GND

13/35

L6918 L6918A

Figure 3. Soft Start

Forcing the master OSC/INH/FAULT pin to a voltage lower than 0.8V, the devices enter in INHIBIT mode: all

the power mosfets are turned off until this condition is removed. When this pin is freed, the OSC/INH/FAULT

pin reaches the band-gap voltage and the soft start begin as previously explained.

In INHIBIT mode the Slave device still have both OVP and UVP protection active referring the thresholds to the

incoming reference present at the VPROG_IN pin if this one is greater than 0.8V. Otherwise (VPROG_IN <

0.8V) UVP is disabled and the OVP threshold is fixed at 0.8V.

DRIVER SECTION

The integrated high-current drivers allow using different types of power MOS (also multiple MOS to reduce the

RDSON), maintaining fast switching transition.

The drivers for the high-side mosfets use BOOT pins for supply and PHASE pins for return. The drivers for the

low-side mosfets use VCCDRV pin for supply and PGND pin for return. A minimum voltage of 5V at VCCDRV

pin is required to start operations of the device. The controller embodies a sophisticated anti-shoot-through sys-

tem to minimize low side body diode conduction time so maintaining good efficiency saving the use of Schottky

diodes. The conduction time is reduced to few nanoseconds assuring that high-side and low-side mosfets are

never switched on simultaneously: when the high-side mosfet turns off, the voltage on its source begins to fall;

when the voltage reaches 2V, the low-side mosfet gate drive is applied with 30ns delay. When the low-side mos-

fet turns off, the voltage at LGATE pin is sensed. When it drops below 1V, the high-side mosfet gate drive is

applied with a delay of 30ns. If the current flowing in the inductor is negative, the source of high-side mosfet will

never drop. To allow the turning on of the low-side mosfet even in this case, a watchdog controller is enabled:

if the source of the high-side mosfet don't drop for more than 240ns, the low side mosfet is switched on so al-

lowing the negative current of the inductor to recirculate. This mechanism allows the system to regulate even if

the current is negative.

The BOOT and VCCDRV pins are separated from IC's power supply (VCC pin) as well as signal ground (SGND

pin) and power ground (PGND pin) in order to maximize the switching noise immunity.

The peak current is shown for both the upper and the lower driver of the two phases in figure 4.A 10nF capacitive

load has been used.

For the upper drivers, the source current is 1.9A while the sink current is 1.5A with V

BOOT

-V

PHASE

= 12V; sim-

ilarly, for the lower drivers, the source current is 2.4A while the sink current is 2A with V

CCDR

= 12V.

LS

VPROG_OUT

SLAVE_OK

V

CC

PGOOD

SYNC_OUT

CH1=PGOOD; CH2=LGATEx; CH3=VPROG_OUT; CH4=SLAVE_OK

L6918 L6918A

14/35

Figure 4. Drivers peak current: High Side (left) and Low Side (right)

CURRENT READING AND OVER CURRENT

Each device involved in the four phase conversion has its own current reading circuitry and over current protec-

tion. As a results, the OCP network design for each device must be performed fort half of the maximum output

current.

The current flowing trough each phase is read using the voltage drop across the low side mosfets R

DSON

or

across a sense resistor (R

SENSE

) and internally converted into a current. The transconductance ratio is issued

by the external resistor Rg placed outside the chip between ISENx and PGNDSx pins toward the reading points.

The full differential current reading rejects noise and allows to place sensing element in different locations with-

out affecting the measurement's accuracy. The current reading circuitry reads the current during the time in

which the low-side mosfet is on (OFF Time). During this time, the reaction keeps the pin ISENx and PGNDSx

at the same voltage while during the time in which the reading circuitry is off, an internal clamp keeps these two

pins at the same voltage sinking from the ISENx pin the necessary current (Needed if low-side mosfet R

dsON

sense is implemented to avoid absolute maximum rating overcome on ISENx pin).

