| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: HV111K4 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Inrush Limiter/Circuit Breaker/Hotswap Controller IC

HV111

Initial Release

(No External Parts Required)

Features

No External Parts Required

On Board 80V, 2A MOSFET

No Rsense Needed

±

8.0V to

±

80V Input Voltage Range

Two Level Current Limiting

1.2A Initial Inrush Limit

2.0A Second Inrush Limit/Circuit Breaker Triggers

Servo Limit to 1.2A for T

oc

then shuts down

Fast Response Current Limit when Over Current or Step

Voltage at Input Supply (eg. Diode `OR'ing)

UVLO/ENABLE & POR Supervisory Circuits

Programmable

UVLO

Over Current Protection

9.0sec Auto Retry

Built in Thermal Shutdown with Hysteresis

80V Open Drain PWRGD bar Flag

Thermally Rugged DPAK5 Package

Applications

Power Ethernet Systems

Routers, Switches

Chargers

Security Peripherals & Cameras

Automotive

Protection

Negative Supply Rail Breaking Applications

Networking Line Cards

Telecom

Line

Cards

Description

The HV111 is a complete power management solution for

switched or pluggable backplane applications up to 1.65A,

running from ≠8.0 to -80V, requiring no external components

or programming in many applications. The HV111 is not

limited to only negative input voltages. It can also be

used in +8.0 to +80V systems.

An internally programmed supervisor UVLO/ ENABLE may

be overridden with external resistors for custom settings.

Satisfying this supervisor will begin a POR phase to ensure

de-bouncing. Thereafter, a servo loop controls an internal

80V, 2A pass element to limit current. The circuit uses

internal mirrors to measure current, eliminating the need for

a sense resistor.

The HV111 includes two current modes: i) initial current limit

mode limits the current to 1.2A during turn on; ii) thereafter a

2A monitor circuit will re-trigger the servo mechanism back

to 1.2A limit if it is tripped. An on-board thermal supervisor

ensures that the device can never be damaged by over

current conditions.

Circuit breaker functionality is obtained through a either a

current limit timeout or a PWM current limiter for severe

faults. If the servo limits for more than 75ms then the part

will shut down the pass element, and initiate a 9sec timer

after which the turn on sequence will restart.

The HV111 is available in a thermally rugged DPAK-5

package which provides improved thermal resistance when

compared to SO-8 based solutions.

