Programmable Adaptive Laser Power Controller with Dual Lookup Tables

Preliminary Information

1

(See Last Page)

� SUMMIT Microelectronics, Inc. 2004 � 1717 Fox Drive � San Jose CA 95131-2312 � Phone 408 436-9890 � Fax 408 436-9897 � www.summitmicro.com

2066 6.3 1/22/04

1

SML2120

�

FEATURES AND APPLICATIONS

Features:

� Integrated Automatic Power Control (APC) circuit

� 100 mA bias current sink capability

� Dual low-current outputs (up to 2.5 mA) based on two

independent 256x8 Lookup Table values

� Bias current and/or temperature monitoring capability

� Dual high/low alert registers

� Advanced lookup algorithm eliminates unnecessary

output changes

� Flexible voltage operation;

0 to 5V, 0 to 3.3V, or -5.2V to +3.3V

� I

2

C 2-wire serial bus interface for programming

configuration, control values, monitoring, and

operational status - 100KHz and 400KHz

� Small 5X5 28-Pin QFN Package

Applications:

� Laser power management for Telecom/Datacom

motherboards

� Direct modulation and electro-absorptive modulation

applications

�

INTRODUCTION

The SML2120 is an advanced, programmable laser diode

power controller ideal for optical networking applications.

The integrated automatic power control (APC) circuit adapts

to variations in the laser's power output as detected by a

photo diode.

The SML2120 drives two low current outputs derived from

values stored in independent 256x8 Lookup Tables. The low

current outputs are suitable for controlling the MODSET

input of typical laser driver IC's. The input stimulus for each

Lookup Table can be configured as the laser temperature,

the bias current, or an external signal. Characteristics of the

laser's performance over time and temperature are stored

in the lookup tables, allowing the outputs to adapt to system

conditions and optimize overall performance.

Programming of configuration and control values by the

user are simplified with the I

2

C interface adapter

(SMX3200) and Windows Programming software available

from Summit Microelectronics.