The proprietary current reading circuit allows a very precise and high bandwidth reading for both positive and

negative current. This circuit reproduces the current flowing through the sensing element using a high speed

Track & Hold Tran conductance amplifier. In particular, it reads the current during the second half of the OFF

time reducing noise injection into the device due to the high side mosfet turn-on (See fig. 5). Track time must

be at least 200ns to make proper reading of the delivered current.

This circuit sources a constant 50

µ

A current from the PGNDSx pin and keeps the pins ISENx and PGNDSx at

the same voltage. Referring to figure 5, the current that flows in the ISENx pin is then given by the following

equation:

Where R

SENSE

is an external sense resistor or the R

dsON

of the low side mosfet and Rg is the transconductance

resistor used between ISENx and PGNDSx pins toward the reading points; I

PHASE

is the current carried by each

phase.

The current information reproduced internally is represented by the second term of the previous equation as

follow:

CH3 = HGATE1; CH4 = HGATE2

CH3 = LGATE1; CH4 = LGATE2

I

I SEN x

50

µ

A

R

SEN SE

I

P H ASE

R

g

---------------------------------------------

50

µ

A

I

IN F Ox

+

=

+

=

15/35

L6918 L6918A

Since the current is read in differential mode, also negative current information is kept; this allow the device to

check for dangerous returning current between the two phases assuring the complete equalization between the

phase's currents.

Figure 5. Current reading timing (left) and circuit (right)

From the current information for each phase, information about the total current delivered ( I

FB

=II

NFO1

+I

INFO2

)

and the average current for each phase ( I

AVG

=(I

INFO1

+I

INFO2

)/2 ) is taken. I

INFOX

is then compared to I

AVG

to

give the correction to the PWM output in order to equalize the current carried by the two phases.

The transconductance resistor Rg can be designed in order to have current information of 25

µ

A per phase at

full nominal load; the over current intervention threshold is set at 140% of the nominal (II

NFOx

= 35

µ

A). Accord-

ing to the above relationship, the over current threshold (I

OCPx

) for each phase, which has to be placed at one

half of the total delivered maximum current, results:

An over current is detected when the current flowing into the sense element is greater than IOCP (I

INFOx

>35

µ

A):

the device enters in Quasi-Constant-Current operation. The low-side mosfets stays ON until IINFO becomes

lower than 35

µ

A skipping clock cycles. The high side mosfets can be turned ON with a T

ON

imposed by the

control loop at the next available clock cycle and the device works in the usual way until another OCP event is

detected.

The device limits the bottom of the inductor current triangular waveform. So the average current delivered can

slightly increase also in Over Current condition since the current ripple increases. In fact, the ON time increases

due to the OFF time rise because of the current has to reach the I

OCP

bottom. The worst-case condition is when

the duty cycle reaches its maximum value (d=50% internally limited). When this happens, the device works in

Constant Current and the output voltage decrease as the load increase. Crossing the UVP threshold causes the

Slave device to pull down the SLAVE_OK line. All mosfets are turned off and all the devices involved in the reg-

ulation stop working. Cycle the power supply to restart operation.

Figure 6 shows the constant current working condition

I

IN F Ox

R

SEN S E

I

P H ASE

R

g

---------------------------------------------

=

R

SE

N

S

E

Rg

50

µ

µ

A

I

ISENx

I

PH

A

S

E

Rg

LGATEX

ISENX

PGNDSX

I

LS1

I

LS2

Track & Hold

Total

current

information

R

g

I

OC Px

R

SEN SE

35

µ

A

------------------------------------------

=

I

OC Px

35

µ

A R

g

R

SE N SE

--------------------------

=

L6918 L6918A

16/35

Figure 6. Constant Current operation

It can be observed that the peak current (Ipeak) is greater than the 140% but it can be determined as follow:

Where Vout

MIN

is the minimum output voltage (UVP threshold).

