| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: U842B | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

U842B

TELEFUNKEN Semiconductors

Rev. A2, 03-Feb-97

1 (12)

Wiper Control for Intermittent and Wipe/ Wash Mode

Description

The U842B circuit is designed as an interval and

wipe/ wash timer for automotive wiper control. The

interval pause can be set in a range from 3 s to 11 s by an

external 1-k

W potentiometer. Wipe/wash mode has

priority over the interval mode. The U842B controls the

wiper motor with/without park switch signal.

The integrated relay driver is protected against short

circuits and is switched to conductive condition in the

case of a load-dump. With only a few external

components, protection against RF interference and

transients (ISO/TR 7637-1/3) can be achieved.

Features

D Interval input: low side

D Wipe/ wash input: low side

D Park input: high side (park position)

D Output driver protected against short circuit

D All time periods determined by RC oscillator

D Fixed relay activation time of 500 ms

D Adjustable interval pause from 3 s to 11 s

D Fixed pre-wash delay of 400 ms

D Dry wiping

≠ With park switch signal: 3 cycles

≠ Without park switch signal: 2.8 s

D Inputs INT, WASH and PARK digitally debounced

D All inputs with integrated RF protection

D Load-dump protection and interference protection ac-

cording to ISO 7637-1/3 (DIN 40839)

Application

Digital/ wipe-wash control for rear or front wiper

Ordring Information

Extended Type Number

Package

Remarks

U842B

DIP8

U842B≠FP

SO8

Pin Description

Pin

Symbol

Function

1

INT

Interval input

2

WASH

Wipe/ wash input

3

PARK

Park switch input

4

PAUS

Pause time adjust

5

OSC

Oscillator input

6

V

S

Supply voltage

7

GND

Ground

8

OUT

Relay output

1

2

3

4

8

7

6

5

INT

WASH

PARK

PAUS

OSC

Vs

GND

13300

OUT

U842B

Figure 1. Pinning

U842B

TELEFUNKEN Semiconductors

Rev. A2, 03-Feb-97

2 (12)