�

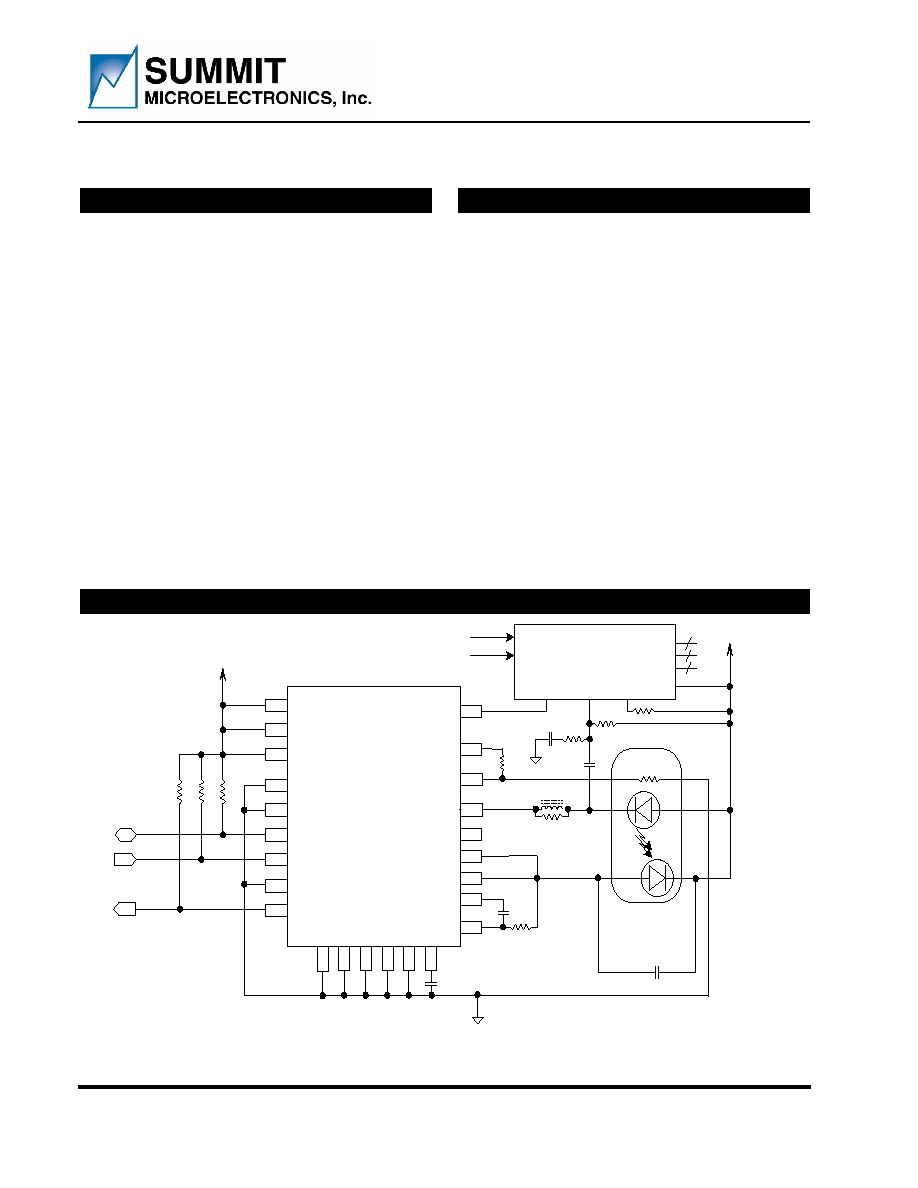

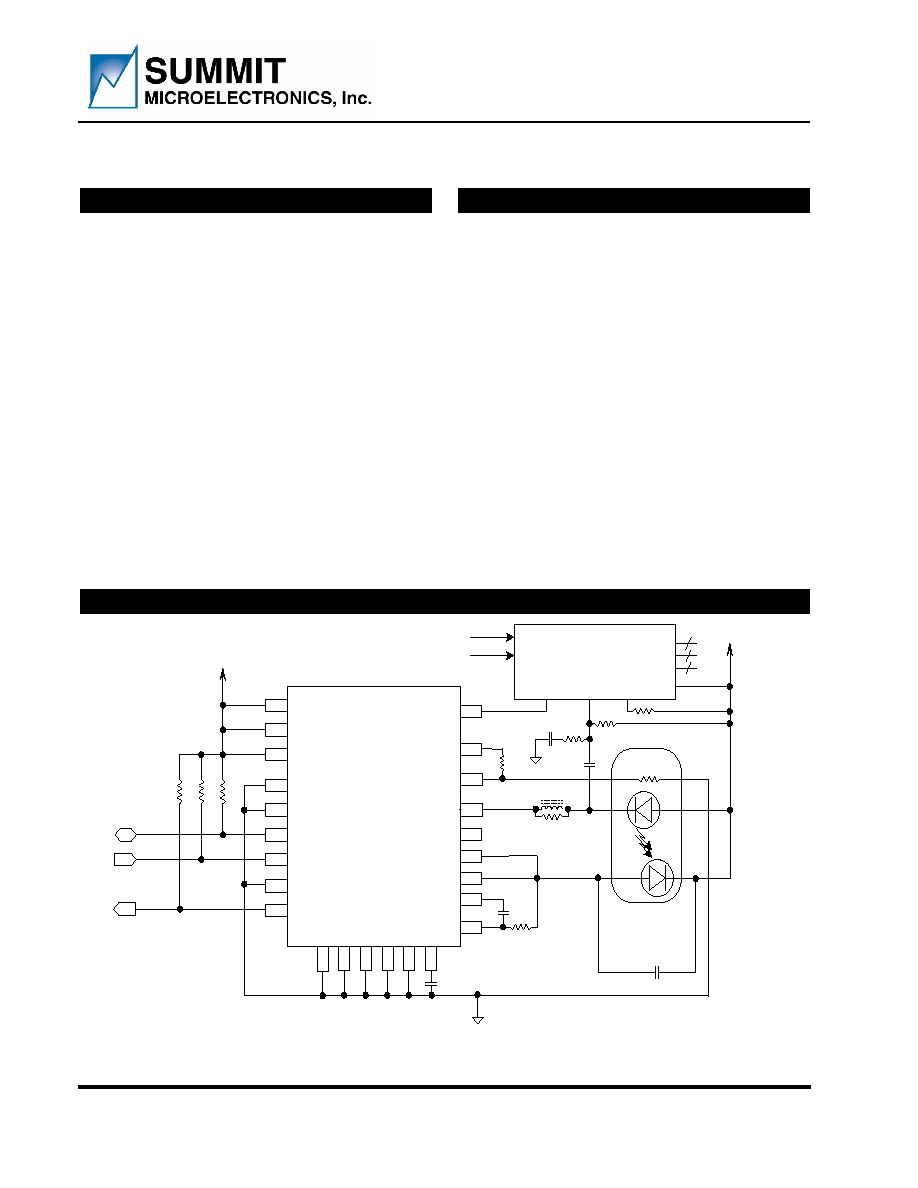

SIMPLIFIED APPLICATION DRAWING

Figure 1. Typical SML2120 Connections to a Laser Driver and Laser Diode

SML2120

V

DD

(+3.3V)

ILU1

THERMISTOR

14

11

20

18

BIAS

MPD

16

17

C1

C2

13

10

21

9

VS

S

15

24

25

VDD

VHI

+3.3V

8V

L

O

W

EN

A

#

1

2

3

4

5

A1

A2

SDA

SCL

6

7

AM#

ALERT#

A

d

d

r

ess = 0

DATA�

DATA+

MODSET

BIASMAX

APCSET

CAPC

V

DD

OUT�

OUT+

No Co

nne

c

t

s

Typical

Laser Driver

Typical Laser

Diode with

Photo Diode

and Thermistor

ILU0

C

INT

R

INT

12

VBRIDGE

NTC

LD

MPD

VDD

VS

S

VS

S

EXT_TEMP

23

22

VA

P

C

Note: This is an applications example only. Some pins, components and values are not shown.