The device works in Constant-Current, and the output voltage decreases as the load increase, until the output

voltage reaches the under-voltage threshold (Vout

MIN

). When this threshold is crossed, all mosfets are turned

off, the FAULT pin is driven high and the device stops working. Cycle the power supply to restart operation. The

maximum average current during the Constant-Current behavior results:

In this particular situation, the switching frequency results reduced.

The ON time is the maximum allowed (T

onMAX

) while the OFF time depends on the application:

Over current is set anyway when I

INFOx

reaches 35

µ

A. The full load value is only a convention to work with con-

venient values for I

FB

. Since the OCP intervention threshold is fixed, to modify the percentage with respect to

the load value, it can be simply considered that, for example, to have on OCP threshold of 170%, this will cor-

respond to I

INFOx

= 35

µ

A (I

FB

= 70

µ

A). The full load current will then correspond to I

INFOx

= 20.5

µ

A (I

FB

= 41

µ

A).

INTEGRATED DROOP FUNCTION

The devices use the droop function to satisfy the requirements of high performance microprocessors, reducing

the size and the cost of the output capacitor.

This method "recovers" part of the drop due to the output capacitor ESR in the load transient, introducing a de-

pendence of the output voltage on the load current

As shown in figure 7, the ESR drop is present in any case, but using the droop function the total deviation of the

output voltage is minimized. In practice the droop function introduces a static error proportional to the output

current that can be represented by an equivalent output resistance R

OUT

. Since the device has an average cur-

rent mode regulation, the information about the total current delivered is used to implement the Droop Function.

This current (equal to the sum of both I

INFOx

) is sourced from the FB pin. Connecting a resistor between this pin

and Vout, the total current information flows only in this resistor because the compensation network between

TonMAX

TonMAX

I

OCPx

Ipeak

I

MAX

Vout

Iout

(I

FB

=50

µ

A)

2∑I

OCPx

(I

FB

=70

µ

A

I

MAX,TO

UVP

Droop effect

Ipeak

I

OC Px

V

IN

Vout

m in

≠

L

-------------------------------------

Ton

M AX

I

O C Px

V

IN

Vout

M IN

≠

L

--------------------------------------

0.5 T

+

=

+

=

I

M A X T OT

,

2 I

M AX

2

I

O C Px

Ipeak

I

OC P x

≠

2

--------------------------------------

+

=

=

f

1

Ton

M AX

T

OF F

+

------------------------------------------

=

T

OF F

L

Ipea k

I

OC Px

≠

V

O U T

--------------------------------------

=

17/35

L6918 L6918A

FB and COMP has always a capacitor in series (See fig. 8). The voltage regulated by each device is then equal

to:

Where I

OUT

is the output current of each device (equal to the total load current I

LOAD

divided by the number of

devices N)

Since I

FB

depends on the current information about the two phases of each device, the output characteristic vs.

load current is given by:

Where R

OUT

is the equivalent output resistance due to the droop function and I

OUT

is still the output current of

each device (that is the total current delivered to the load I

LOAD

divided by 2.

