1/20

October 2002

s

COMPLETE INTERFACE BETWEEN LNB

AND I2CTM BUS

s

BUILT-IN DC/DC CONTROLLER FOR

SINGLE 12V SUPPLY OPERATION

s

ACCURATE BUILT-IN 22KHz TONE

OSCILLATOR

s

SUITS WIDELY ACCEPTED STANDARDS

s

FAST OSCILLATOR START-UP FACILITATES

DiSEqCTM ENCODING

s

BUILT-IN 22KHz TONE DETECTOR

SUPPORTS BI-DIRECTIONAL DiSEqCTM

s

LOOP-THROUGH FUNCTION FOR SLAVE

OPERATION

s

LNB SHORT CIRCUIT PROTECTION AND

DIAGNOSTIC

s

CABLE LENGTH DIGITAL COMPENSATION

s

INTERNAL OVER TEMPERATURE

PROTECTION

s

ESD RATING 4KV ON POWER

INPUT-OUTPUT PINS

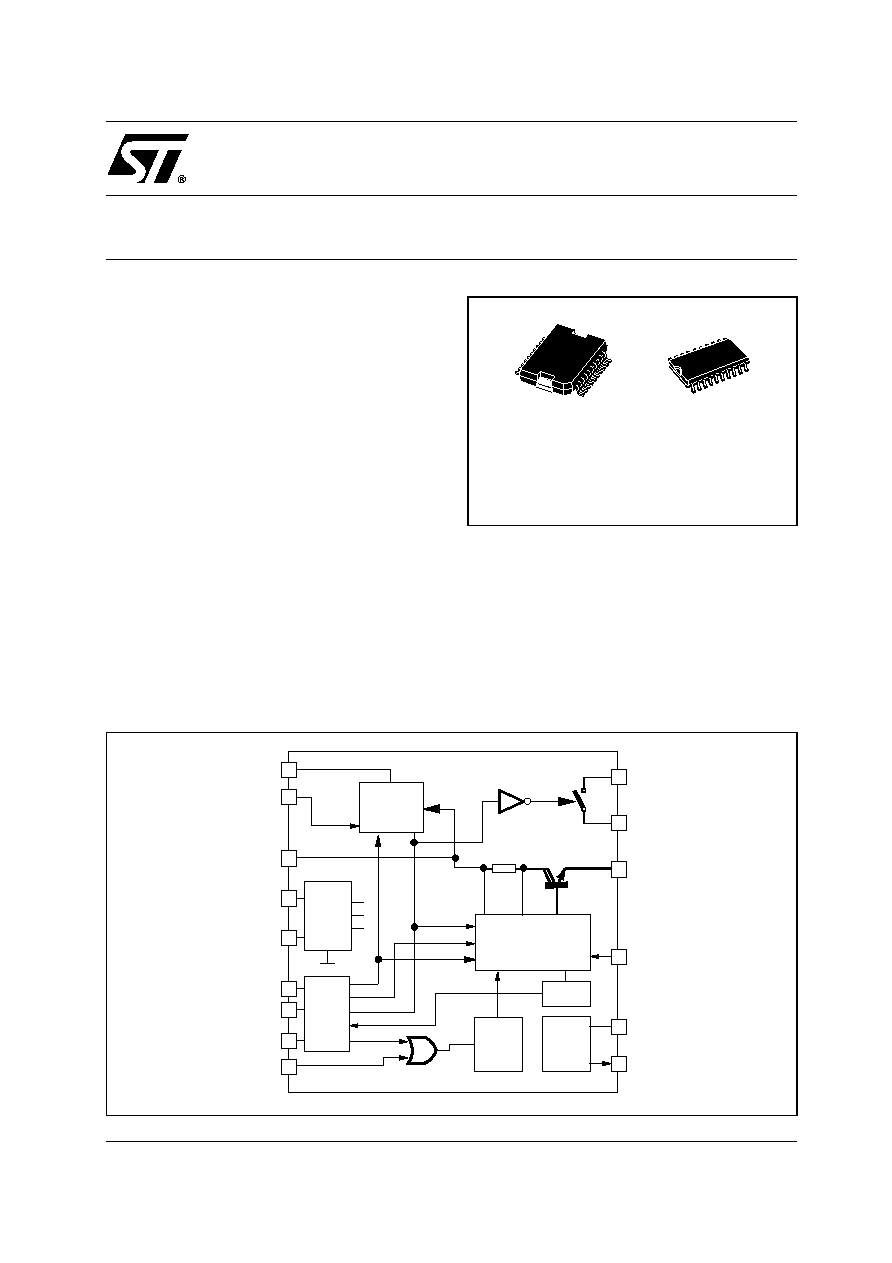

DESCRIPTION

Intended for analog and digital satellite STB

receivers/SatTV, sets/PC cards, the LNBP21 is a

monolithic voltage regulator and interface IC,

assembled

in

SO-20

and

PowerSO-20,

specifically designed to provide the power and the

13/18V, 22KHz tone signalling to the LNB

LNBP21

LNBP SUPPLY AND CONTROL IC WITH

STEP-UP CONVERTER AND I

2

C INTERFACE

Enable

I Select

Preregul.+

U.V.lockout

+P.ON res.

Feedback

Step-up

Controller

V Select

Linear Post-reg

+Modulator

+Protections

22KHz

Oscill.

Vup

LT1

OUT

SDA

SCL

DSQIN

Vcc

Diagnostics

I≤C

interf.

Tone

Detector

DSQOUT

LT2

DETIN

LNBP21

Byp

Gate

Sense

EXTM

ADDR

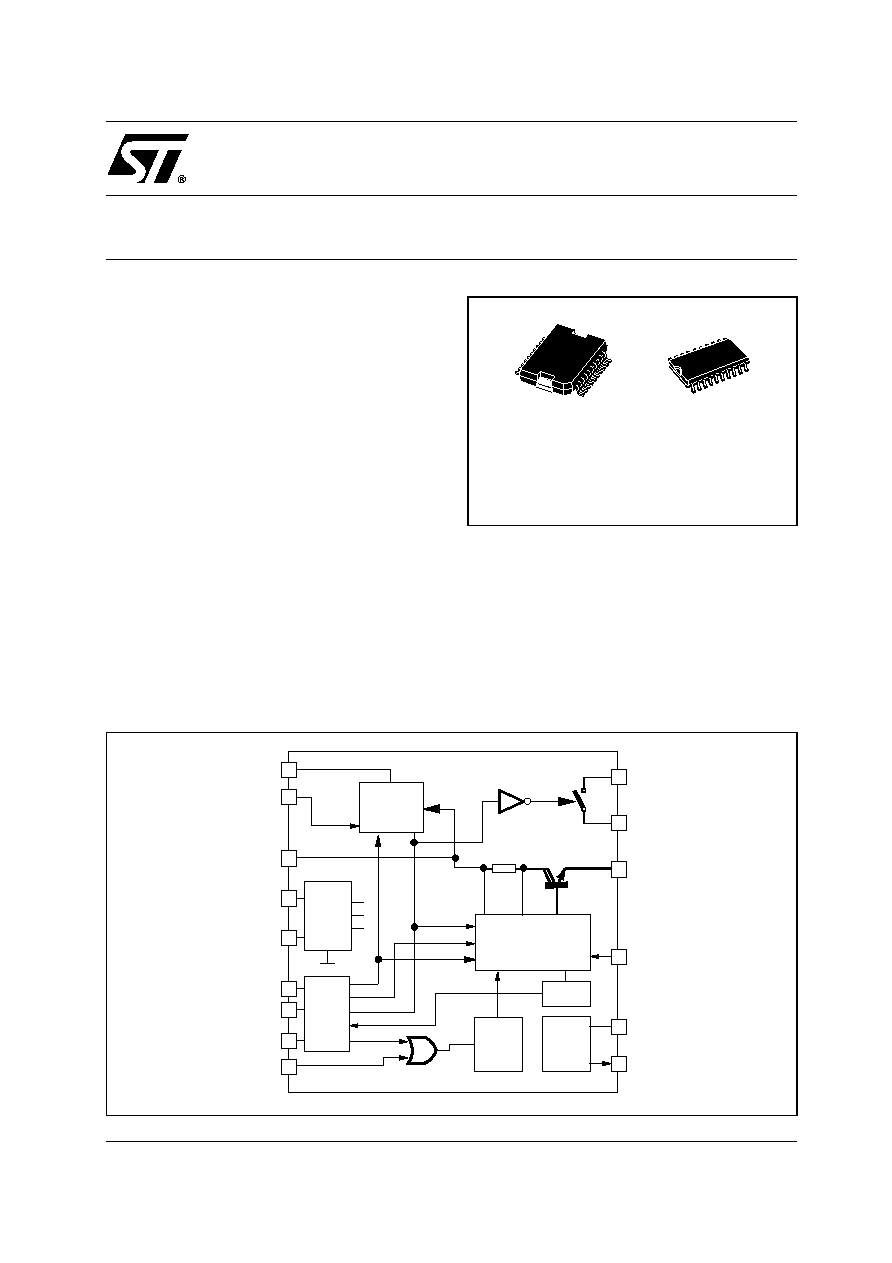

SCHEMATIC DIAGRAM

SO-20

PowerSO-20

LNBP21

2/20

downconverter in the antenna or to the multiswitch

box. In this application field, it offers a complete

solution with extremely low component count, low

power dissipation together with simple design and

I

2

CTM standard interfac-ing.

This IC has a built in DC/DC step-up controller

that, from a single supply source ranging from 8 to

15V, generates the voltages that let the linear

post-regulator to work at a minimum dissipated

power. An UnderVoltage Lockout circuit

will

disable the whole circuit when the supplied V

CC

drops below a fixed threshold (6.7V typically). The

internal 22KHz tone generator is factory trimmed

in accordance to the standards, and can be

controlled either by the I

2

C

TM

interface or by a

dedicated pin (DSQIN) that allows immediate

DiSEqC

TM

data encoding (*). All the functions of

this IC are controlled via I

2

C

TM

bus by writing 6

bits on the System Register (SR, 8 bits) . The

same register can be read back, and two bits will

report the diagnostic status. When the IC is put in

Stand-by (EN bit LOW), the power blocks are

disabled

and the loop-through switch between

LT1 and LT2 pins is closed, thus leaving all LNB

powering and control

functions to the Master

Receiver (**). When the regulator blocks are

active (EN bit HIGH), the output can be logic

controlled to be 13 or 18 V (typ.) by mean of the

VSEL bit (Voltage SELect) for remote controlling

of non-DiSEqC LNBs. Additionally, it is possible

to increment by 1V (typ.) the selected voltage

value to compensate for the excess voltage drop

along the coaxial cable (LLC bit HIGH). In order to

minimise the power dissipation, the output voltage

of the internal step-up converter is adjusted to

allow the linear regulator to work at minimum

dropout. Another bit of the SR is addressed to the

remote control of non-DiSEqC LNBs: the TEN

(Tone ENable) bit. When it is set to HIGH, a

continuous 22KHz tone is generated regardless

of the DSQIN pin logic status. The TEN bit must

be set LOW when the DSQIN pin is used for

DiSEqC

TM

encoding. The fully bi-directional

DiSEqC

TM

interfacing is completed by the built-in

22KHz tone detector. Its input pin (DETIN) must

be AC coupled to the DiSEqC

TM

bus, and the

extracted

PWK

data

are

available

on

the

DSQOUT pin (*).

In order to improve design flexibility and to allow

implementation of newcoming LNB remote control

standards, an analogic modulation input pin is

available (EXTM). An appropriate DC blocking

capaci-tor must be used to couple the modulating

signal source to the EXTM pin. When external

modulation is not used, the relevant pin can be left

open.

The current limitation block has two thresholds

that can be selected by the I

SEL

bit of the SR; the

lower threshold is between 400 and 550mA

(I

SEL

=HIGH),

while

the

higher

threshold

is

between 500 and 650mA (I

SEL

=LOW).

The current protection block is SOA type. This

limits the short circuit current (Isc) typically at

200mA with I

SEL

=HIGH and at 300mA with

I

SEL

=LOW when the output port is connected to

ground.

It is possible to set the Short Circuit Current

protection either statically (simple current clamp)

or dy-namically by the PCL bit of the SR; when

the PCL (Pulsed Current Limiting) bit is set to

LOW, the overcurrent protection circuit works

dynamically: as soon as an overload is detected,

the output is shut-down for a time t

off

, typically

900ms. Simultaneously the OLF bit of the System

Register is set to HIGH. After this time has

elapsed, the output is resumed for a time t

on

=1/

10t

off

(typ.). At the end of t

on

, if the overload is still

detected, the protection circuit will cycle again

through Toff and Ton. At the end of a full Ton in

which no overload is detected, normal operation is

resumed and the OLF bit is reset to LOW. Typical

Ton+Toff time is 990ms and it is determined by an

internal timer. This dynamic operation can greatly

reduce the power dissipation in short circuit

condition, still ensuring excellent power-on start

up in most conditions (**) .

However, there could be some cases in which an

highly capacitive load on the output may cause a

difficult start-up when the dynamic protection is

chosen. This can be solved by initiating any power

start-up in

static mode (PCL=HIGH) and then

switching to the dynamic mode (PCL=LOW) after

a chosen amount of time. When in static mode,

the OLF bit goes HIGH when the current clamp

limit is reached and returns LOW when the

overload condition is cleared.

This IC is also protected against overheating:

when the junction temperature exceeds 150∞C

(typ.), the step-up converter and the linear

regulator are shut off, the loop-trough switch is

opened, and the OTF bit of the SR is set to HIGH.

Normal operation is resumed and the OTF bit is

reset to LOW when the junction is cooled down to

140∞C (typ.).

(*): External components are needed to comply to bi-directional DiSEqC

TM

bus hardware require-ments. Full compliance of the whole appli-

cation to DiSEqC

TM

specifications is not implied by the use of this IC.

(**): The current limitation circuit has no effect on the loop-through switch. When EN bit is LOW, the current flowing from LT1 to LT2 must

be externally limited.

