SMM150

Preliminary Information

1

(See Last Page)

© SUMMIT Microelectronics, Inc. 2005 ∑

1717 Fox Drive ∑ San Jose CA 95131 ∑ Phone 408 436-9890 ∑ FAX 408 436-9897

www.summitmicro.com

2075 2.6 05/13/05

1

FEATURES

∑ Capable of margining supplies with trim inputs

using either positive or negative trim pin control

∑ Wide Margin range from 0.3V to VDD using

internal reference

∑ 10-bit ADC readout of supply voltage over I

2

C bus

∑ Margining Controlled Via:

I

2

C Command

Input Pins (M

UP

, M

DN

)

∑ Two programmable general purpose sensor inputs

(COMP1/2) ≠ UV/OV with FAULT Output

∑ Programmable glitch filter (COMP1/2)

∑ Programmable internal VREF, 0.5V or 1.25V

∑ Operates from 2.7V to 5.5V supply

∑ General Purpose 256-Byte EEPROM with Write

Protect

∑ I

2

C 2-wire serial bus for programming

configuration and monitoring status

∑ 28 lead QFN

∑ 20 ball Ultra CSP

TM

(Chip-Scale) package

Applications

∑ In-system test and control of Point-of-Load (POL)

Power Supplies for Multi-voltage Processors,

DSPs and ASICs

∑ Routers, Servers, Storage Area Networks

INTRODUCTION

The SMM150 is a highly accurate power supply

voltage supervisor and environmental monitor with

provisions for voltage margining of the monitored supply.

The part includes an internal voltage reference to

accurately monitor and margin the supply to within ±1%.

The SMM150 has the capability to margin over a wide

range from 0.3V to VDD using the internal reference and

can read the value of the supply over the I

2

C bus using

an on-chip 10-bit ADC. The monitor and margin levels

are set using the I

2

C serial bus. The SMM150 initiates

margining via the I

2

C bus or by using the M

UP

or M

DN

inputs. Once the pre-programmed margin target voltage

is reached, the SMM150 holds the converter at this

voltage until receiving an I

2

C command or de-asserting

the margin input pin. When the SMM150 is not

margining, the TRIM output pin is held in a high

impedance state allowing the converter to operate at its

nominal set point. Two general purpose input pins are

provided for sensing under or overvoltage conditions. A

programmable glitch filter associated with these inputs

allows the user to ignore spurious noise signals. A

FAULT# pin is asserted once either input set point is

exceeded.

Using the I

2

C interface, a host system can communicate

with the SMM150 status register and utilize 256-bytes of

nonvolatile memory.

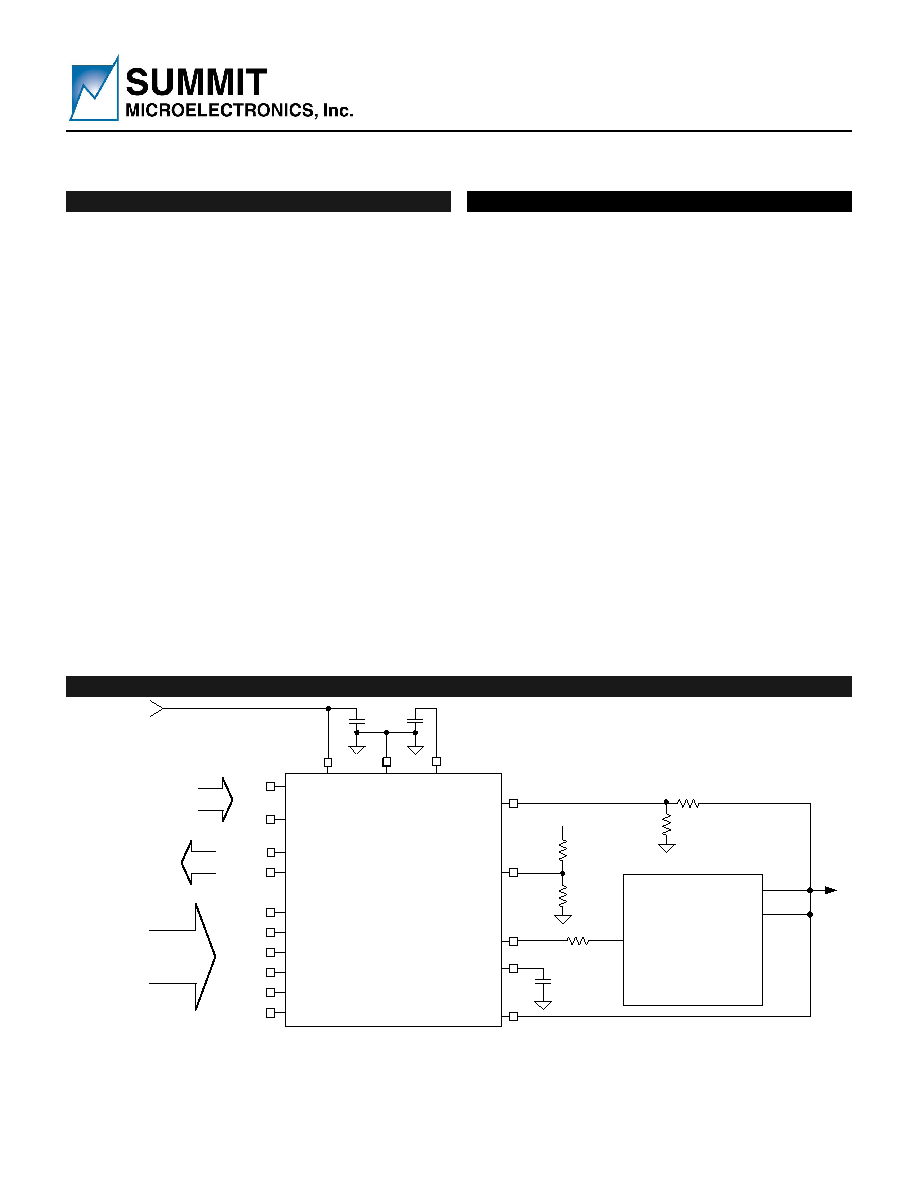

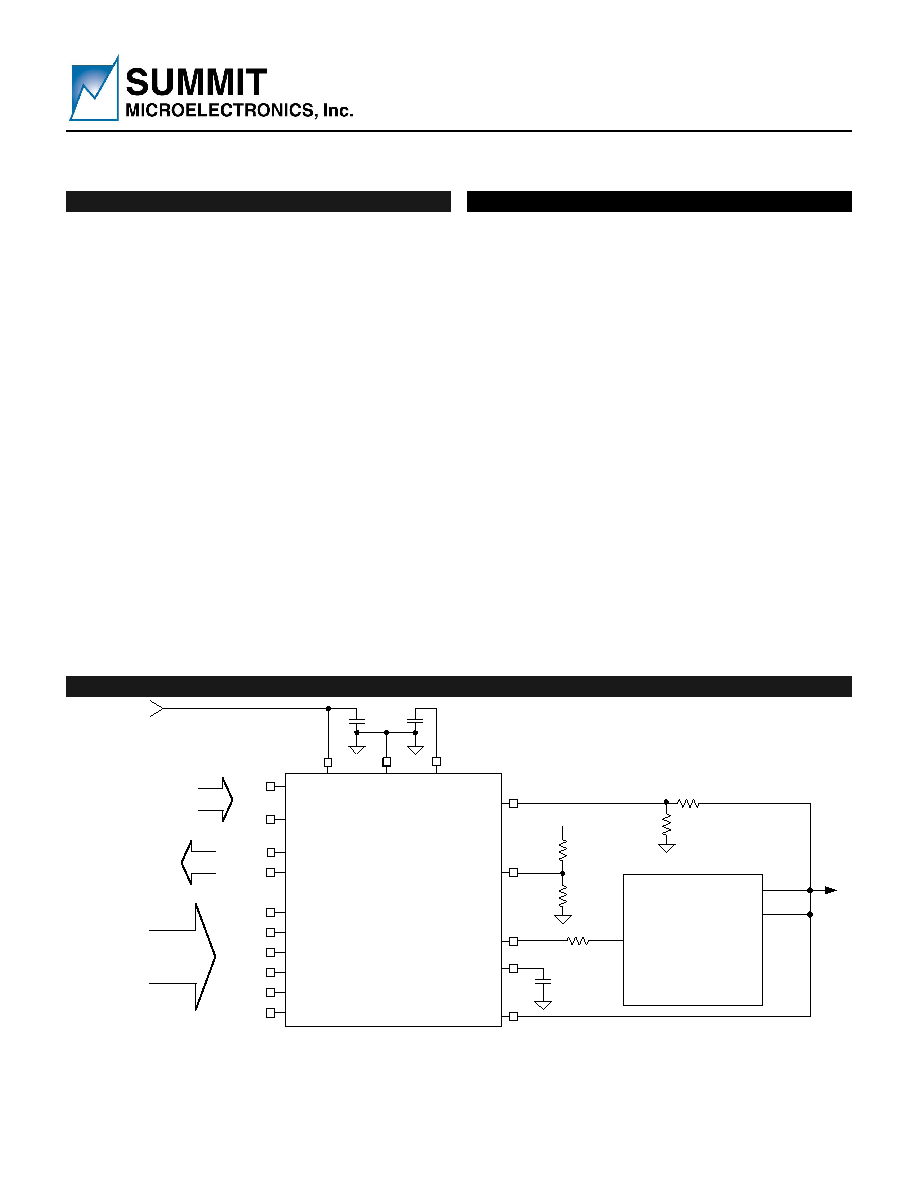

SIMPLIFIED APPLICATIONS DRAWING

VM

TRIM

TRIM

VOUT+

SEN+

DC-DC Converter

VDD

WP

A0

A1

A2

COMP1

COMP2

SCL

SDA

FAULT#

CAPM

MUP

MDN

I

2

C

Interface

Margin

Commands

V1

2.7V-5.5V

SMM150

READY

GND

VDD_CAP

Status

Outputs

Figure 1 ≠ Applications using the SMM150 Controller to control the Voltage Margining of a DC/DC Converter.

Note: This is an applications example only. Some components and values are not shown.

Single-Channel Supply Voltage Marginer/Monitor

SMM150

Preliminary Information

Summit Microelectronics, Inc

2075 2.6 05/13/05

2

GENERAL DESCRIPTION

The SMM150 is capable of margining the DC output

voltage of LDOs or DC/DC converters that use a

trim/adjust pin. The Margin function is programmable

over a standard 2-wire I

2

C serial data interface and is

used to set the margin low/high DC output voltages.

In margining mode the user communicates with the

SMM150 via the I

2

C serial data bus to select the

desired values for margining. This allows the part to

margin the supplies up or down to these set values

either through asserting the MUP and MDN pins or by

writing to the margin register directly. The margin high

and margin low voltage settings can range from 0.3V

to VDD around the converter's nominal output voltage

setting depending on the specified margin range of the

DC-DC converter and/or system components, usually

±

10%.

When the SMM150 receives the command to margin,

the TRIM output will begin adjusting the supply to the

selected margin voltage. This is accomplished by

incrementing (or decrementing) an internal counter

based on the digital comparison between the voltage

margin target value and that read by the ADC from the

VM input. This operation is repeated until the 2 values

are equal, after which the SMM150 holds the TRIM

output pin at the voltage required to maintain the

margin setting. An I

2

C command or de-assertion of the

MUP/MDN pin will return the TRIM output pin to a high

impedance state thus allowing the converter to return

to its nominal operating voltage.

The SMM150 has two additional input pins and one

additional output pin. The input pins, COMP1 and

COMP2, are high impedance inputs, each connected

to a comparator and compared against the internal

reference (VREF, 0.5V or 1.25V). Each comparator

can be independently programmed to monitor for UV

or OV. When either of the COMP1 or COMP2 inputs

are in fault the open-drain FAULT# output will be

pulled low. A configuration option exists to disable the

FAULT# output during margining.

Programming of the SMM150 is performed over the

industry standard I

2

C 2-wire serial data interface. A

status register is available to read the state of the part

and a Write Protect (WP) pin is available to prevent

writing to the configuration registers and EE memory.

SMM150

Preliminary Information

Summit Microelectronics, Inc

2075 2.6 05/13/05

3

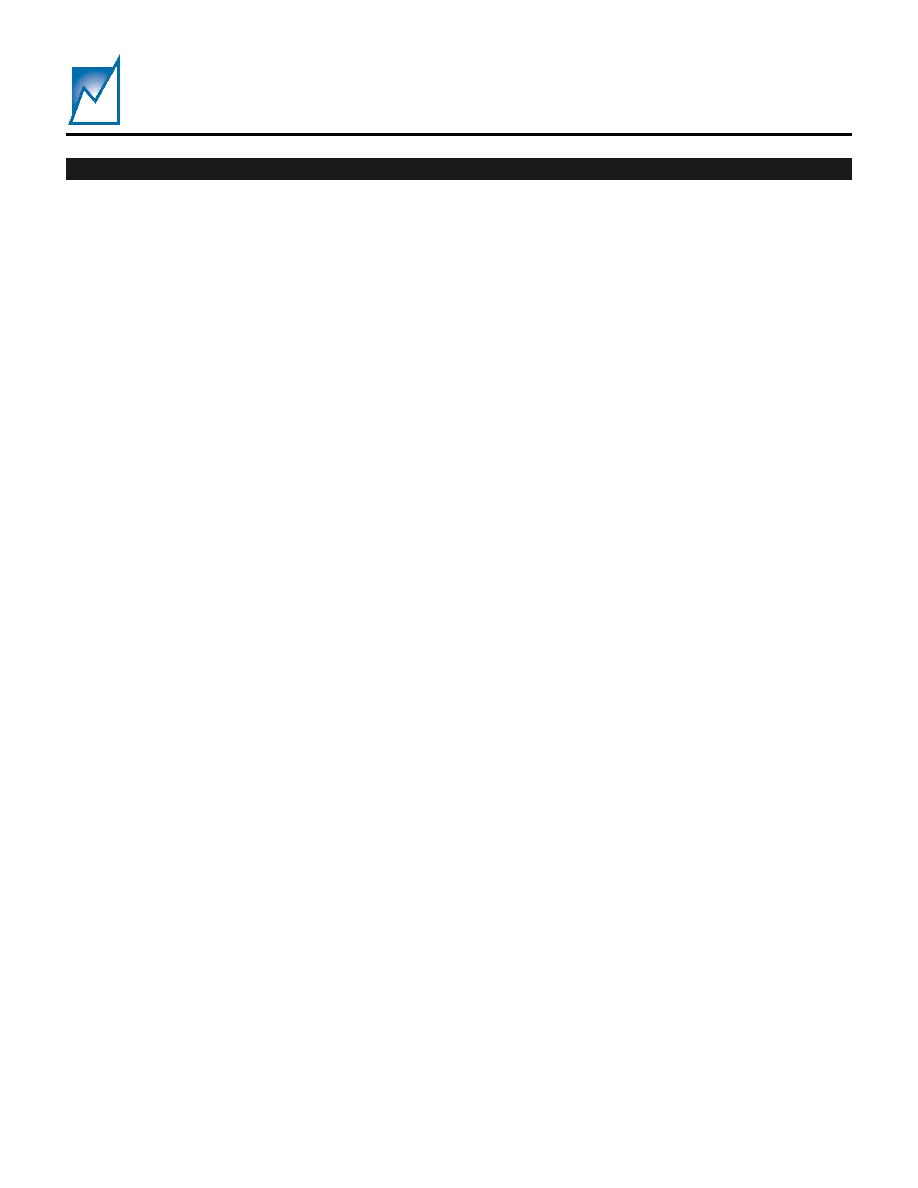

VM

Control

Logic

TRIM

10Bit

ADC

Digital

Comparator

8-bit DAC

I

2

C

Interface

Clock

Up/Dn

Halt

Margin

Target

OV/UV

OV/UV

Output

Control

VDD

WP

A0

A1

A2

COMP1

COMP2

SCL

SDA

FAULT#

EE

Configuration

Registers

& Memory

GND

Glitch

Filter

V

REF

SW1

SW2

MUX

CAPM

MUP

MDN

READY

VREF =

1.25V or 0.5V

50k

50k

VDD_CAP

VREF

Figure 2 ≠ SMM150 Controller Internal Block Diagram.