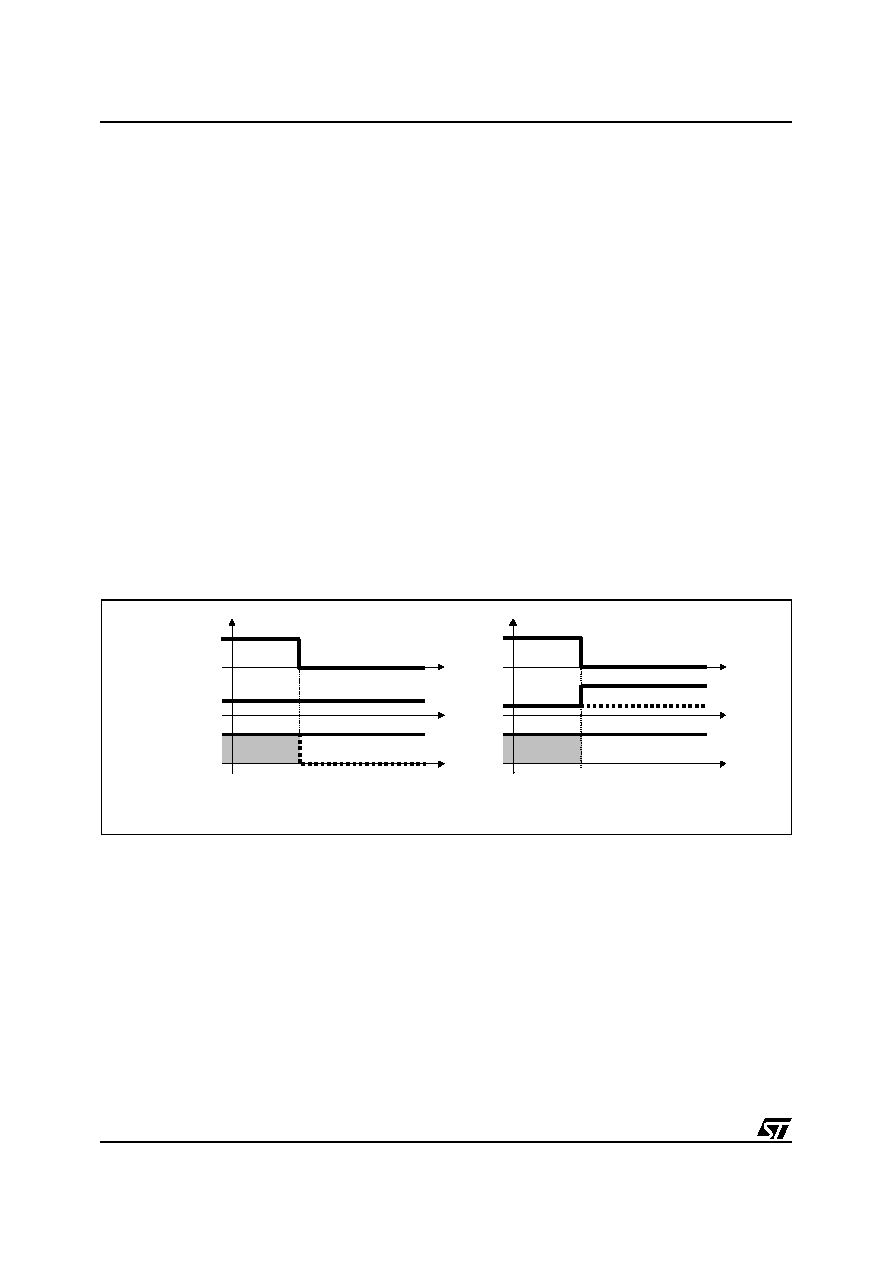

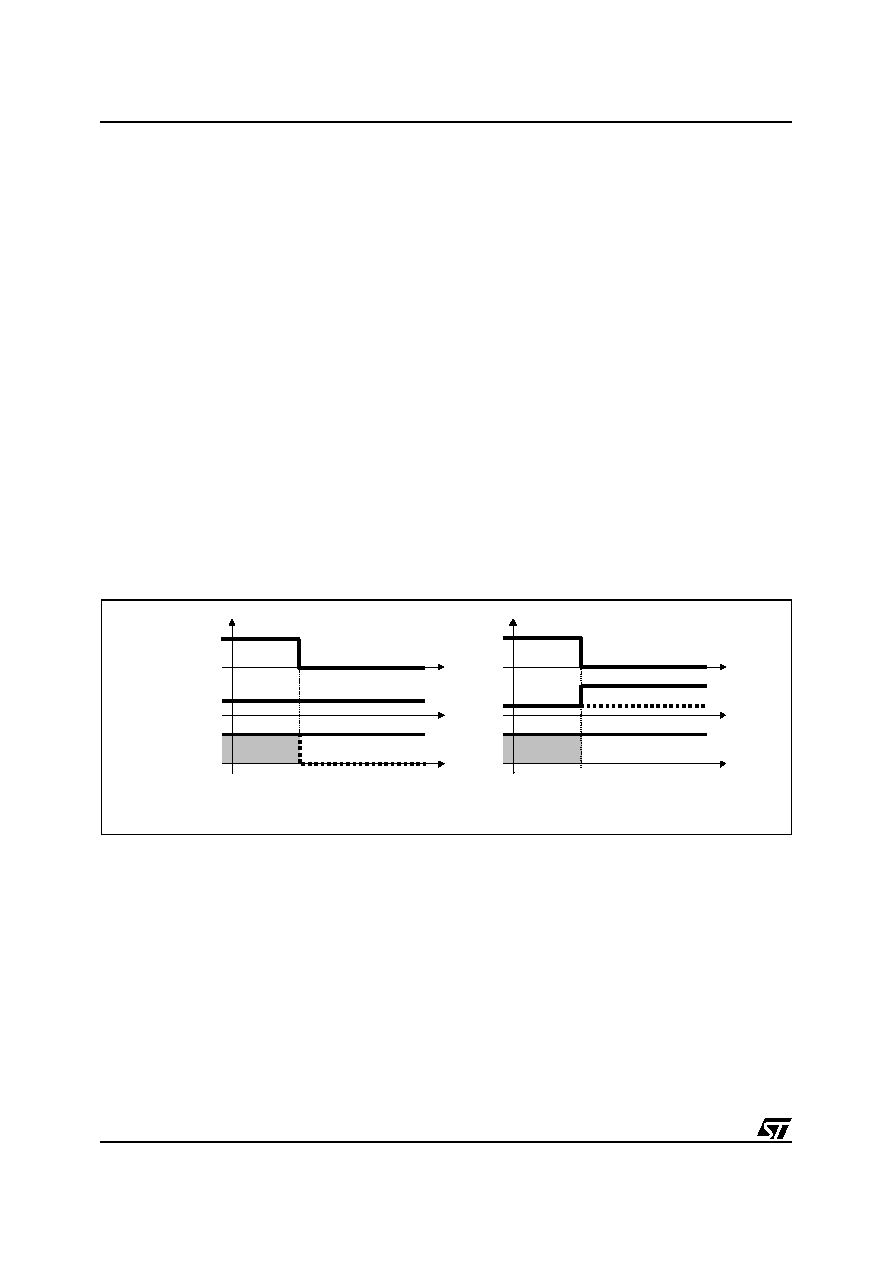

Figure 7. Output transient response without (a) and with (b) the droop function

Figure 8. Active Droop Function Circuit

The feedback current is equal to 50

µ

A at nominal full load (I

FB

= I

INFO1

+ I

INFO2

) and 70

µ

A at the OCP interven-

tion threshold, so the maximum output voltage deviation is equal to:

V

OU T

VID

R

FB

I

F B

VID

R

F B

R

SEN SE

Rg

----------------------

I

OU T

≠

=

≠

=

V

OU T

VID

R

FB

I

O U T

VID

R

F B

R

SEN SE

Rg

----------------------

I

OU T

VID

R

F B

R

S EN SE

Rg

----------------------

I

L OAD

2

---------------

≠

=

≠

=

≠

=

V

MAX

V

MIN

V

NOM

(a)

(b)

ESR DROP

ESR DROP

V

DROOP

Ref

COMP

FB

To V

OUT

Total Cu rrent Info (I

INFO1

+I

INFO2

)

V

DROOP

R

FB

Ref

COMP

FB

To V

OUT

Total Cu rrent Info (I

INFO1

+I

INFO2

)

V

DROOP

R

FB

V

O L_INTERVENTION

+R

F B

70

µ

A

=

V

FU LL _POSITIVE_LOAD

+R

F B

50

µ

A

=

L6918 L6918A

18/35

Droop function is provided only for positive load; if negative load is applied, and then IINFOx<0, no current is

sunk from the FB pin. The device regulates at the voltage programmed by the VID.