LNBP21

3/20

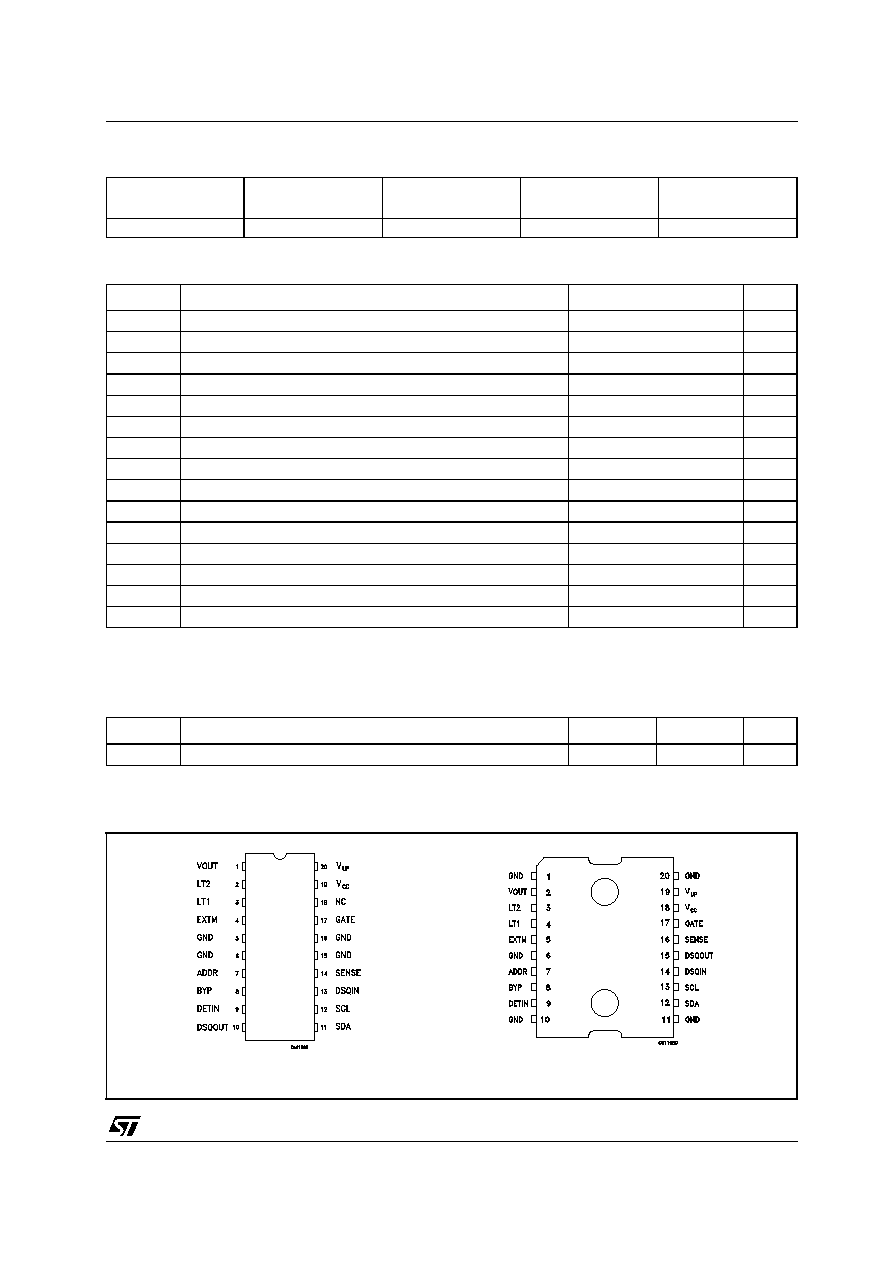

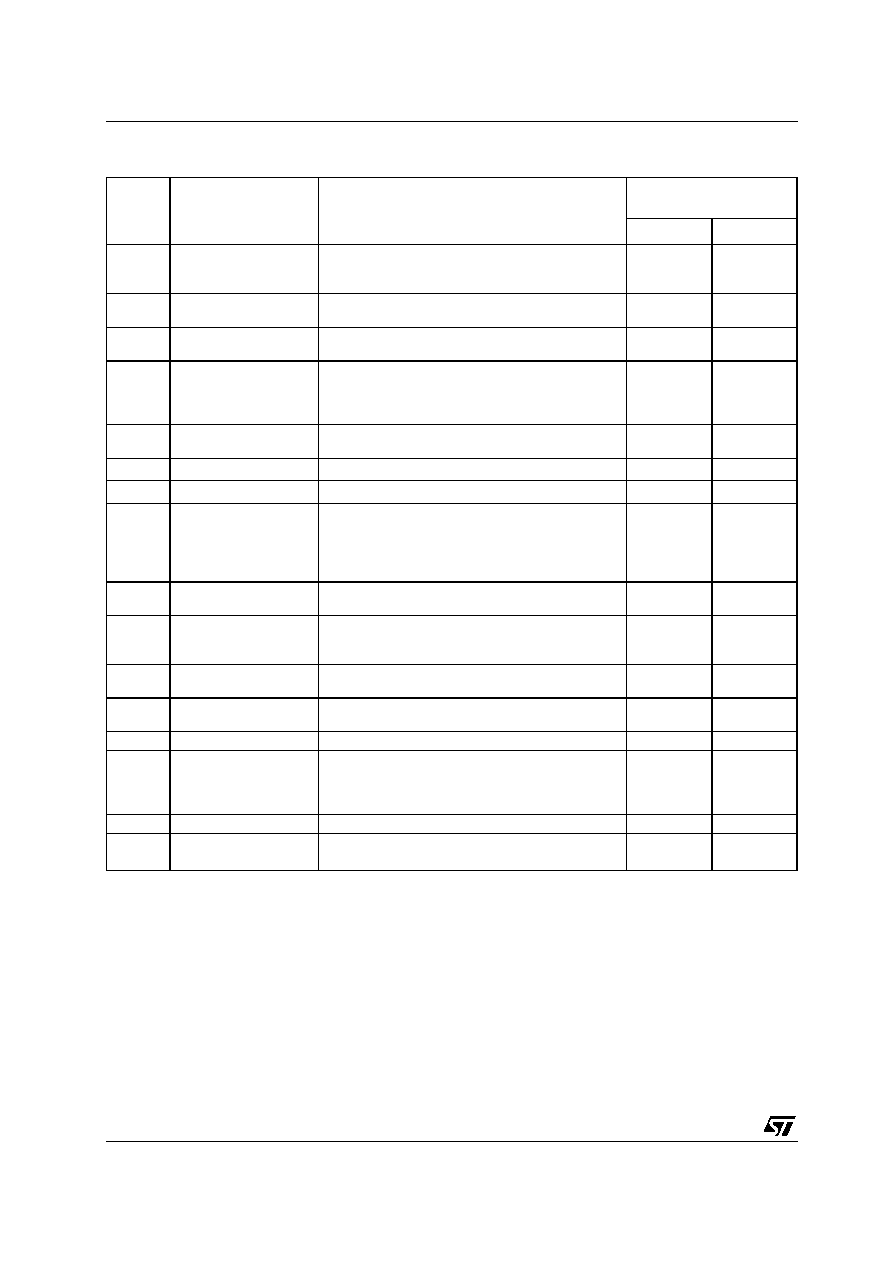

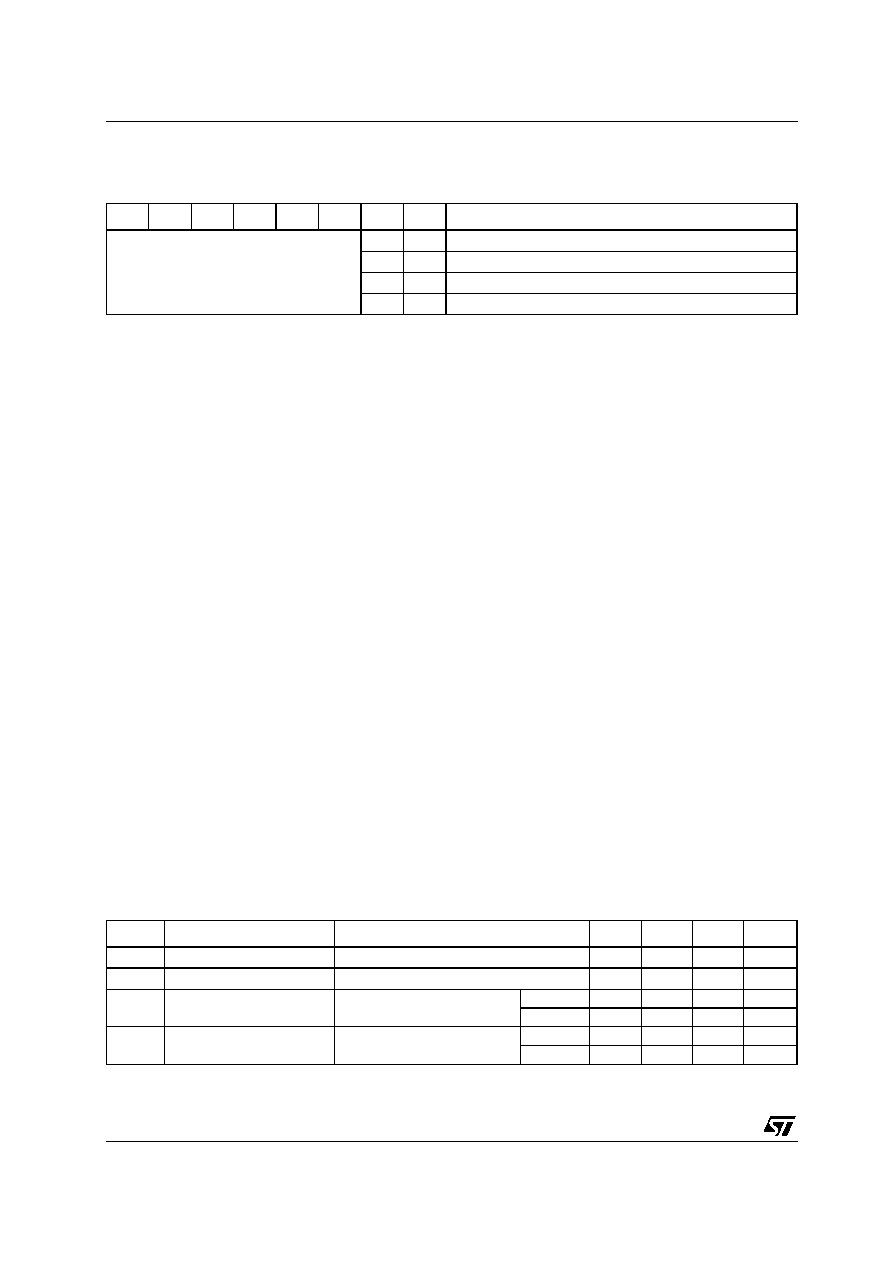

ORDERING CODES

ABSOLUTE MAXIMUM RATINGS

Absolute Maximum Ratings are those values beyond which damage to the device may occur. Functional operation under these condition is

not implied.

THERMAL DATA

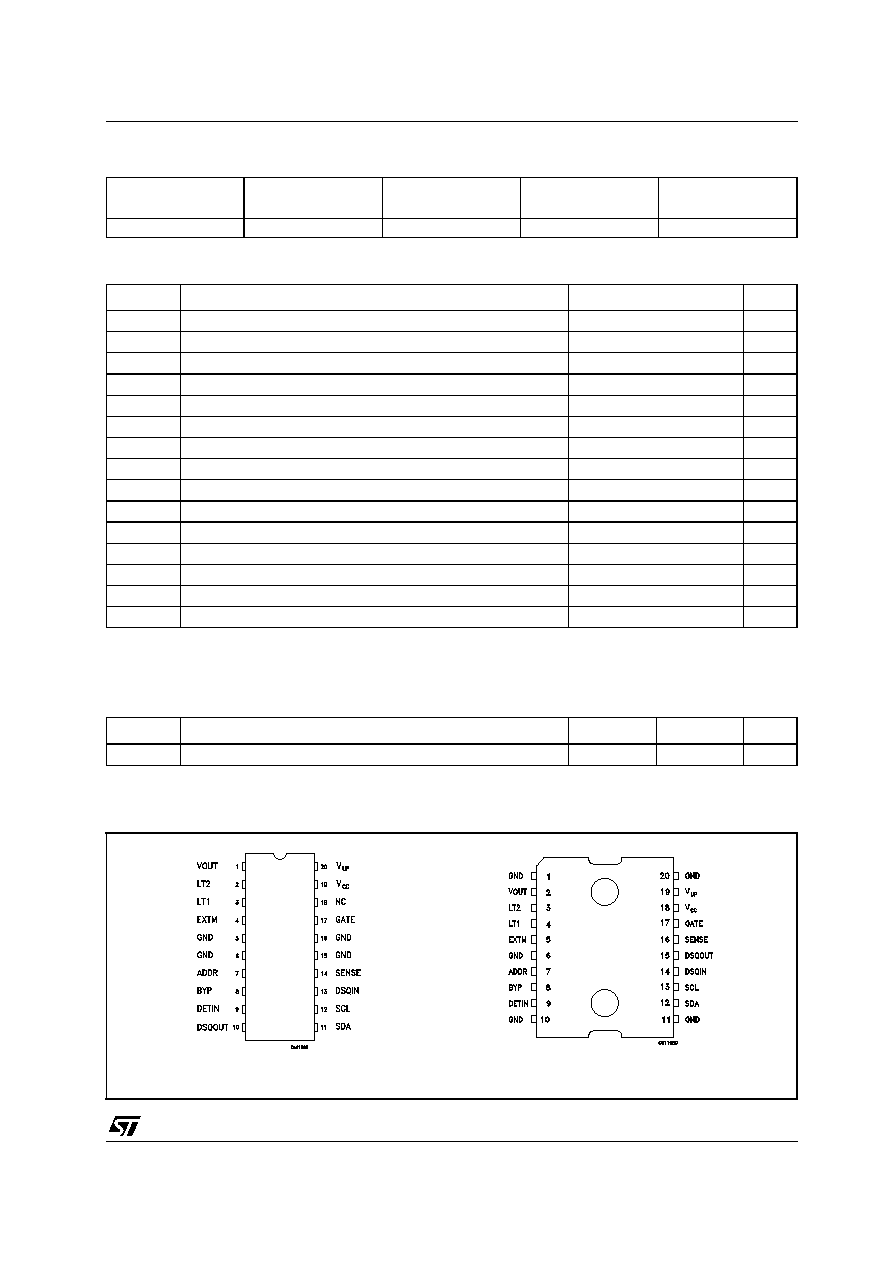

PIN CONFIGUARATION (top view)

TYPE

SO-20

(Tube)

SO-20

(Tape & Reel)

PowerSO-20

(Tube)

PowerSO-20

(Tape & Reel)

LNBP21

LNBP21D2

LNBP21D2-TR

LNBP21PD

LNBP21PD-TR

Symbol

Parameter

Value

Unit

V

CC

DC Input Voltage

16

V

V

UP

DC Input Voltage

25

V

V

LT1

, V

LT2

DC Input Voltage

20

V

I

O

Output Current

Internally Limited

mA

V

O

DC Output Pin Voltage

-0.3 to 22

V

V

I

Logic Input Voltage (SDA, SCL, DSQIN)

-0.3 to 7

V

V

DETIN

Detector Input Signal Amplitude

2

V

PP

V

OH

Logic High Output Voltage (DSQOUT)

7

V

I

LT

Bypass Switch ON Current

900

mA

V

LT

Bypass Switch OFF Voltage

±20

V

I

GATE

Gate Current

±400

mA

V

SENSE

Current Sense Voltage

-0.3 to 1

V

V

ADDRESS

Address Pin Voltage

-0.3 to 7

V

T

stg

Storage Temperature Range

-40 to +150

∞C

T

op

Operating Junction Temperature Range

-40 to +125

∞C

Symbol

Parameter

SO-20

PowerSO-20

Unit

R

thj-case

Thermal Resistance Junction-case

15

2

∞C/W

PowerSO-20

SO-20

LNBP21

4/20

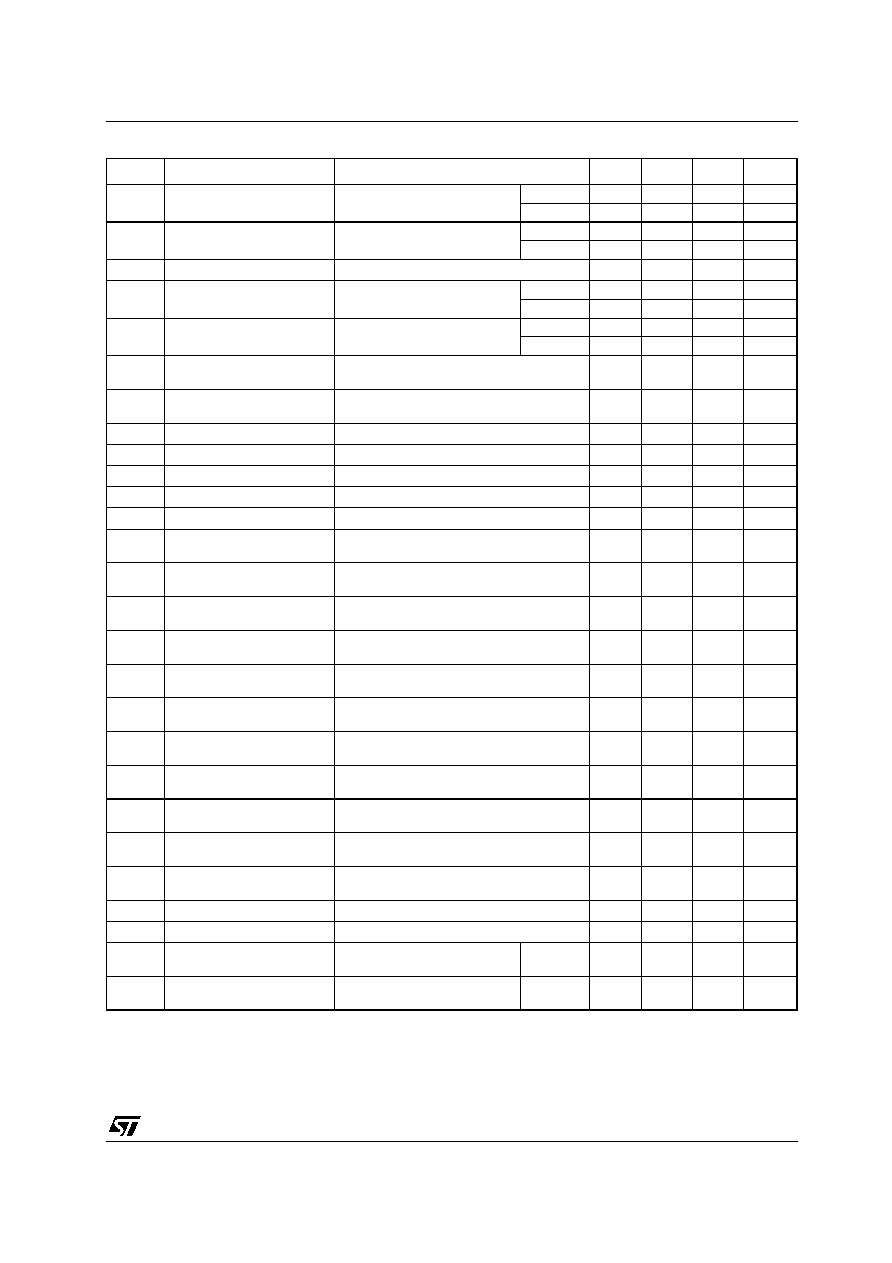

TABLE A: PIN CONFIGURATIONS

SYMBOL

NAME

FUNCTION

PIN NUMBER

vs PACKAGE

SO-20

PowerSO-20

V

CC

Supply Input

8V to 15V supply. A 220µF bypass capacitor to

GND with a 470nF (ceramic) in parallel is

recommended

19

18

GATE

Exrernal Switch Gate

External MOS switch Gate connection of the

step-up converter

17

17

SENSE

Current Sense Input

Current Sense comparator input. Connected to

current sensing resistor

14

16

V

up

Step-up Voltage

Input of the linear post-regulator. The voltage on this

pin is monitored by internal step-ut controller to

keep a minimum dropout across the linear pass

transistor

20

19

OUT

Output Port

Output of the linear post regulator modulator to the

LNB. See truth table for voltage selections.

1

2

SDA

Serial Data

Bidirectional data from/to I

2

C bus.

11

12

SCL

Serial Clock

Clock from I

2

C bus.

12

13

DSQIN

DiSEqC Input

When the TEN bit of the System Register is LOW,

this pin will accept the DiSEqC code from the main

µ

controller. The LNBP21 will use this code to

modulate the internally generated 22kHz carrier. Set

to GND thi pin if not used.

13

14

DETIN

Detector In

22kHz Tone Detector Input. Must be AC coupled to

the DiSEcQ bus.

9

9

DSQOUT DiSEqC Output

Open collector output of the tone Detector to the

main

µ

controller for DiSEcQ data decoding. It is

LOW when tone is detected.

10

15

EXTM

Extrernal Modulator

External Modulation Input. Need DC decoupling to

the AC source. If not used, can be left open.

4

5

GND

Ground

Circuit Ground. It is internally connected to the die

frame for heat dissipation.

5, 6, 15, 16

1, 10, 11, 20

BYP

Bypass Capacitor

Needed for internal preregulator filtering

8

8

LT1

Loop Through Switch

In standby mode the power switch between LT1

and LT2 is closed. Max allowed current is 900mA.

this pin can be left open if loopthrough function is

not needed.