Functional Description

SML2120

2

2066 6.3 1/22/04

Summit Microelectronics

�\

FUNCTIONAL DESCRIPTION

The SML2120 is an adaptive power controller for laser

diodes. The device contains an active feedback loop used

to calibrate and control the mean and modulation power of

high-speed high-power laser diodes.

Inherent manufacturing tolerances introduce variations of

performance in laser diodes. These variations, combined

with parametric changes over the laser's extreme operating

temperature range and laser aging, require an efficient

compensation solution. The SML2120, together with a

minimum number of external components, is designed to

compensate for these variations using a digital control loop

and dual programmable nonvolatile calibration lookup

tables.

Figure 2 shows the output light power of a typical laser

diode versus its operating current. Depicted in the graph are

laser diode characteristics at two different temperatures. At

the first temperature (T

Cold

), the laser requires an average

bias current of I

BIAS1

. The modulation current required to

switch the laser between its ON and OFF states is labeled

I

MOD1

.

The ratio of light power of its ON state divided by the light

power of its OFF state is referred to as the extinction ratio.

Ideally the laser requires a constant extinction ratio over its

entire operating temperature range, as the receiver module

is calibrated to this level. Operating the laser driver at a

higher extinction ratio indicates that power is being wasted,

whereas operating at a lower extinction ratio indicates that

data may possibly be lost.

The required bias current increases to I

BIAS2

when the laser

is operated at a second temperature (T

Hot

). The laser

requires a modulation of I

MOD2

to maintain a constant

extinction ratio as in the T

Cold

curve. The SML2120, with its

dual lookup table architecture (Figure 3), is capable of

providing variable output currents based on a function of

either the bias current or the external temperature, and

thereby enables the system designer to optimize the

extinction ratio of the laser driver module.

The SML2120 eliminates the need for any manual

calibration of the laser control circuit. All calibration values

are programmed through the I

2

C industry-standard 2-wire

communication interface whose protocol and functions can

be controlled by automated test equipment (ATE).

Figure 2. Laser Current Increase Caused by Temperature Increase, Constant Light Power Out