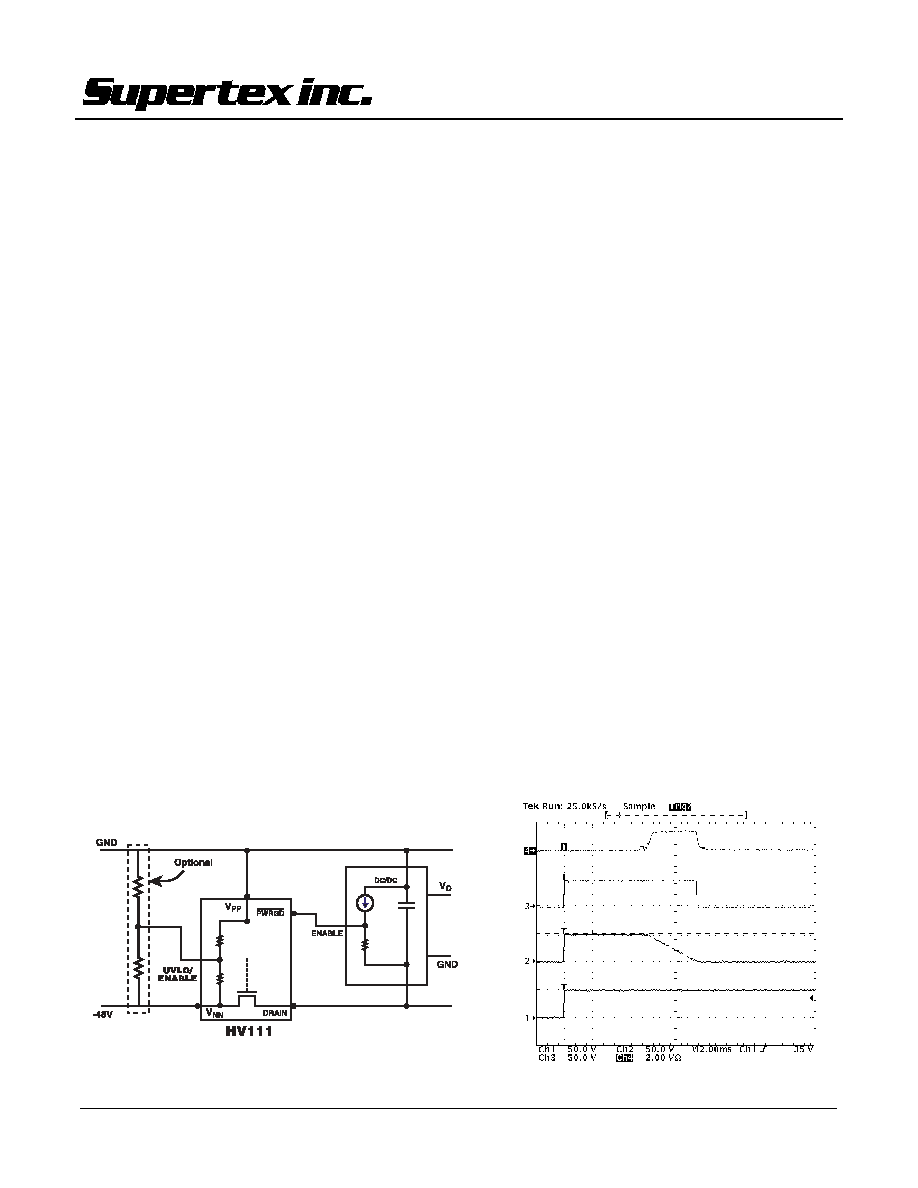

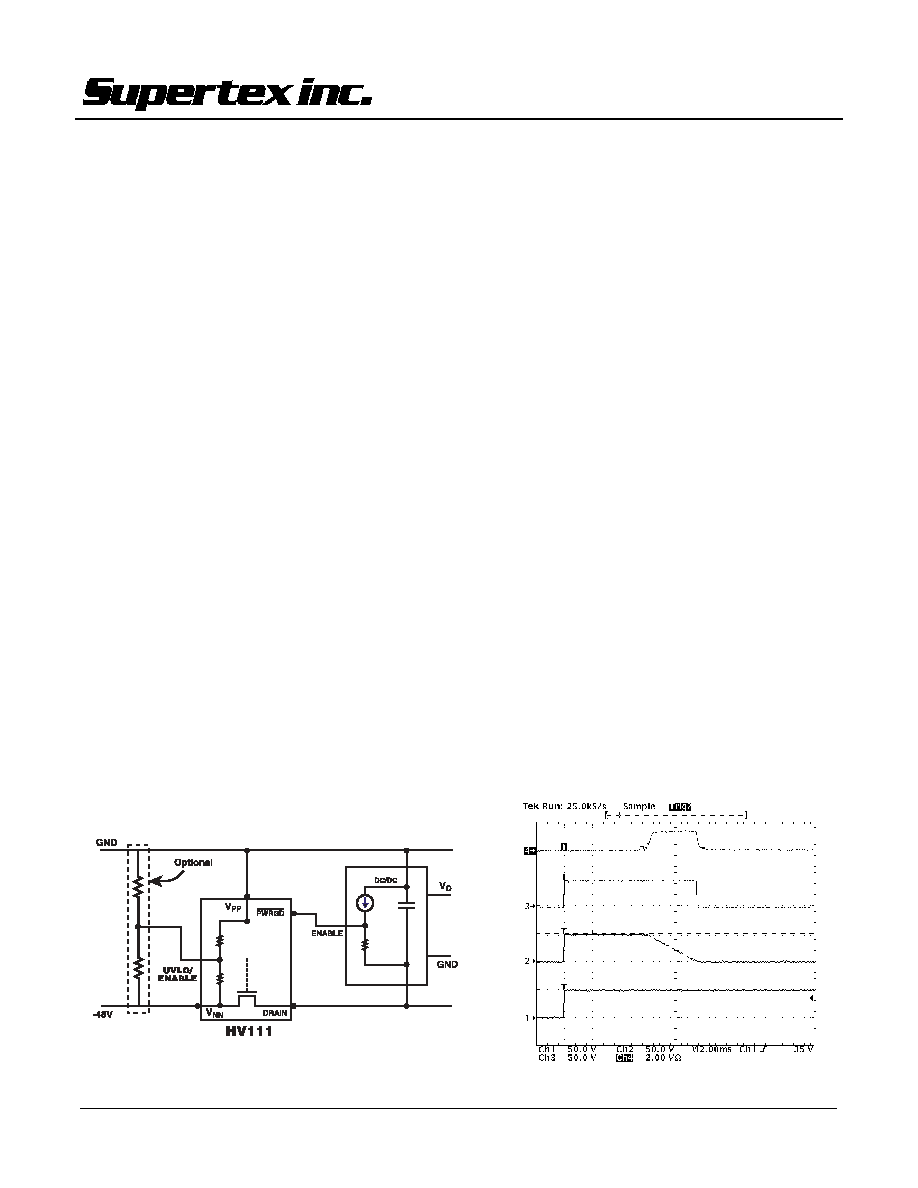

Typical Schematics and Waveforms

INRUSH

PWRGD

DRAIN

GND*

*Referred to ≠48V

*

*

Supertex Inc. does not recommend the use of its products in life support applications and will not knowingly sell its products for use in such applications unless it receives an adequate

"products liability indemnification insurance agreement." Supertex does not assume responsibility for use of devices described and limits its liability to the replacement of devices determined

to be defective due to workmanship. No responsibility is assumed for possible omissions or inaccuracies. Circuitry and specifications are subject to change without notice. For the latest

product specifications, refer to the Supertex website: http://www.supertex.com. For complete liability information on all Supertex products, refer to the most current databook or to the

Legal/Disclaimer page on the Supertex website.