3

4

LT2

Loop Through Switch

Same as above

2

3

ADDR

Address Setting

Four I

2

C bus addresses available by setting the

Address Pin level voltage

7

7

LNBP21

5/20

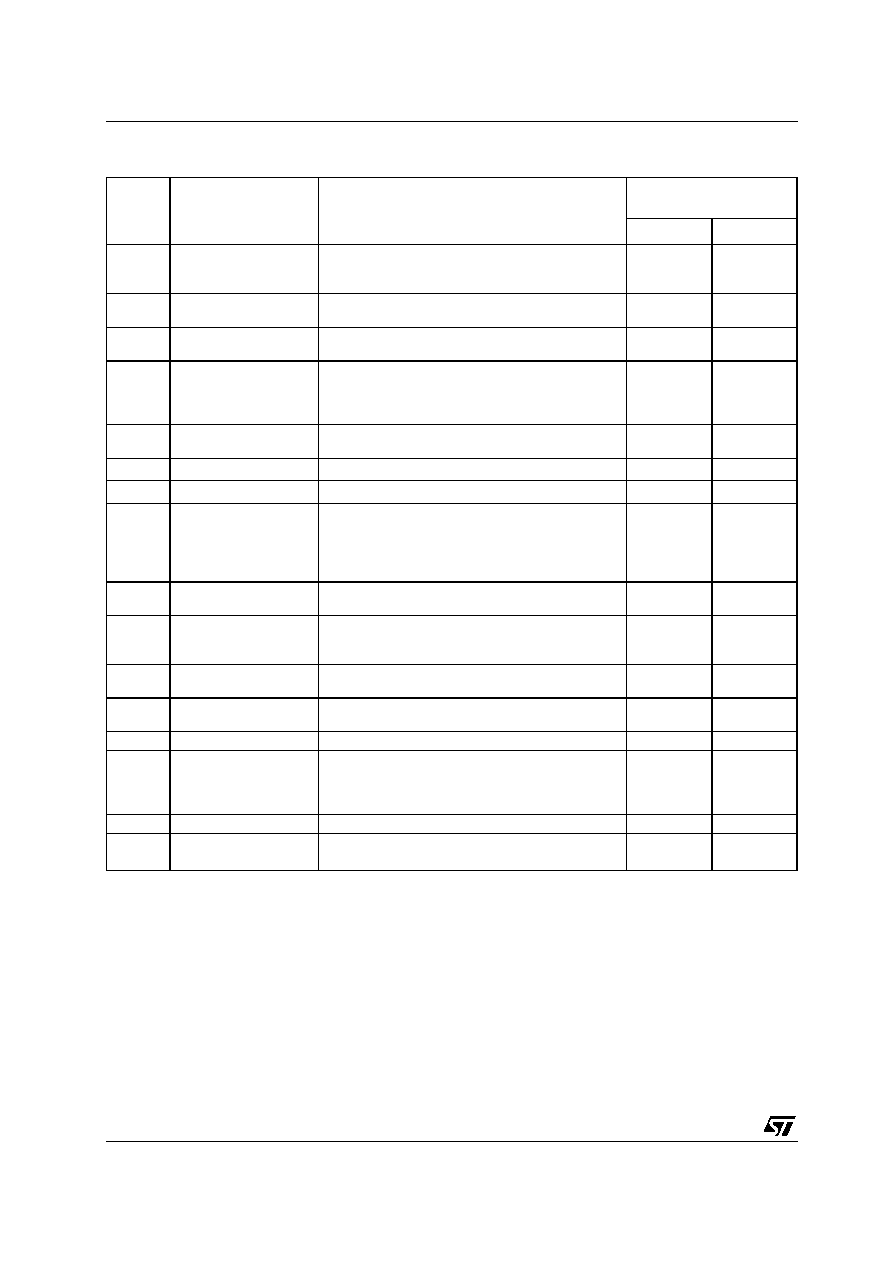

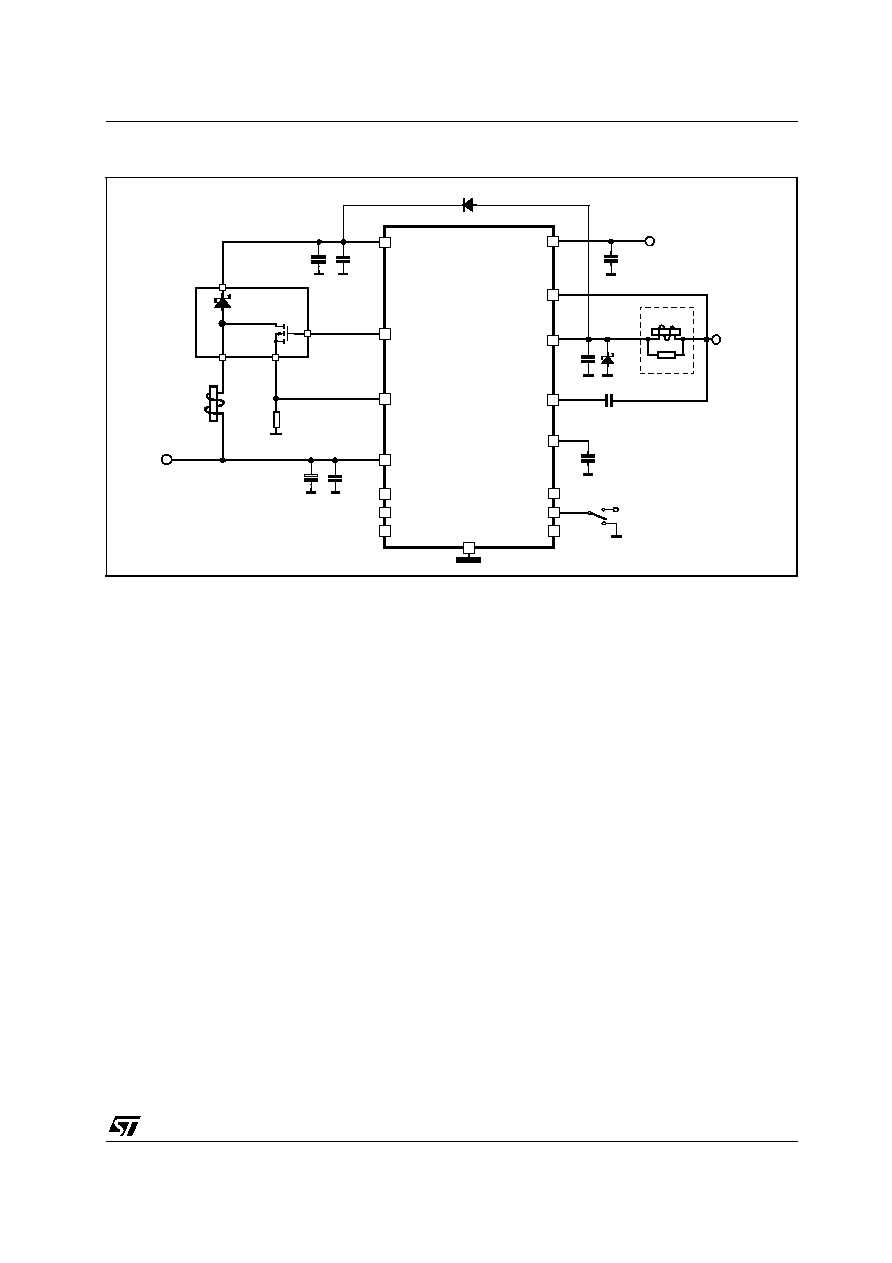

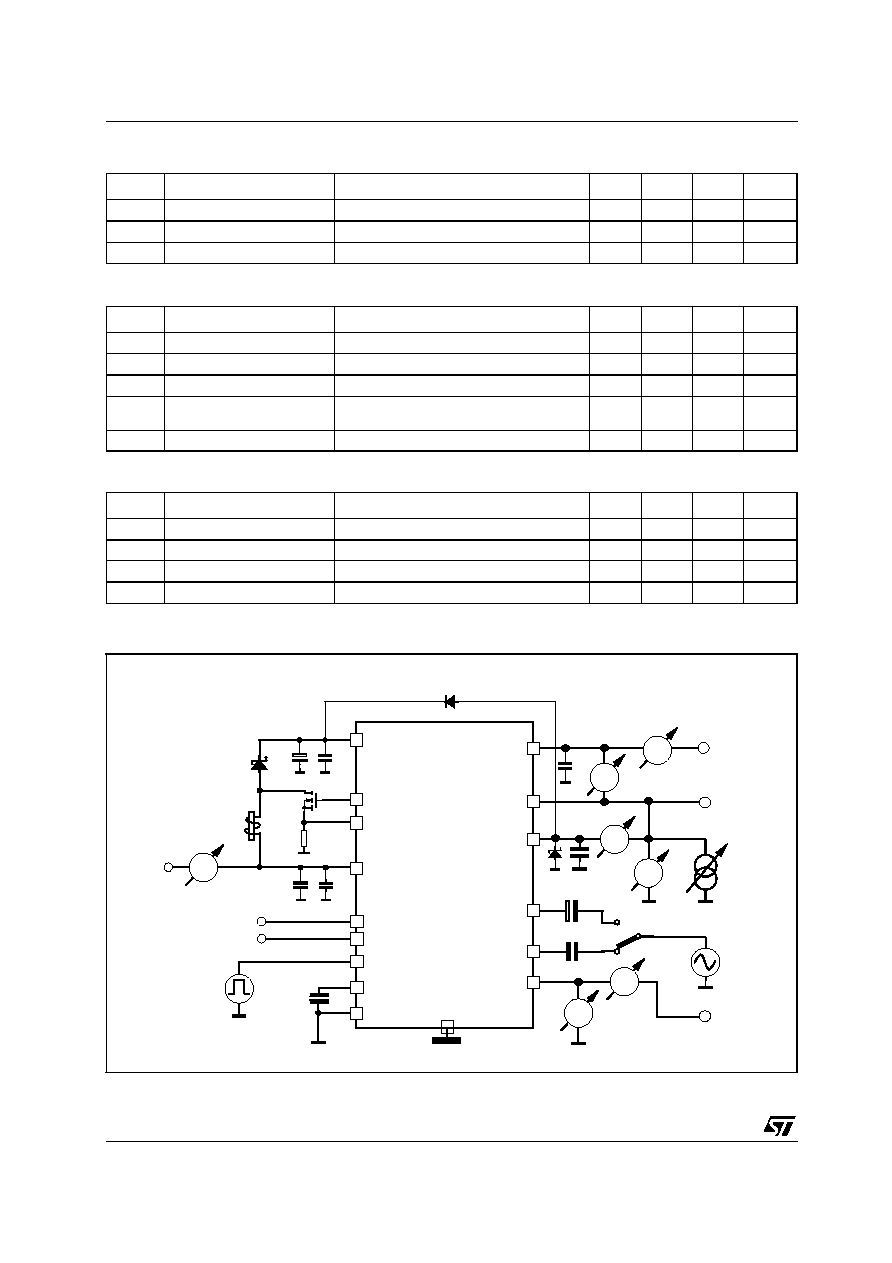

TYPICAL APPLICATION CIRCUIT

(*) Set to GND if not used

(**) filter to be used according to EUTELSAT reccomendation to implement the DiSEqC

TM

2.x, not needed if bidirectional DiSEqC

TM

2.x is

not implemented (see DiSEqC implementation note)

(***) IC2 is a ST Fettky, STS4DNFS30L, that includes both the schottky diode and the N-Channel Mos-Fet, needed for the DC/DC converter,

in a So-8 package. It can be replaced by a schottky diode (STPS2L3A or similar) and a N-Channel Mos-Fet (STN4NF03L or similar)

I

2

C BUS INTERFACE

Data transmission from main µP to the LNBP21

and viceversa takes place through the 2 wires I2C

bus interface, consisting of the two lines SDA and

SCL (pull-up resistors to positive supply voltage

must be externally connected).

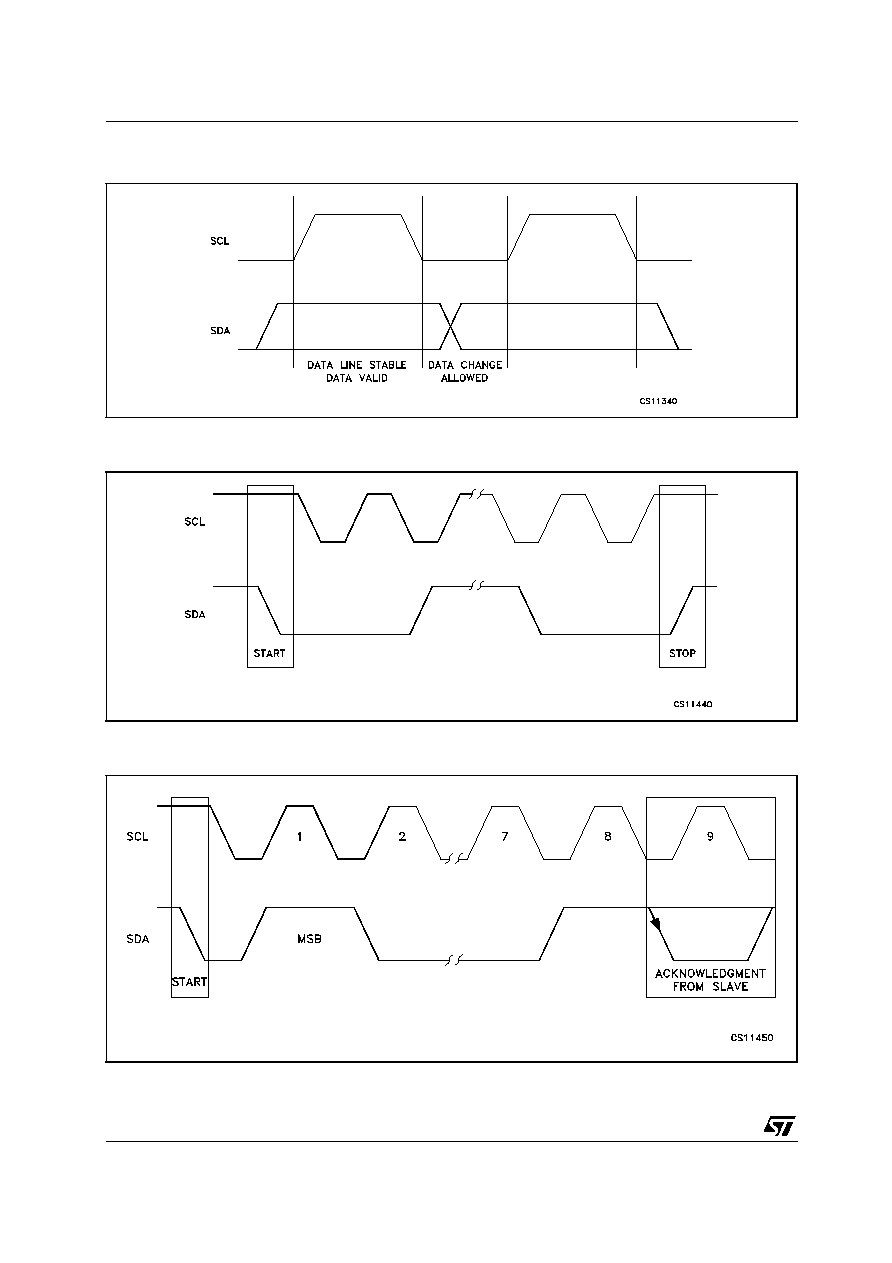

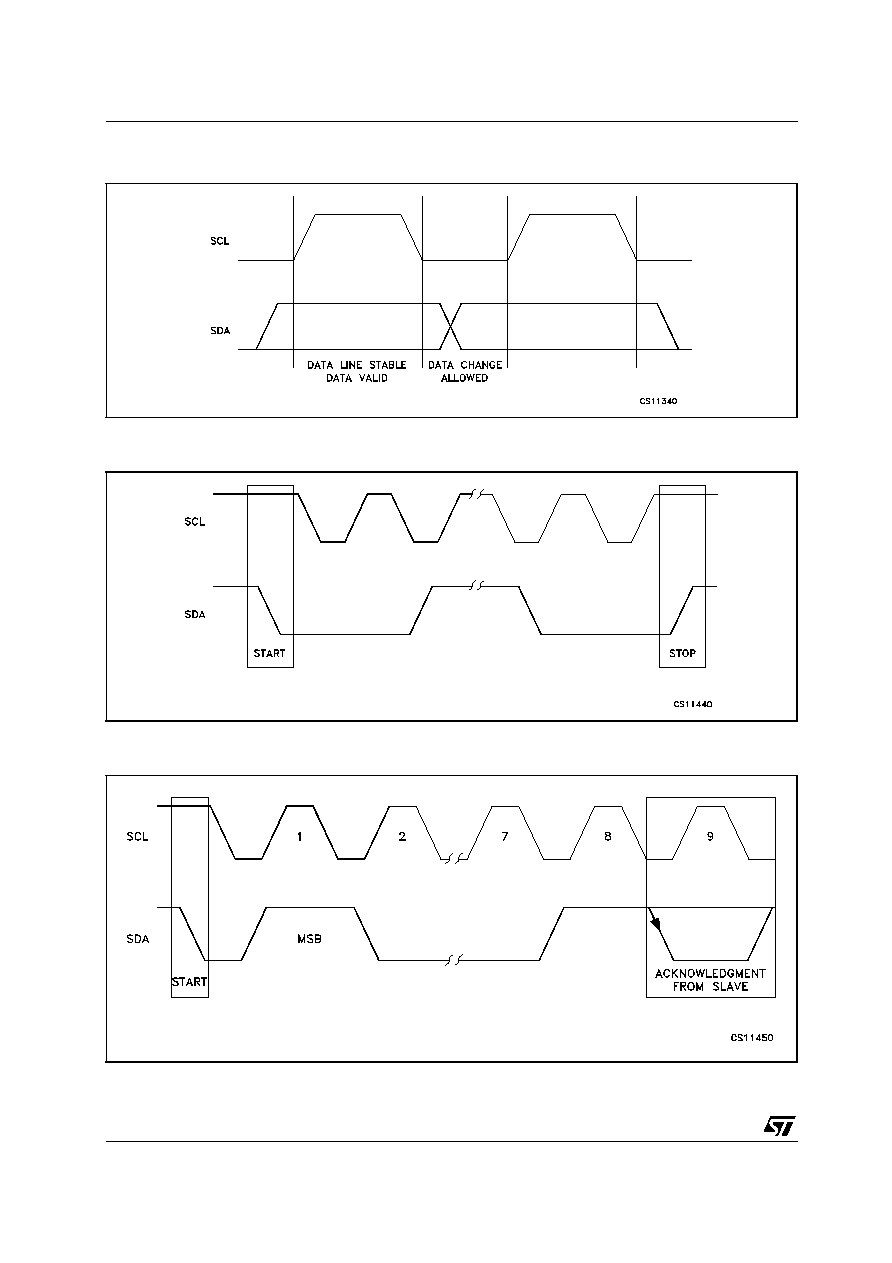

DATA VALIDITY

As shown in fig. 1, the data on the SDA line must

be stable during the high period of the clock. The

HIGH and LOW state of the data line can only

change when the clock signal on the SCL line is

LOW.

START AND STOP CONDITIONS

As shown in fig.2 a start condition is a HIGH to

LOW transition of the SDA line while SCL is HIGH.

The stop condition is a LOW to HIGH transition of

the SDA line while SCL is HIGH. A STOP

condi-tions must be sent before each START

condition.

BYTE FORMAT

Every byte transferred to the SDA line must

contain 8 bits. Each byte must be followed by an

ac-knowledge bit. The MSB is transferred first.

ACKNOWLEDGE

The master (µP) puts a resistive HIGH level on the

SDA line during the acknowledge clock pulse (see

fig.

3).

The

peripheral

(LNBP21)

that

acknowledges has to pull-down (LOW) the SDA

line during the acknowledge clock pulse, so that

the SDA line is stable LOW during this clock pulse.

The peripheral which has been addressed has to

generate an acknowledge after the reception of

each byte, other-wise the SDA line remains at the

HIGH level during the ninth clock pulse time. In

this case the master transmitter can generate the

STOP information in order to abort the transfer.

The LNBP21 won't gen-erate the acknowledge if

the Vcc supply is below the Undervoltage Lockout

threshold (6.7V typ.).

TRANSMISSION WITHOUT ACKNOWLEDGE

Avoiding to detect the acknowledge of the

LNBP21, the µP can use a simpler transmission:

simply it waits one clock without checking the

slave acknowledging, and sends the new data.

This approach of course is less protected from

misworking and decreases the noise immunity.

270µH

15 ohm

see Note 2

LNBP21

Vup

Gate

Vin

12V

L1=22µH

Sense

C2

220µF

Vcc

LT1

Master STB

Vo

LT2

DETIN

(Note 1)

C8

10nF

to LNB

SDA

SCL

DSQOUT

DSQIN(Note 1)

ADDRESS

Byp

C5

470nF

GND

0<Vaddr<V

Byp

EXTM

C6

10nF

R

sc

0.1

C3

470nF

Ceramic

D1 1N4001

C1

220µF

C4

470nF

Ceramic

D2

BAT43

C7

10nF

STS4DNFS30L

IC2

(Note 3)

IC1

(Note 4)