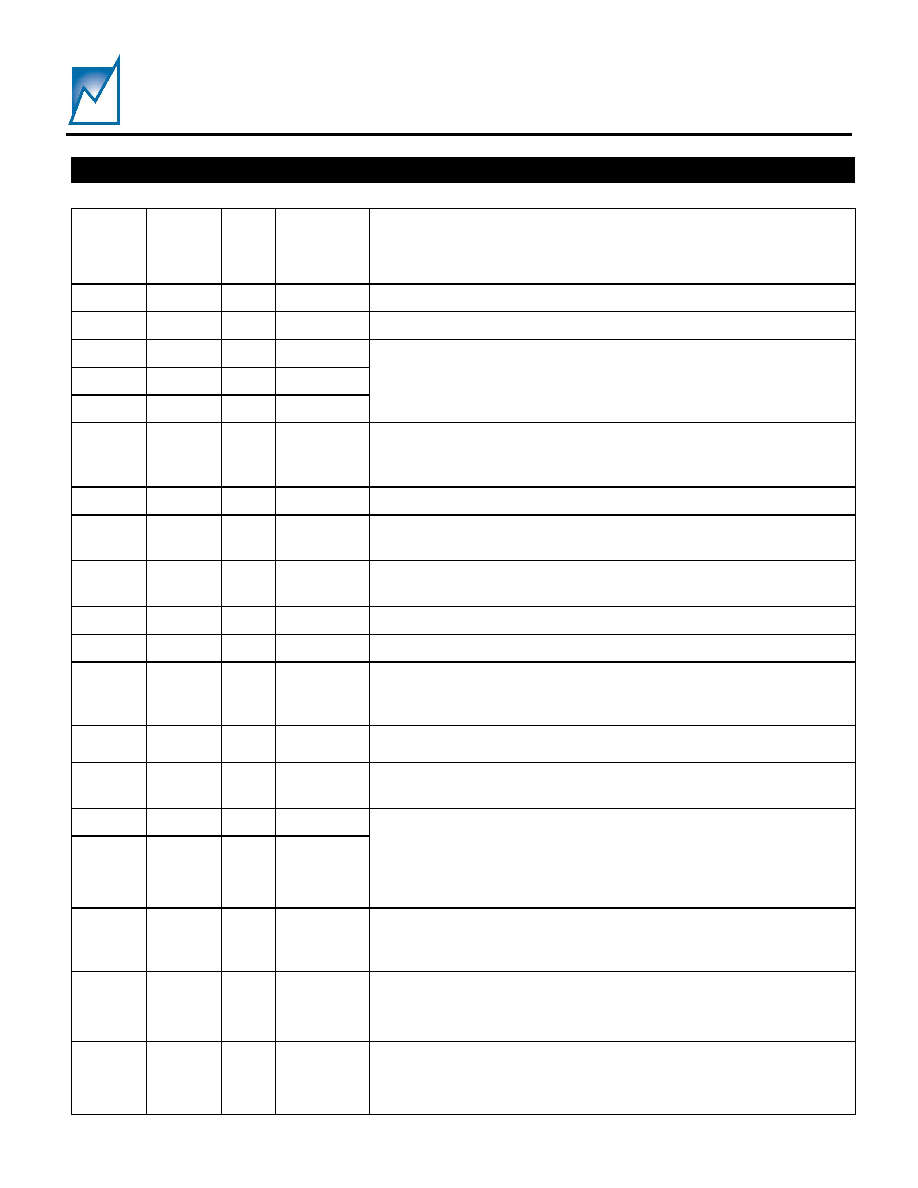

PACKAGE AND PIN CONFIGURATION

1

28

21

20

19

18

17

16

15

22

23

24

25

26

27

2

3

4

5

6

7

14

13

SMM150

Pin 1

SCL

A2

NC

A1

READY

A0

GND

WP

NC

CA

P

_

M

FAU

LT#

NC

CO

M

P

2

VM

VDD

TRIM

COMP1

NC

NC

NC

NC

SDA

NC

NC MDN MUP V

D

D_

CA

P

NC

12

11

10

9

8

GND

or

NC

INTERNAL BLOCK DIAGRAM

28 Pad QFN

Top View

A1

A2

A4

A3

B1

B2

B4

B3

C1

C2

C4

C3

D1

D2

D4

D3

E1

E2

E4

E3

SCL

MDN VDD_CAP VDD

A2

SDA

TRIM

COMP1

A1

READY

MUP

NC

A0

WP

FAULT#

NC

GND

CAP_M COMP2

VM

Pin 1

20 Ball Ultra CSP

TM

Bottom View

SMM150

Preliminary Information

Summit Microelectronics, Inc

2075 2.6 05/13/05

4

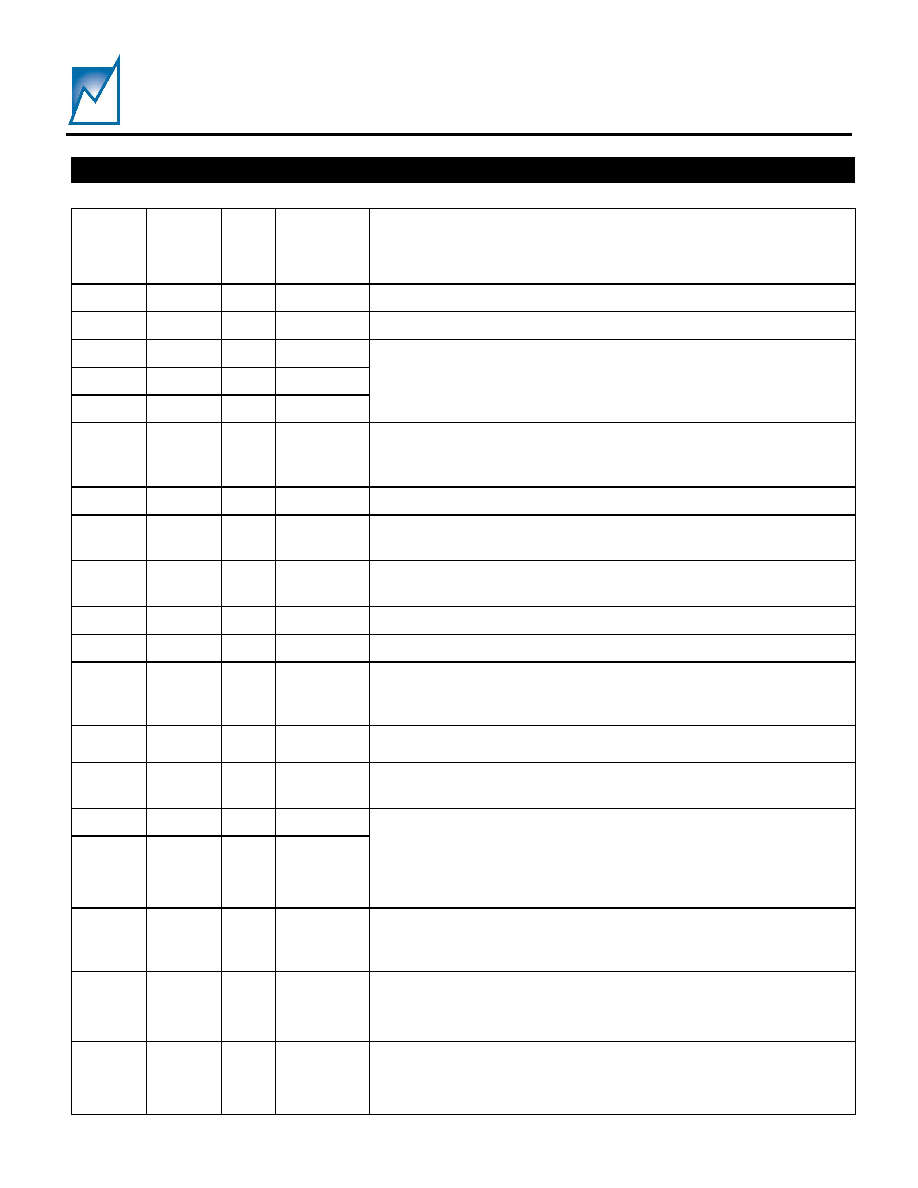

PIN DESCRIPTIONS

QFN

Pad

Number

Ultra

CSP

TM

Ball

Number

Pin

Type

Pin Name

Pin Description

28

B2

I/O

SDA

I

2

C Bi-directional data line

1

A1

I

SCL

I

2

C clock input.

2

B1

I

A2

4

C1

I

A1

6

D1

I

A0

The address pins are biased either to VDD, GND or left floating. This

allows for a total of 21 distinct device addresses. When

communicating with the SMM150 over the 2-wire bus these pins

provide a mechanism for assigning a unique bus address.

8

D2

I

WP

Programmable Write Protect active high/low input. When asserted,

writes to the configuration registers and general purpose EE are not

allowed. The WP input is internally tied to VDD with a 50K

resistor.

10

E2

CAP CAPM

External capacitor input used to filter the VM input, 0.2

µF.

20

B3

O

TRIM

Output voltage used to control and/or margin converter voltages.

Connect to the converter trim input.

14

E4

I

VM

Voltage monitor input. Connect to the DC-DC converter positive sense

line or its' +Vout pin.

21

A4

PWR VDD

Power supply of the part.

23

A3

PWR VDD_CAP

External capacitor input used to filter the internal VDD supply rail.

7

E1

GND GND

Ground of the part. The SMM150 ground pin should be connected to

the ground of the device under control or to a star point ground. PCB

layout should take into consideration ground drops.

24

C3

I

MUP

Margin up command input. Asserted high. The MUP input is internally

tied to VDD with a 50K

resistor.

25

A2

I

MDN

Margin down command input. Asserted high. The MDN input is

internally tied to VDD with a 50K

resistor.

19

B4

I

COMP1

12

E3

I

COMP2

COMP1 and COMP2 are high impedance inputs, each connected

internally to a comparator and compared against the internally

programmable VREF voltage. Each comparator can be independently

programmed to monitor for UV or OV. The monitor level is set

externally with a resistive voltage divider.

11

D3

O

FAULT#

When either of the COMP1 or COMP2 inputs are in fault the open-

drain FAULT# output will be pulled low. A configuration option exists

to disable the FAULT# output while the device is margining.

5

C2

I/O

READY

Programmable active high/low open drain output indicates that VM is

at its set point. When programmed as an active high output, READY

can also be used as an input. When pulled low, it will latch the state of

the comparator inputs.

3, 9, 13,

15-18,

22, 26,

27, 29

C4, D4

NC

NC

No Connect. The bottom side metal plate (Pad 29) can be connected

to GND or left floating.

SMM150

Preliminary Information

Summit Microelectronics, Inc

2075 2.6 05/13/05

5

ABSOLUTE MAXIMUM RATINGS

Temperature Under Bias ...................... -55

∞

C to 125

∞

C

Storage Temperature QFN ................... -65

∞

C to 150

∞

C

Terminal Voltage with Respect to GND:

VDD Supply Voltage ..........................-0.3V to 6.0V

All Others ................................-0.3V to V

DD

+ 0.7V

FAULT#..................................... GND to 15.0V

Output Short Circuit Current ............................... 100mA

Reflow Solder Temperature (10 secs).................240

∞

C

Junction Temperature..........................................150∞C

ESD Rating per JEDEC..................................2000V

Latch-Up testing per JEDEC..........................

±100mA

Note - The device is not guaranteed to function outside its operating

rating. Stresses listed under Absolute Maximum Ratings may cause

permanent damage to the device. These are stress ratings only and

functional operation of the device at these or any other conditions

outside those listed in the operational sections of the specification is

not implied. Exposure to any absolute maximum rating for extended

periods may affect device performance and reliability. Devices are

ESD sensitive. Handling precautions are recommended.