SML2120

Functional Block Diagram

Summit Microelectronics

2066 6.3 1/22/04

3

�

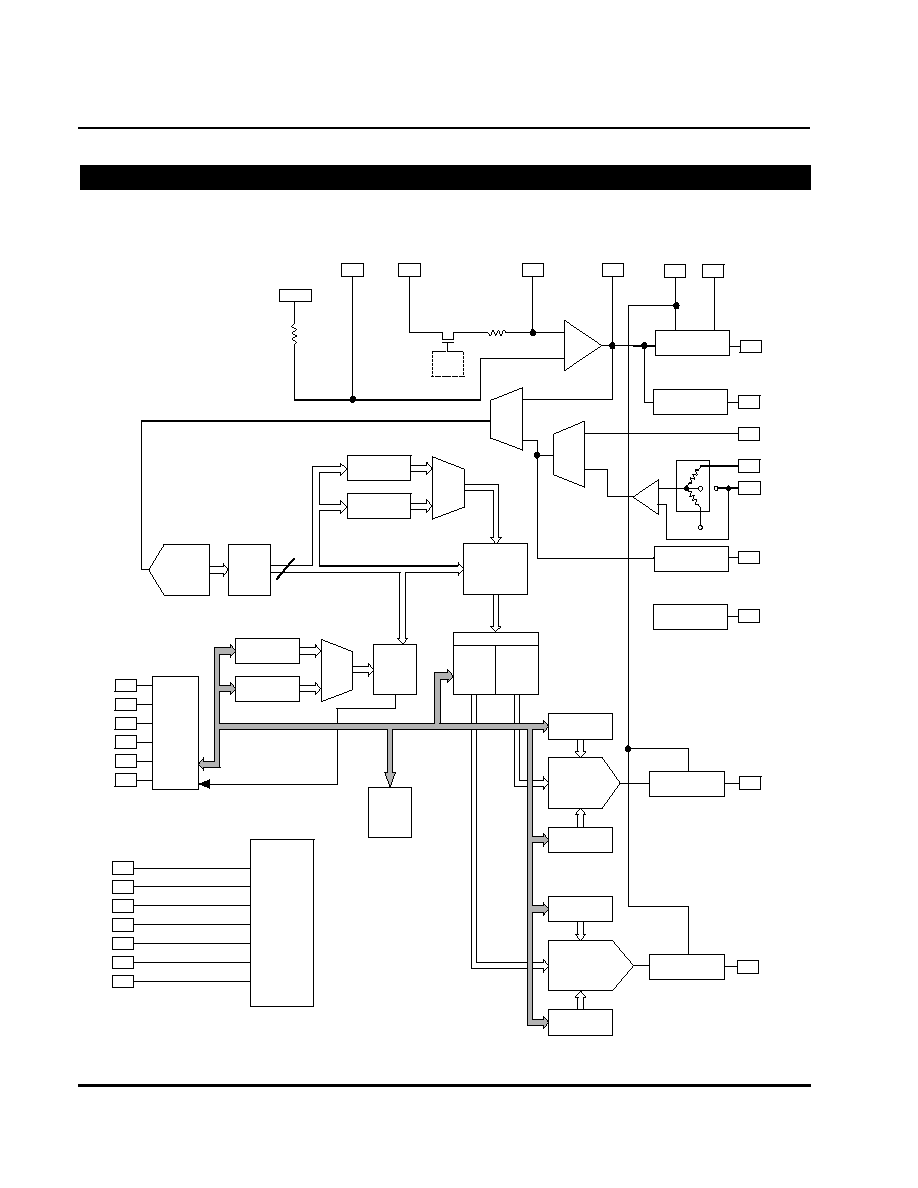

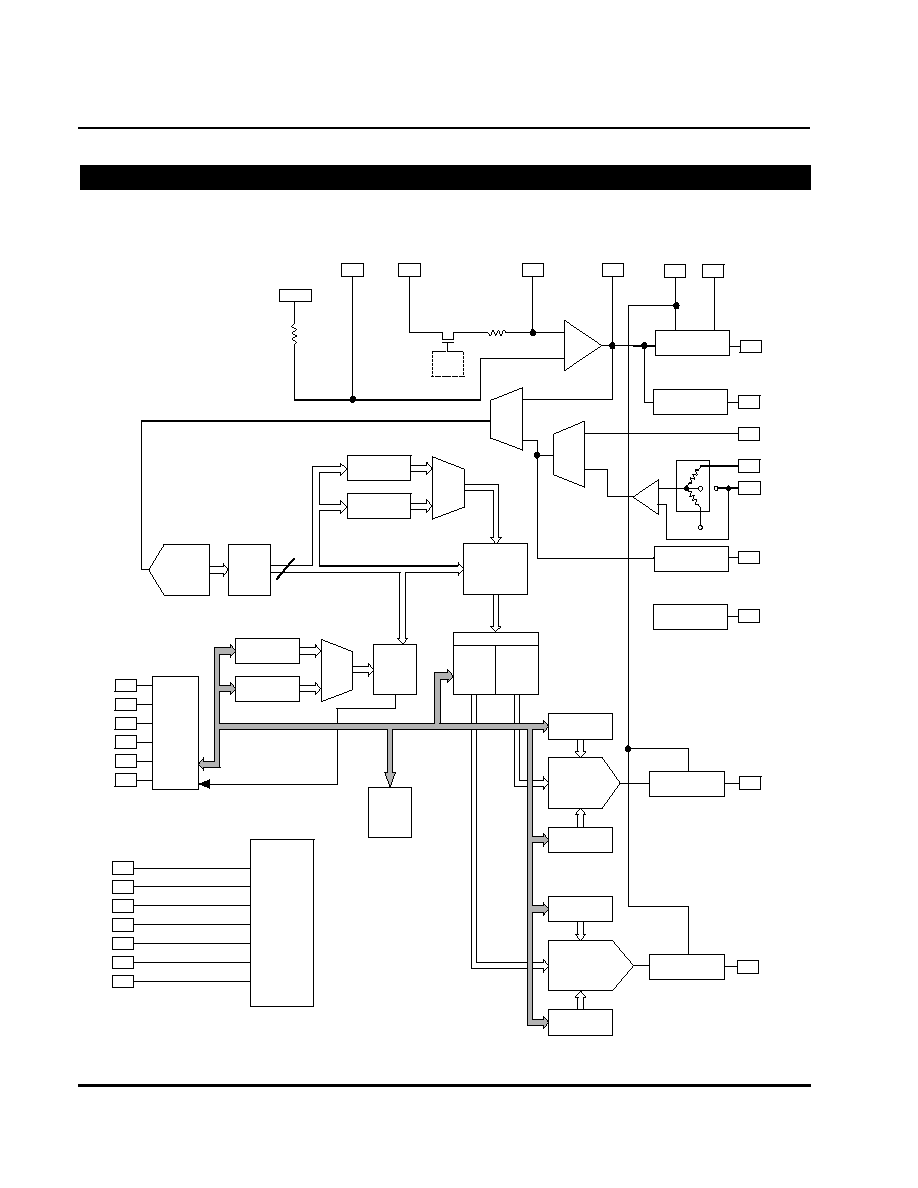

FUNCTIONAL BLOCK DIAGRAM

Figure 3. SML2120 Block Diagram

10-BIT ADC

Comparison

Logic

Alarm

Logic

Address Decode

256 x 8

E

2

PROM

Lookup

Table

256 x 8

E

2

PROM

Lookup

Table

CH1 Previous

Conversion

CH2 Previous

Conversion

CH1 High/Low

Limits

CH2 High/Low

Limits

8-BIT DAC

High Range

DAC

Low Range

DAC

+

-

Quick

Start

18

MPD

17

16

1

28

BIASMON

23

11

EXT_TEMP

THERMISTOR

8-BIT DAC

High Range

DAC

Low Range

DAC

2

3

4

5

7

I

2

C

2-Wire

Serial

Interface

A1

SCL

A2

SDA

ALERT#

13

ILU1

27

TEMPMON

26

POWERMON

Power

Distribution

8

9

10

VSS

VSS

VLOW

VSS

15

21

VDD

VHI

VDD