Block Diagram

+

≠

21 V

25 pF

+

≠

21 V

25 pF

+

≠

21 V

25 pF

Stabilization

POR

Load≠dump ≠

detection

V

S

21 V

Logic

28 V

+

≠

250 mV

0.5

Oscillator

+

≠

V

S

21 V

25 pF

21 V

Upper

switching

point

1/2 V

S

6

GND

7

8

OUT

5

OUT

OSC

4

INT

1

WASH

2

PARK

3

13287

PAUS

Figure 2. Block diagram

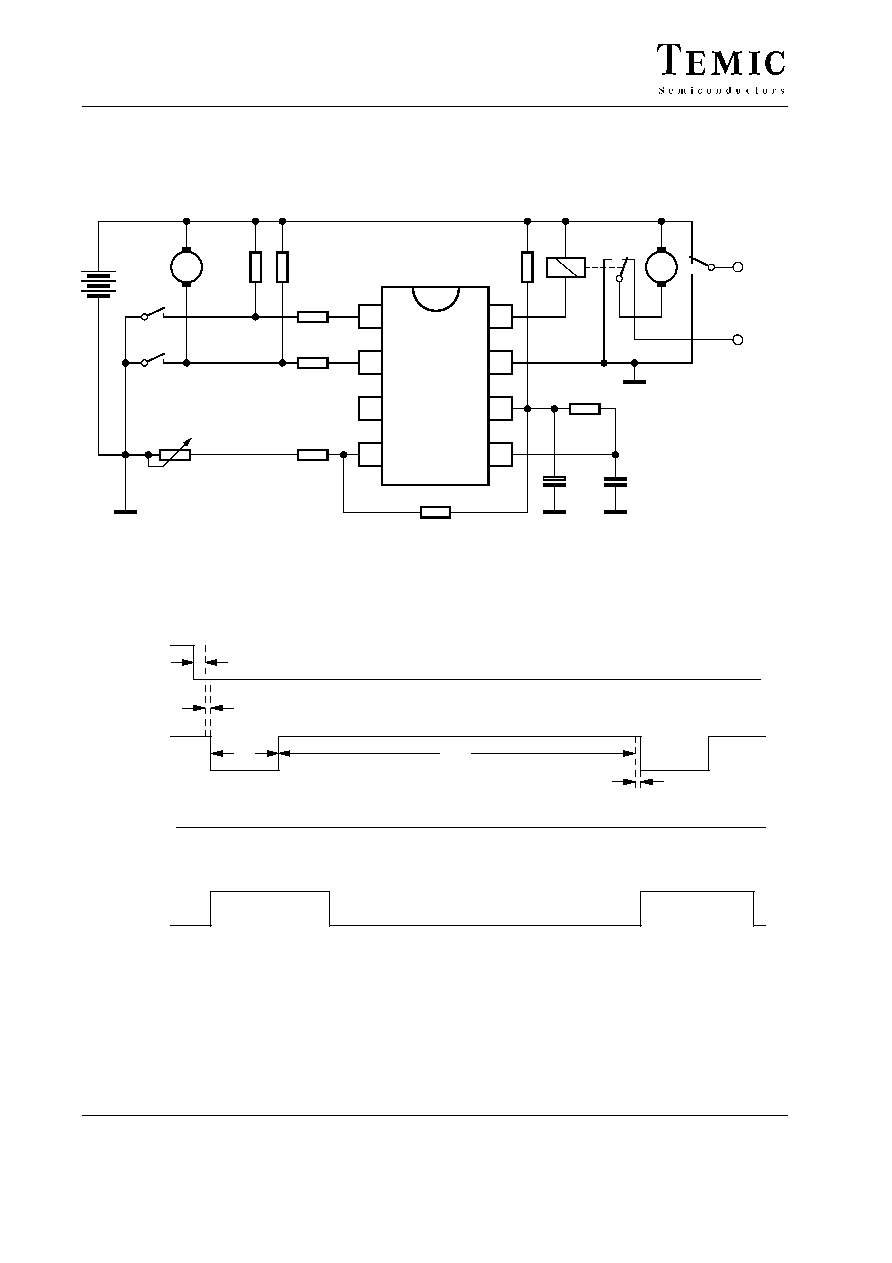

Basic Circuit

Power Supply

For reasons of interference protection and surge immu-

nity, a RC circuitry has to be provided to limit the current,

and to supply the integrated circuit in the case of supply

voltage drops.

Suggested values: R

1

= 180

W, C

1

= 47

mF,

(see figure 2)

The supply (Pin 6) is clamped with a 21-V Zener diode.

The operation voltage ranges between V

Batt

= 9 V to 16 V.

The capacitor, C

1,

can be dimensioned smaller (typically:

10

mF) if a diode is used in the supply against polarity re-

versal. In this case of negative interference pulses, there,

is only a small discharge current of the circuit.

Oscillator

All timing sequences in the circuit are derived from an RC

oscillator which is charged by an external resistor, R

9,

and

discharged by an integrated 2-k

W resistor. The basic

frequency, f

0,

is determined by the capacitor, C

2,

and an

integrated voltage divider. The basic frequency is

adjusted to 320 Hz ( 3.125 ms ) by C

2

= 100 nF and

R

9

= 220 k

W.

The tolerances and the temperature coefficients of the ex-

ternal components determine the precision of the

oscillator frequency. A 1% metallic-film resistor and a

5% capacitor are recommended..

The debouncing times of the inputs, the turn-on time of

the relay (t

5

), the pre-wash delay (t

1

), the dry wiping time

(t

2

) and the debouncing time (t

7

, short circuit detection)

depend on the oscillator frequency (f

0

) as follows:

U842B

TELEFUNKEN Semiconductors

Rev. A2, 03-Feb-97

3 (12)