7/24/03

HV111

Ordering Information

Package Options

DEVICE

DPAK-5

HV111 HV111K4

A

bsolute Maximum Ratings

Supply Voltage*, V

pp

-0.5V to 90V

Operating Temperature Range

-40∞C to +85∞C

Storage Temperature Range

-65∞ to +150∞C

5 Pin DPAK Thermal Resistance R

JA

80∞C/W

5 Pin DPAK Thermal Resistance R

JC

11∞C/W

* Relative to V

NN

(1) Shorted-circuit timer starts after POR timer. If V

DS

drops more than º(V

PP

-V

NN

) after t

SC

then a shorted-circuit condition exists.

Electrical Characteristics

( * means -20

∞

C< T

A

<

+85

∞

C)

Symbol Parameter

Min

Typ

Max

Units

T

A

Conditions

V

PP

Supply Voltage

-80

-8.0

V

*

V

PP

≠ V

NN

I

PP

Supply Current

1

mA

V

NN

= -48V, Standby Mode

V

UVLO

Internal UVLO Threshold (High to

Low ie. Turning Off)

-23.5 -26.0 -28.5 V *

Subtract

V

HYS

for Low-to-High

V

HYS

Internal UVLO Hysteresis

1.5

2.5

3.5

V

*

V

UV

UVLO Comparator Threshold

1.10 1.20 1.30 V * Referenced

to

V

NN

V

UVHYS

UVLO Comparator Hysteresis

60

100

140

mV

*

R

UVLO

UVLO Input Resistance

78

111

144

k

R

DS

MOSFET On Resistance

1

1.5

*

I

LEAK

Output Leakage Current

10

µ

A

*

MOSFET is off

I

INRUSH

Inrush Current Limit

1.15

1.40

1.65

A

*

I

CB

Circuit Breaker Trip Current 1.65

2.00

2.35

*

Trips then limits to I

LIMIT

until toc

expires.

I

LIMIT

Over Load Current Limiting

1.2

A

*

I

SC

Shorted Circuit PWM Average

Current

230 mA

V

PP

-V

DRAIN

< ~1V

VOL

PWRGD

PWRGD Output Low Voltage

0.4

V

I=1mA; Reference to V

NN

IOH

PWRGD

PWRGD Output leakage Current

10

µ

A

*

V=5V; Reference to V

NN

t

SC

Shorted-Circuit Timer (1) (4)

40

75

110

ms

*

t

OC

Over-Current Timer (2) (4)

40

75

110

ms

*

t

LIMIT

Current Limit Delay Time (3)

10

µ

s

*

Limits within 10

µ

s. May take

up to 100

µ

s to reach final level.

t

POR

POR Timer

2.5

4.5

6.5

ms

*

t

RESTART

Restart Timer (4)

9

Sec

*

T

OVER

Over Temperature Trip Point

120

135

150

∞

C

*

Low to High

T

RESET

Temperature Reset

70

100

∞

C

*

High to Low

(2) If the output current is in an overload condition then the output immediately goes to current limit and starts the over-current timer. If I

OUT

does not drop back

below I

LIMIT

before the timer expires then an over current condition exists. The timer is immediately reset when a fault is cleared.

(3) Time for fast return to limit circuit to react.

(4) Guaranteed by design.

2

HV111

3

Pin Description

HV111

Regulator

UVLO

POR Timer

Restart

TImer

CONTROL

LOGIC

Temperature

Sense

M1

M2

1

2000

M0

D

S

DRAIN

PWRGD

V

NN

V

PP

UVLO/

Enable

V

PP

≠

Positive voltage supply input

V

NN

≠ Negative voltage power supply input

DRAIN ≠ Internal N-Channel MOSFET drain output

UVLO/ENABLE ≠ Under Voltage lockout input or Enable

PWRGD ≠ Active Low Power Good Output

Functional Description

Many systems include front end capacitance to provide low

impedance energy and filtering to power systems. These

systems include hot pluggable live-backplane systems, such

as ≠48V telecom systems and switched systems such as

battery connected backed-up loads.