LNBP21

6/20

Figure 1 : DATA VALIDITY ON THE I

2

C BUS

Figure 2 : TIMING DIAGRAM ON I

2

C BUS

Figure 3 : ACKNOWLEDGE ON I

2

C BUS

LNBP21

7/20

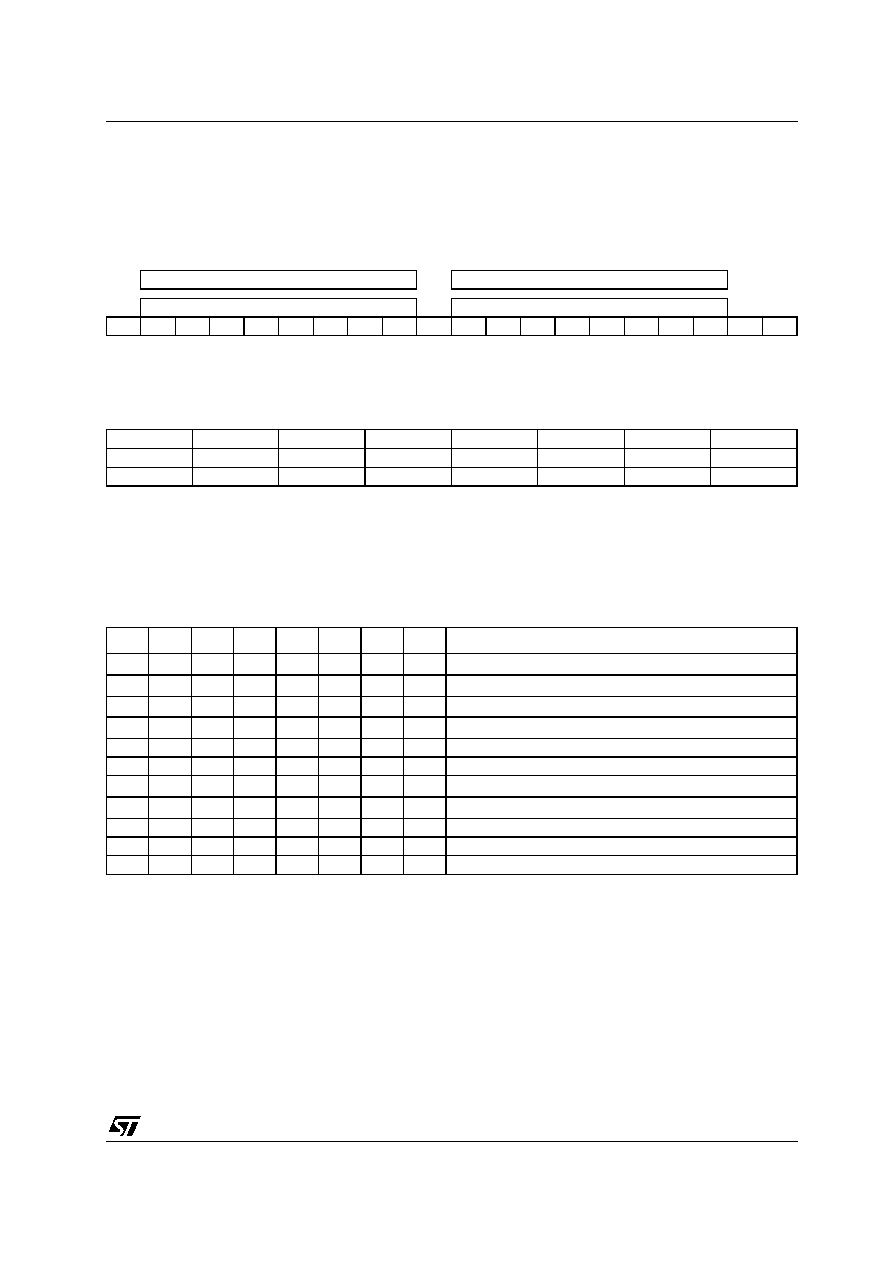

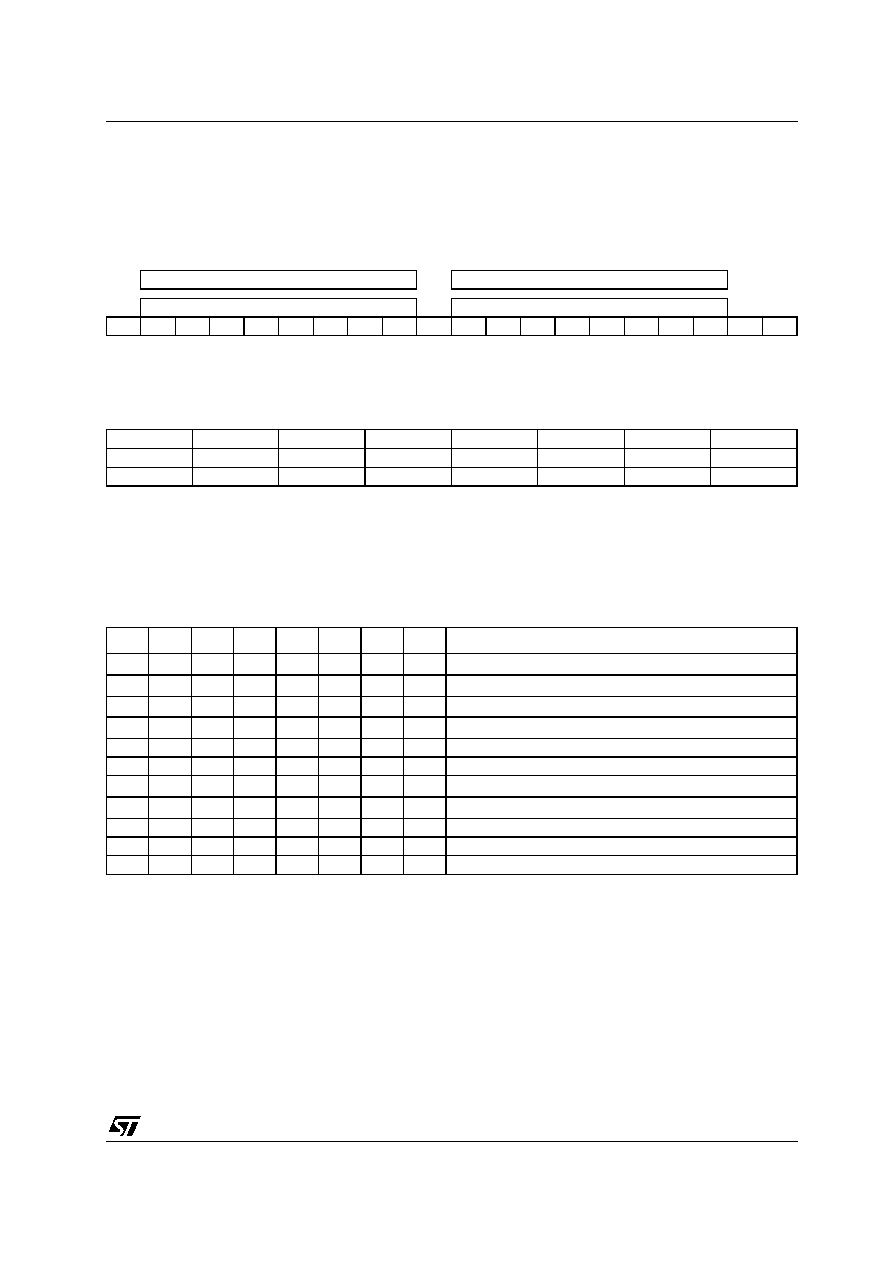

LNBP1 SOFTWARE DESCRIPTION

INTERFACE PROTOCOL

The interface protocol comprises:

- A start condition (S)

- A chip address byte = hex 10 / 11 (the LSB bit

determines read(=1)/write(=0) transmission)

- A sequence of data (1 byte + acknowledge)

- A stop condition (P)

ACK= Acknowledge

S= Start

P= Stop

R/W= Read/Write

SYSTEM REGISTER (SR, 1 BYTE)

R,W= read and write bit

R= Read-only bit

All bits reset to 0 at Power-On

TRANSMITTED DATA (I

2

C BUS WRITE MODE)

When the R/W bit in the chip address is set to 0,

the main µP can write on the System Register

(SR) of the LNBP21 via I

2

C bus. Only 6 bits out of

the 8 available can be written by the µP, since the

re-maining 2 are left to the diagnostic flags, and

are read-only.

X= don't care.

Values are typical unless otherwise specified

RECEIVED DATA (I

2

C bus READ MODE)

The LNBP21 can provide to the Master a copy of

the SYSTEM REGISTER information via I2C bus

in read mode. The read mode is Master activated

by sending the chip address with R/W bit set to 1.

At the following master generated clocks bits, the

LNBP21 issues a byte on the SDA data bus line

(MSB transmitted first).

At the ninth clock bit the MCU master can:

- acknowledge the reception, starting in this way

the

transmission

of

another

byte

from

the

LNBP21;

CHIP ADDRESS

DATA

MSB

LSB

MSB

LSB

S

0

0

0

1

0

0

0

R/W ACK

ACK

P

MSB

LSB

R, W

R, W

R, W

R, W

R, W

R, W

R

R

PCL

ISEL

TEN

LLC

VSEL

EN

OTF

OLF

PCL

ISEL

TEN

LLC

VSEL

EN

OTF

OLF

Function

0

0

1

X

X

V

OUT

=13V, V

UP

=16V Loopthrough switch open

0

1

1

X

X

V

OUT

=18V, V

UP

=21V Loopthrough switch open

1

0

1

X

X

V

OUT

=14V, V

UP

=17V Loopthrough switch open

1

1

1

X

X

V

OUT

=19V, V

UP

=22V Loopthrough switch open

0

1

X

X

22KHz tone is controlled by DSQIN pin

1

1

X

X

22KHz tone is ON, DSQIN pin disabled

0

1

X

X

I

OUT(min)

=500mA, I

OUT(max)

=650mA I

SC

=300mA

1

1

X

X

I

OUT(min)

=400mA, I

OUT(max)

=550mA I

SC

=300mA

0

1

X

X

Pulsed (dynamic) current limiting is selected

1

1

X

X

Static current limiting is selected

X

X

X

X

X

0

X

X

Power blocks disabled, Loopthrough switch closed

LNBP21

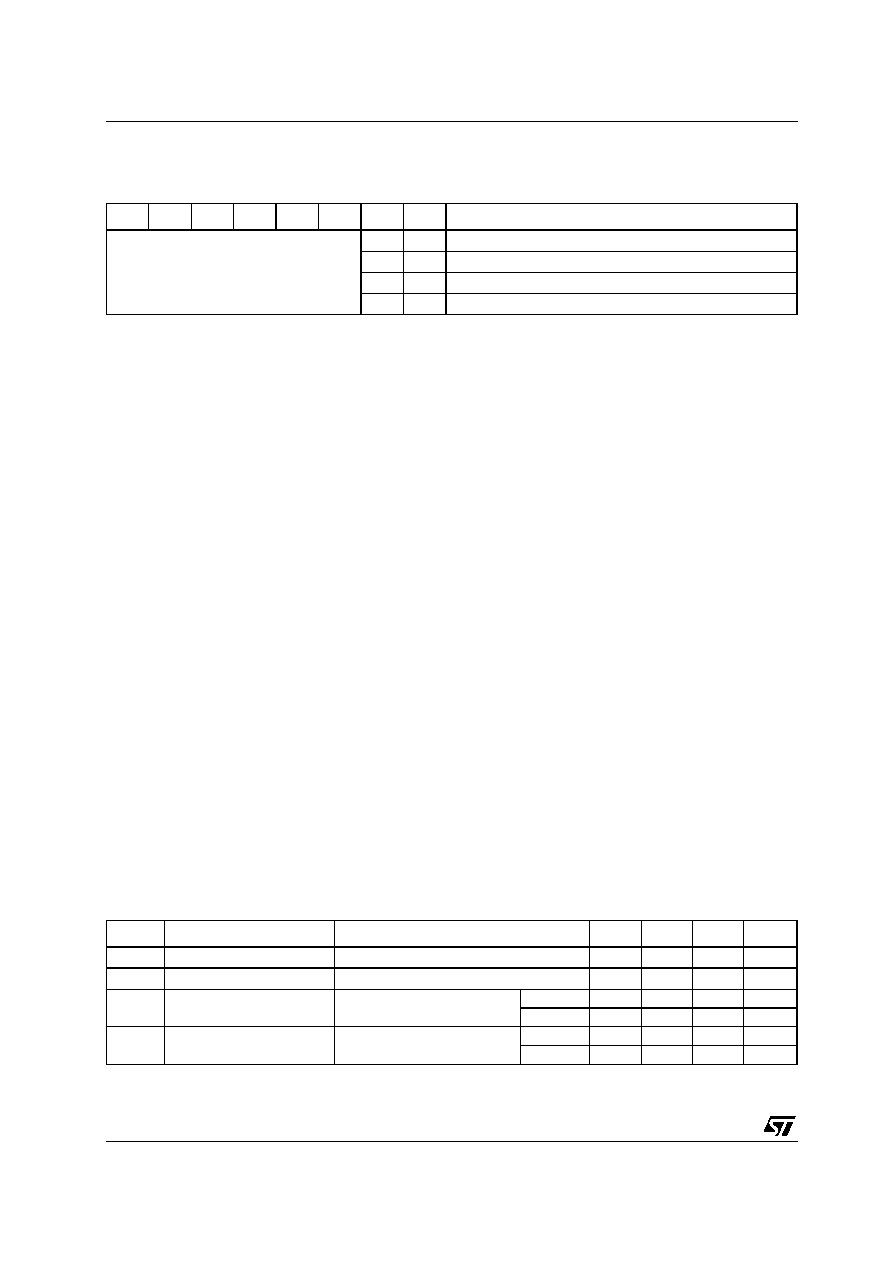

8/20

- no acknowledge, stopping the read mode

communication.

While the whole register is read back by the µP,

only the two read-only bits OLF and OTF convey

di-agnostic informations about the LNBP21.

Values are typical unless otherwise specified

POWER-ON I2C INTERFACE RESET

The

I2C

interface

built

in

the

LNBP21

is

automatically reset at power-on. As long as the

Vcc stays be-low the UnderVoltage Lockout

threshold (6.7V typ.), the interface will not respond

to any I2C com-mand and the System Register

(SR) is initialised to all zeroes, thus keeping the

power blocks disabled. Once the Vcc rises above

7.3V, the I2C interface becomes operative and the

SR can be configured by the main µP. This is due

to About 500mV of hysteresis provided in the UVL

threshold to avoid false retriggering of the

Power-On reset circuit.

DiSEqCTM IMPLEMENTATION

The LNBP21 helps the system designer to

implement the bi-directional (2.x) DiSEqC protocol

by

al-lowing

an

easy

PWK

modulation/

demodulation of the 22KHz carrier. The PWK data

are exchanged between the LNBP21 and the

main µP using logic levels that are compatible with

both 3.3 and 5V mi-crocontrollers. This data

exchange is made through two dedicated pins,

DSQIN and DSQOUT, in or-der to maintain the

timing relationships between the PWK data and

the PWK modulation as accurate as possible.

These two pins should be directly connected to

two I/O pins of the µP, thus leaving to the resident

firmware the task of encoding and decoding the

PWK data in accordance to the DiSEqC pro-tocol.

Full compliance of the system to the specification

is thus not implied by the bare use of the LNBP21.

The

system

designer

should

also

take

in

consideration the bus hardware requirements,

that include the source impedance of the Master

Transmitter measured at 22KHz. To limit the

attenuation at car-rier frequency, this impedance

has to be 15ohm at 22KHz, dropping to zero ohm

at DC to allow the power flow towards the

peripherals. This can be simply accomplished by

the LR

termination put on the OUT pin of the

LNBP, as shown in the Typical Application Circuit

on page 5.

Unidirectional (1.x) DiSEqC and non-DiSEqC

systems normally don't need this termination, and

the OUT pin can be directly connected to the LNB

supply port of the Tuner. There is also no need of

Tone Decoding, thus, it is recommended to

connect the DETIN and DSQOUT pins to ground

to avoid EMI.

ADDRESS PIN

Connecting this pin to GND the Chip I2C interface

address is 0001000, but, it is possible to choice

among 4 different addresses simply setting this

pin at 4 fixed voltage levels (see table on page

10).

ELECTRICAL CHARACTERISTICS FOR LNBP SERIES (T

J

= 0 to 85∞C, EN=1, LLC=0, TEN=0, ISEL=0,

PCL=0, DSQIN=0, V

IN

=12V, I

OUT

=50mA, unless otherwise specified. See software description section

for I

2

C access to the system register)

PCL

ISEL

TEN

LLC

VSEL

EN

OTF

OLF

Function

These bits are read exactly the same as

they were left after last write operation

0

T

J

<140∞C, normal operation

1

T

J

>150∞C, power block disabled, Loothrough switch open

0

I

OUT

<I

OMAX

, normal operation

1

I

OUT

>I

OMAX

, overload protection triggered

Symbol

Parameter

Test Conditions

Min.

Typ.

Max.

Unit

V

IN

Supply Voltage

I

O

= 500 mA TEN=VSEL=LLC=1

8

15

V

V

LT1

LT1 Input Voltage

20

V

I

IN

Supply Current

I

O

= 0mA TEN=VSEL=LLC=1

EN=1

20

40

mA

EN=0

2.5

5

mA

V

O

Output Voltage

I

O

= 500 mA VSEL=1

LLC=0

17.3

18

18.7

V

LLC=1

19

V

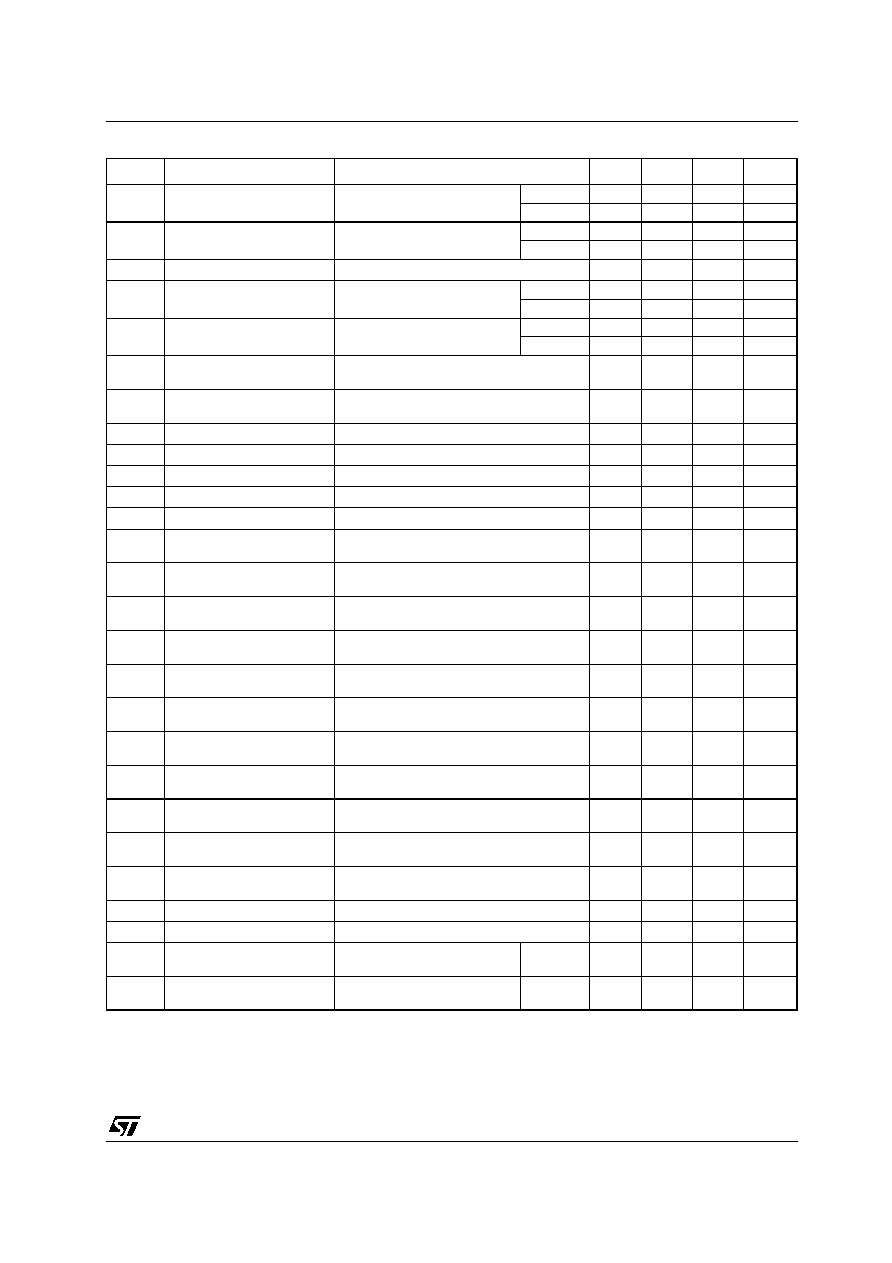

LNBP21

9/20

V

O

Output Voltage

I

O

= 500 mA VSEL=0

LLC=0

12.5

13

13.5

V

LLC=1

14

V

V

O

Line Regulation

V

IN1

=15 to 18V

VSEL=0

5

40

mV

VSEL=1

5

60

mV

V

O

Load Regulation

VSEL=0 or 1 I

OUT

= 50 to 500mA

200

mV

I

MAX

Output Current Limiting

ISEL=1

400

550

mA

ISEL=0

500

650

mA

I

SC

Output Short Circuit Current

ISEL=1

200

mA

ISEL=0

300

mA

t

OFF

Dynamic Overload

protection OFF Time

PCL=0

Output Shorted

900

ms

t

ON

Dynamic Overload

protection ON Time

PCL=0

Output Shorted

t

OFF

/10

ms

f

TONE

Tone Frequency

TEN=1

20

22

24

KHz

A

TONE

Tone Amplitude

TEN=1

0.55

0.72

0.9

Vpp

D

TONE

Tone Duty Cycle

TEN=1

40

50

60

%

t

r

, t

f

Tone Rise and Fall Time

TEN=1

5

10

15

µ

s

G

EXTM

External Modulation Gain

V

OUT

/

V

EXTM

,

f = 10Hz to 40KHz

6

V

EXTM

External Modulation Input

Voltage

AC Coupling

400

mVpp

Z

EXTM

External Modulation

Impedance

f = 10Hz to 50KHz

260

V

LT

Loopthrough Switch Voltage

Drop (lt1 to LT2)

EN=0,

I

LT

=300mA,

V

MI

=12 or 19V

0.35

0.6

V

f

SW

DC/DC Converter Switch

Frequency

220

kHz

f

DETIN

Tone Detector Frequency

Capture Range

0.4Vpp sinewave

18

24

kHz

V

DETIN

Tone Detector Input

Amplitude

f

IN

=22kHz sinewave

0.2

1.5

Vpp

Z

DETIN

Tone Detector Input

Impedance

150

k

V

OL

Overload Flag Pin Logic

LOW

Tone present

I

OL

=2mA

0.3

0.5

V

I

OZ

Overload Flag Pin OFF

State Leakage Current

Tone absent

V

OH

= 6V

10

µ

A

V

IL

DSQIN Input Pin Logic

LOW

0.8

V

V

IH

DSQIN Input Pin Logic

HIGH

2

V

I

IH

DSQIN Pins Input Current

V

IH

= 5V

15

µ

A

I

OBK

Output Backward Current

EN=0

V

OBK

= 18V

-4

-10

mA

T

SHDN

Temperature Shutdown

Threshold

150

∞C

T

SHDN

Temperature Shutdown

Hysteresis

15

∞C

Symbol

Parameter

Test Conditions

Min.

Typ.

Max.