RECOMMENDED OPERATING CONDITIONS

Temperature Range (Industrial) .......... ≠40

∞

C to +85

∞

C

(Commercial).............. 0

∞

C to +70

∞

C

VDD Supply Voltage.................................. 2.7V to 5.5V

Inputs.........................................................GND to VDD

Package Thermal Resistance (

JA

)

28 Pad QFN............................................80

o

C/W

20 Ball Ultra

CSP

TM

..................................TBD

o

C/W

Moisture Classification Level 1 (MSL 1) per J-STD- 020

RELIABILITY CHARACTERISTICS

Data Retention........................................100 Years

Endurance......................................100,000 Cycles

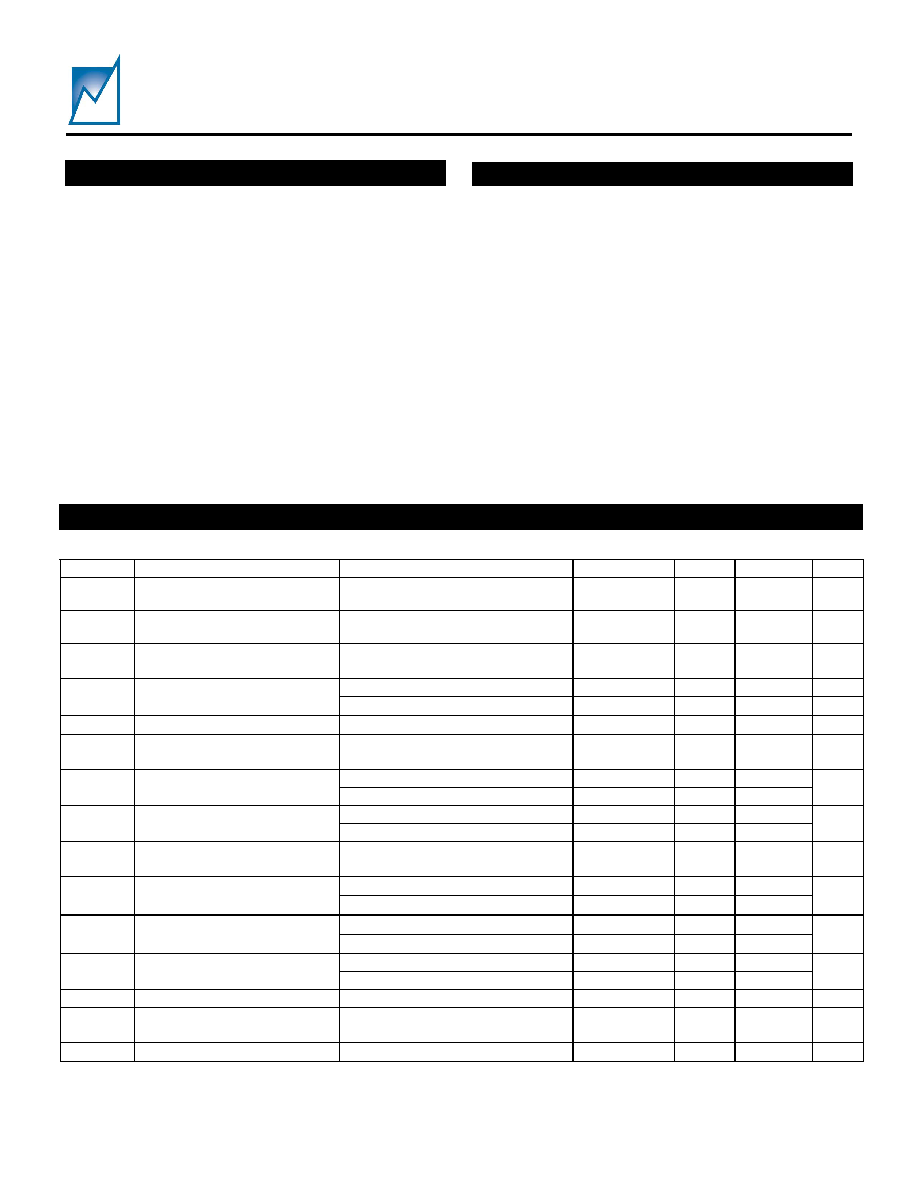

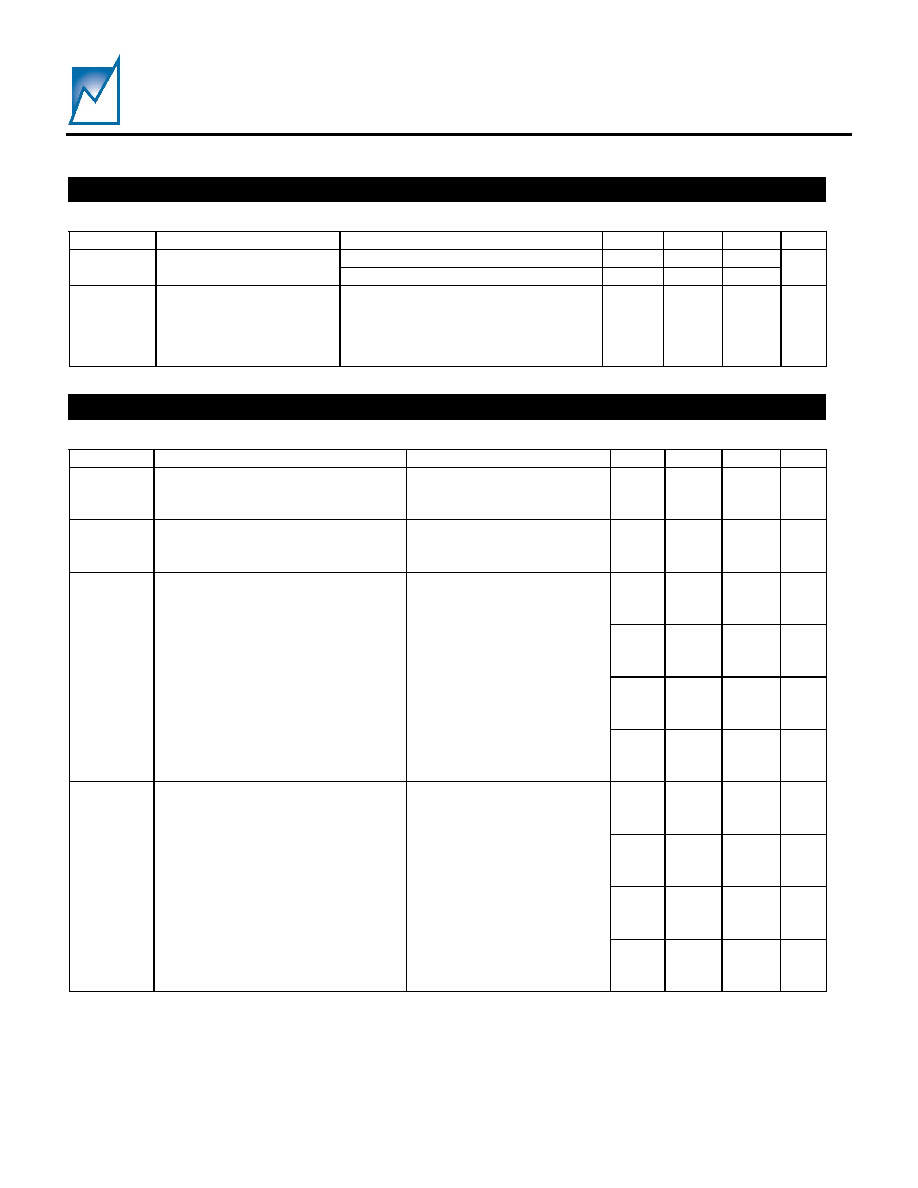

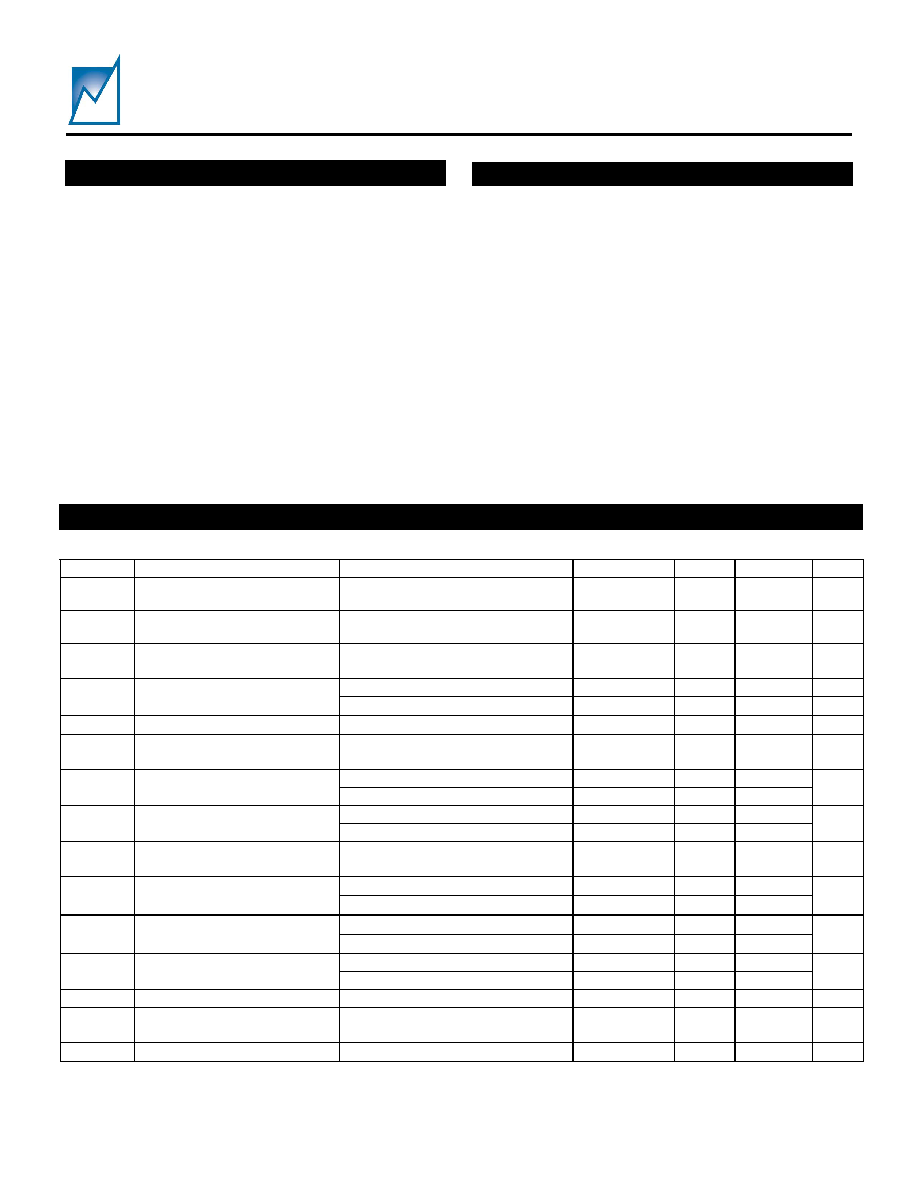

DC OPERATING CHARACTERISTICS

(Over recommended operating conditions, unless otherwise noted. All voltages are relative to GND.)

Symbol Parameter

Notes

Min.

Typ.

Max

Unit

VDD Supply

Voltage

2.7

3.3 5.5 V

VM

Positive Sense Voltage

VM pin

0.3

VDD

V

I

DD

Power Supply Current from

VDD

TRIM pin floating

3

mA

TRIM Sourcing Max Current

1.5

mA

I

TRIM

TRIM output current through

100

to 1.0V

TRIM Sinking Max Current

-1.5

mA

V

TRIM

TRIM output voltage range

I

TRIM

±1.5mA

GND 2.5

V

V

ADOC

Margin

Range

Depends on Trim range of DC-

DC Converter

0.3

VDD

V

VDD = 2.7V

0.9xVDD

VDD

V

IH

Input High Voltage

SDA,SCL,WP,MUP,MDN

VDD = 5.0V

0.7xVDD

VDD

V

VDD = 2.7V

0.1xVDD

V

IL

Input Low Voltage

SDA,SCL,WP,MUP,MDN

VDD = 5.0V

0.3xVDD

V

V

OL

Open Drain Output

FAULT#, READY

ISINK = 1mA

0.2

V

VDD = 2.7V, R

pullup

300k

0.9xVDD VDD

V

AIH

Address Input High Voltage,

A2, A1, A0

VDD = 5.0V, R

pullup

300k

0.7xVDD VDD

V

VDD = 2.7V, R

pulldown

300k

0.1xVDD

V

AIL

Address Input Low Voltage,

A2, A1, A0

VDD = 5.0V, R

pulldown

300k

0.3xVDD

V

VDD = 2.7V

-1.8

+1.4

I

AIT

Address Input Tristate

Maximum Leakage ≠ High Z VDD = 5.0V

-2.0

+1.6

µA

OV/UV

Monitor Voltage Range

COMP1 and COMP2 pins

0

VDD

V

V

HYST

COMP1/2

DC

Hysteresis

COMP1 and COMP2 pins,

V

TH

-V

TL

(see Note 1)

10

mV

R

Pull-Up

Input Pull-Up Resistors

See Pin Descriptions

50

k

Note 1 ≠ The Base DC Hysteresis voltage is measured with a 1.25V external voltage source. The resulting value is determined by subtracting

Threshold Low from Threshold High, V

TH

-V

TL

while monitoring the FAULT# pin state. Base DC Hysteresis is measured with a 1.25V input. Actual DC

Hysteresis is derived from the equation: (V

IN

/V

REF

)(Base Hysteresis). For example, if V

IN

=2.5V and V

REF

=1.25V then Actual DC Hysteresis=

(2.5V/1.25V)(0.003V)=6mV.

SMM150

Preliminary Information

Summit Microelectronics, Inc

2075 2.6 05/13/05

6

DC OPERATING CHARACTERISTICS (CONTINUED)

(Over recommended operating conditions, unless otherwise noted. All voltages are relative to GND.)

Symbol Parameter

Notes

Min.

Typ.