This filter capacitance, usually implemented as large

electrolytic capacitors, looks like a low impedance

connected directly across the power supply terminals and

causes high inrush currents which could damage

connectors, traces or components (such as the capacitors

themselves). These high currents may also cause localized

glitching of the backplane or EMI that could reset or interrupt

surrounding circuit cards.

The HV111 is a single chip solution that provides bullet-

proof power management control for systems with loads

less than 1.65A. See Thermal Shutdown section for power

dissipation limitation. The HV111 does not require the use of

any external components or programming and eliminates

the need for a sense resistor. Where desired, however,

internal set points may be overridden with external

components ≠ for example an external resistor divider may

be used to set the UVLO/ENABLE threshold.

High Voltage Regulator

The HV111 includes a high voltage regulator capable of

operation with V

PP

-V

NN

=8.0V to 80V. The regulator provides

an internal voltage to operate circuitry and drive the internal

1

MOSFET pass element.

Turn on Protection

(UVLO/POR for Debounce + PWM limit)

V

PP

UVL

O/

ENABLE

PWRGD

DRAIN

V

NN

PWM I

limit

POR

Figure 1

-

Internal Blocks of HV111

I

DS

200mA/div

V

PP

-V

NN

Figure 2

-

UVLO & POR + Dead Short Protection

The second subsystem is the UVLO/POR that work together

to debounce. Leave the UVLO input open to use the default

setting of ≠26V with 2.5V hysteresis. This default setting can

be over driven with an external resistive divider. The

comparator threshold is 1.2V with respect to V

NN

. The HV111

is capable of operation down to 8.0V for automotive

applications to 80V for the most rugged telecom

applications.

The third subsystem, PWM Iimit, is protection for turning on

into a short (or a later dead short). In this case the HV111

helps avoid the dumping of large currents into the load by

pulse width modulating (PWM) the current to limit Inrush

current to <250mA average if V

pp

-V

DRAIN

<~1V.

HV111

Programming UVLO

PWRGD

Internal to

HV111

DRAIN

V

NN

DC/DC

V

PP

1mA

V

PP

R

1

Q

1

Enable

GND

V

PP

R1

R2

-48V

UVLO

116k

2.4M

1.2V

V

NN

Figure 4

-

PWRGD Active High

Figure 3

-

Programming UVLO

The above circuit works as follows for ACTIVE HIGH

operation. If the PWRGD is low, then the current sourced by

the pullup is pulled to V

NN

and the BJT, Q1, is starved for

base drive current and remains off. The reverse Vbe voltage

is protected by the series diode, D1. If PWRGD is open,

then the current has no alternative but to flow into the base

and thus connects the DC/DC ENABLE pin to the DC/DC

ground reference (DRAIN pin of the HV111). As the clamp is

inverting, therefore proper ACTIVE high polarity is

established.

The UVLO/ENABLE pin makes it easy to override the

internal 26V nominal under voltage. The 26V nominal setting

is produced by a resistor divider of 2.4M

and 116k. These

are 20% resistors, however, 1% accurate relative to one

another. To override there are two options. The first is to

simply use a much lower impedance divider, for example

200k, and largely ignore the internal divider. Alternatively,

the internal impedance may be taken into a account in the

network and the UVLO calculated as:

V

PP

*(R2||116k) / (R1||2.4M

+R2||116k)

The resistor, R1, should be sized as V

PP

/1mA to ensure that

the maximum PWRGD transistor current is not exceeded

(remember to use the maximum possible V

PP

your circuit will

see rather than the nominal value of V

PP

).

Keep in mind, however, that the 30% variation on the

internal resistors will reduce the accuracy of the UVLO set

point using this approach.

Note that the UVLO/ENABLE pin may also be used as an

enable with a nominal 1.20V trip point and 10% of

hysteresis.

Further, Q1 must be rated for operation to maximum

expected V

PP

and have a beta large enough that the

minimum V

PP

min/V

PP

max*1mA*

min

> Ipullupmax of the

DC/DC converter (or external resistor if used).

PWRGD Active High or Active Low

(for DC/DC HV Interface / Enable)

The PWRGD pin is an open drain active low MOSFET which

is enabled when the gate voltage on the internal power

MOSFET reaches its full on voltage. The PWRGD output is

nominally ACTIVE LOW, however, the simple circuit shown

(Figure 4) can convert it to active high operation.

BA

Also shown in Figure 5 is decoupling capacitor is not strictly

required, a fast dv/dt on PWRGD bar can result in coupling

that can glitch the UVLO pin. This decoupling capacitor

ensures that glitches will be eliminated.