25

24

C1

C2

ENA#

6

AM#

Bias to Voltage

Converter

MPD to Voltage

Converter

14

20

BIAS

Current Generator

256 x 8

E

2

PROM

General

Purpose

Scale

&

Offset

8

ILU0

19

VBURST

Current Generator

Current Generator

Temp to Voltage

Converter

22

VAPC

0.75V

Internal

Reference

12

VBRIDGE

Bridge

Circuit

VSS

+

-

+

-

Package and Pin descriptions

SML2120

4

2066 6.3 1/22/04

Summit Microelectronics

�

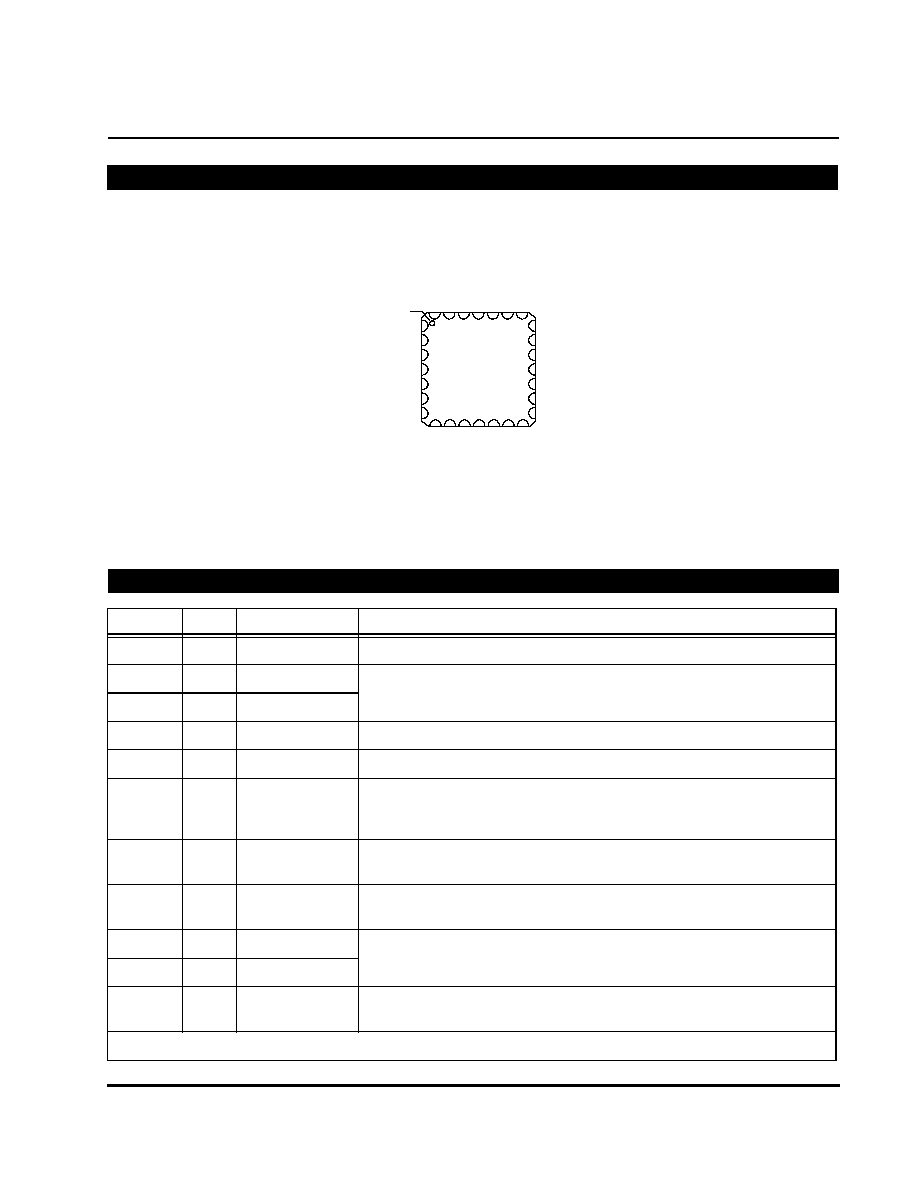

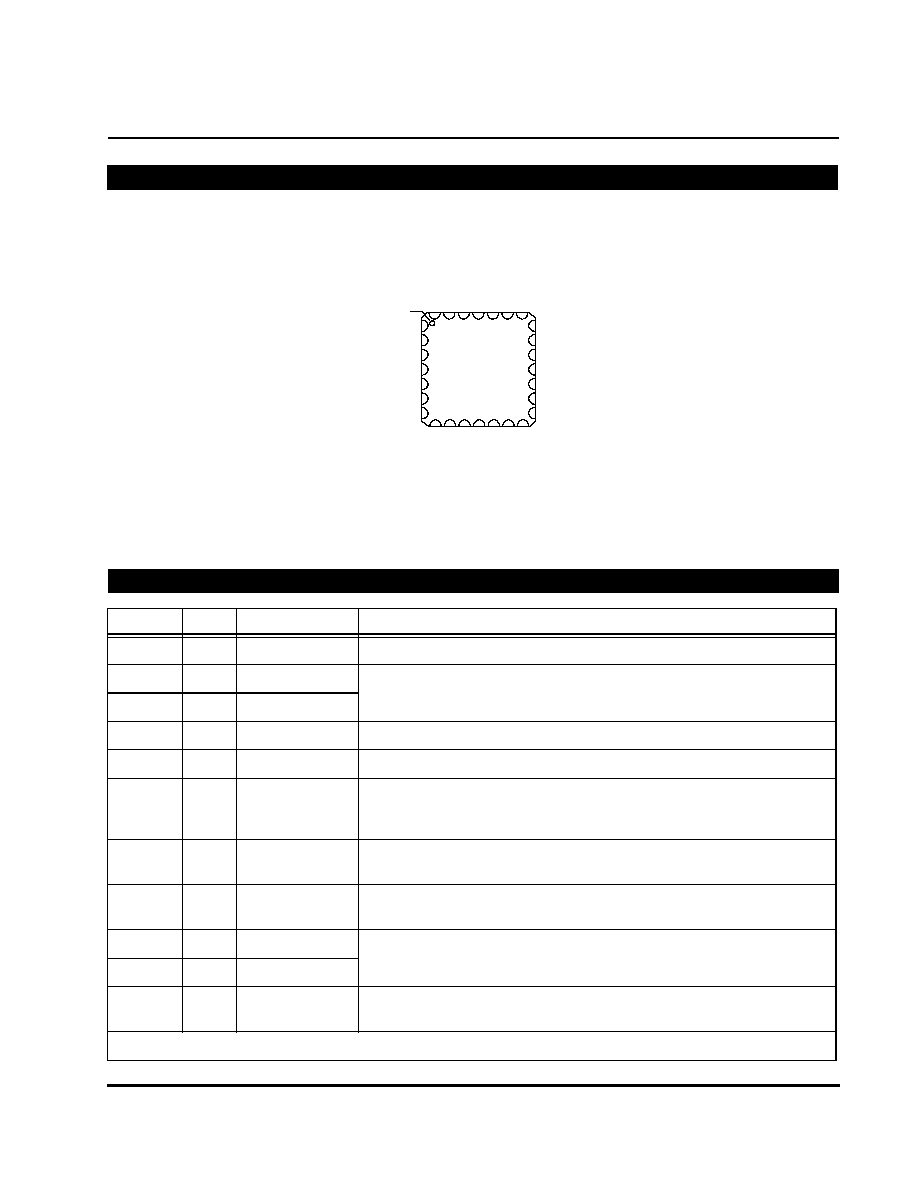

PACKAGE AND PIN DESCRIPTIONS

Figure 4. 28-Pin QFN Package Pinout (top view)

PIN DESCRIPTIONS

PIN DESCRIPTIONS

Pin 1

ENA#

A1

A2

SDA

SCL

AM#

ALERT#

VSS

BIAS

VBURST

MPD

C1

C2

VDD

VL

OW

VS

S

VS

S

THERMI

ST

OR

V

B

RIDGE

IL

U0

IL

U1

BI

ASMO

N

TEMPMO

N

PO

WERMON

VHI

VDD

EX

T_

TM

P

V

APC

Pin Number Pin Type

Pin Name

Description

1

I

ENA#

*

Active low input enables the BIAS, ILU0 and ILU1 output currents.

2

I

A1*

The address pins are connected to either the VHI or VLOW pins to provide a

mechanism for assigning a unique I

2

C bus address to the SML2120.

3

I

A2

*

4

I/O

SDA

*

Bi-directional I

2

C serial data pin

5

I

SCL

*

I

2

C serial clock input

6

I

AM#

*

AM# is an active low input, when asserted the SML2120 is placed in the Auto-

Monitor mode. AM# must be high for programming the Configuration registers

and the Lookup Tables, ILU0 and ILU1 and the general purpose E

2

PROM.

7

O

ALERT#

*

Active low, open-drain output indicates when one of the monitored inputs

exceeds its user-programmable high or low alert levels.