OUTPUT VOLTAGE MONITORING AND PROTECTION: POWER GOOD

The output voltage is monitored by the Slave device through the pin VSEN. If it is not within +12/-10% (typ.) of

the programmed value, the PGOOD output is forced low. PGOOD is always active in the Slave device, also dur-

ing soft-start. PGOOD in the Master device has the only masking function during soft-start. Since the master

has not the output voltage sense, it keeps the PGOOD to GND during soft-start and after this step it is freed.

The Slave device provides Over-Voltage protection: when the voltage sensed by VSEN reaches 117% (typ.) of

the reference voltage present at the VPROG_IN pin, the Slave device stops switching keeping the LS mosfets

ON. The FAULT pin is driven high (5V) and the SLAVE_OK line is pulled low. The master device then stops

switching keeping the LS mosfets ON, too. Since the condition is latched, power supply (Vcc) turn off and on is

required to restart operations.

Under voltage protection is also provided and still detected by the Slave device. If the output voltage drops be-

low the 60% (typ.) of the reference voltage present at the VPROG_IN pin for more than one clock period, the

Slave device stops switching turning OFF all mosfets and pulling down the SLAVE_OK line: the Master device

stops switching with LS mosfets ON. The OSC/INH/FAULT is not driven high in this case.

Both Over Voltage and Under Voltage are active also during soft start (Under Voltage after than Vout reaches

0.8V). During soft-start the reference voltage used to determine the UV threshold is the increasing voltage driv-

en by the 2048 soft start digital counter. Moreover, OVP is always active, even during INHIBIT (see relevant

section).

Over / Under Voltage behavior are shown in Figure 9.

Figure 9. OVP and UVP latch

REMOTE VOLTAGE SENSE

A remote sense buffer is integrated into the device to allow output voltage remote sense implementation without

any additional external components. In this way, the output voltage programmed is regulated between the re-

mote buffer inputs compensating motherboard trace losses or connector losses if the device is used for a VRM

module.

The very low offset amplifier senses the output voltage remotely through the pins FBR and FBG (FBR is for the

regulated voltage sense while FBG is for the ground sense) and reports this voltage internally at VSEN pin with

unity gain eliminating the errors. Keeping the FBR and FBG traces parallel and guarded by a power plane re-

sults in common mode coupling for any picked-up noise.

If remote sense is not required, the output voltage is sensed by the VSEN pin connecting it directly to the output

voltage. In this case the FBG and FBR pins must be connected anyway to the regulated voltage

LS

OSC

SLAVE_OK

LS

OSC

SLAVE_OK

UNDER VOLTAGE LATCH

OVER VOLTAGE LATCH

L6918

L6918A

L6918A

L6918

19/35

L6918 L6918A

INPUT CAPACITOR

The input capacitor is designed considering mainly the input rms current that depends on the duty cycle as re-

ported in figure. Considering the four phase topology, the input rms current is highly reduced comparing with

single or dual phase operation.

It can be observed that the input rms value is one half of the dual-phase equivalent input current in the worst-

case condition that happens for D=1/8, 3/8,5/8 and 7/8.

The power dissipated by the input capacitance is then equal to:

Input capacitor is designed in order to sustain the ripple relative to the maximum load duty cycle. To reach the

high rms value needed by the CPU power supply application and also to minimize components cost, the input

capacitance is realized by more than one physical capacitor. The equivalent rms current is simply the sum of

the single capacitor's rms current.

Figure 10. Input rms Current vs. Duty Cycle.