C

1

13288

8

7

6

5

1

2

3

4

U842B

1.5 k

R

7

R

9

220 k

C

2

100 nF

180

R

1

47

µ

F

V

Batt

47 k

R

5

10 k

R

6

10 k

R

4

360

R

11

Switch

INT

Button

WASH

PARK

1 k

VR

1

Figure 3. Basic cicuitry

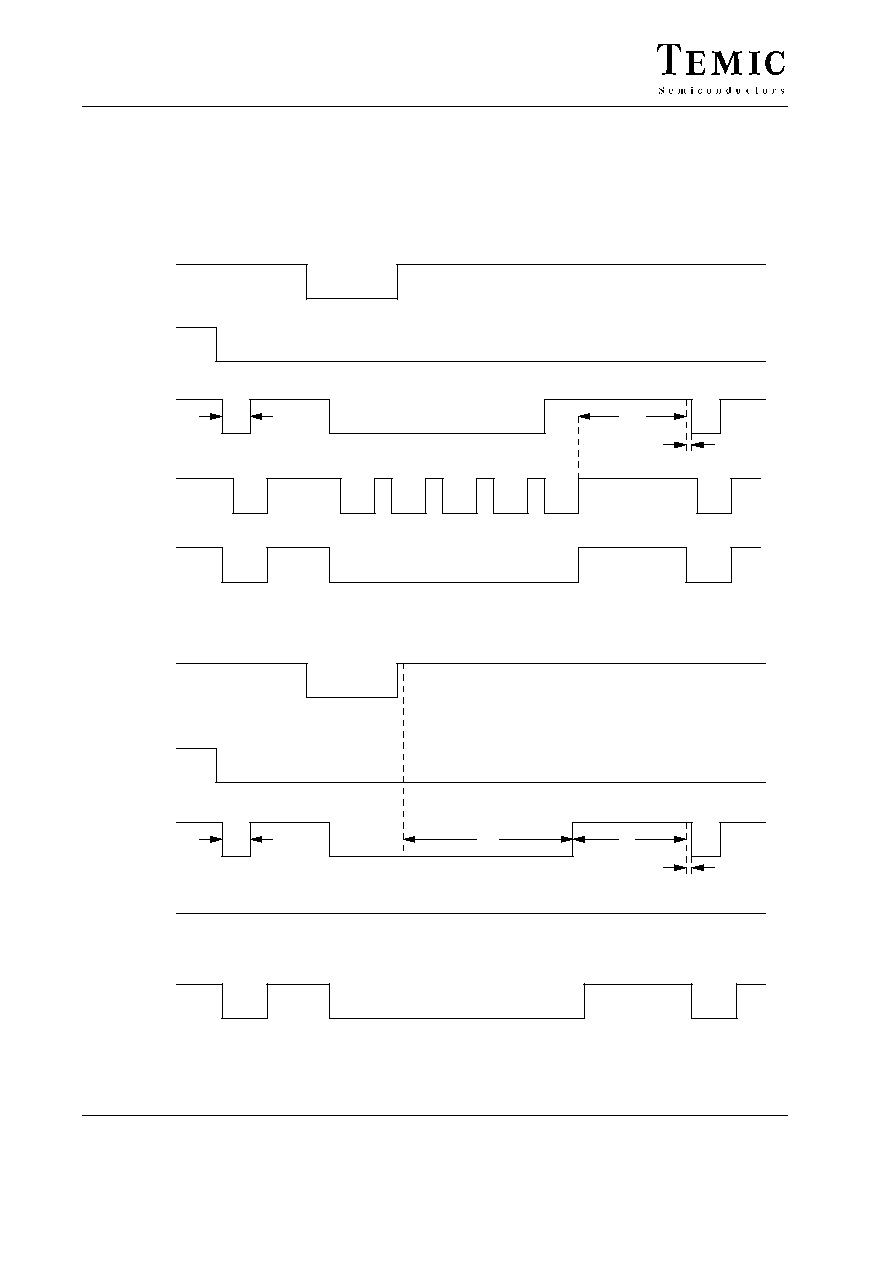

Variable Debouncing Times

Debouncing is basically done by counting oscillator

clocks starting with the occurance of any input signal.

Caused by the asynchronism of input signal and IC-clock,

the debouncing time may vary in a certain range.