Unit

LNBP21

10/20

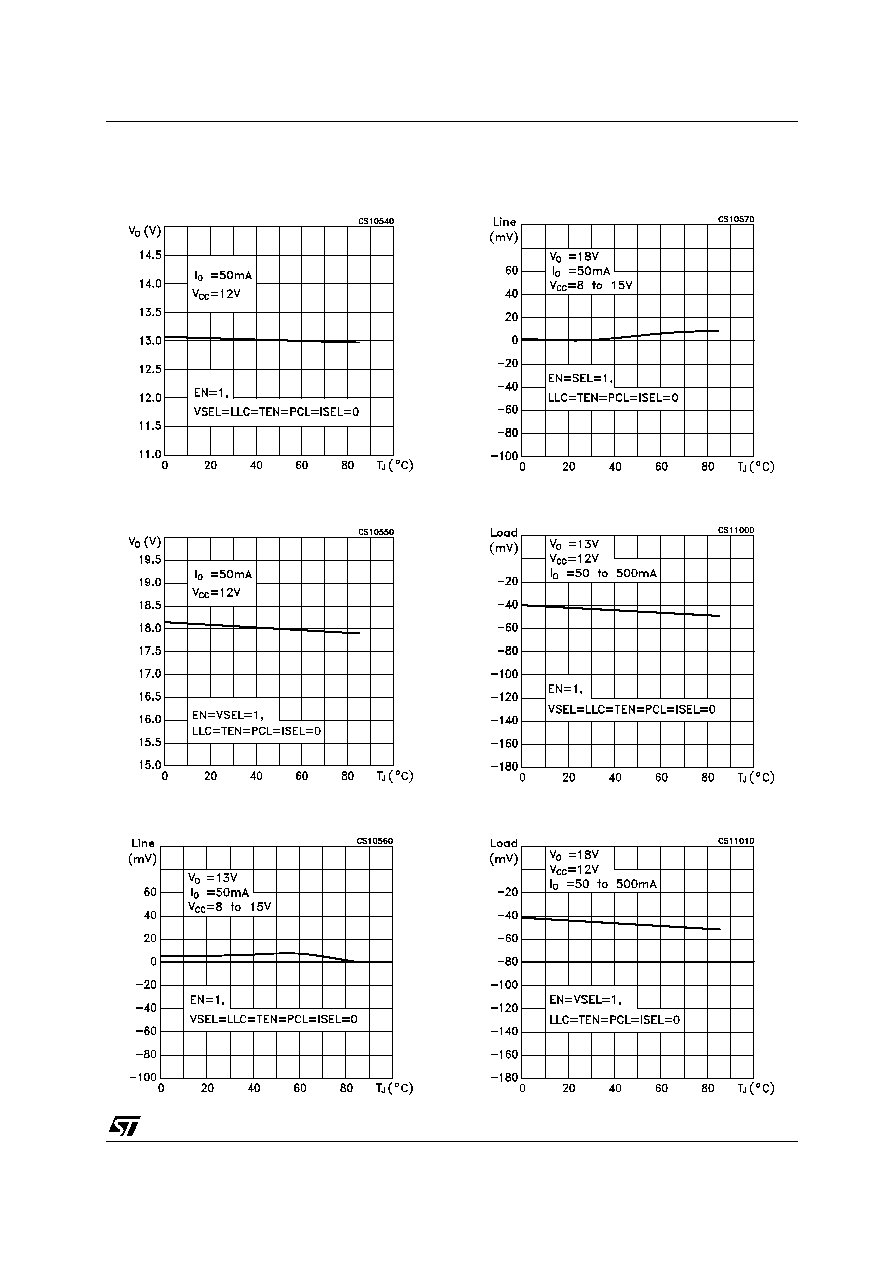

GATE AND SENSE ELECTRICAL CHARACTERISTICS (T

J

= 0 to 85∞C, V

IN

=12V)

I

2

C ELECTRICAL CHARACTERISTICS (T

J

= 0 to 85∞C, V

IN

=12V)

ADDRESS PIN CHARACTERISTICS (T

J

= 0 to 85∞C, V

IN

=12V)

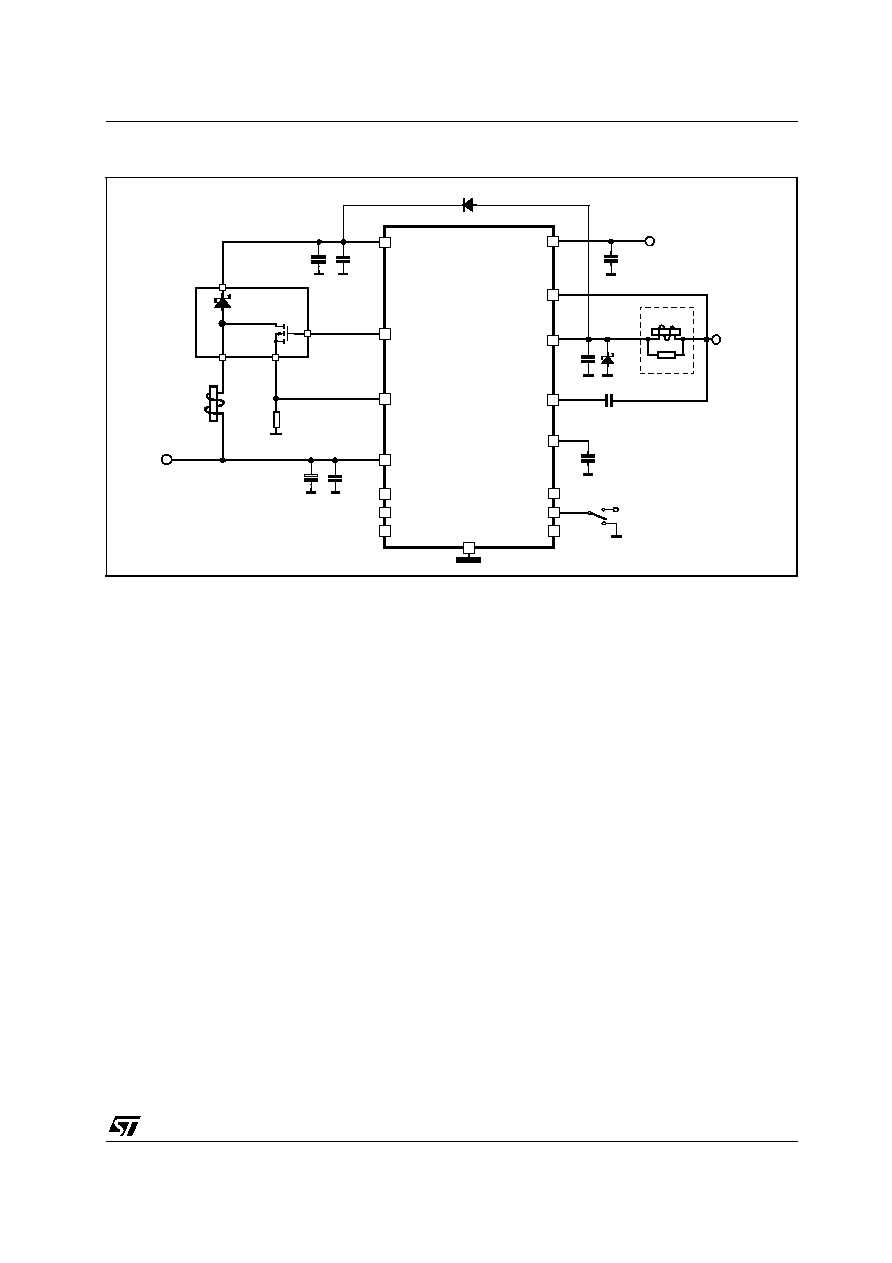

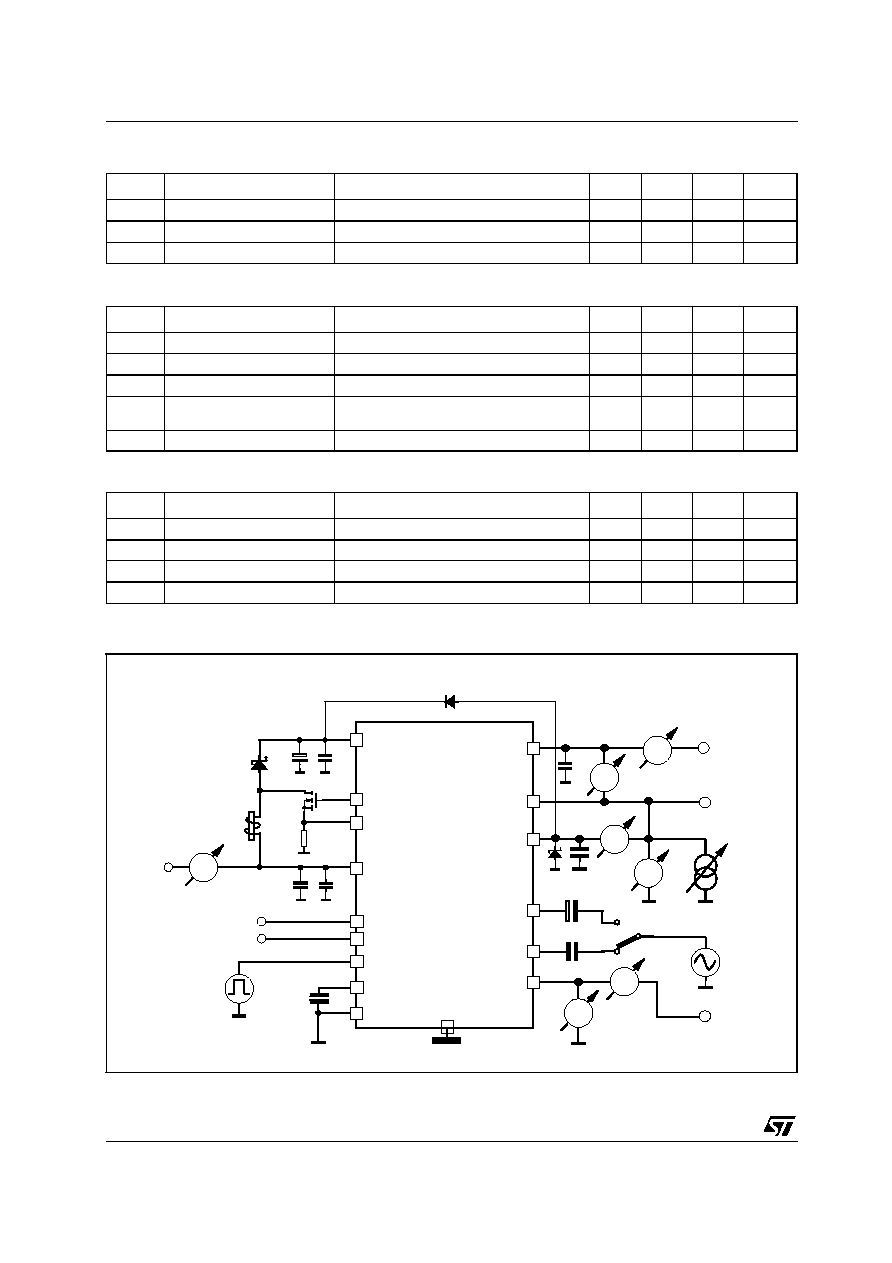

TEST CIRCUIT

Symbol

Parameter

Test Conditions

Min.

Typ.

Max.

Unit

R

DSON-L

Gate LOW R

DSON

I

GATE

=-100mA

4.5

R

DSON-H

Gate LOW R

DSON

I

GATE

=100mA

4.5

V

SENSE

Current Limit Sense Voltage

200

mV

Symbol

Parameter

Test Conditions

Min.

Typ.

Max.

Unit

V

IL

LOW Level Input Voltage

SDA, SCL

0.8

V

V

IH

HIGH Level Input Voltage

SDA, SCL

2

V

I

IH

Input Current

SDA, SCL, V

IN

= 0.4 to 4.5v

-10

10

µ

A

V

IL

DSQIN Input Pin Logic

LOW

SDA (open drain), I

OL

= 6mA

0.6

V

f

MAX

Maximum Clock Frequency SCL

500

KHz

Symbol

Parameter

Test Conditions

Min.

Typ.

Max.

Unit

V

ADDR-1

"0001000" Addr Pin Voltage

0

0.7

V

V

ADDR-2

"0001001" Addr Pin Voltage

1.3

1.7

V

V

ADDR-3

"0001010" Addr Pin Voltage

2.3

2.7

V

V

ADDR-4

"0001011" Addr Pin Voltage

3.3

5

V

Gate

Vup

LT1

OUT

Vcc

EXTM

DSQOUT

10nF

LT2

DETIN

10nF

Scope Probe

V

MI,

V

OBK

LNBP21

470nF

BYP

I

O

, I

OBK

A

Vin

A

I

IN

A

I

LT

V

V

OUT

Load

20µF

V

A

I

OZ

/ I

OL

OL

V

OH

/ I

OL

SDA

SCL

SCL

SDA

{

From I

2

C

Master

DSQIN

Pulse Gen.

V

EXTM,

V

DETIN

Sense

STN4NF03L

R

sc

0.1

220µF

470nF

STPS2L30A

220µF

470nF

L1=22µH

ADDRESS

V

1N4001

V

V

LT

10nF

LNBP21

11/20

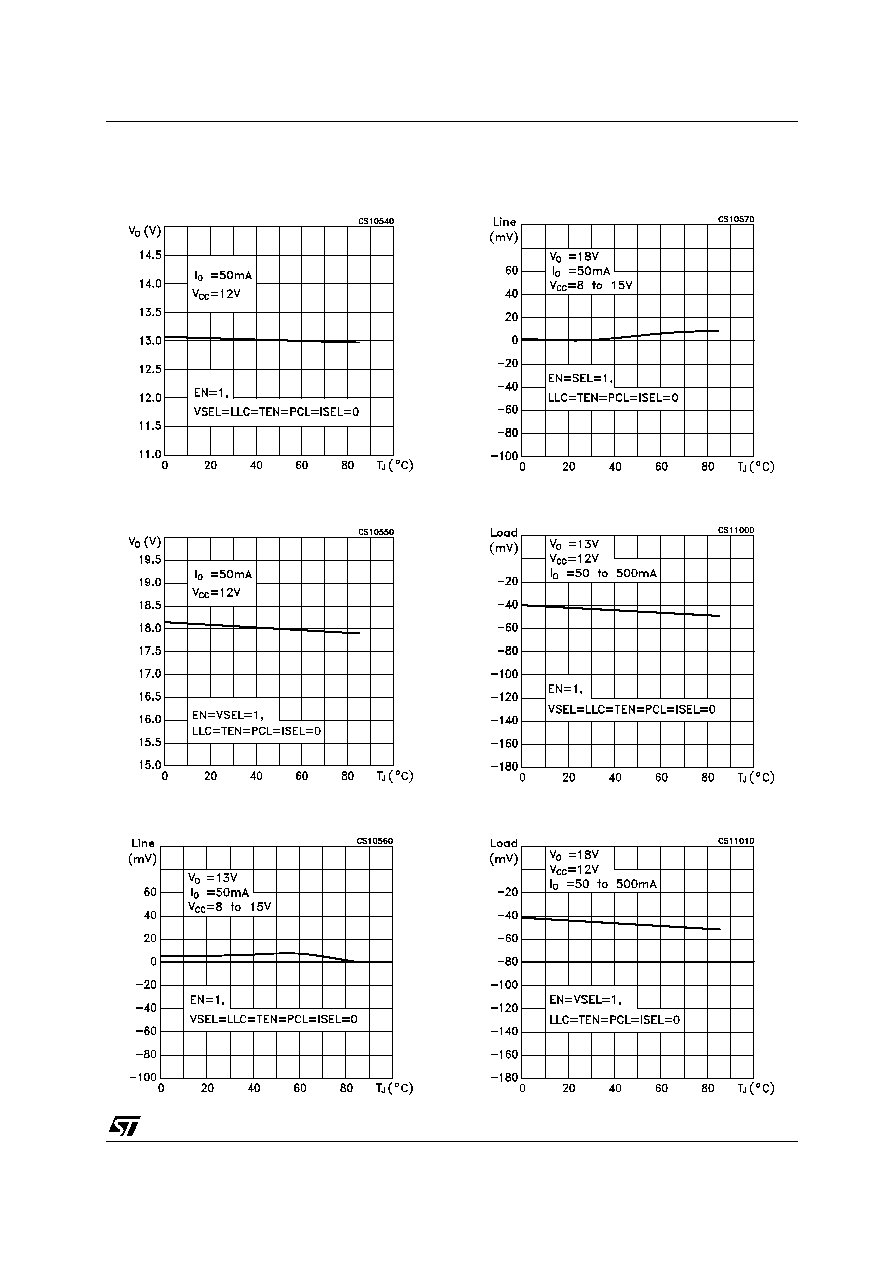

TYPICAL CHARACTERISTICS

(unless otherwise specified T

j

= 25∞C)

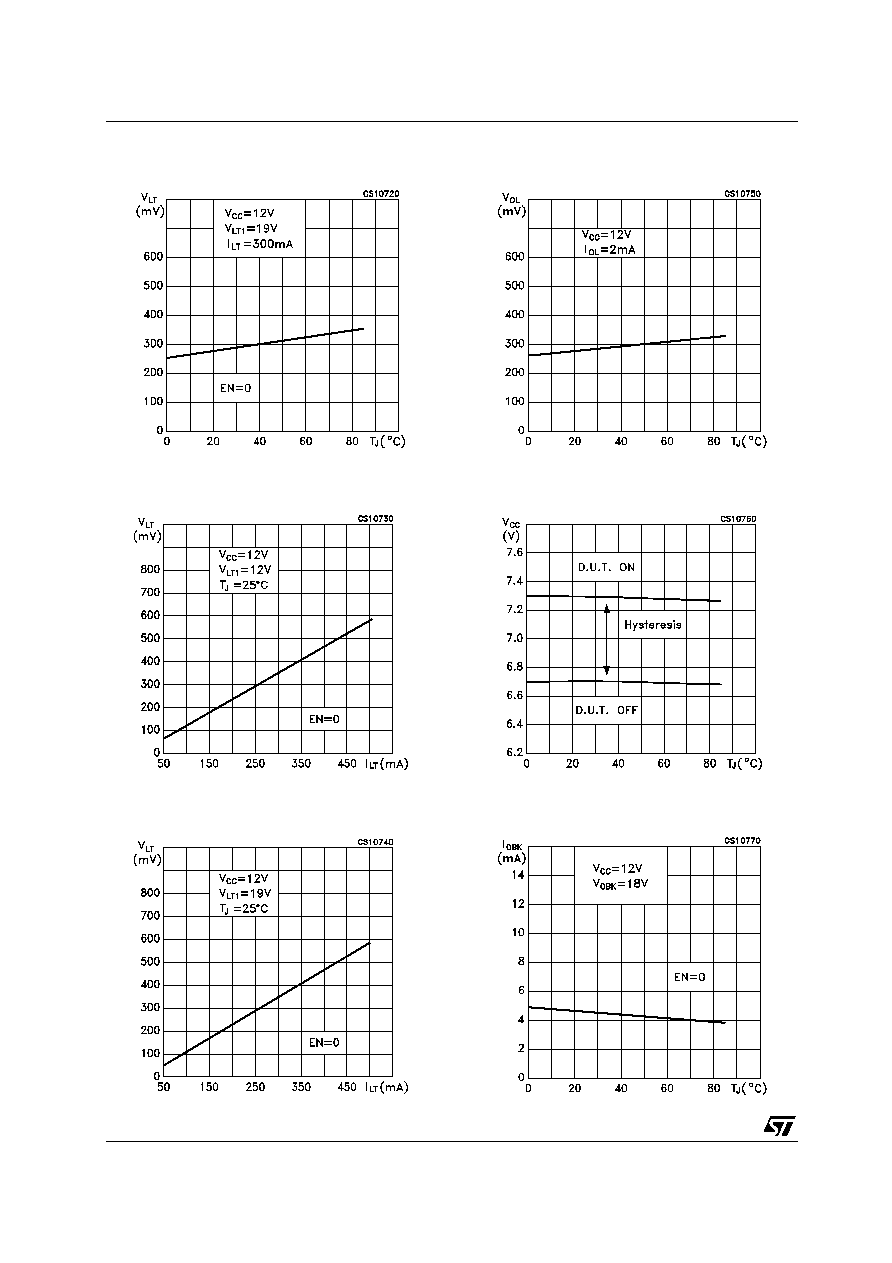

Figure 4 :

Output Voltage vs Temperature

Figure 5 :

Output Voltage vs Temperature

Figure 6 :

Line Regulation vs Temperature

Figure 7 :

Line Regulation vs Temperature

Figure 8 :

Load Regulation vs Temperature

Figure 9 :