OUTPUT CAPACITOR

Since the microprocessors require a current variation beyond 100A doing load transients, with a slope in the

range of tenth A/

µ

s, the output capacitor is a basic component for the fast response of the power supply.

Dual phase topology reduces the amount of output capacitance needed because of faster load transient re-

sponse (switching frequency is doubled at the load connections). Current ripple cancellation due to the 180∞

phase shift between the two phases also reduces requirements on the output ESR to sustain a specified voltage

ripple.

When a load transient is applied to the converter's output, for first few microseconds the current to the load is

supplied by the output capacitors. The controller recognizes immediately the load transient and increases the

duty cycle, but the current slope is limited by the inductor value.

The output voltage has a first drop due to the current variation inside the capacitor (neglecting the effect of the

ESL):

P

RM S

ESR

I

R M S

(

)

2

=

0.50

0.75

0.25

0.50

0.25

Single Phase

Dual Phase

Duty Cycle (V

OUT

/V

IN

)

Rm

s

Cu

r

r

e

n

t

No

r

m

a

l

i

z

e

d

(

I

RM

S

/I

OUT

)

4 Phase

V

OU T

I

OU T

ESR

=

L6918 L6918A

20/35

A minimum capacitor value is required to sustain the current during the load transient without discharge it. The

voltage drop due to the output capacitor discharge is given by the following equation:

Where D

MAX

is the maximum duty cycle value. The lower is the ESR, the lower is the output drop during load

transient and the lower is the output voltage static ripple.

INDUCTOR DESIGN

The inductance value is defined by a compromise between the transient response time, the efficiency, the cost

and the size. The inductor has to be calculated to sustain the output and the input voltage variation to maintain

the ripple current

I

L

between 20% and 30% of the maximum output current. The inductance value can be cal-

culated with this relationship:

Where f

SW

is the switching frequency, V

IN

is the input voltage and V

OUT

is the output voltage.

Increasing the value of the inductance reduces the ripple current but, at the same time, reduces the converter

response time to a load transient. The response time is the time required by the inductor to change its current

from initial to final value. Since the inductor has not finished its charging time, the output current is supplied by

the output capacitors. Minimizing the response time can minimize the output capacitance required.

The response time to a load transient is different for the application or the removal of the load: if during the ap-

plication of the load the inductor is charged by a voltage equal to the difference between the input and the output

voltage, during the removal it is discharged only by the output voltage. The following expressions give approx-

imate response time for DI load transient in case of enough fast compensation network response:

The worst condition depends on the input voltage available and the output voltage selected. Anyway the worst

case is the response time after removal of the load with the minimum output voltage programmed and the max-

imum input voltage available.

Figure 11. Inductor ripple current vs. Vout

V

OU T

i

O U T

2

L

2 C

O U T

V

IN m in

D

M A X

V

OU T

≠

(

)

-------------------------------------------------------------------------------------------

=

L

V

IN

V

O U T

≠

f

S W

I

L

------------------------------

V

OU T

V

IN

--------------

=

t

a ppli ca tion

L

I

V

IN

V

O U T

≠

------------------------------

=

t

r em oval

L

I

V

O UT

--------------

=

Figure 12 ≠ Inductor ripple current vs. Vout

0

1

2

3

4

5

6

7

8

9

0 .5

1 .5

2 .5

3 .5

Output V oltage [V ]

Inductor Ripple [A]

L=3

µ

H,

Vin=12V

L=2

µ

H,

Vin=12V

L=1.5

µ

H, Vin=12V

L=2

µ

H,

Vin=5V

L=1.5

µ

H,

Vin=5V

L=3

µ

H, Vin=5V

21/35

L6918 L6918A

MAIN CONTROL LOOP

The four phases control loop is composed by two dual phases devices that are independent each other. So, the

compensation network and the control loop stability of each device don't depend on the other except for the fact

that the other converter represents a load for this one.