Max

Unit

VREF=1.25V 1.24

1.25

1.26

VREF

VREF Internal Reference

VREF=0.5V 0.496

0.500

0.504

V

MARG

ACC

Margin

Accuracy

-1.0

±

0.75

+1.0 %

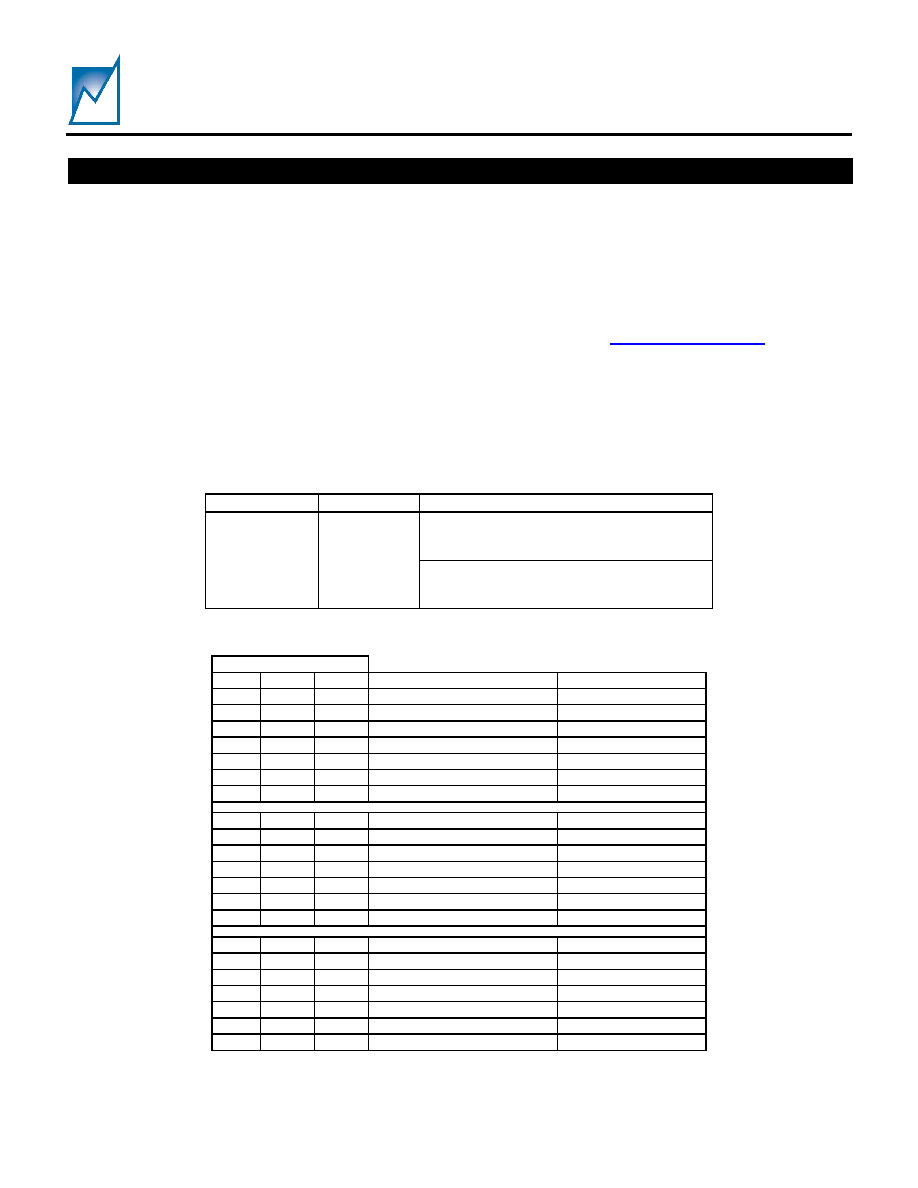

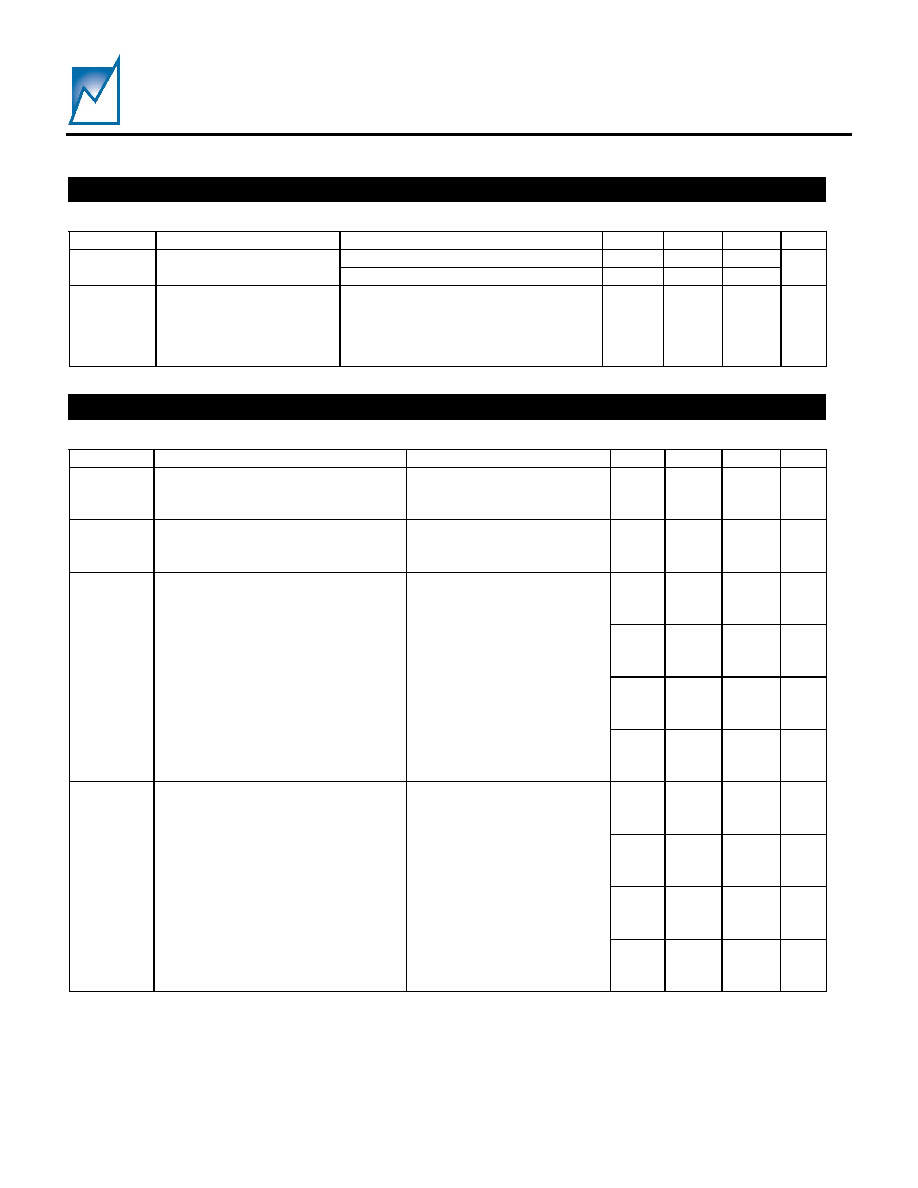

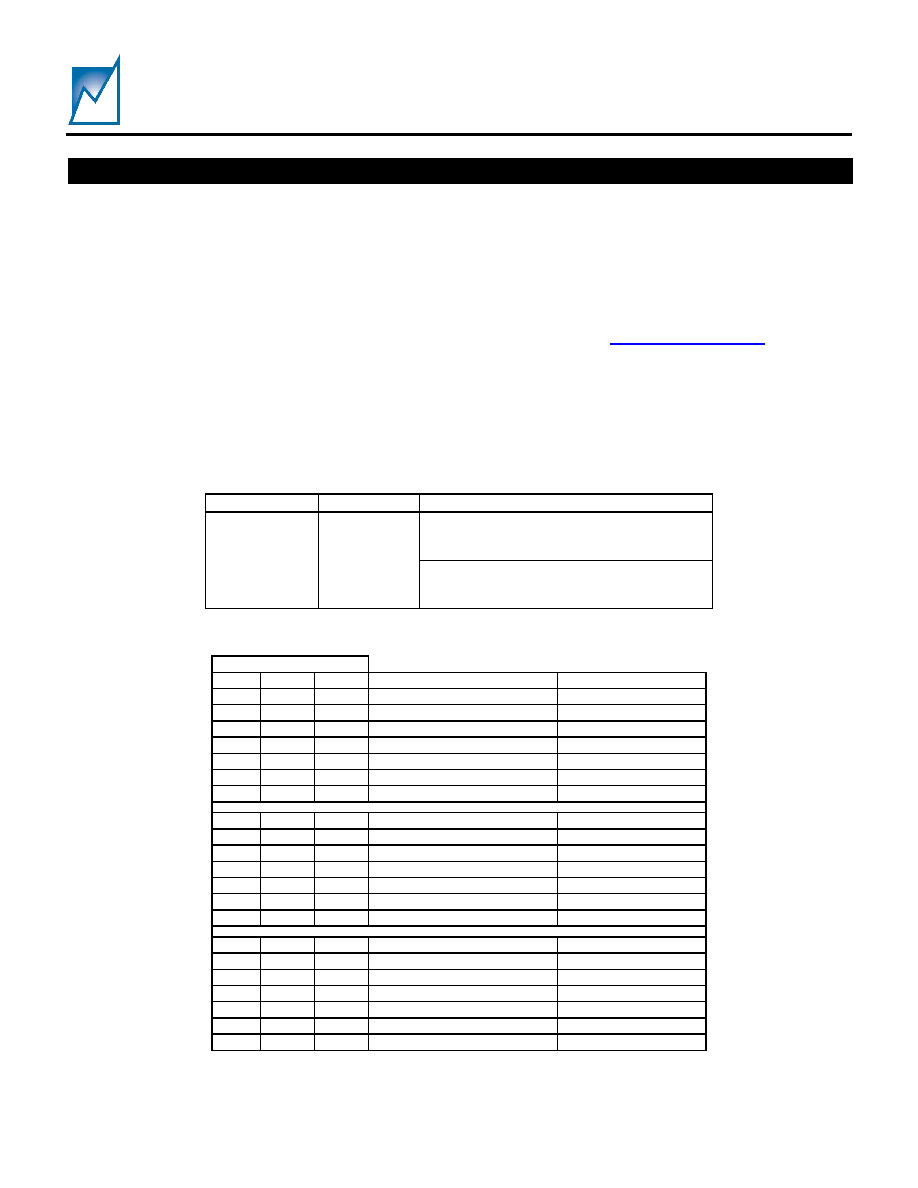

AC OPERATING CHARACTERISTICS

(Over recommended operating conditions, unless otherwise noted. All voltages are relative to GND.)

Symbol Parameter

Notes

Min.

Typ.

Max

Unit

t

ADC_DAC

Monitor sampling/conversion

period

Update period for ADC

conversion and DAC

update

1.8 ms

t

MARG_I/D

Margin single bit increment or

decrement time

T

MARG_UPDATE

= (X)(1.8ms) where:

X=step number of possible 256

and 1 step=5mV

1.8 ms

0

µs

15 µs

40 µs

t

GLITCH

Programmable glitch filter times

120 µs

2.5 ms

5

ms

10 ms

t

MARGIN

Programmable Margin Delay Times

Note 1 ≠ See Figure 4

17.5 ms

SMM150

Preliminary Information

Summit Microelectronics, Inc

2075 2.6 05/13/05

7

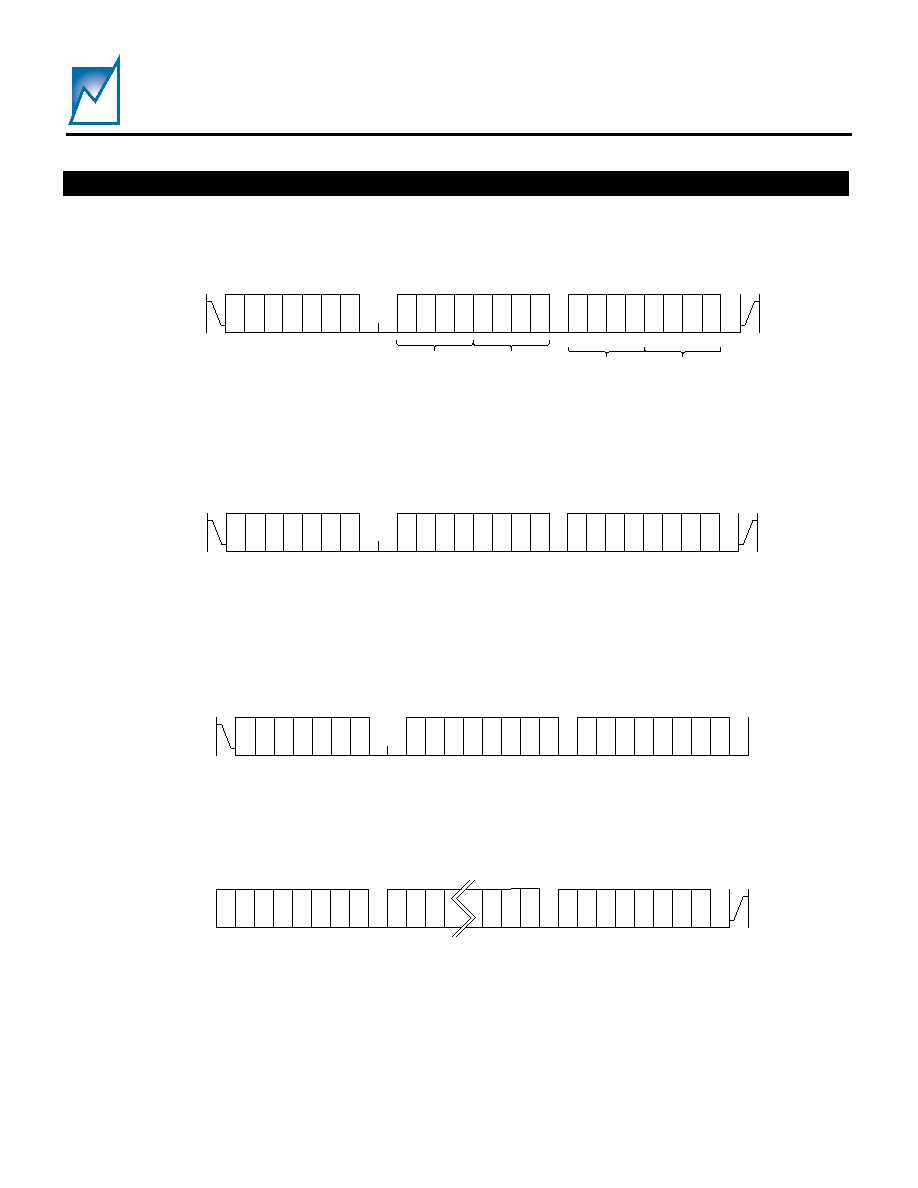

I

2

C 2-WIRE SERIAL INTERFACE AC OPERATING

CHARACTERISTICS ≠ 100kHz

Over recommended operating conditions, unless otherwise noted. All voltages are relative to GND. See Figure 3 Timing Diagram.

Symbol Description

Conditions

Min Typ Max Units

f

SCL

SCL Clock Frequency

0

100

KHz

t

LOW

Clock Low Period

4.7

µs

t

HIGH

Clock

High

Period

4.0

µs

t

BUF

Bus Free Time

Before New Transmission

-

Note 1/

4.7 µs

t

SU:STA

Start Condition Setup Time

4.7

µs

t

HD:STA

Start Condition Hold Time

4.0

µs

t

SU:STO

Stop Condition Setup Time

4.7

µs

t

AA

Clock Edge to Data Valid

SCL low to valid SDA (cycle n)

0.2

3.5

µs

t

DH

Data Output Hold Time

SCL low (cycle n+1) to SDA

change

0.2 µs

t

R

SCL and SDA Rise Time

Note 1/

1000

ns

t

F

SCL and SDA Fall Time

Note 1/

300

ns

t

SU:DAT

Data In Setup Time

250

ns

t

HD:DAT

Data In Hold Time

0

ns

TI

Noise Filter SCL and SDA

Noise suppression

100

ns

t

WR

Write

Cycle

Time

5

ms

Note: 1/ - Guaranteed by Design.