Figure 5

-

PWRGD Enable

UVLO/

Enable

V

NN

V

PP

DRAIN

PWRGD

GND

optional

ENABLE

DC/DC

GND

V

O

HV111

-48V

T

4

HV111

Thermal Shutdown

Auto-Retry

In addition to the above parameters, the HV111 will

shutdown if the temperature on the die reaches ~135∞C and

it will not restart until the temperature drops to 100∞C or less

(could be significantly less). The thermal sensor is key in

providing a bullet proof power management solution

because it ensures that the device will turn off long before

damage can occur. This is a significant advantage over

solutions that do not contain an integral MOSFET as then

the temperature cannot be easily sensed quickly and

accurately.

Any fault condition will cause an automatic 9sec retry to

occur. This retry will occur indefinitely (as long as the

thermal supervisor is satisfied). Figure 6 shows typical

waveforms for the auto-retry.

50V/div

200ma/div

PWRGD

V

PP

-V

NN

I

DS

Thermal engineering using the HV111 is key to proper

system operation. The 1

MOSFET pass element may

reach a value as high as 1.5

at high temperatures. There

are numerous methods to reduce the thermal resistance of

the R

JA

. The following table describes some options:

Method

R

JA

Description

FR4 70-80∞

C/W

Straight

Convection

FR4 Heat Sink

40∞ C/W

10cm

2

PCB H/S

FR4 + H/S

13∞ C/W

External Sink + Holes

IMS (40cm

2

)

9∞ C/W

Floating in Air

IMS* w/ H/S

4.5∞ C/W

External Heatsink

Timers

* IMS is a metal substrate board

The timer subsystems are critical to successful operation of

the HV111. Timers are as follows:

To determine your required thermal impedance, R

JA

, is quite

simple. In a parallel to Ohms law, Power x

R

JA

=

T.

Junction temperature, which is limited to 120

∞

C minimum, is

Tmaxambient +

T. For example, if the highest operating

ambient temperature were 55

∞

C as with many networking

applications, and the current were 1.6A, then the required

thermal resistance would be calculated as follows:

Timer Duration

Power-on-Reset

1

4.5ms

Initial Inrush Timeout

2

75ms

Shorted Inrush PWM

10

µ

s

Shorted Circuit Timer

75ms

Second Inrush (Diode

`OR'ing):

Return to Limit

Timeout

10

µ

s

(100

µ

s)

3

75ms

Auto-Retry 9sec

Determine maximum ambient = 55

∞

C.

Determine max junction temp. = 120

∞

C

1

.

Determine max operating current = 1.6A.

Therefore

T = 120-55

∞

C = 65

∞

C.

1

This is the time from satisfying the undervoltage comparator. Each "bounce" will reset this

timer & therefore observed delay may be higher than this "ideal" delay.

Max. Power

2

= 1.23A

2

*1.5

= 3.84W.

Now

T / Power = R

JA

= 65

∞

/3.84W = 20

∞

C/W.

2

Shorted-circuit timer starts after POR timer. If V

DS

drops more than º(V

PP

-V

NN

) after t

SC

then a shorted-circuit condition exists.

To achieve a R

JA

of 20

∞

C/W or better the table above shows

that it will be necessary to use a DPAK external heatsink or

IMS substrate.

3

Limit within 10

µ

s, but may take up to 100

µ

s to settle.

Current Sensing ≠ No R

SENSE

Required

1

This is the minimum value of the low to high thermal shutdown according to the electrical

specifications on pg. 2.

2

This is the maximum MOSFET on resistance at high temperature.

The HV111 uses an internal 6000:1 current mirror to

eliminate the need for a sense resistor. This saves energy

and eliminates the need for a power component. The current

mirror used by Supertex is unique in that it utilizes special

circuitry to normalize for the variations in V

DS

between the

primary pass element and the internal element which would

otherwise cause current mismatch ≠ and forces competitors

to use internal sense resistors in similar applications. This

mechanism also provides the shorted circuit PWM

functionality which can help protect systems in the case of

severe short circuits.

5

HV111

Fast Clamp

Any MOSFET includes parasitic capacitances Ciss and Cfb.

Until power is available and the HV111 initializes, these

parasitic capacitances form a capacitor divider which will

apply to the gate the ratio of Cfb/(Ciss+Cfb)*V

PP

until the

chip is initialized. To combat this the HV111 includes a fast

acting clamp which will hold off the pass element if it sees

voltage applied on the gate of the internal pass element

even before the HV111 has initialized.

During power-up, the HV111 provides an inrush limiting

current that supplies both the load capacitor and the static

load. If the static load current is too high, not enough current

will be available to charge the capacitor before the inrush

breaker trips and disconnects the load.

PWM Current Limit (PWM I

limit

)

200ma/div

V

PP

-V

NN

I

DS

1V

Inrush Breaker Trip

V

LO

AD

0V

40ms

V

o

l

t

a

g

e

Time

1.2A limiting current

230mA

limiting

current

0ms

æ(V

PP

-V

NN

)

Figure 7 ≠ Shorted PWM I

limit

Figure 8 ≠ Inrush Breaker Timing

The HV111 includes a unique protection mode not found in

other hotswap controllers. This protection mode is directed

towards severe faults ≠ faults in which the DRAIN voltage is

unable to move more than ~1V from V

PP

.