The L6918/A control loop is composed by the Current Sharing control loop and the Average Current Mode con-

trol loop. Each loop gives, with a proper gain, the correction to the PWM in order to minimize the error in its

regulation: the Current Sharing control loop equalize the currents in the inductors while the Average Current

Mode control loop fixes the output voltage equal to the reference programmed by VID. Figure 12 reports the

block diagram of the main control loop

Figure 12. Main Control Loop Diagram

CURRENT SHARING (CS) CONTROL LOOP

The devices are configured to work in a four synchronized phase application. Since the application is composed

by two-phase devices that share reference and synchronization signals, the current sharing between the phases

is realized in two different steps:

1. Sharing between the phases of the same device;

2. Sharing between devices.

The Current Sharing between phases of the same device uses the internal current information to correct the

PWM signal in order to equalize the current. Active current sharing is implemented using the information from

Tran conductance differential amplifier in an average current mode control scheme. A current reference equal

to the average of the read current (I

AVG

) is internally built; the error between the read current and this reference

is converted to a voltage with a proper gain and it is used to adjust the duty cycle whose dominant value is set

by the error amplifier at COMP pin (See fig. 13).

The current sharing control is a high bandwidth control allowing current sharing even during load transients.

The current sharing error is affected by the choice of external components; choose precise Rg resistor (±1% is

necessary) to sense the current. The current sharing error is internally dominated by the voltage mismatch of

Tran conductance differential amplifier between phases; considering a voltage mismatch equal to 2mV across

the sense resistor, the current reading error is given by the following equation:

Where

I

READ

is the difference between one phase current and the ideal current (I

MAX/2

).

For Rsense=4m

and Imax=40A the current sharing error is equal to 2.5%, neglecting errors due to Rg and

Rsense mismatches.

L1

L2

+

+

PWM1

1/5

+

-

1/5

I

INFO2

I

INFO1

4/5

Z

F(S)

PWM2

C

O

FB

COMP

R

O

ERROR

AMPLIFIER

REFERENCE

PROGRAMMED

BY VID

CURRENT

SHARING

DUTY CYCLE

CORRECTION

R

FB

D02IN1392

I

R EA D

I

M AX

--------------------

2mV

R

S EN SE

I

M AX

---------------------------------------

=

L6918 L6918A

22/35

Figure 13. Current Sharing Control Loop.

The current sharing between devices uses the droop function. Each device can be modeled with its Thevenin

equivalent circuit (that is an ideal voltage source equal to the programmed voltage by VIDs and its related output

resistance R

OUT

), while the whole converter is modeled by the same ideal voltage source and an equivalent

output resistance R

DROOP

=R

OUT

/2;

Considering this modelization reported in figure 14, it can be seen that the recirculating current between devices

depends on the accuracy of the regulation.

The accuracy of the voltage source is given by the offset of the master error amplifier Vos (6mV typ) and de-

pends on the ratio between this offset and the output voltage variation with load (R

OUT

,I

OUT

). The mismatch

between the regulated voltages causes a converter to source a current that is sunk by the other one. The accu-

racy related to droop resistance depends on precision of feedback current of the device I

FB

, sense resistors

R

SENSE

, Transconductance resistors Rg and feedback resistors R

FB

.

The current sharing error (CSE) results:

Considering the external resistors tolerance of 1%, the typical current feedback accuracy of 2.5

µ

A/50

µ

A (5%),

4 phases operation, Error Amplifier offset Vos=6mV, droop resistance R

DROOP

=1.5m

(R

OUT

=2,R

DROOP

) and

I

LOAD

=60A (I

OUT

=I

LOAD

/2), it results:

Figure 14. Equivalent Circuit for current sharing error calculation

L1

L2

+

+

PWM1

1/5

1/5

I

INFO2

I

INFO1

PWM2

COMP

V

OUT

CURRENT

SHARING

DUTY CYCLE

CORRECTION

D02IN1393

CSE

I

OU T

I

O U T