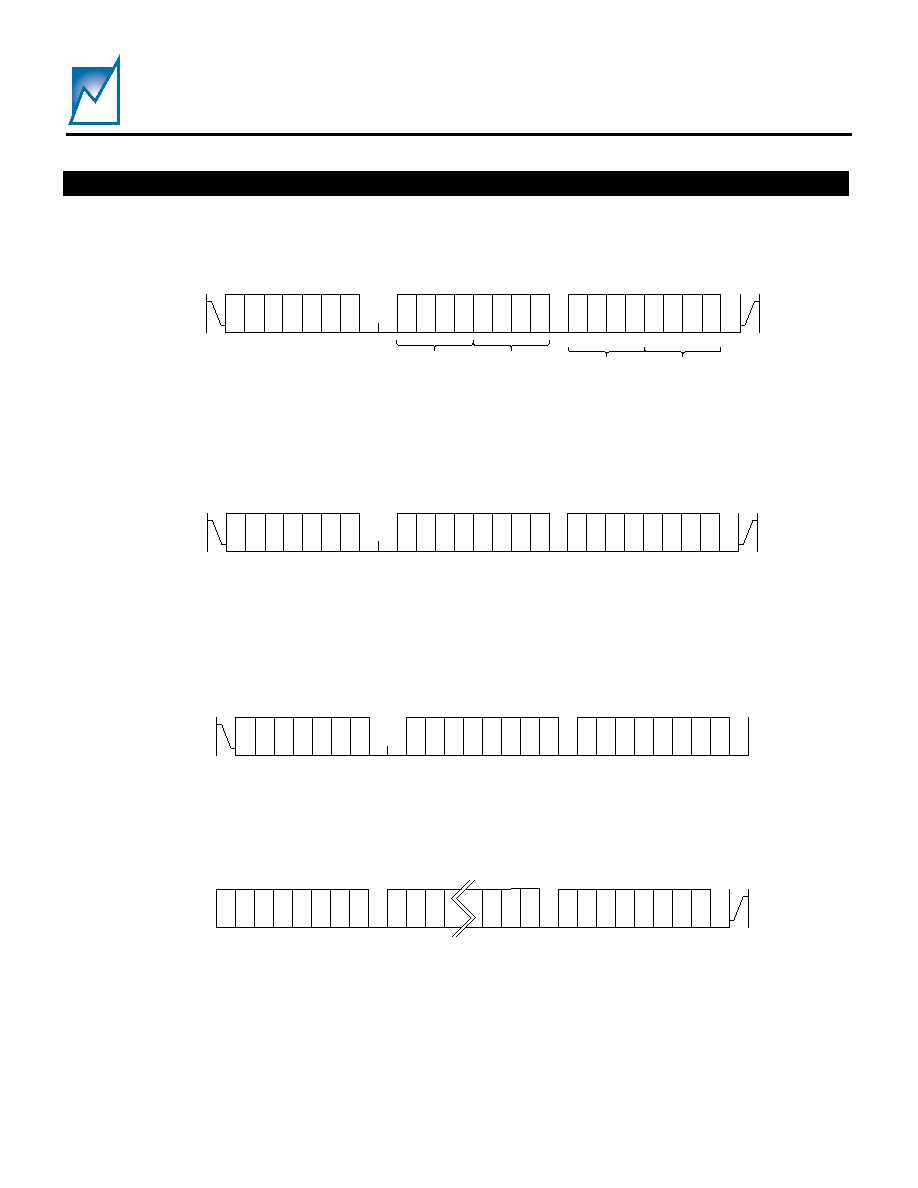

t

R

t

F

t

HIGH

t

LOW

t

SU:SDA

t

HD:SDA

t

SU:DAT

t

HD:DAT

t

SU:STO

t

BUF

t

DH

t

AA

SCL

SDA

(IN)

SDA

(OUT)

t

W R (For W rite Operation Only)

Figure 3. Basic I

2

C Serial Interface Timing

TIMING DIAGRAMS

SMM150

Preliminary Information

Summit Microelectronics, Inc

2075 2.6 05/13/05

8

APPLICATIONS INFORMATION

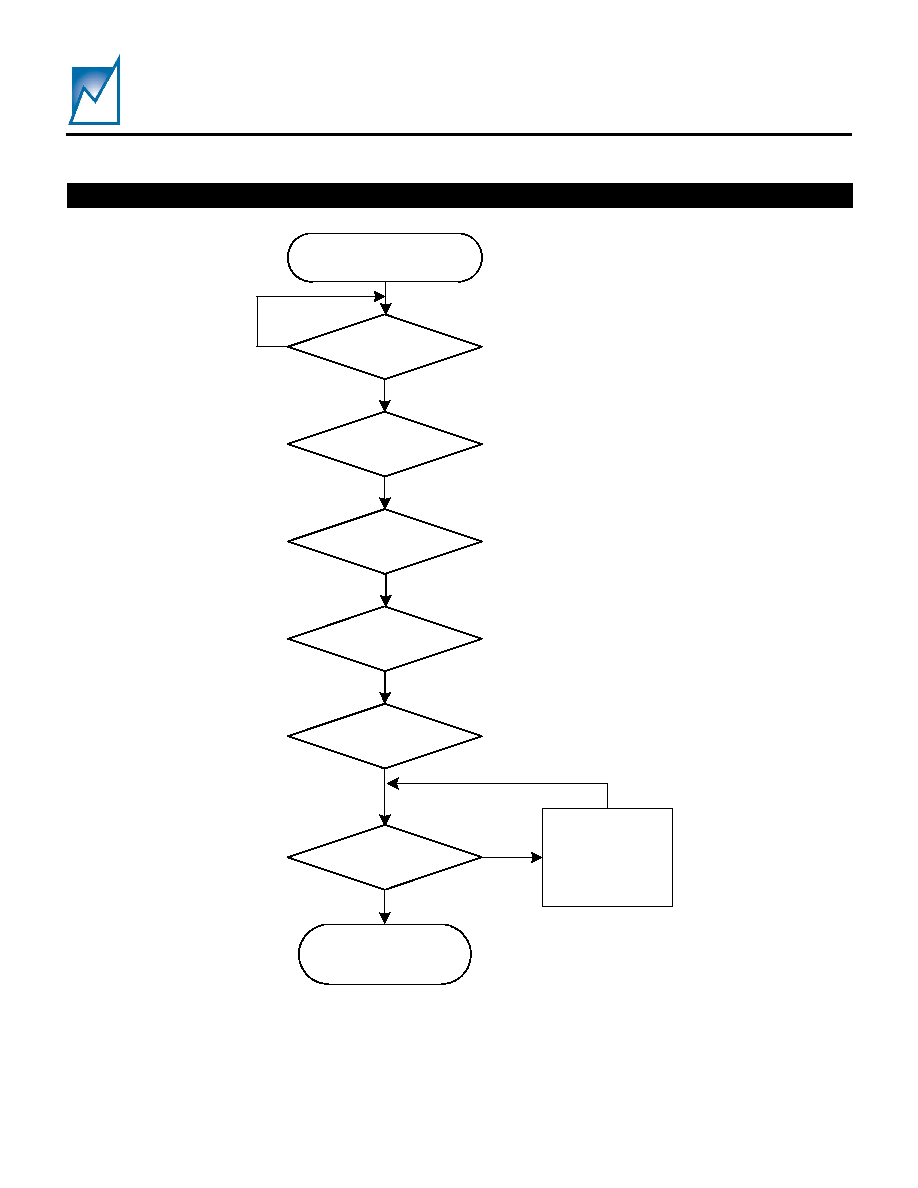

DEVICE OPERATION

POWER SUPPLY

The SMM150 can be powered by a 2.7V to 5.5V input

to the VDD pin (Figure 1). Care should be exercised

that noise from the DC/DC converter is filtered from

the SMM150 VDD pin. See figure 6 for suggestions.

VOLTAGE REFERENCE

The SMM150 uses an internal voltage reference,

VREF with a user programmable level of 0.5V or

1.25V. Total accuracy of VREF is ±0.8% over

temperature and supply variations. For DC/DC

converters that have output voltages below 1.25V, set

the internal VREF to 0.5V.

MODES OF OPERATION

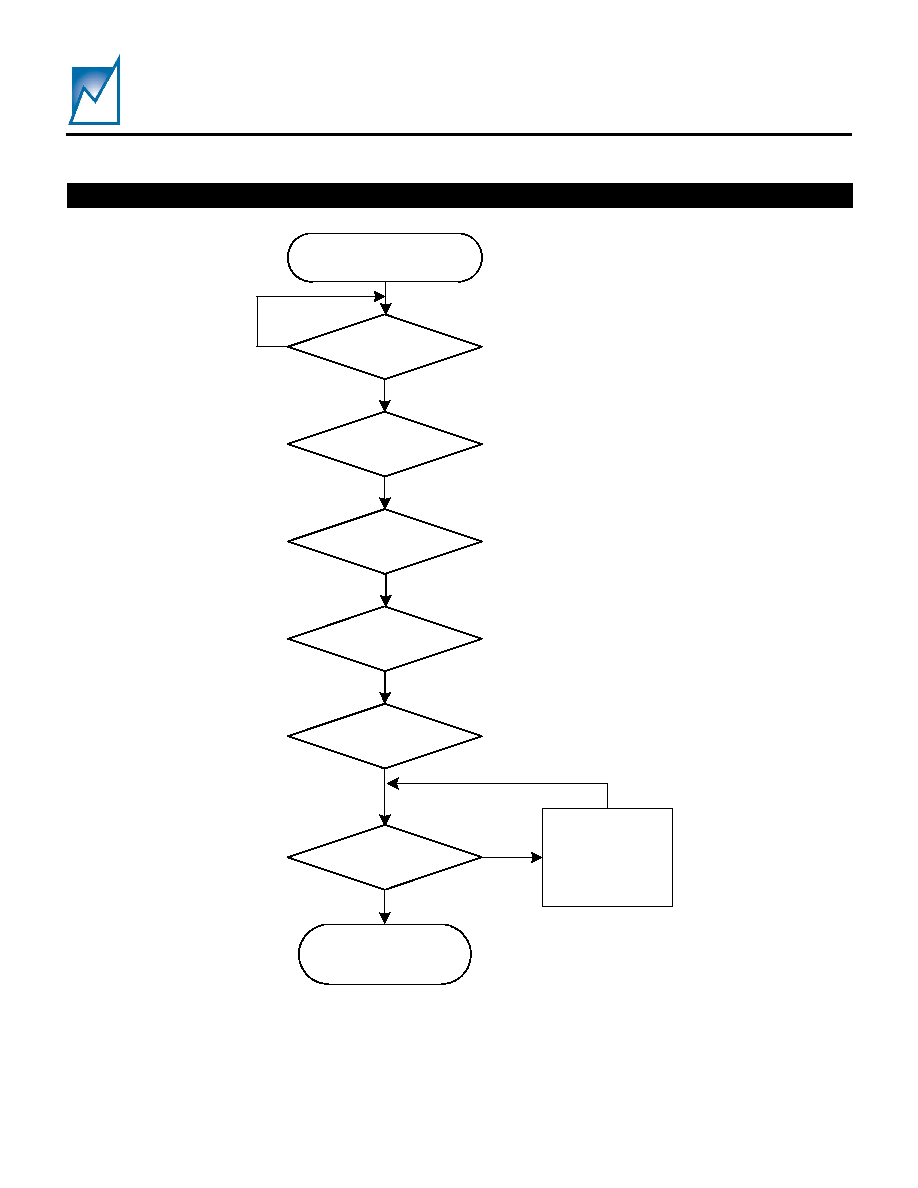

The SMM150 has two basic modes of operation: UV

and OV monitoring mode and supply margining mode.

A detailed description of each mode and feature

follows. A flow diagram is shown in Figure 5.

MARGIN MODE

The SMM150 can control margining of a DC/DC

converter that has a trim pin or any regulator having

access to its feedback node. The TRIM pin on the

SMM150 is connected to the trim input pin on the

power supply converter. A sense line from the

converter's point-of-load connects to the VM input.

The margin function begins upon an I

2

C command or

assertion of the MUP/MDN pins. The TRIM pin is

driven by a DAC whose input is incremented or

decremented every 200µS based on the digital

comparison of the margin target value and the actual

converter output voltage. The voltage on the TRIM

output will continue increasing (decreasing) until the

converter's output voltage equals the target margin

voltage. This voltage adjustment allows the SMM150

to control the margined output voltage of the power

supply converter to within ±1.0% in an open-loop

manner.

The converter is held at the margin voltage until the

SMM150 receives an I

2

C command or the respective

MUP/MDN pin is de-asserted. When not margining,

the TRIM pin on the SMM150 is in a high impedance

state. The voltage on the TRIM pin is buffered and

applied to the ADC at the beginning of a margin cycle

to ensure the converter is margined from its nominal

setpoint. This allows a smooth transition from the

converter's nominal voltage to the SMM150 controlling

that margin voltage to the margin target setting. After

margining high, low or nominal, issuing a margin Off

command will cause the trim pin to go high

impedance. The part margin time from Off to High or

Off to Low is specified as a typical according to the

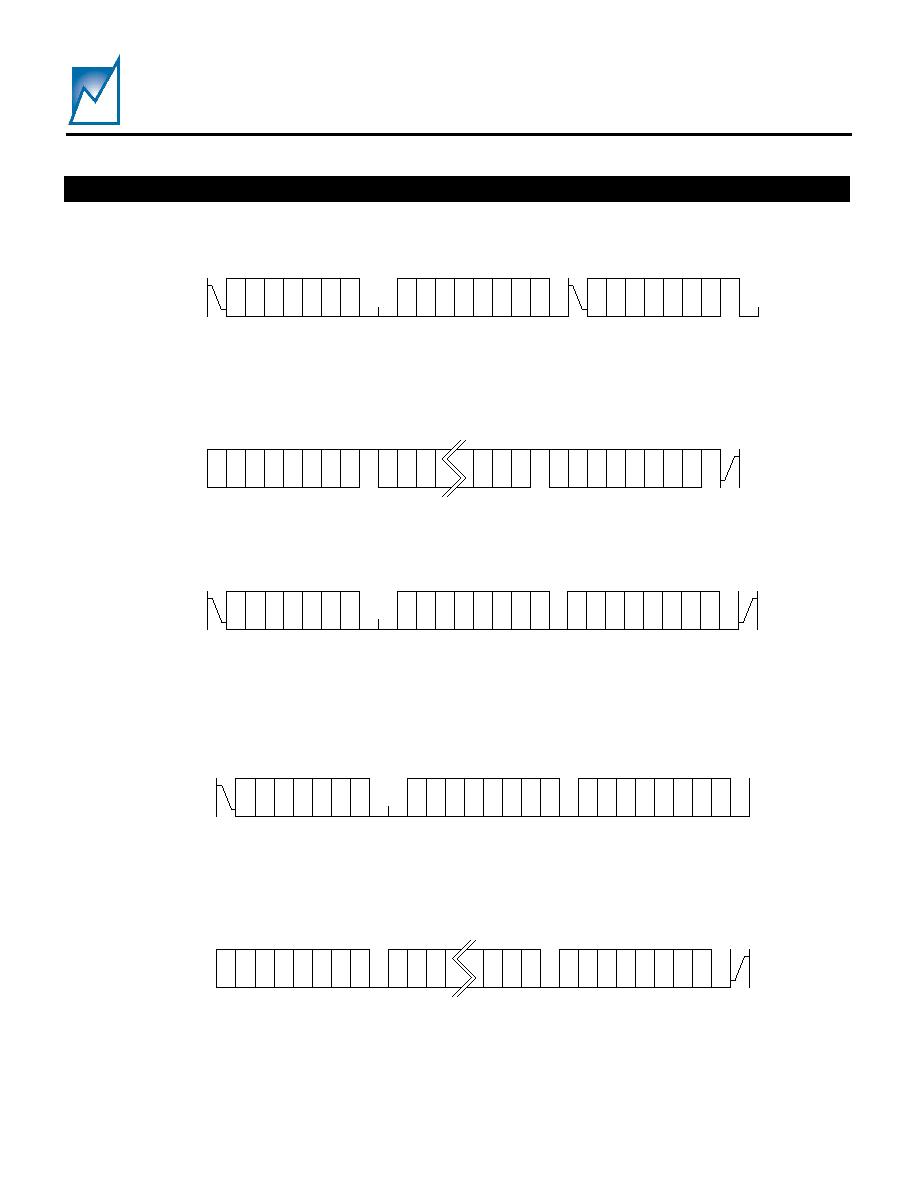

equation:

T

MARG_UPDATE

= (X)(1.8ms) where:

X=step number of possible 256 and 1 step=5mV

The Active Margin Command Delay Time using the

MUP and MDN pins is shown in Figure 4

DC/DC

Supply

GND

SMM150

MPU/D/EN

Total Margin Delay Time

Margin

N/H/L

t

ADC_DAC

ADC/DAC

Sample/

Conversion time

1.8ms

1.8ms

T

MARGIN_UPDATE

t

MARGIN

- Internal

Programmable Active

Margin Delay Time

Turn on Time

t

ADC_DAC

ADC/DAC

Sample/

Conversion time

Figure 4 ≠ Margin Delay Time

SMM150

Preliminary Information

Summit Microelectronics, Inc

2075 2.6 05/13/05

9

YES

POWER OK?