Load Regulation vs Temperature

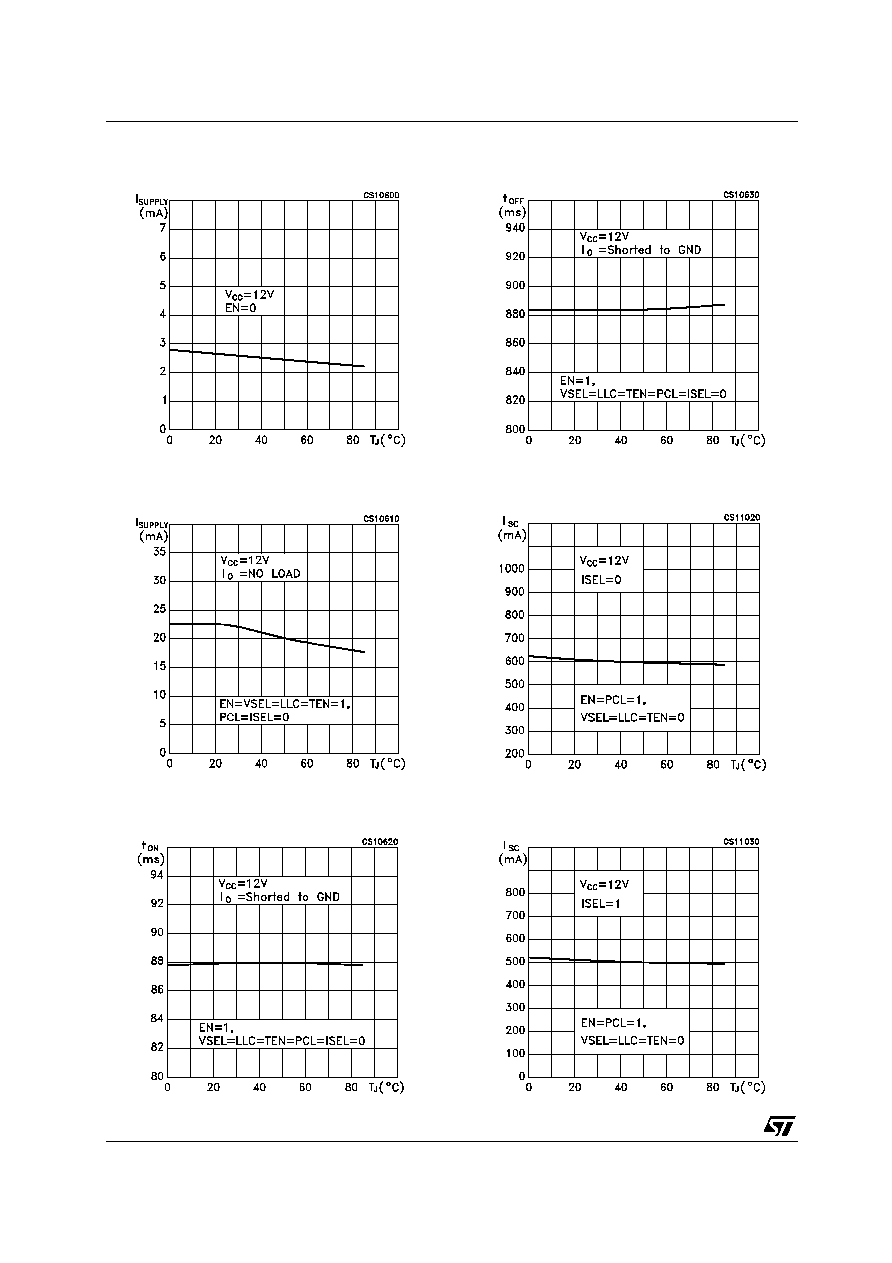

LNBP21

12/20

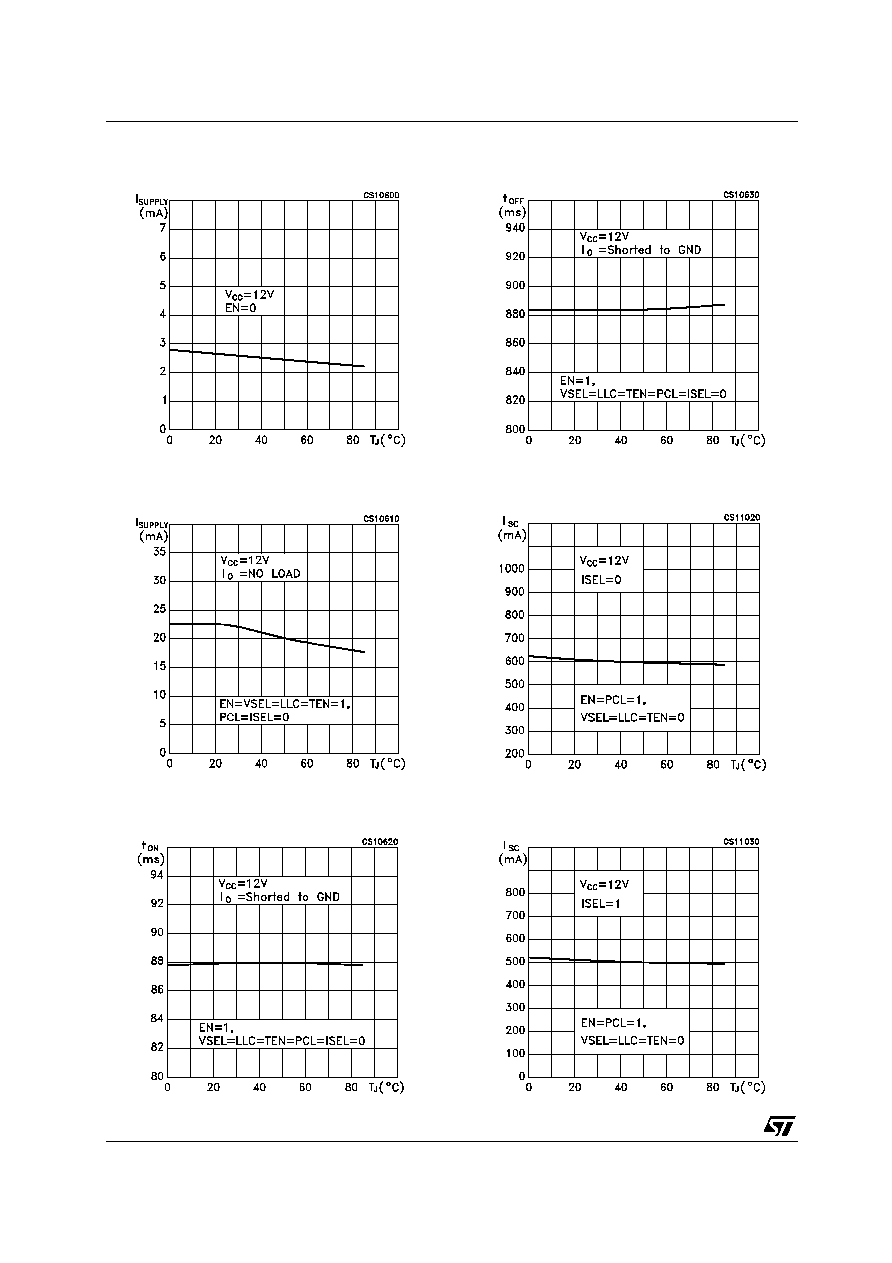

Figure 10 :

Supply Current vs Temperature

Figure 11 :

Supply Current vs Temperature

Figure 12 :

Dynamic Overload Protection ON

Time vs Temperature

Figure 13 :

Dynamic Overload Protection OFF

Time vs Temperature

Figure 14 :

Output Current Limiting vs

Temperature

Figure 15 :

Output Current Limiting vs

Temperature

LNBP21

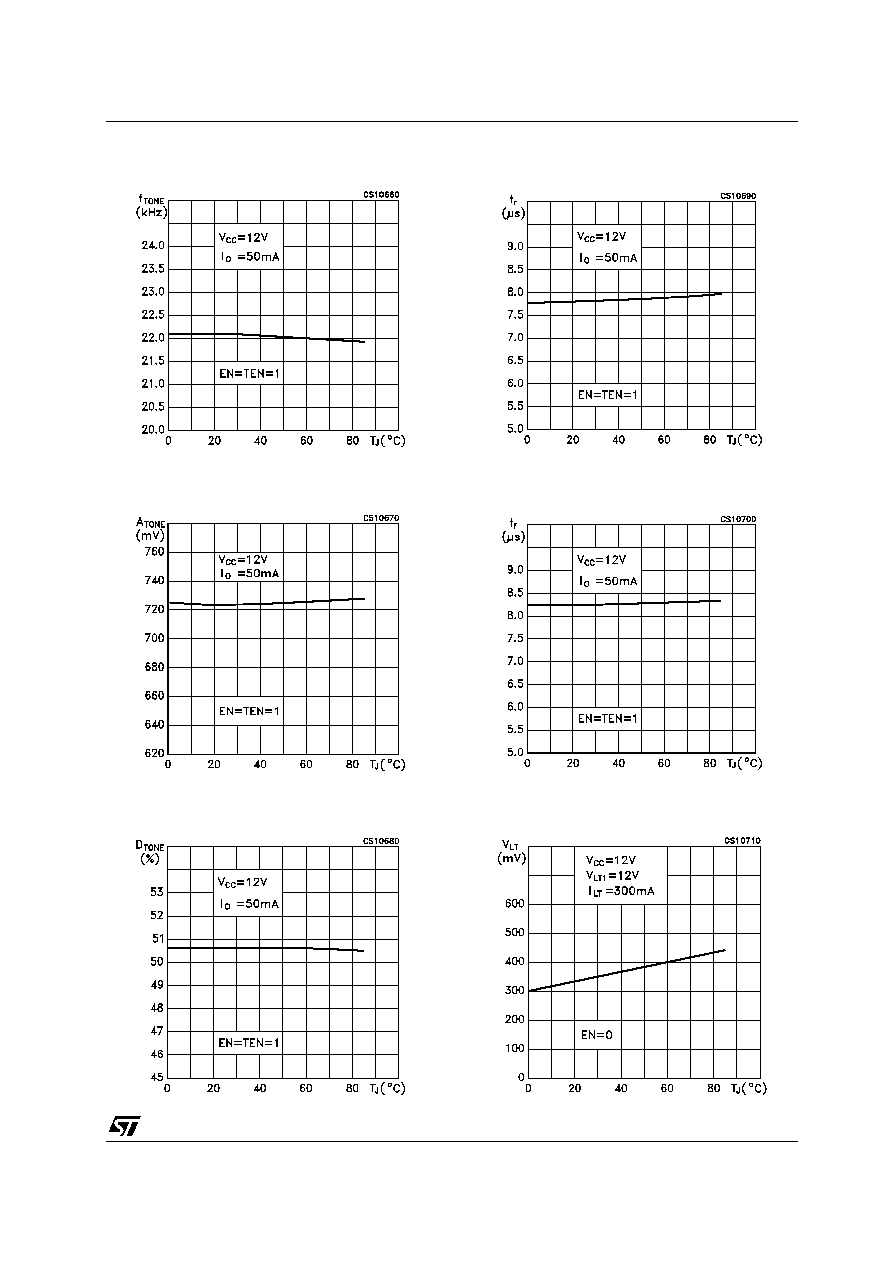

13/20

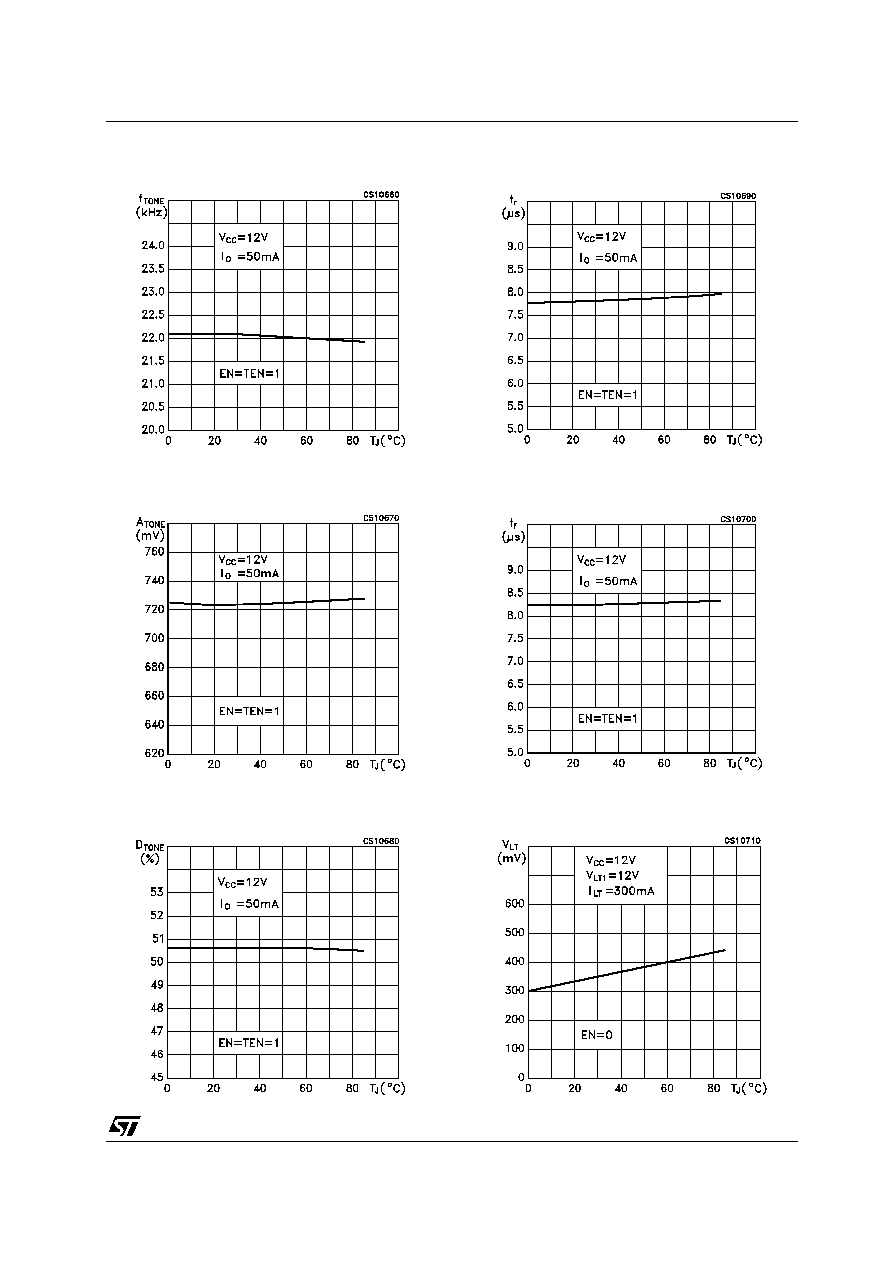

Figure 16 :

Tone Frequency vs Temperature

Figure 17 :

Tone Amplitude vs Temperature

Figure 18 :

Tone Duty Cicle vs Temperature

Figure 19 :

Tone Rise Time vs Temperature

Figure 20 :

Tone Fall Time vs Temperature

Figure 21 :

Loopthrought Switch Drop Voltage vs

Temperature

LNBP21

14/20

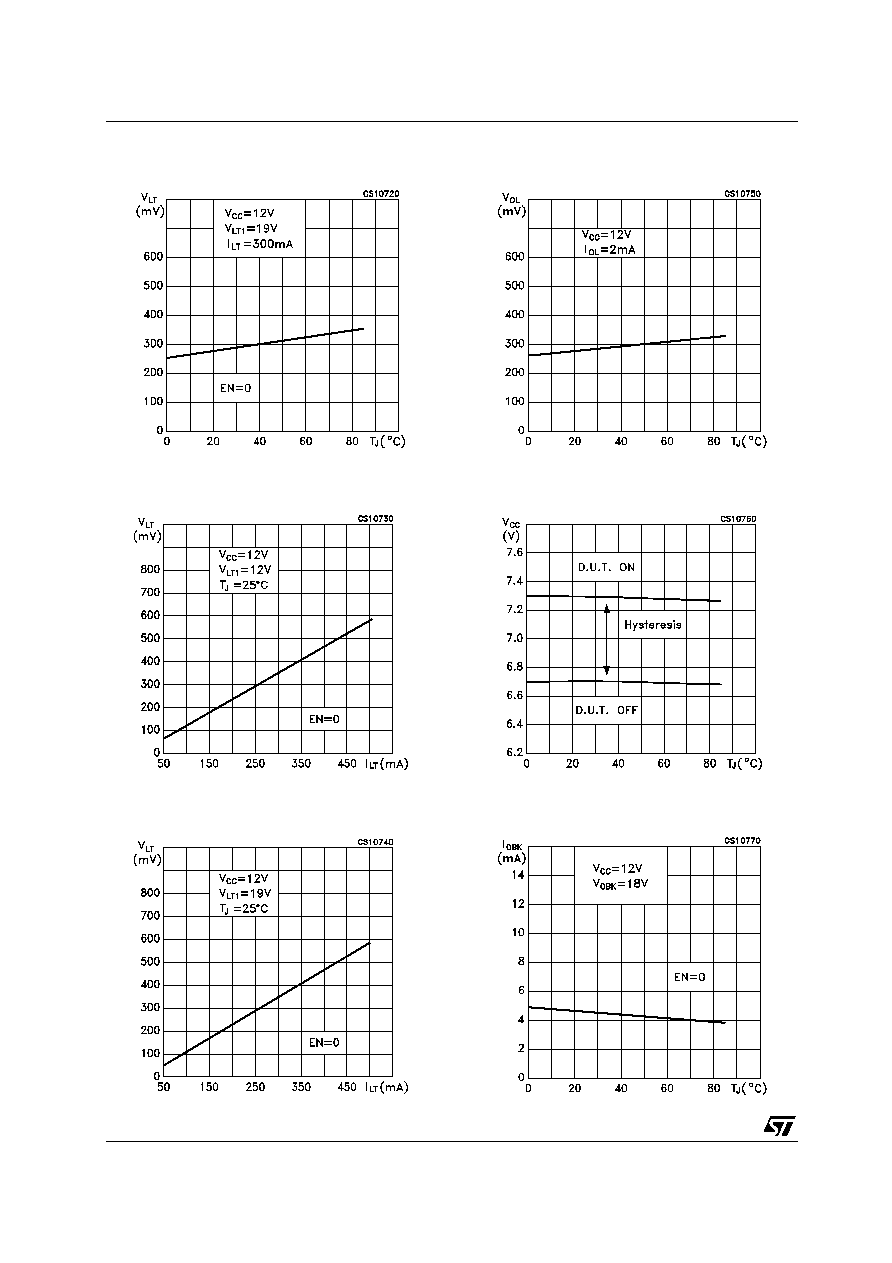

Figure 22 :

Loopthrought Switch Drop Voltage vs

Temperature

Figure 23 :

Loopthrought Switch Drop Voltage vs

Loopthrought Current

Figure 24 :

Loopthrought Switch Drop Voltage vs

Loopthrought Current

Figure 25 :

DSQOUT Pin Logic Low vs

Temperature

Figure 26 :

Undervoltage Lockout Threshold vs

Temperature

Figure 27 :