8

PWR

VLOW

In dual-rail supply voltage systems, VLOW is tied to the system logic low

potential. It is a logic low reference for all pins marked with an asterisk (*).

9

PWR

VSS

VSS must be tied to the lowest system voltage potential.

10

PWR

VSS

11

I

THERMISTOR

Connect a thermistor to this pin to provide an alternative source of temperature

sensing (see VBRIDGE description).

* See VLOW and VHI pin descriptions.

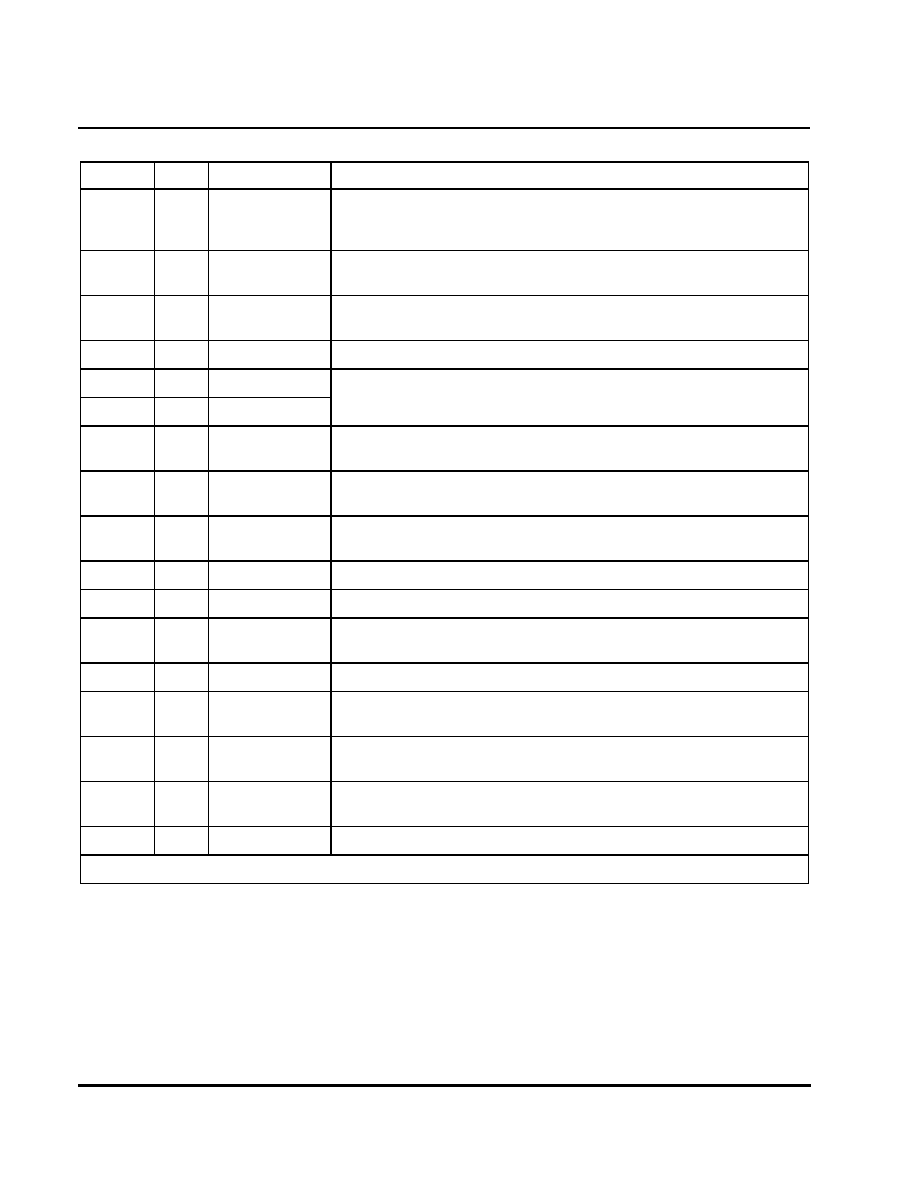

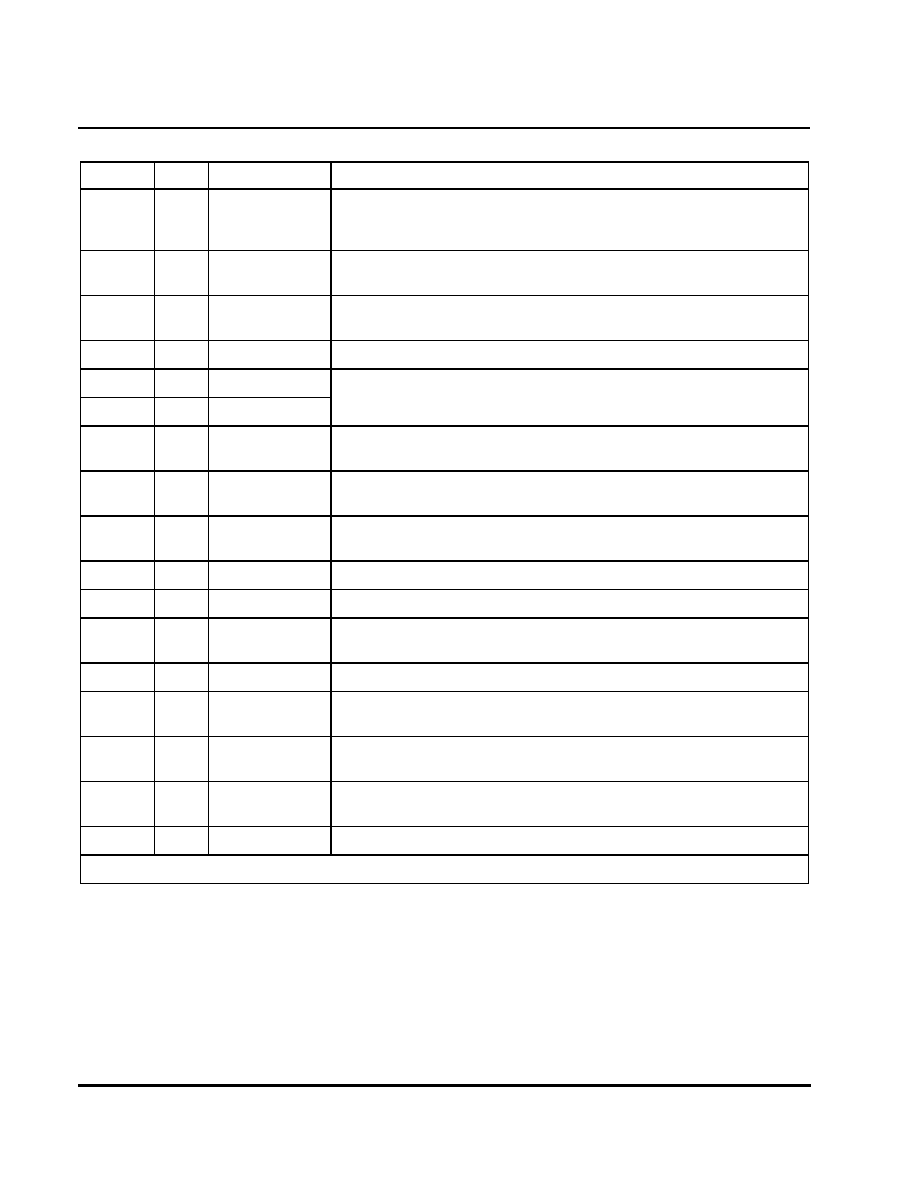

PACKAGE AND PIN DESCRIPTIONS

PIN DESCRIPTIONS

SML2120

Pin Descriptions

Summit Microelectronics

2066 6.3 1/22/04

5

12

O

VBRIDGE

Connection to an external Full-Bridge Sensor when used with the Thermistor pin.

Two of the full-bridge resistors are internal. See the Bridge Circuit Diagram in

Figure 1 and 3. Voltage level is 0.2V with respect to VSS.

13

I/O

ILU0

Current output resulting from Lookup Table 0. User-programmable to either sink

(to VSS) or source (to VDD) up to 2.5mA.

14

I/O

ILU1

Current output resulting from Lookup Table 1. User-programmable to either sink

(to VSS) or source (to VDD) up to 2.5mA.

15

PWR

VDD

VDD is the positive rail for most internal functions.

16

I

C2

Place a capacitor (C

INT

) between C1 and C2 to increase the time constant for the