MARGINING OPERATION

1. HOLD DAC

2. CLEAR STATUS REGISTER

3. WAIT FOR NEXT COMMAND

INPUT VTRIM TO ADC

NO

DUMP ADC INTO DAC

DAC DRIVES BRICK

(TRIM OUTPUT LO-Z)

INPUT VOUT TO ADC

NO

ADC EQUAL TARGET?

YES

INCREMENT/

DECREMENT

DAC

Figure 5 - SMM150 Margin Flow Chart

APPLICATIONS INFORMATION (CONTINUED)

SMM150

Preliminary Information

Summit Microelectronics, Inc

2075 2.6 05/13/05

10

When measuring the delay time external to the device,

ADC sample time and Update Trim time (

4ms) must

be added to the internally programmed delay time as

shown:

Spec

Actual measurement

2.5 ms

6.5 ms

5 ms

9 ms

10 ms

14 ms

17.5 ms

22 ms

MONITOR

The SMM150 monitors the COMP1 and COMP2 pins.

COMP1 and COMP2 are high impedance inputs, each

connected internally to a comparator and compared

against the programmable internal reference voltage.

Each comparator can be independently programmed

to monitor for either UV or OV. The monitor level is

set externally with a resistive voltage divider. The

COMP pins can be connected to Vin, Vout or any

voltage that needs to be monitored. The internal

comparators COMP1/2 are compared to VREF, so the

voltage dividers are set above or below the

programmed VREF level depending on whether

monitoring UV or OV. As an example, with VREF set

to 1.25V, to monitor an OV of 1.7V on COMP1 and a

UV of 1.3V on COMP2, the voltage divider resistors

are:

For OV, RUpper = 1.37k, 1% RLower = 3.83k, 1%.

For UV, RUpper = 1.02k, 1% RLower = 25.5k, 1%.

The part can be programmed to trigger the FAULT#

pin when either COMPx comparator has exceeded the

UV or OV range. The READY and FAULT# outputs of

the SMM150 are active as long as the triggering limit

remains in a fault condition. The READY pin is

programmable active high/low open drain output

indicates that VM is at its' set point.

When programmed as an active high output, READY

can also be used as an input. When pulled low, it will

latch the state of the comparator inputs. When either

of the COMP1 or COMP2 inputs are in fault, the open-

drain FAULT# output will be pulled low. A

configuration option exists to disable the FAULT#

output while the device is in margining mode.

STATUS REGISTER

A status register exists for I

2

C polling of the status of

the COMP1 and COMP2 inputs. Two bits in this

status register reflect the current state of the inputs (1

= fault, 0 = no fault). Two additional bits show the

state of the inputs latched by one of two events

programmed in the configuration.

The first event option is the FAULT# output going

active. The second event option is the READY pin

going low. The READY pin is an I/O. As an output,

the READY output pin goes active when the DC

controlled voltages are at their set point. As an input

programmed to active high, it can be pulled low

externally and latch the state of the COMP inputs.

This second event option allows the state of the

COMP inputs on multiple devices to be latched at the

same time while a host monitors their FAULT#

outputs.

MARGINING

The SMM150 has two additional control voltage

settings: margin high and margin low. The margin

high and margin low settings can be as much as

±10%

of the nominal setting depending on the manufacturer.

The margin high and margin low voltage settings can

range from 0.3V to VDD around the converters'

nominal output voltage setting depending on the

specified margin range of the DC-DC converter. These

settings are stored in the configuration registers and

are loaded into the control voltage setting by margin

commands issued via the I

2

C bus.

The margin command registers contain two bits that

decode the commands to margin high or margin low.

Once the SMM150 receives the command to margin

the supply voltage, it begins adjusting the supply

voltage to move toward the desired setting. When this

voltage setting is reached, a bit is set in the margin

status registers and the READY signal becomes

active.

Note: Configuration writes or reads of registers 00

HEX

to 03

HEX

should not be performed while the SMM150

is margining.

FAULTS

When either of the COMP1 or COMP2 inputs are in

fault, the open-drain FAULT# output will be pulled low.

A configuration option exists to disable the FAULT#

output while the device is margining. If "Fault Output

Disabled while Margining" is selected, Faults are

disabled for all margining except when margining to

the `Off' and `Nominal' states. Also, the programmable

feature `Fault Holds Off and Shutdown Control' is

enabled only for the Nominal margin state.

APPLICATIONS INFORMATION (CONTINUED)

SMM150

Preliminary Information

Summit Microelectronics, Inc

2075 2.6 05/13/05

11

Fault Latched by a Fault Condition:

The "Fault Latched by a Fault Condition"

programmable option is triggered only on the leading

edge of a Fault. That is, a latched fault can be cleared

while the Fault yet exists.

Fault Latched by Ready I/O Pin:

Fault Latched by Ready I/O pin functions on the

margin transitions from Off to Hi/Low/Nominal or from

Nominal to Hi/Low or Hi/Low to Nominal but not from

Hi/Low/Nominal to Off.

WRITE PROTECTION

Write protection for the SMM150 is located in a volatile

register where the power-on state is defaulted to write

protect. There are separate write protect modes for the

configuration registers and memory. In order to

remove write protection, the code 55

HEX

is written to

the write protection register.

Other codes will enable write protection. For example,

writing 59

HEX

will allow writes to the configuration

register but not to the memory, while writing 35

HEX

will

allow writes to the memory but not to the configuration

registers. The SMM150 also features a Write Protect

pin (WP input) which, when asserted, prevents writing

to the configuration registers and EE memory. In

addition to these two forms of write protection there is

a configuration register lock bit which, once

programmed, does not allow the configuration

registers to be changed.

A2, A1, A0

The address bits A[2:0] can be hard wired High or Low

or may be left open (High-Z) to allow for a total of 21

distinct device addresses. When floating, the inputs

can tolerate the amount of leakage as described by

the specification I

AIT

. An external 100k pull-up or pull

down resistor is sufficient to set a High or Low logic

level.

U2

DC-DC Converter

1

2

3

4

5 6

7

8

9

10

11

+Vout

+Vout

Sense

+Vout

Gnd Gnd

+Vin

+Vin

+Vin

Trim

Enable

C10

0.1uF

READY

C7

0.01uF

R8

25.

5K 1%

Vdd

R6

3.

83K 1%

FAULT#

J2

Programming Supply

1

2

1

2

VOUT = 1.5V

U3

SMM150

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15 16 17 18

19

20

21

22

23

24

25

26 27

28

SCL

A2

NC

A1

READY

A0

GND

WP

NC

CAP_M

FAULT#

COMP2

NC

VM

NC NC NC NC

COMP1

TRIM

VDD

NC

VDD_CAP

MUP

MDN

NC NC

SDA

C4

0.02uF

C3

10uF

C6

0.01uF

D1

DIODE

MDN

J1

I2C SMX3200 Connector

1

2

3

4

5

6

7

8

9

10

Gnd

SCL

Gnd3

SDA

Rsrv5

MR

+10V

Rsrv8

+5V

Rsrv10

C8

0.1uF

Vdd

R7

1.

02K 1%

C1

0.01uF

R3

20

C2

0.1uF

MUP

C5

1uF

R4 2.5k

C9

0.01uF

R5

1.

37K 1%

+VIN - 2.7V to 5.5V

Figure 6 ≠ Typical applications schematic which shows the SMM150 controlling a 3.3V in/1.5V out DC/DC

converter. Care should be taken to filter DC/DC converter noise from the SMM150 VDD supply pin. This is

accomplished with optional components R3, C1, C2, C3 and C10. This example, using a 1.25V VREF, also

shows the COMP1/2 pins monitoring the DC/DC converter VOUT set to an OV of 1.7V on COMP1 and a UV of

1.3V on COMP2, the voltage divider resistors are:

For OV, R5 = 1.37k, 1% R6 = 3.83k, 1%, For UV, R7= 1.02k, 1% R8 = 25.5k, 1%.

The jumper J2 can be used to supply the SMM150 VDD voltage from the SMX3200 programmer when the

device is programmed with board power off and the controlled supply unloaded.

APPLICATIONS INFORMATION (CONTINUED)

SMM150

Preliminary Information

Summit Microelectronics, Inc

2075 2.6 05/13/05

12

Maximizing Accuracy

Maximum margining accuracy is obtained by placing a

resistor between the SMM150 TRIM output and the

TRIM input of the converter. From the manufacturer's

data sheet obtain the value of the internal voltage

reference and equivalent TRIM input series resistance.

Figure 7 below displays the internal trimming circuit for

a typical isolated DC-DC converter. In this example,

the converter uses positive trimming, i.e., an increase

in voltage at the TRIM pin causes an increase in

output voltage.

DC-DC

Converter

TRIM

VREF

V-

V+

-S

+S

L

O

A

D

VREF

R

TRIM

SMM150

TRIM Pin

R1

R2

Figure 7 - Simplified TRIM circuit of an isolated DC-DC converter connects to SMM150 TRIM output

For this example R

TRIM

is found:

(

)

(

)

(

)

◊ -0.3

2◊

(

-0.3)

=

◊

-0.3

1-

-0.3

TRIM

VREF k

R

VREF

R

k VREF

VREF

Where:

VNom

Low

VM

)

arg(

k

=

0.3 = TRIM output saturation voltage

Vnom = Nominal (non-trimmed output voltage)

The next example applies to most non-isolated DC-DC

converters, LDO's and in-system designed converters

using monolithic PWM controllers. Figure 8 is a

simplified schematic showing the resistor divider

network used to close the loop from the output to the

circuit's feedback node. These type circuits employ

negative trimming, meaning any decrease in voltage

into the feedback node cause an increase in output

voltage.

(

)

( )

1◊

-0.3

=

◊ -1

TRIM

R

VREF

R

VNom k

VNom

High

VM

)

arg(

k

=

0.3 = TRIM output saturation voltage

Vnom = Nominal (non-trimmed output voltage)

VOUT

To FB node

(VREF)

R

TRIM

SMM150

TRIM Pin

R1

R2

Figure 8 - Simplified TRIM circuit of a non-isolated DC-DC converter connects to SMM150 TRIM output

APPLICATIONS INFORMATION (CONTINUED)

SMM150

Preliminary Information

Summit Microelectronics, Inc

2075 2.6 05/13/05

13

The end user can obtain the Summit SMX3200

programming system for device prototype

development. The SMX3200 system consists of a

programming Dongle, cable and Windows

TM

GUI

software. It can be ordered on the website or from a

local representative. The latest revisions of all

software and an application brief describing the

SMX3200 is available from the website

(

www.summitmicro.com

).

The SMX3200 programming Dongle/cable interfaces

directly between a PC's parallel port and the target

application. The device is then configured on-screen

via an intuitive graphical user interface employing

drop-down menus.

The Windows GUI software will generate the data and

send it in I

2

C serial bus format so that it can be directly

downloaded to the SMM150 via the programming

Dongle and cable. An example of the connection

interface is shown in Figure 9.

When design prototyping is complete, the software

can generate a HEX data file that should be

transmitted to Summit for approval. Summit will then

assign a unique customer ID to the HEX code and

program production devices before the final electrical

test operations. This will ensure proper device

operation in the end application.

Pin 9, 5V

Pin 7, 10V

Pin 5, Reserved

Pin 3, GND

Pin 1, GND

Pin 6, MR#

Pin 4, SDA

Pin 2, SCL

Pin 8, Reserved

Pin 10, Reserved

Top view of straight 0.1" x 0.1 closed-side

connector. SMX3200 interface cable connector.

9

7

5

3

1

10

8

6

4

2

SMM150

SDA

SCL

VDD

GND

0.1

µF

Common

Ground

WP

D1

C1

1N4148

Positive

Supply

Jumper

Figure 9≠ SMX3200 Programmer I

2

C serial bus connections to program the SMM150. The SMM150 has a

Write Protect pin (WP input) which when, asserted, prevents writing to the configuration registers and EE

memory. In addition, there is a configuration register lock bit, which, once programmed, does not allow the

configuration registers to be changed.

DEVELOPMENT HARDWARE & SOFTWARE

SMM150

Preliminary Information

Summit Microelectronics, Inc

2075 2.6 05/13/05

14

SERIAL INTERFACE

Access to the configuration registers, general-purpose

memory and command and status registers is carried

out over an industry standard 2-wire serial interface

(I

2

C). SDA is a bi-directional data line and SCL is a

clock input. Data is clocked in on the rising edge of

SCL and clocked out on the falling edge of SCL. All

data transfers begin with the MSB. During data

transfers SDA must remain stable while SCL is high.

Data is transferred in 8-bit packets with an intervening

clock period in which an Acknowledge is provided by

the device receiving data. The SCL high period (t

HIGH

)

is used for generating Start and Stop conditions that

precede and end most transactions on the serial bus.

A high-to-low transition of SDA while SCL is high is

considered a Start condition while a low-to-high

transition of SDA while SCL is high is considered a

Stop condition.

The interface protocol allows operation of multiple

devices and types of devices on a single bus through

unique device addressing. The address byte is

comprised of a 4-bit device type identifier (slave

address) and a unique (three-state) 3-bit bus address.