Output Backward Current vs

Temperature

LNBP21

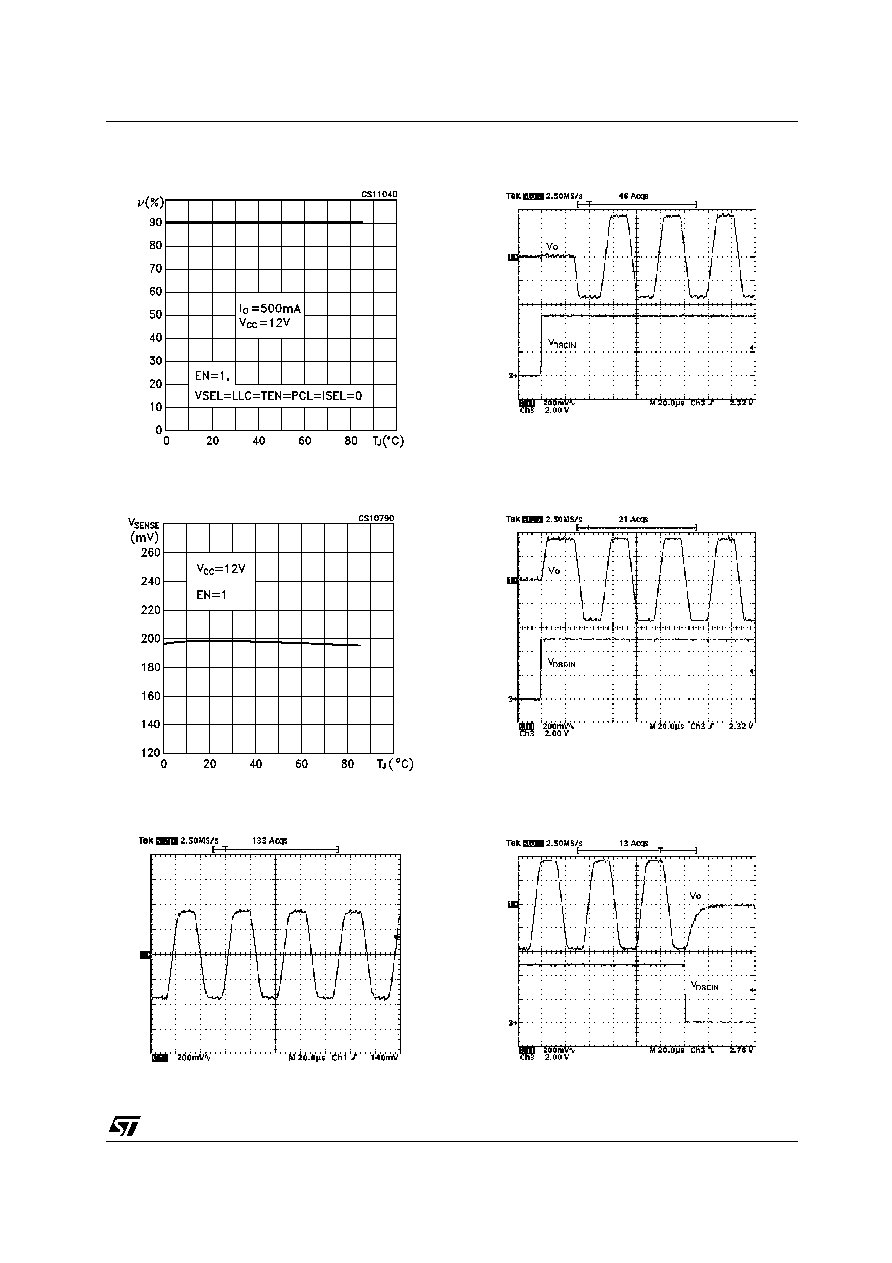

15/20

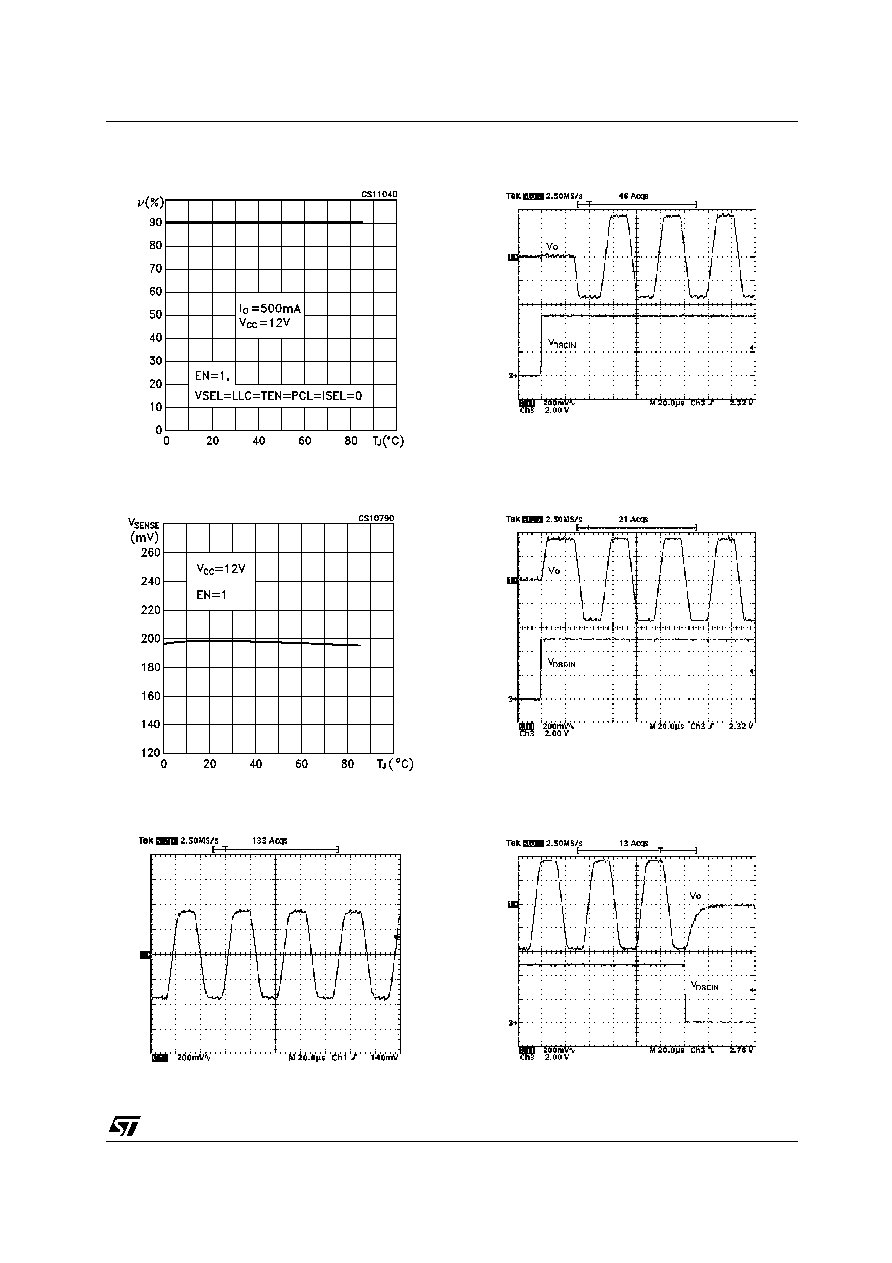

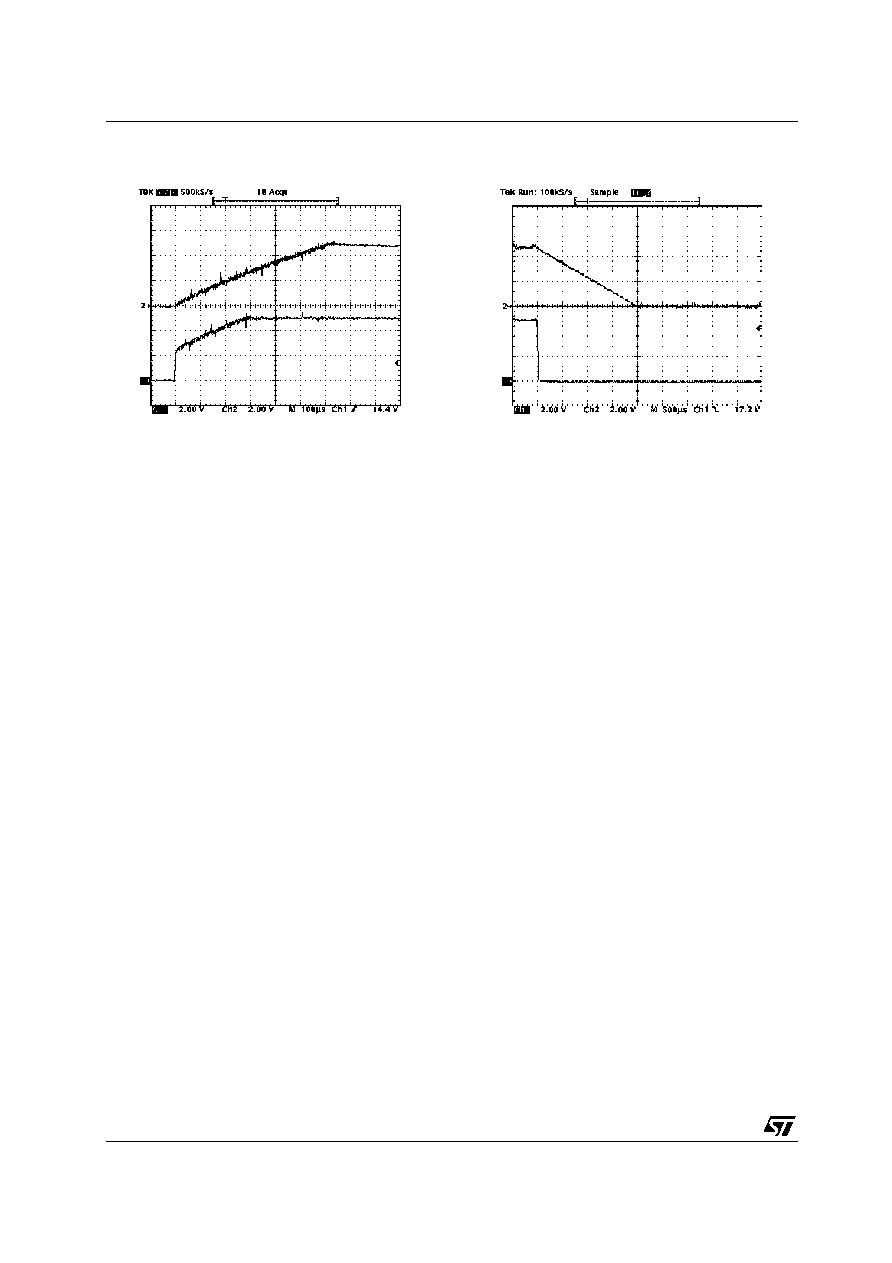

Figure 28 :

DC/DC Converter Efficiency vs

Temperature

Figure 29 :

Current Limit Sense vs Temperature

Figure 30 :

22kHz Tone

Figure 31 :

DSQIN Tone Enable Transient

Response

Figure 32 :

DSQIN Tone Enable Transient

Response

Figure 33 :

DSQIN Tone Disable Transient

Response

V

CC

=12V, I

O

=50mA, EN=TEN=1

V

CC

=12V, I

O

=50mA, EN=1, TEN=0

V

CC

=12V, I

O

=50mA, EN=1, TEN=0

V

CC

=12V, I

O

=50mA, EN=1, TEN=0

LNBP21

16/20

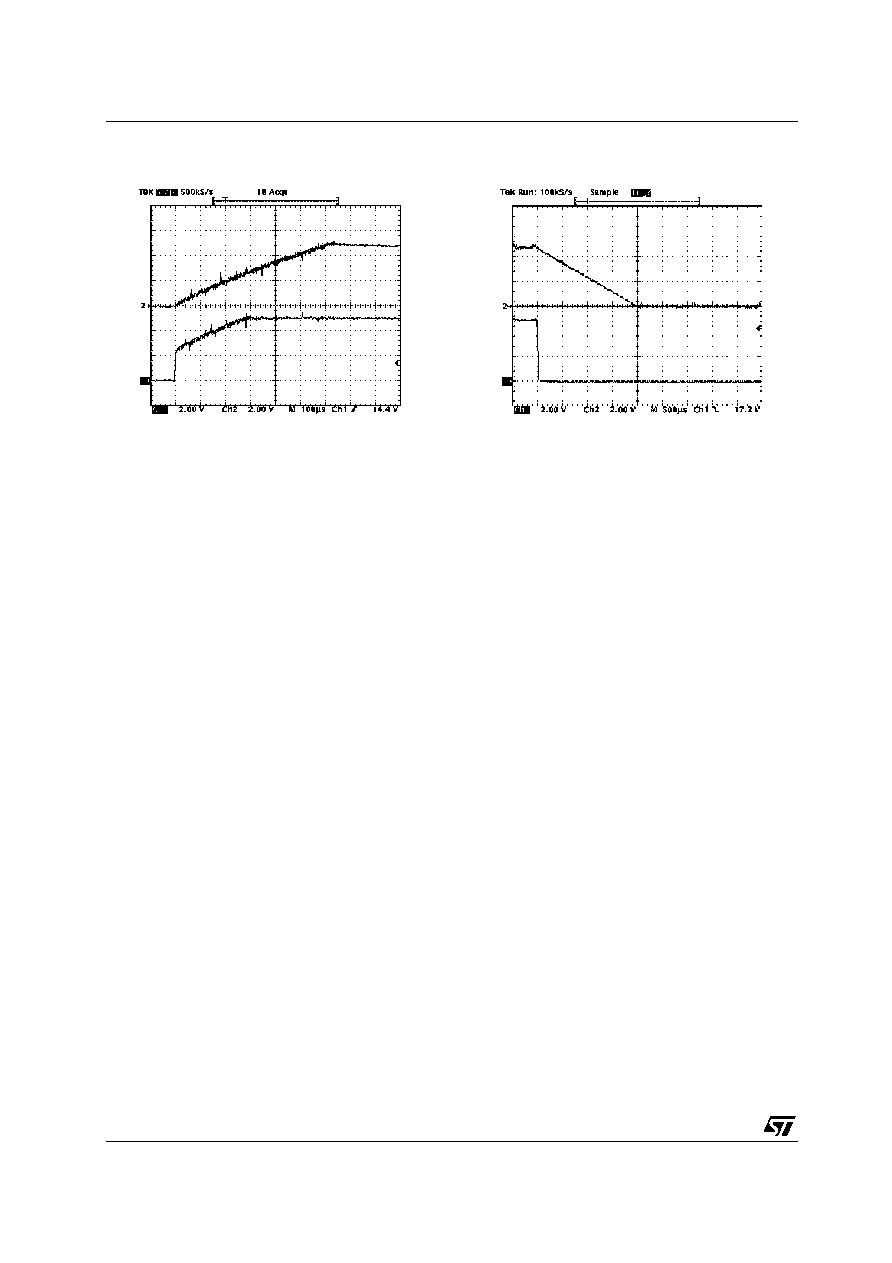

Figure 34 :

Output Voltage Transient Response

from 13V to 18V

Figure 35 :

Output Voltage Transient Response

from 13V to 18V

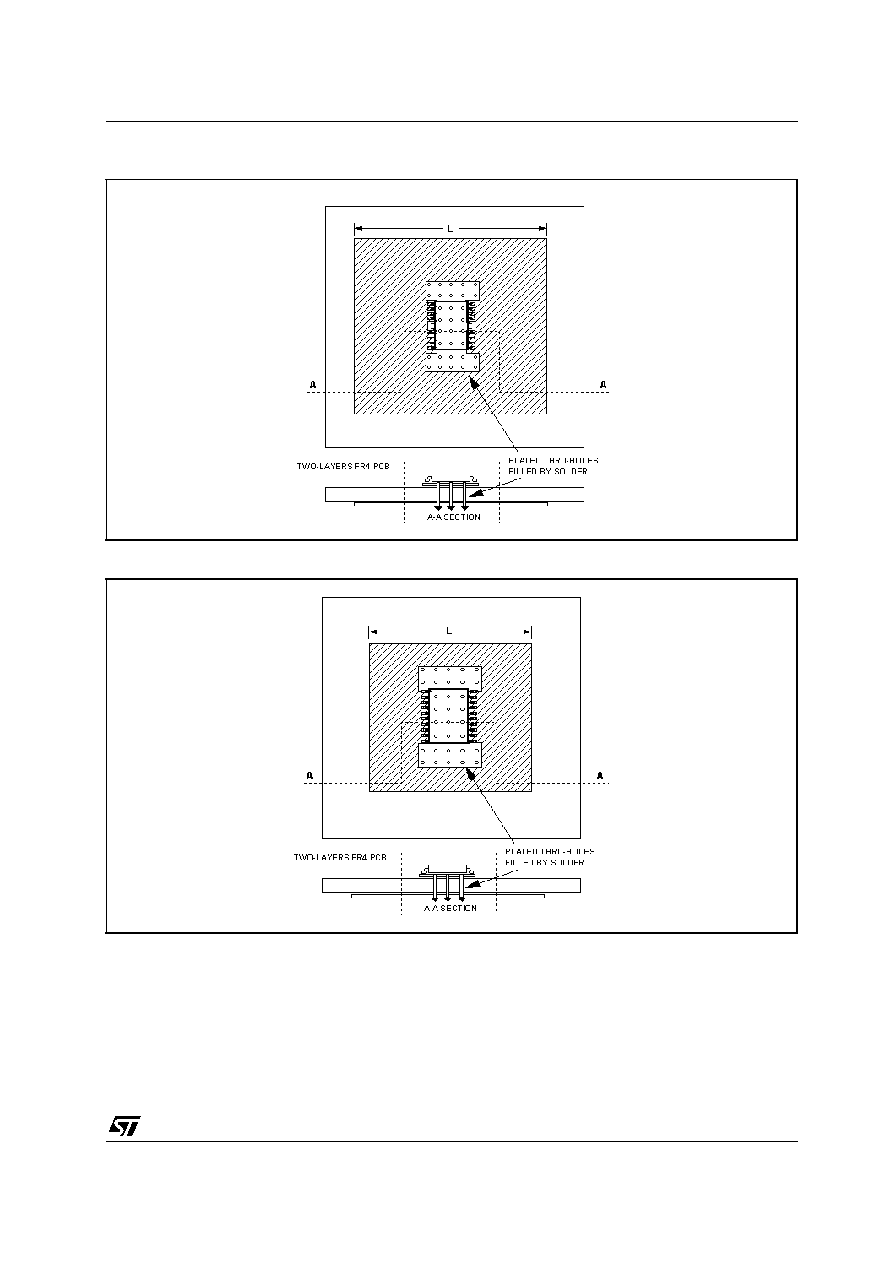

TERMAL DESIGN NOTES

During normal operation, this device dissipates

some power. At maximum rated output current

(500mA), the voltage drop on the linear regulator

lead to a total dissipated power that is of about

1.7W. The heat generated requires a suitable

heatsink to keep the junction temperature below

the

overtemperature

protection

threshold.

Assuming

a

40∞C

temperature

inside

the

Set-Top-Box case, the total Rthj-amb has to be

less than 50∞C/W.

While this

can be easily

achieved using a

through-hole power package that can be attached

to a small heatsink or to the metallic frame of the

receiver, a surface mount power package must

rely on PCB solutions whose thermal efficiency is

often limited. The simplest solution is to use a

large, con-tinuous copper area of the GND layer to

dissipate the heat coming from the IC body.

The SO-20 package of this IC has 4 GND pins that

are

not

just

intended

for

electrical

GND

connec-tion, but also to provide a low thermal

resistance path between the silicon chip and the

PCB heatsink. Given an Rthj-c equal to 15∞C/W,

a maximum of

35∞C/W

are left to the PCB

heatsink. This figure is achieved if a minimum of

25cm2 copper area is placed just below the IC

body. This area can be the inner GND layer of a

multi-layer PCB, or, in a dual layer PCB, an

unbroken GND area even on the opposite side

where the IC is placed. In both cases, the thermal

path between the IC GND pins and the dissipating

copper area must exhibit a low thermal resistance.