To prevent the inrush breaker from tripping, load voltage

(V

LOAD

) must exceed æ(V

PP

-V

NN

) within 40ms. The rate at

which V

LOAD

ramps up is determined by the current available

to charge the load capacitor (after the static load current is

subtracted from the HV111's inrush limiting current). Inrush

limiting initially is 230mA until load voltage exceeds 1V, at

which point it becomes 1.2A. Thus to prevent the inrush

breaker from tripping, the following equation must be

satisfied. Note that the static load cannot exceed 230mA.

If such a shorted condition exists then the current will be

limited as shown in Figure 7 above (where the upper

waveform is the ~230mA PWM current and the lower

waveform is the input voltage). Reducing the current under

severe shorts overcomes thermal cycling in which the

HV111 turns on and off as it heats up and cools down in a

severe fault (limiting the current successively to 1.2A until

overheat). It also protects downstream systems by relieving

them of the requirement to handle the 1.2A.

(

)

3

1V

1 V

4

40ms

230mA

1.15A

PP

NN

LOAD

STATIC

STATIC

V

V

C

I

I

-

-

+

<

-

-

Although this protection is extremely helpful in the case of a

severe fault condition, it does put a limit on the charging

current available for static loads.

This equation holds as long as the static load is a constant

current. If the static load is a resistance, the equation is a

little more complicated.

A special case exists when an always-on (static) load is

present at power-up.

(

)