The remaining bit indicates either a read or a write

operation. Refer to Table 1 for a description of the

address bytes used by the SMM150. Refer to Table 2

for an example of the unique address handling of the

SMM150.

The device type identifier for the memory array, the

configuration registers and the command and status

registers are accessible with the same slave address.

It can be set using the address pins as described in

table 2.

The bus address bits A[2:0] are hard wired only

through address pins 2, 4 and 6 (A2, A1 and A0) or

may be left open (Z) to allow for a total of 21 distinct

device addresses. The bus address accessed in the

address byte of the serial data stream must match the

setting on the SMM150 address pins.

WRITE

Writing to the memory or a configuration register is

illustrated in Figures 10, 11, 12, 14, 15 and 17. A Start

condition followed by the address byte is provided by

the host; the SMM150 responds with an Acknowledge;

the host then responds by sending the memory

address pointer or configuration register address

pointer; the SMM150 responds with an acknowledge;

the host then clocks in one byte of data. For memory

and configuration register writes, up to 15 additional

bytes of data can be clocked in by the host to write to

consecutive addresses within the same page. After

the last byte is clocked in and the host receives an

Acknowledge, a Stop condition must be issued to

initiate the nonvolatile write operation.

READ

The address pointer for the configuration registers,

memory, command and status registers and ADC

registers must be set before data can be read from the

SMM150. This is accomplished by issuing a dummy

write command, which is simply a write command that

is not followed by a Stop condition. The dummy write

command sets the address from which data is read.

After the dummy write command is issued, a Start

command followed by the address byte is sent from

the host. The host then waits for an Acknowledge and

then begins clocking data out of the slave device. The

first byte read is data from the address pointer set

during the dummy write command. Additional bytes

can be clocked out of consecutive addresses with the

host providing an Acknowledge after each byte. After

the data is read from the desired registers, the read

operation is terminated by the host holding SDA high

during the Acknowledge clock cycle and then issuing a

Stop condition. Refer to Figures 13, 15 and 18 for an

illustration of the read sequence.

WRITE PROTECTION

The SMM150 powers up into a write protected mode.

Writing a code to the volatile write protection register

(write only) can disable the write protection. The write

protection register is located at address 38

HEX

. Writing

to the write protection register is shown in Figure 10.

Writing 0101

BIN

to bits [7:4] of the write protection

register allow writes to the general-purpose memory

while writing 0101

BIN

to bits [3:0] allow writes to the

configuration registers. The write protection can be re-

enabled by writing other codes (not 0101

BIN

) to the

write protection register.

I

2

C PROGRAMMING INFORMATION

SMM150

Preliminary Information

Summit Microelectronics, Inc

2075 2.6 05/13/05

15

I

2

C PROGRAMMING INFORMATION (CONTINUED)

CONFIGURATION REGISTERS

The majority of the configuration registers are grouped

with the general-purpose memory. Writing and reading

the configuration registers is shown in Figures 11, 12

and 13. See Application Note 46 for a complete

description.

Note: Configuration writes or reads of registers 00 to

03

HEX

should not be performed while the SMM150 is

margining.

GENERAL-PURPOSE MEMORY

The 256-byte general-purpose memory is located at

any slave address. The bus address bits are hard

wired by the address pins A2, A1 and A0. They can be

tied low, high or left floating, (Z). Memory writes and

reads are shown in Figures 14, 15 and 16.

COMMAND AND STATUS REGISTERS

Writes and reads of the command and status registers

are shown in Figures 17 and 18.

GRAPHICAL USER INTERFACE (GUI)

Device configuration utilizing the Windows based

SMM150 graphical user interface (GUI) is highly

recommended. The software is available from the

Summit website (

www.summitmicro.com

). Using the

GUI in conjunction with this datasheet simplifies the

process of device prototyping and the interaction of

the various functional blocks. A programming Dongle

(SMX3200) is available from Summit to communicate

with the SMM150. The Dongle connects directly to the

parallel port of a PC and programs the device through

a cable using the I

2

C bus protocol. See Figure 5 and

the SMX3200 Data Sheet.

Slave Address Bus Address Register Type

Configuration Registers are located in

00

HEX

thru 05

HEX

and 30

HEX

thru 3E

HEX

10XX

A2 A1 A0

General-Purpose Memory is located in

40

HEX

thru FF

HEX

Table 1 - Address bytes used by the SMM150.

Slave Address programmed as 10XX

Pins A[2:0]

A2 A1 A0

Slave

Address

Bus

Address

0 0 0

1000

000

0 0 1

1000

001

0 0 Z

1000

010

0 1 0

1000

100

0 1 1

1000

101

0 1 Z

1000

110

0 Z X

1000

011

1 0 0

1001

000

1 0 1

1001

001

1 0 Z

1001

010

1 1 0

1001

100

1 1 1

1001

101

1 1 Z

1001

110

1 Z X

1001

011

Z 0 0

1010

000

Z 0 1

1010

001

Z 0 Z

1010

010

Z 1 0

1010

100

Z 1 1

1010

101

Z 1 Z

1010

110

Z Z X

1010

011

Table 2 ≠ Example device addresses allowed by the SMM150.

SMM150

Preliminary Information

Summit Microelectronics, Inc

2075 2.6 05/13/05

16

S

T

A

R

T

W

A

C

K

Master

Slave

A

C

K

Configuration

Register Address = 38

HEX

0

0

1

1

1

0

0

0

0

1

0

1

0

1

0

1

S

T

O

P

Data = 55

HEX

A

C

K

A

2

Bus Address

A

1

A

0

5

HEX

Unlocks

General Purpose

EE

5

HEX

Unlocks

Configuration

Registers

Write Protection

Register Address

1

0

S

A

1

S

A

0

3

HEX

8

HEX

Figure 10 ≠ Write Protection Register Write

S

T

A

R

T

Bus Address

W

A

C

K

Master

Slave

A

C

K

Configuration

Register Address

C

7

C

6

C

5

C

4

C

3

C

2

C

1

C

0

D

7

D

6

D

5

D

4

D

3

D

2

D

1

D

0

S

T

O

P

Data

A

C

K

A

2

A

1

A

0

1

0

S

A

1

S

A

0

Figure 11 ≠ Configuration Register Byte Write

S

T

A

R

T

Bus Address

W

A

C

K

D

7

D

6

D

5

D

4

D

3

D

2

D

1

D

0

S

T

O

P

Master

Master

Slave

Slave

A

C

K

Data (16)

Configuration

Register Address

C

7

C

6

C

5

C

4

C

3

C

2

C

1

C

0

A

C

K

D

7

D

6

D

5

D

4

D

3

D

2

D

1

D

0

Data (1)

A

C

K

D

7

D

6

D

5

D

4

D

3

D

2

D

1

D

0

Data (2)

A

C

K

D

7

D

6

D

5

D

2

D

1

D

0

A

C

K

A

2

A

1

A

0

1

0

S

A

1

S

A

0

Figure 12 ≠ Configuration Register Page Write

I

2

C PROGRAMMING INFORMATION (CONTINUED)

SMM150

Preliminary Information

Summit Microelectronics, Inc

2075 2.6 05/13/05

17

S

T

A

R

T

Bus Address

W

A

C

K

D

7

D

6

D

5

D

4

D

3

D

2

D

1

D

0

S

T

O

P

N

A

C

K

Master

Master

Slave

Slave

A

C

K

Data (n)

Configuration

Register Address

C

7

C

6

C

5

C

4

C

3

C

2

C

1

C

0

S

T

A

R

T

R

A

C

K

Bus Address

A

C

K

D

7

D

6

D

5

D

2

D

1

D

0

A

C

K

D

7

D

6

D

5

D

4

D

3

D

2

D

1

D

0

Data (1)

A

2

A

1

A

0

1

0

S

A

1

S

A

0

A

2

A

1

A

0

S

A

3

S

A

2

S

A

1

S

A

0

Figure 13 - Configuration Register Read

S

T

A

R

T

Bus Address

W

A

C

K

Master

Slave

A

C

K

Configuration

Register Address

C

7

C

6

C

5

C

4

C

3

C

2

C

1

C

0

D

7

D

6

D

5

D

4

D

3

D

2

D

1

D

0

S

T

O

P

Data

A

C

K

A

2

A

1

A

0

1

0

S

A

1

S

A

0

Figure 14 ≠ General Purpose Memory Byte Write

Bus Address

S

T

A

R

T

W

A

C

K

D

7

D

6

D

5

D

4

D

3

D

2

D

1

D

0

S

T

O

P

Master

Master

Slave

Slave

A

C

K

Data (16)

Configuration

Register Address

C

7

C

6

C

5

C

4

C

3

C

2

C

1

C

0

A

C

K

D

7

D

6

D

5

D

4

D

3

D

2

D

1

D

0

Data (1)

A

C

K

D

7

D

6

D

5

D

4

D

3

D

2

D

1

D

0

Data (2)

A

C

K

D

7

D

6

D

5

D

2

D

1

D

0

A

C

K

A

2

A

1

A

0

1

0

S

A

1

S

A

0

Figure 15 - General Purpose Memory Page Write

I

2

C PROGRAMMING INFORMATION (CONTINUED)

SMM150

Preliminary Information

Summit Microelectronics, Inc

2075 2.6 05/13/05

18

S

T

A

R

T

W

A

C

K

D

7

D

6

D

5

D

4

D

3

D

2

D

1

D

0

S

T

O

P

N

A

C

K

Master

Master

Slave

Slave

A

C

K

Data (n)

Configuration

Register Address

C

7

C

6

C

5

C

4

C

3

C

2

C

1

C

0

S

T

A

R

T

R

A

C

K

A

C

K

D

7

D

6

D

5

D

2

D

1

D

0

A

C

K

D

7

D

6

D

5

D

4

D

3

D

2

D

1

D

0

Data (1)

Bus Address

Bus Address

A

2

A

1

A

0

1

0

S

A

1

S

A

0

A

2

A

1

A

0

S

A

3

S

A

2

S

A

1

S

A

0

Figure 16 - General Purpose Memory Read

S

T

A

R

T

W

A

C

K

Master

Slave

A

C

K

Command and Status

Register Address

C

7

C

6

C

5

C

4

C

3

C

2

C

1

C

0

D

7

D

6

D

5

D

4

D

3

D

2

D

1

D

0

S

T

O

P

Data

A

C

K

Bus Address

A

2

A

1

A

0

1

0

S

A

1

S

A

0

Figure 17 ≠ Command and Status Register Write

S

T

A

R

T

W

A

C

K

D

7

D

6

D

5

D

4

D

3

D

2

D

1

D

0

S

T

O

P

N

A

C

K

Master

Master

Slave

Slave

A

C

K

Data (n)

Command and Status

Register Address

C

7

C

6

C

5

C

4

C

3

C

2

C

1

C

0

S

T

A

R

T

R

A

C

K

A

C

K

D

7

D

6

D

5

D

2

D

1

D

0

A

C

K

D

7

D

6

D

5

D

4

D

3

D

2

D

1

D

0

Data (1)

Bus Address

Bus Address

A

2

A

1

A

0

S

A

3

S

A

2

S

A

1

S

A

0

A

2

A

1

A

0

1

0

S

A

1

S

A

0

Figure 18 - Command and Status Register Read

I

2

C PROGRAMMING INFORMATION (CONTINUED)

SMM150

Preliminary Information

Summit Microelectronics, Inc

2075 2.6 05/13/05

19

DEFAULT CONFIGURATION REGISTER SETTINGS ≠ SMM150NC-356

Register Contents

Function

R00 D5

Glitch filter delay time set to 120

µs.

R01

71

Nominal setting is 1.802V.

R02

9A

Margin high setting is 2.002V.

R03

48

Margin low setting is 1.602V.

R04 E0

COMP1 is UV sensor, COMP2 is OV sensor, Fault output disabled when margining,

Fault does not hold off or shutdown, Fault latched by Ready I/O Pin.

R05 28

Max converter Settling Time is 2.5ms, Margin I

2

C command enabled, MUP/MDN

pins disabled, WP is active low. VREF set to 1.25V

RC1

The default device ordering number is SMM150NC-356, is programmed as described above

and tested over the commercial temperature range. See Application Note 46 for a complete

description of the Configuration Register settings and corresponding Windows GUI

control.