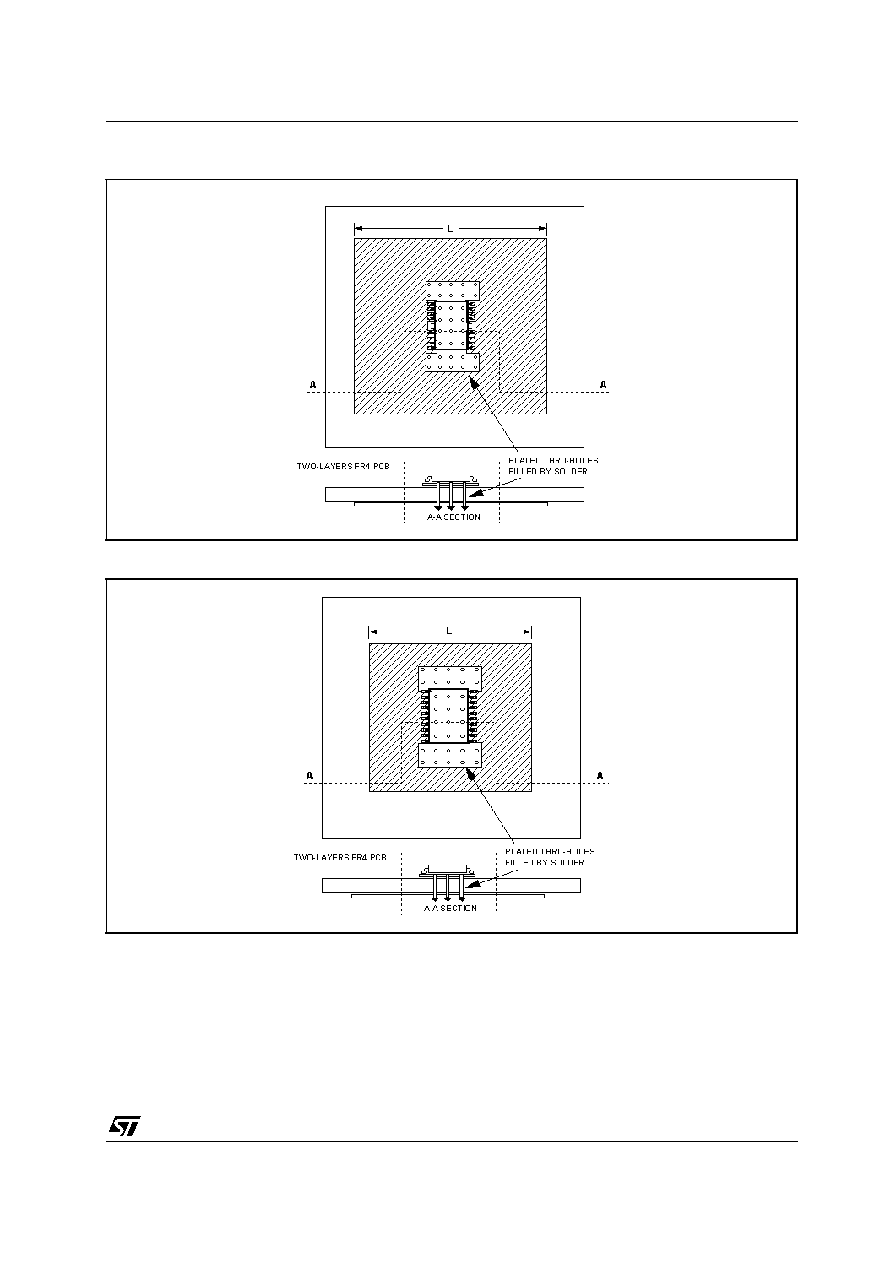

In figure 4 , it is shown a suggested layout for the

SO-20 package with a dual layer PCB, where the

IC Ground pins and the square dissipating area

are thermally connected through 32 vias holes,

filled

by

solder.

This

arrangement,

when

L=50mm, achieves an Rthc-a of about 25∞C/W.

Different

layouts

are

possible,

too.

Basic

principles, however, suggest to keep the IC and its

ground pins approximately in the middle of the

dissipating area; to provide as many vias as

possible; to de-sign a dissipating area having a

shape as square as possible and not interrupted

by other copper traces.

Due to presence of an exposed pad connected to

GND below the IC body, the PowerSO-20

package has a Rthj-c much lower than the SO-20,

only 2∞C/W. As a result, much lower copper area

must be provided to dissipate the same power and

minimum of 12cm2 copper area is enough, see

figure 5.

V

CC

=12V, I

O

=50mA, VSEL=from 0 to 1, EN=1

V

CC

=12V, I

O

=50mA, VSEL=from 1 to 0, EN=1

LNBP21

17/20

Figure 36 :

SO-20 SUGGESTED PCB HEATSINK LAYOUT

Figure 37 :

PowerSO-20 SUGGESTED PCB HEATSINK LAYOUT

LNBP21

18/20

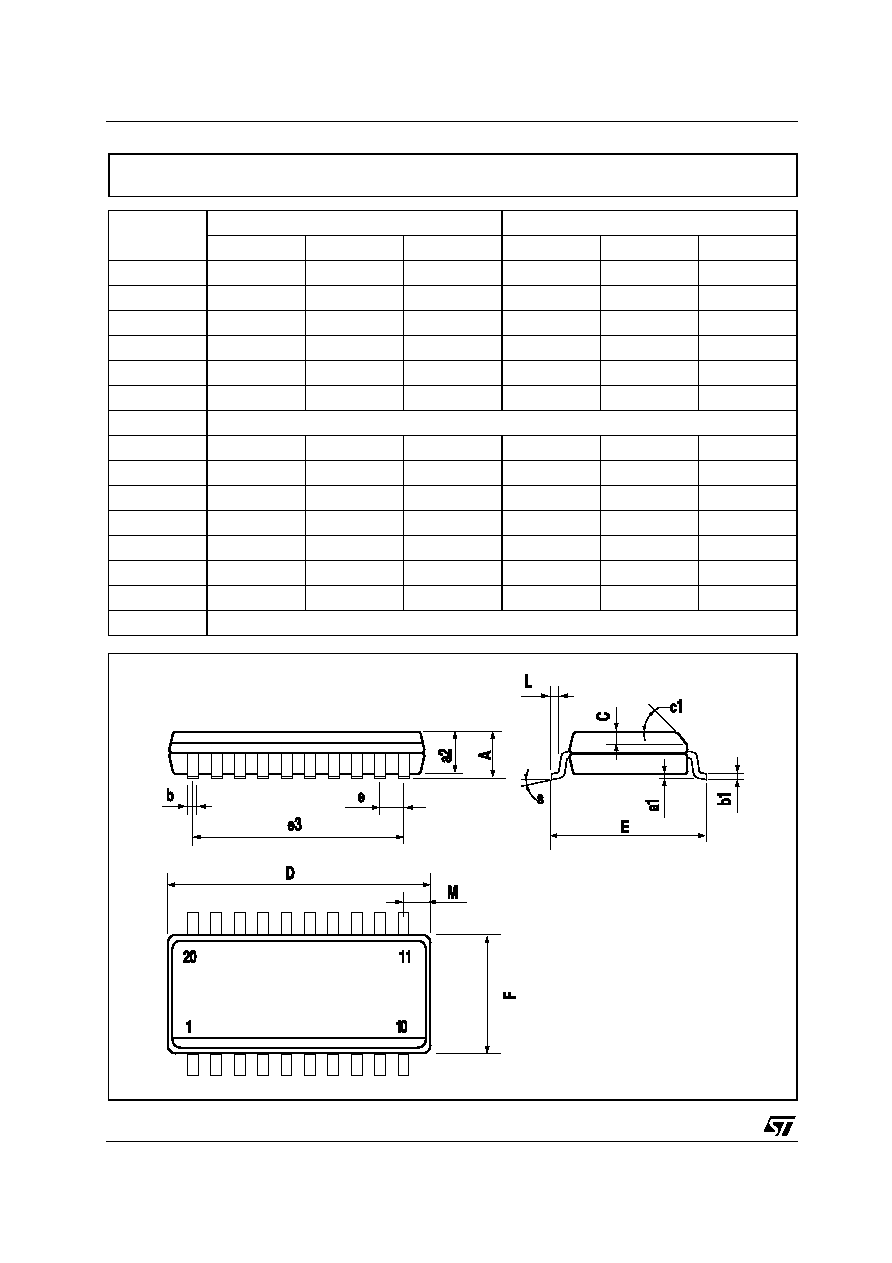

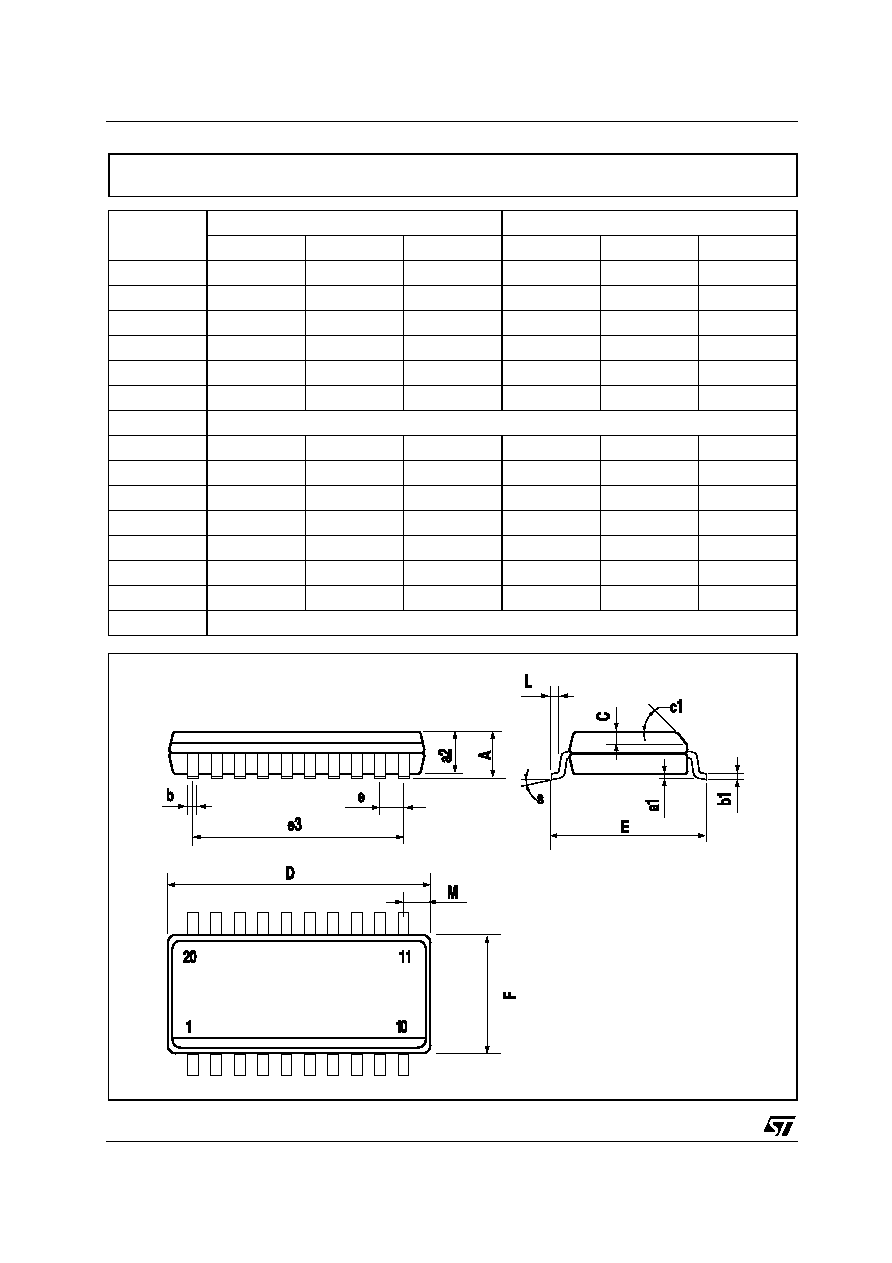

DIM.

mm.

inch

MIN.

TYP

MAX.

MIN.

TYP.

MAX.

A

2.65

0.104

a1

0.1

0.2

0.004

0.008

a2

2.45

0.096

b

0.35

0.49

0.014

0.019

b1

0.23

0.32

0.009

0.012

C

0.5

0.020

c1

45∞ (typ.)

D

12.60

13.00

0.496

0.512

E

10.00

10.65

0.393

0.419

e

1.27

0.050

e3

11.43

0.450

F

7.40

7.60

0.291

0.300

L

0.50

1.27

0.020

0.050

M

0.75

0.029

S

∞ (max.)

SO-20 MECHANICAL DATA

PO13L

8

LNBP21

19/20

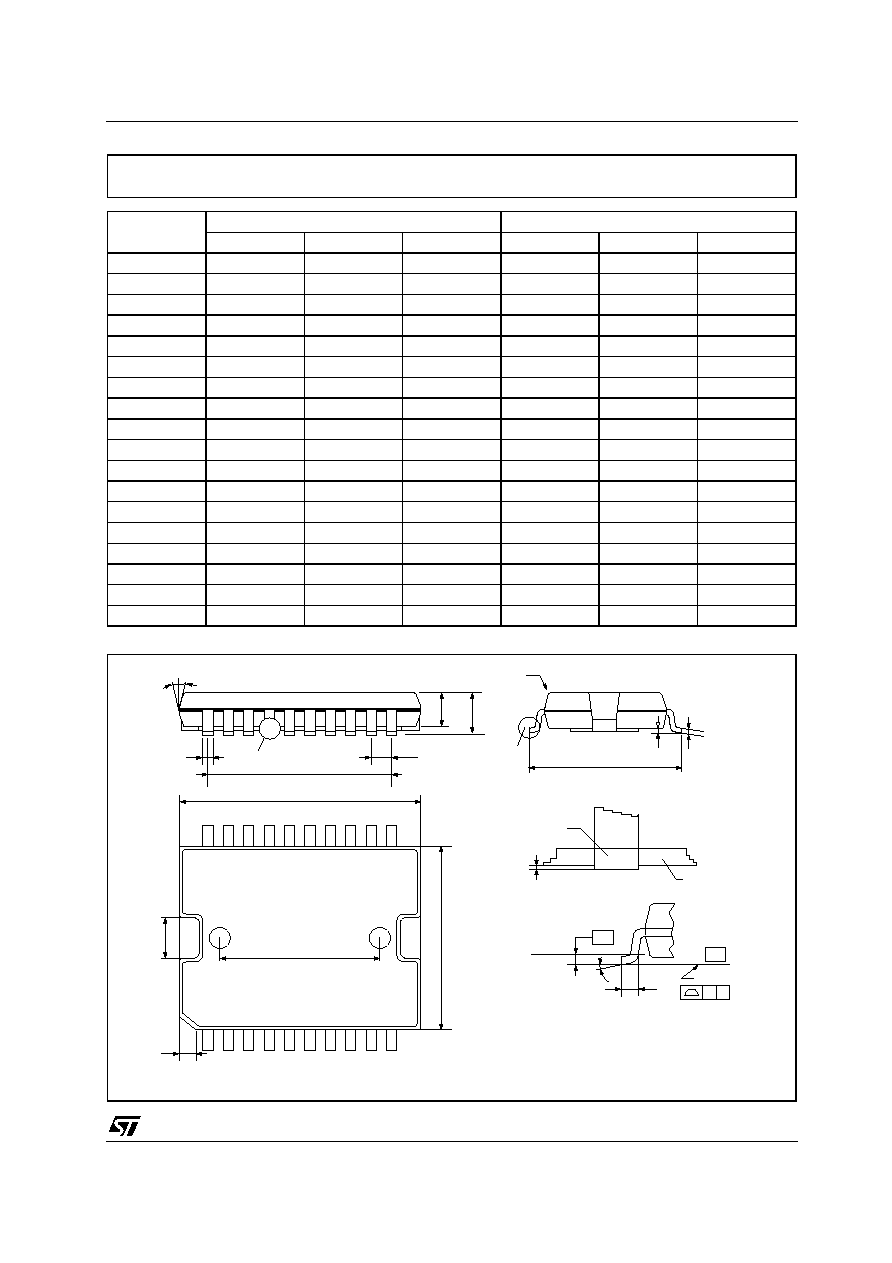

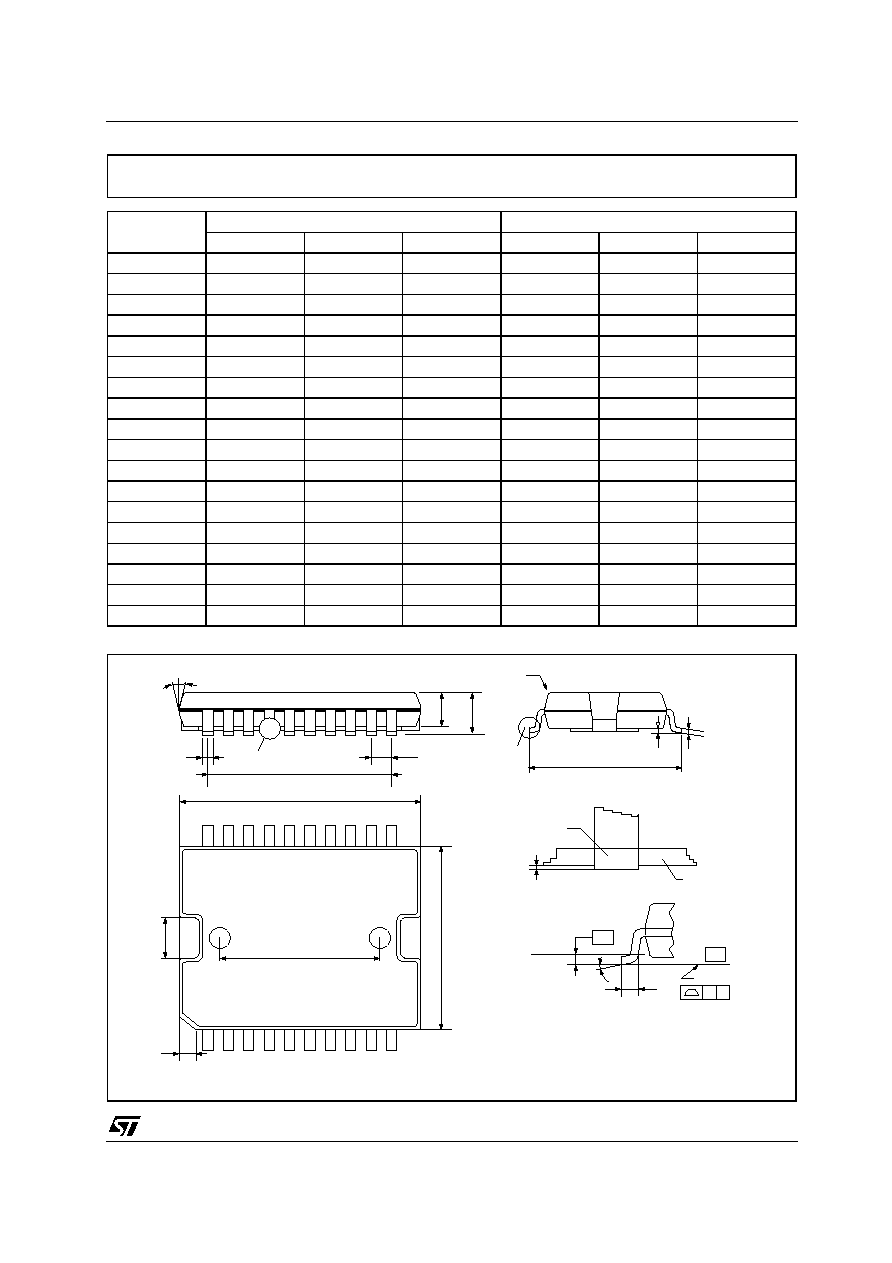

DIM.

mm.

inch

MIN.

TYP

MAX.

MIN.

TYP.

MAX.

A

3.60

0.1417

a1

0.10

0.30

0.0039

0.0118

a2

3.30

0.1299

a3

0

0.10

0

0.0039

b

0.40

0.53

0.0157

0.0209

c

0.23

0.32

0.0090

0.0013

D (1)

15.80

16.00

0.6220

0.630

E

13.90

14.50

0.5472

0.5710

e

1.27

0.0500

e3

11.43

0.4500

E1 (1)

10.90

11.10

0.4291

0.4370

E2

2.90

0.1141

G

0

0.10

0.0000

0.0039

h

1.10

0.0433

L

0.80

1.10

0.0314

0.0433

N

0∞

10∞

S

0∞

8∞

0∞

8∞

T

10.0

0.3937

PowerSO-20 MECHANICAL DATA

0056635

e

a2

A

E

a1

PSO20MEC

DETAIL A

T

D

1

1

0

11

20

E1

E2

h x 45∞

DETAIL A

lea

d

slug

a3

S

Gage

Plan

e

0.35

L

DETAIL B

R

DETAIL B

(COPLANARITY)

G

C

- C -

SEATING PLANE

e3

b

c

N

N

(1) "D and E1" do not include mold flash or protusions - Mold flash or protusions shall not exceed 0.15mm (0.006")

1

LNBP21

20/20

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the

consequences of use of such information nor for any infringement of patents or other rights of third parties which may result from

its use. No license is granted by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications

mentioned in this publication are subject to change without notice. This publication supersedes and replaces all information

previously supplied. STMicroelectronics products are not authorized for use as critical components in life support devices or

systems without express written approval of STMicroelectronics.

© The ST logo is a registered trademark of STMicroelectronics

© 2002 STMicroelectronics - Printed in Italy - All Rights Reserved

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan - Malaysia - Malta - Morocco

Singapore - Spain - Sweden - Switzerland - United Kingdom - United States.

© http://www.st.com