3

1V

1 V

4

ln 1

ln 1

40ms

230mA

1.15A

lV

PP

NN

LOAD

LOAD

LOAD

LOAD

V

V

R

C

R

R

-

-

-

+

-

<

-

6

HV111

Description of Operation

I

DS

I

DS

V

PGRND

-V

NN

V

DRAIN

-V

NN

V

DRAIN

-V

NN

V

PP

-V

NN

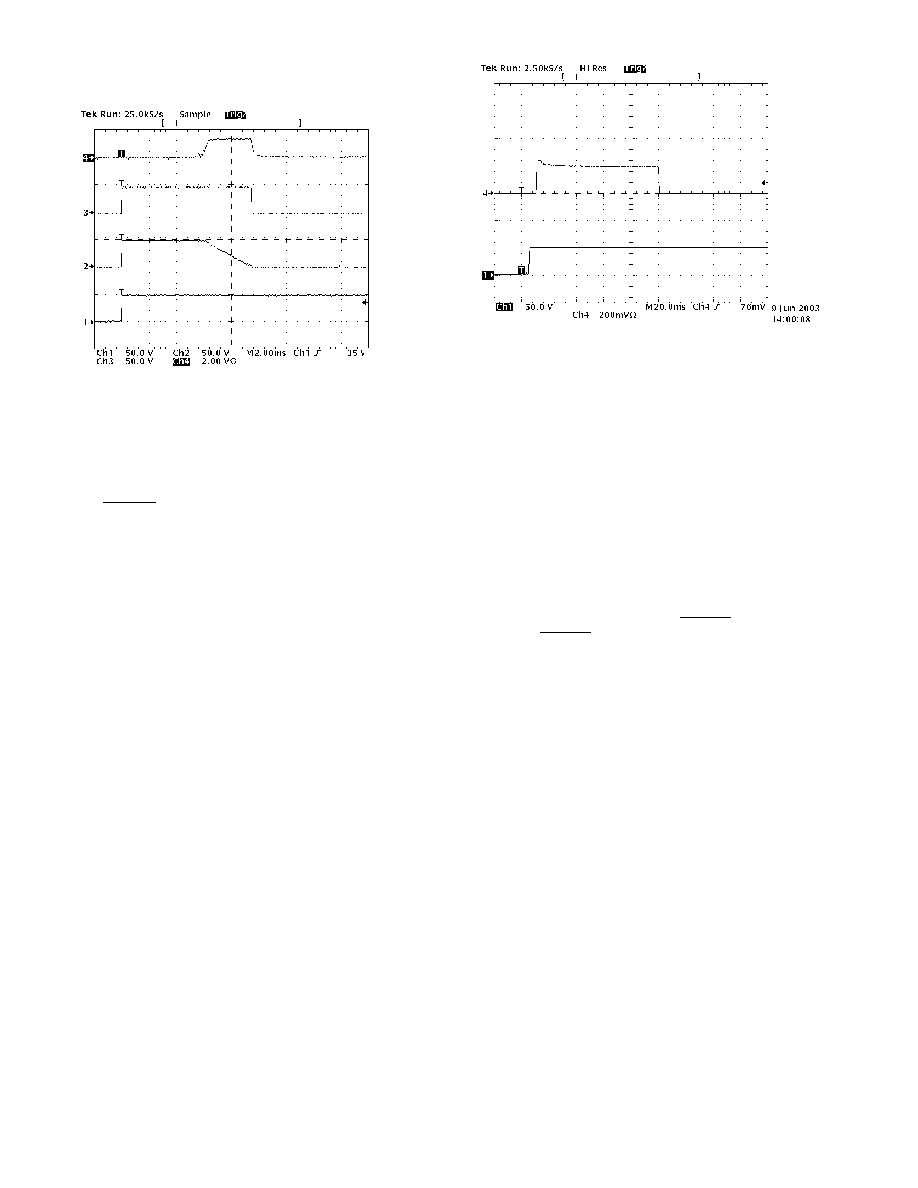

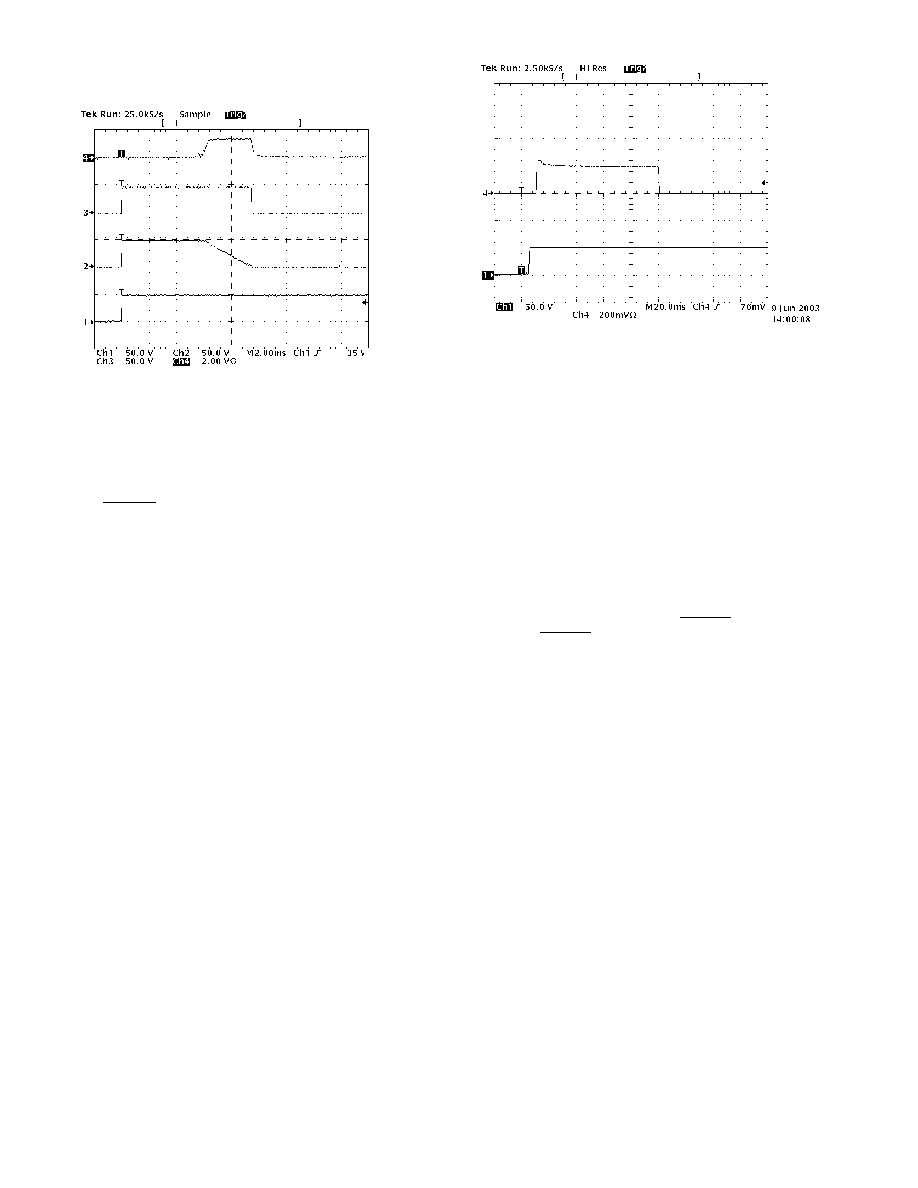

Figure 10 ≠ Limit Timeout

Initial Inrush Timeout

Figure 9 ≠ Turn on Waveforms

The HV111 monitors the drain source voltage and the output

current. During hotswap if the drain source does not drop

below 1/4 of input voltage within a shorted-circuit timer

period (t

SC

= 75ms), then the part will conclude that a short

circuit condition exists, will turn off the internal MOSFET and

auto-retry with a period of 9.0sec. This case is illustrated in

Fig. 10 above (where waveform 4 is DRAIN current and

waveform 1 is V

PP

). Note that if the short circuit is low

enough impedance to hold the DRAIN voltage within ~1V of

V

PP

then the PWM current limit will engage as shown in Fig.