SMM150

Preliminary Information

Summit Microelectronics, Inc

2075 2.6 05/13/05

20

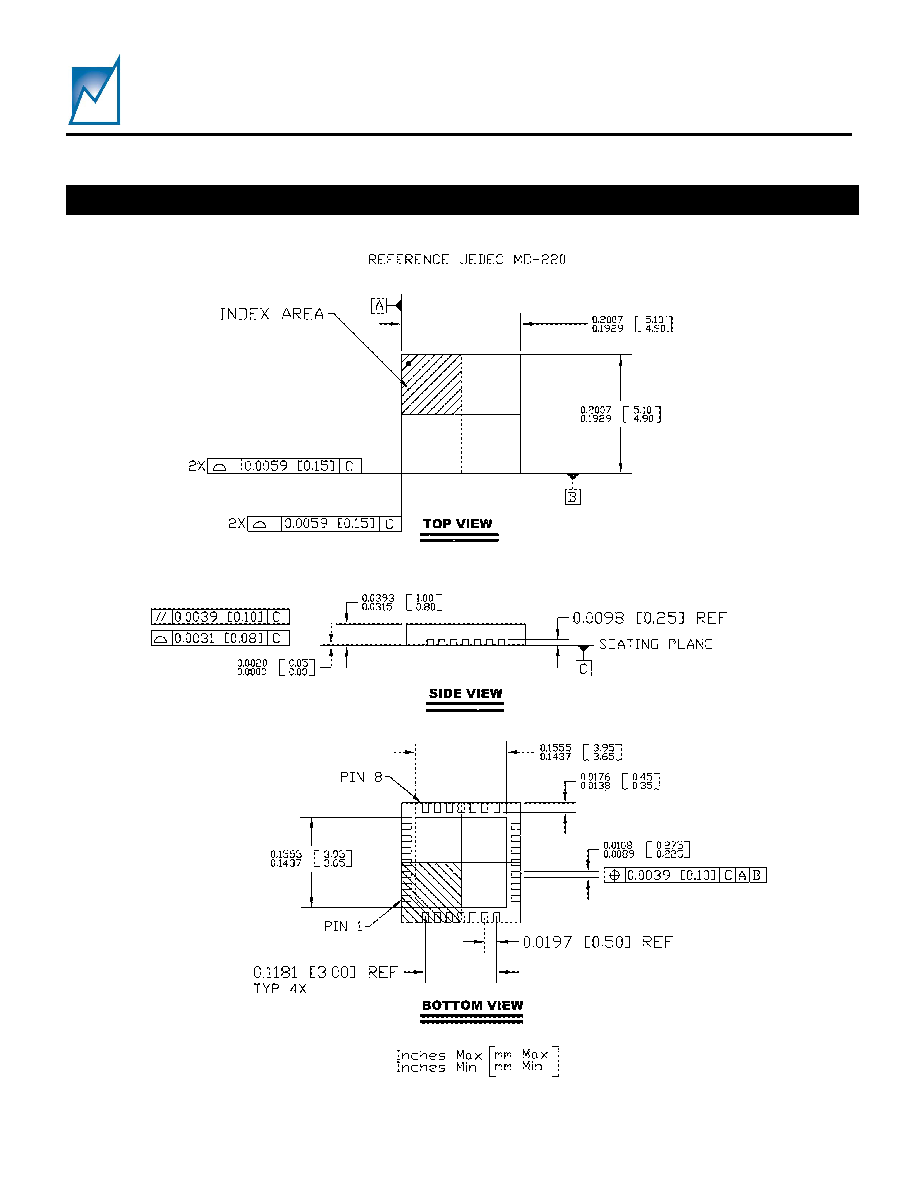

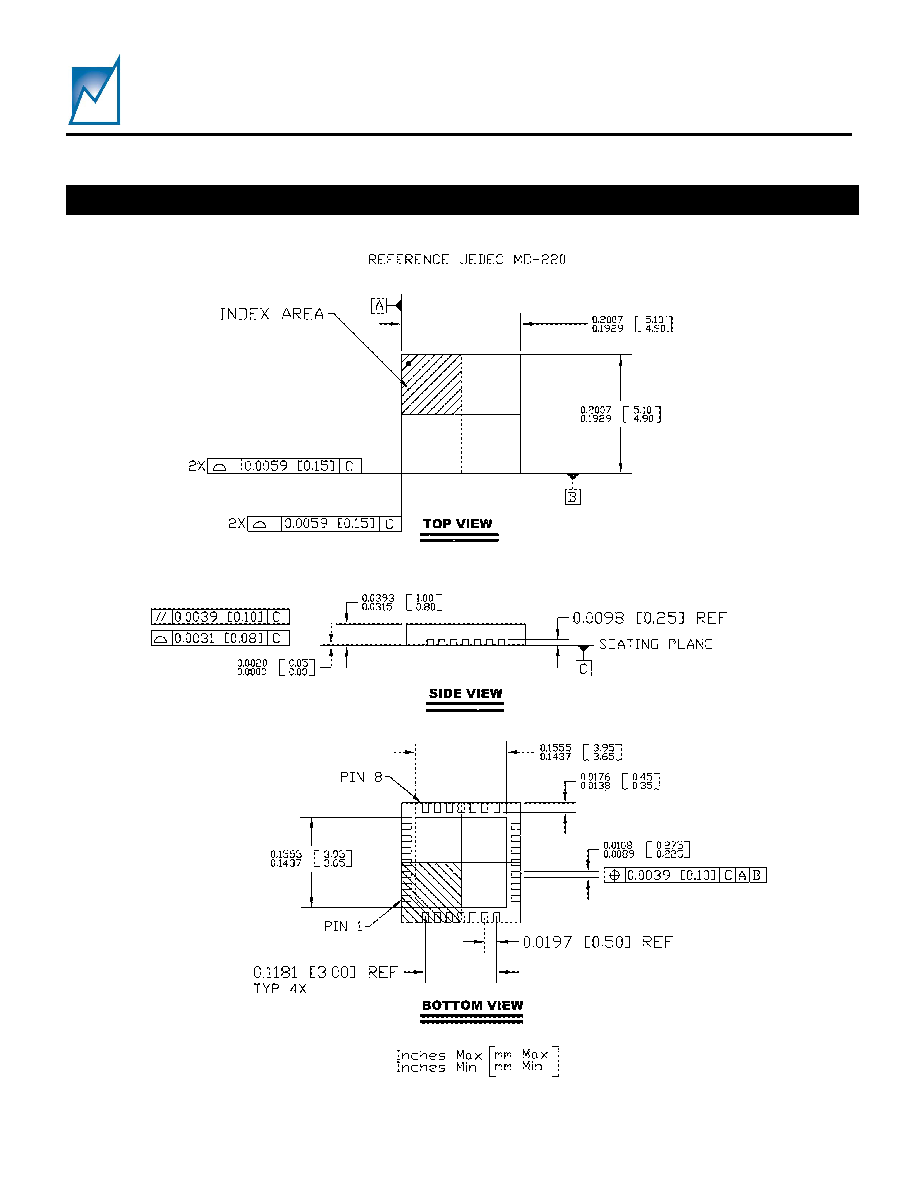

28 Pad QFN

PACKAGE OUTLINES

SMM150

Preliminary Information

Summit Microelectronics, Inc

2075 2.6 05/13/05

21

20 Ball Ultra CSP

TM

PACKAGE OUTLINES (CONTINUED)

SMM150

Preliminary Information

Summit Microelectronics, Inc

2075 2.6 05/13/05

22

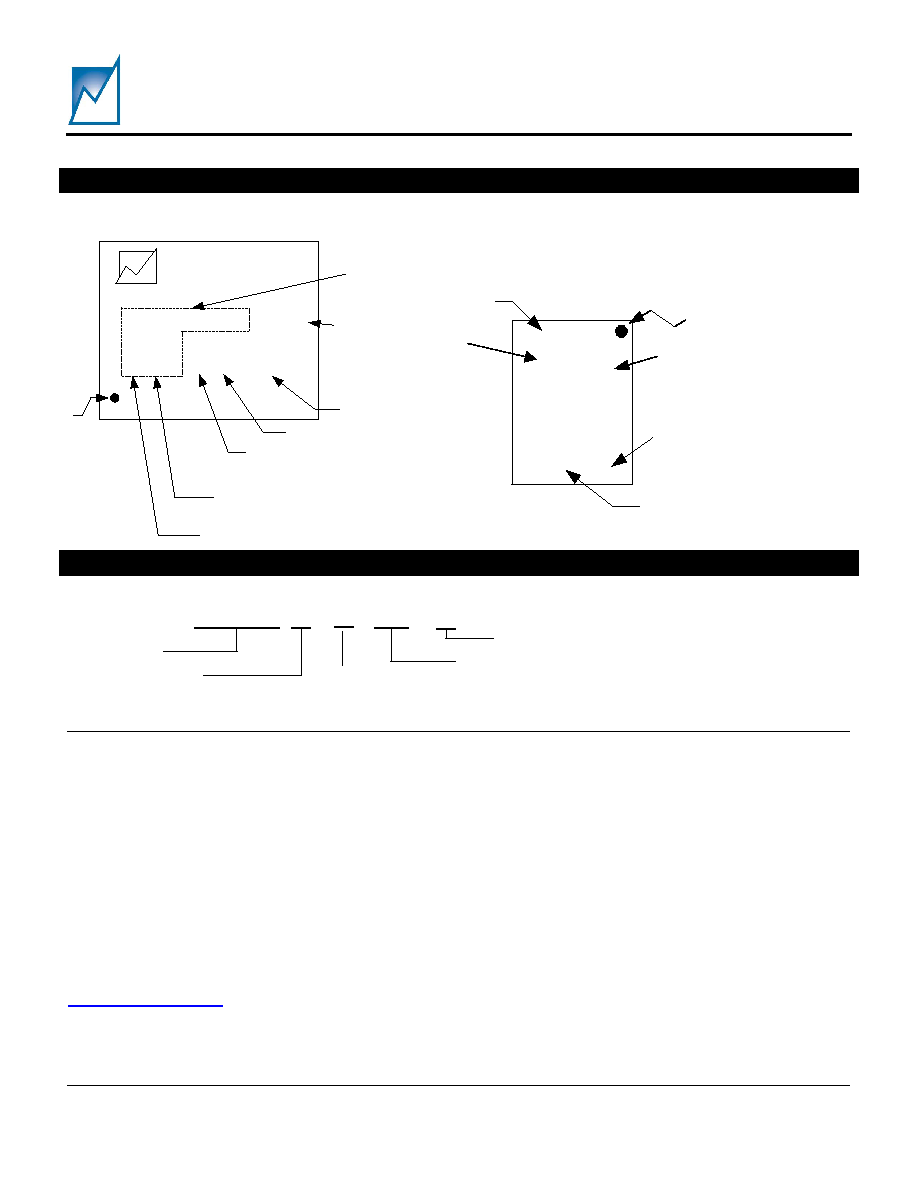

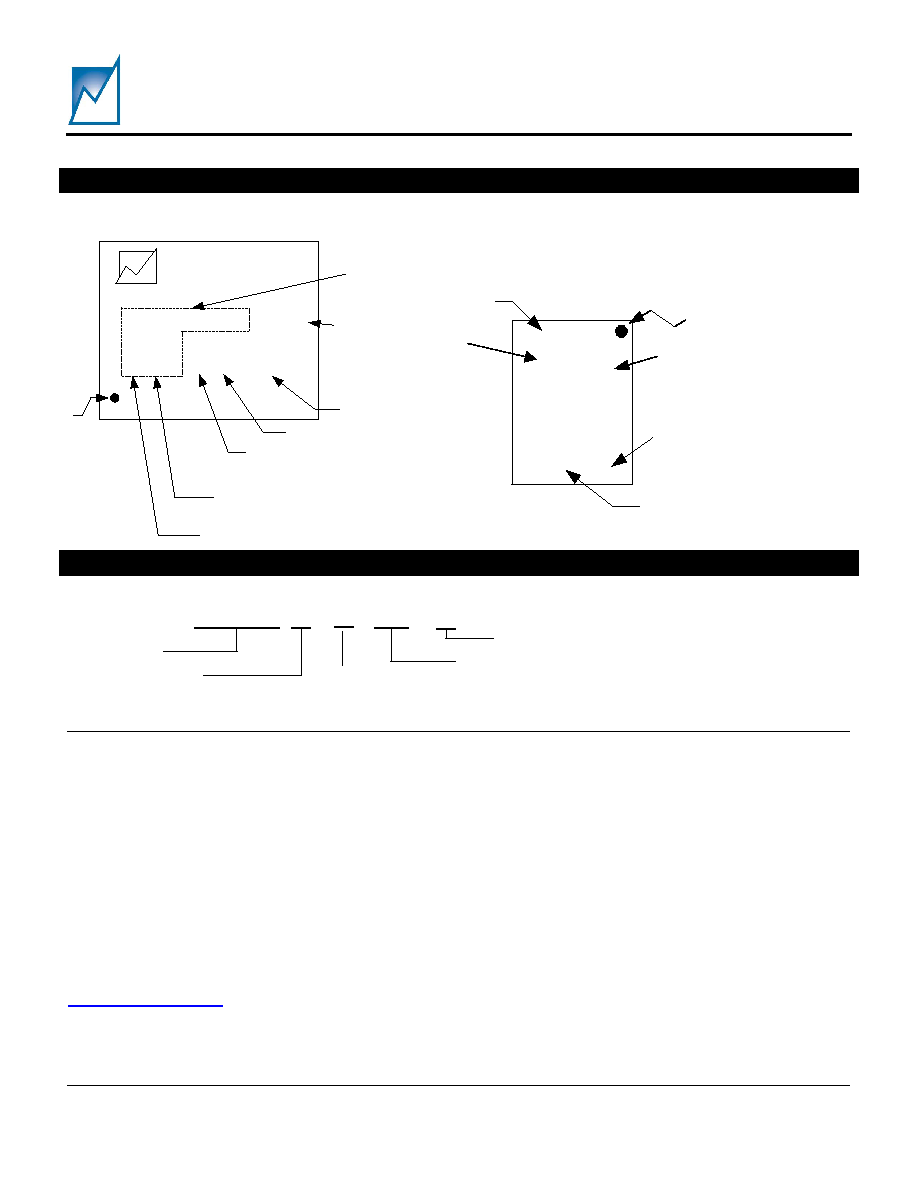

PART MARKING ≠ QFN PACKAGE

SUMMIT

SMM150N

L AYYWW

Pin 1

Annn

Summit

Part Number

Date Code (YYWW)

Part Number suffix

(Contains Customer specific

ordering requirements)

Lot tracking code (Summit use)

Drawing not

to scale

SS

Status Tracking Code

(Blank, MS, ES, 01, 02,...)

(Summit Use)

Product Tracking Code (Summit use)

100% Sn, RoHS compliant, Green

ORDERING INFORMATION

NOTICE

NOTE 1 - This is a

Preliminary Information

data sheet that describes a Summit product currently in pre-production with limited characterization.

SUMMIT Microelectronics, Inc. reserves the right to make changes to the products contained in this publication in order to improve design,

performance or reliability. SUMMIT Microelectronics, Inc. assumes no responsibility for the use of any circuits described herein, conveys no license

under any patent or other right, and makes no representation that the circuits are free of patent infringement. Charts and schedules contained

herein reflect representative operating parameters, and may vary depending upon a user's specific application. While the information in this

publication has been carefully checked, SUMMIT Microelectronics, Inc. shall not be liable for any damages arising as a result of any error or

omission.

SUMMIT Microelectronics, Inc. does not recommend the use of any of its products in life support or aviation applications where the failure or

malfunction of the product can reasonably be expected to cause any failure of either system or to significantly affect their safety or effectiveness.

Products are not authorized for use in such applications unless SUMMIT Microelectronics, Inc. receives written assurances, to its satisfaction, that:

(a) the risk of injury or damage has been minimized; (b) the user assumes all such risks; and (c) potential liability of SUMMIT Microelectronics, Inc.

is adequately protected under the circumstances.

Revision 2.6 - This document supersedes all previous versions. Please check the Summit Microelectronics, Inc. web site at

www.summitmicro.com

for data sheet updates.

© Copyright 2005 SUMMIT MICROELECTRONICS, Inc.

PROGRAMMABLE ANALOG FOR A DIGITAL WORLDTM

I2C is a trademark of Philips Corporation,

Ultra

CSP

TM

is a registered name of FlipChip International, LLC.

SMM150

N

nnn

Package

Part Number Suffix (see page 19)

Summit

Part

Number

Customer specific requirements are contained

in the suffix such as Hex code, Hex code

revision, etc.

C

Temp Range

C=Commercial

Blank=Industrial

N=28 Pad QFN

E=20 Ball Ultra CSP

TM

V

is the Lead-Free Attribute for the CSP

(E Package),

L

is for the QFN (N package)

V

20 Ball Ultra CSP

TM

28 Pad QFN

SMM15

0

EV

XSSYW

W

Ball A1

Identifier

Date Code

Y = Single digit year

(4=2004, 5=2005, etc)

Drawing not

to scale

Summit Part Number

X is the sequential letter per wafer

(i.e. A for the first wafer, B for the second wafer,

C for the third wafer, etc.)

100% Sn, RoHS compliant,

Green