APC integrator.

17

I

C1

18

I

MPD

Monitor Photo Diode anode input. Connect a resistor between MPD and C1 to

work in conjunction with C

INT

to establish the integrator time constant.

19

I

VBURST

In burst mode, this input supplies a ballast current that allows the SML2120 to

quickly restart when ENA# is asserted.

20

I

BIAS

Supplies the main laser current as controlled by the APC circuit; capable of

sinking up to 100mA to VSS.

21

PWR

VSS

VSS must be tied to the lowest system voltage potential.

22

I/O

VAPC

APC Override pin.

23

I

EXT_TEMP

This input can be configured to sense either a voltage or current generated from

an external temperature monitoring device.

24

PWR

VDD

VDD is the positive rail for most internal functions.

25

PWR

VHI

In dual-voltage rail systems, VHI is tied to the system logic high potential. It is the

logic high reference for all pins marked with an asterisk (*).

26

O

POWERMON

*

Analog output voltage indicating the state of the Monitor Photo Diode (MPD)

input.

27

O

TEMPMON

*

Analog output voltage proportional to the temperature as sensed by the

EXT_TEMP or THERMISTOR input.

28

O

BIASMON

*

Analog output voltage proportional to BIAS current.

* See VLOW and VHI pin descriptions.

Pin Number Pin Type

Pin Name

Description