7. Further, the PWM current limit will remain until

V

PP

≠ V

DS

>~1V.

Referring to Figure 9, the operation of the HV111 may be

illustrated. On initial power application (waveform 1 in

Fig. 9) the HV111 provides a regulated supply for the

internal circuitry. Until the proper internal voltage is achieved

all circuits are held reset, the N-channel MOSFET is off and

the PWRGD bar pin is open (INACTIVE). Once the internal

regulator is safe to operate, the under voltage lock out

(UVLO) senses the input voltage. The UVLO will hold the

pass element off until it is satisfied. At any time during the

start up cycle or thereafter, the input voltage falling below

the UVLO threshold will turn off the N-channel MOSFET and

reset all internal circuitry. The IC also includes a clamp for

the spurious inrush through Cload and the Cfb of the

MOSFET pass element. A normal restart sequence will be

initiated once the input voltage rises above the UVLO

threshold.

After the hotswap period is finished successfully, the internal

MOSFET is turned fully on & the PWRGD bar is pulled low

(ACTIVE). PWRGD bar operation (connected to a pullup) is

illustrated by Waveform 3 in Fig. 9.

The UVLO supervisor works in conjunction with a power on

reset (POR) timer. The timer is approximately 4.5ms to

overcome contact bounce. During the contact bounce if

input voltage falls below the UVLO threshold voltage then

the POR timer will reset. In this way the card will be held off

until bouncing ends. The POR timer will restart again when

the input voltage rises above the UVLO threshold once

again. After a full POR period is satisfied, the N-channel

MOSFET begins to turn on to charge the output capacitor

with a current source limited to ~1.2A (illustrated by

Waveform 4 in Fig. 9). Note the PWM protection at the

leading edge of the current rise in Waveform 4; this is the

PWM protection limiting current because a capacitor initially

appears as a dead short. Waveform 2 shows the V

DS

or

DRAIN pin.

7

HV111

Circuit Breaker/Fast Return to

Limit (Diode `OR'ing)

Fast return to limit also acts as a circuit breaker with delay,

in that large currents will be limited and then the system shut

down if it does not recover. Keep in mind, however, that

severe faults which bring V

DRAIN

within ~1V of V

PP

will be

limited with the PWM Ilimit function. Fast return to limit also

overcomes the problem of "second inrush" or "diode `OR'ing

which is illustrated in Fig. 12 above. To understand this

phenomenon, consider what happens when the system has

been operating from the battery from a length of time. The

battery voltage has dropped perhaps ten volts or more.

Suddenly power is restored and the voltage suddenly jumps

from the battery voltage to the fully regulated input voltage.

This voltage jump puts a dv/dt upon the filter capacitances

that creates a second inrush. This second inrush can cause

damage if not limited, which is the purpose of the second

inrush fast return to limit.

V

PWRGD

-V

NN

I

DS

1A/div

V

DRAIN

-V

NN

Test Setup

I

16" Long

V

IN

3" Long

12" Long

Resistive

Load Box

Cload

100

µ

f

100k

V_PWRGD

Vds

GND

Current Probe

Iin

48V

DC Source

C_Source

470

µ

f

+

≠

PWRGD

Drain

Figure 11 ≠ Fast Return to Limit

A current monitor continually examines the current level

(waveform 4 in Fig. 10 & 11) and if it exceeds 2A at any

time, the MOSFET changes to a fixed 1.2A current source.

The MOSFET will remain in this state until the expiration of

an over-current timer (t

OC

= 75ms), whereafter the MOSFET

gate will be turned off and 9sec auto-retry interval will begin

(see DRAIN waveform 2 in Fig. 11, waveform 3 is V

PP

). In

the event that the over-current is cleared before the over-

current timer has expired, then the over-current timer will be

reset.

The 2A breaker will react and begin to limit current in under

10

µ

s, however, it may take up to 100

µ

s for the system to

stabilize at the limit level (1.2A).

UVLO/

Enable

V

NN

V

PP

DRAIN

PWRGD

GND

optional

ENABLE

DC/DC

GND

V

O

HV111

-48V

BAT

Figure 12 ≠ Diode `OR'ing

8

HV111

Package Information

7/24/03

9

Supertex inc.

2003 Supertex Inc. All rights reserved. Unauthorized use ofr reproduction prohibited.

1225 Bordeaux Drive, Sunnyvale, CA 94089

TEL: (408) 222-8888 ∑ FAX: (408) 222-4895

www.supertex.com