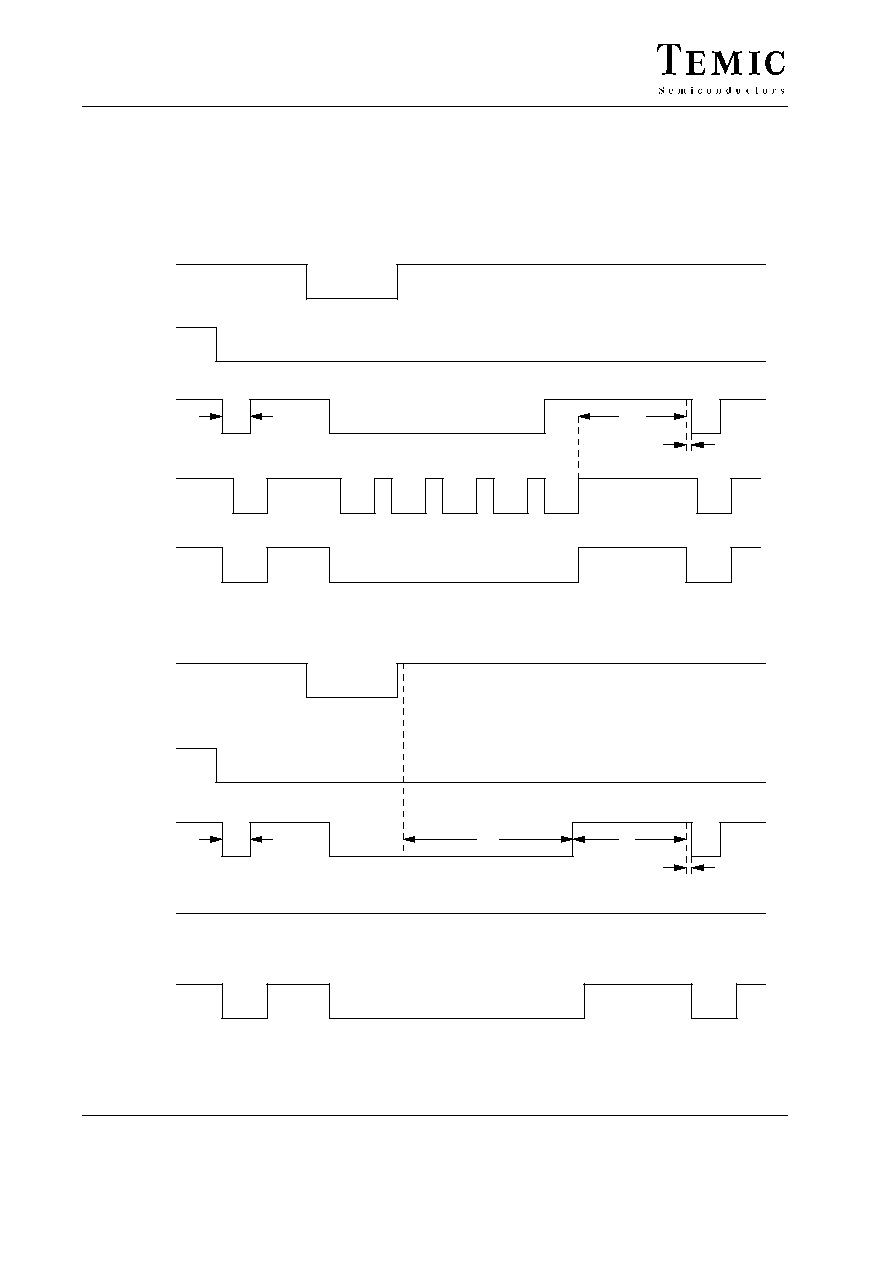

Figure 4 shows the short circuit debouncing as an

example:

During the relay activation, a comparator monitors the

output current at each positive edge of the clock to load

a 3-stage shift register in the case of a detected short cir-

cuit condition i.e., I > 500 mA. With the third edge, the

output stage is disabled. Dependent on the short circuit

occurence the delay time may range from 2 to 3 clock

cycles.

The timing can be adjusted by variation of the external

frequency-determining components ( R/C ).

The potentiometer at Pin 4 determines the interval pause,

which can be varied by adjusting the upper charging

threshold of the oscillator. For all other time periods, an

internal voltage divider determines the upper charging

threshold of the oscillator (see figure 2).

Timing

Fixed:

Relay activation time

t

5

=

160

1/f

0

Dry wiping

t

2

= 896

1/f

0

or 3 cycles

Interval pause

t

6

= 872

1/f

0

Switch-on delay INT

t

4D

= 8

1/f

0

Variable:

Debouncing time INT

t

4

=

24 to 32

1/f

0

Debouncing time WASH

1. pre-wash delay

t

1

=

112 to 128

1/f

0

2. reverse debouncing

t

1.R

=

16 to 32

1/f

0

Debouncing time PARK

t

8

=

6 to 8

1/f

0

Debouncing time SC

t

7

=

2 to 3

1/f

0

U842B

TELEFUNKEN Semiconductors

Rev. A2, 03-Feb-97

4 (12)

Wipe/ Wash Operation

3

2

1

7

t

SC

CL

ON

OFF

OUT

IC>500mA

0

……………

……………

13301

Figure 4. The debouncing of the short circuit detection

Relay Output

The relay output is an open collector Darlington transistor

with an integrated 28-V Z-diode for limitation of the

inductive cut-out pulse of the relay coil. The maximum

static collector current must not exceed 300 mA and the

saturation voltage is typically 1.2 V for a current of

200 mA.

The collector current is permanently measured by an inte-

grated shunt, and in the case of a short circuit

(I

C

> 500 mA) to V

bat

, the relay output is stored disabled.

The short circuit buffer is reset by opening the INT and

WASH switches. As long as the short condition exists a

further activation of these switches will disable the output

stage again. Otherwise the normal wipe operation is per-

formed.

In order to avoid short-term disabling caused by current

pulses of transients, a 10 ms debounce period (t

7

) is pro-

vided (see figure 4).

During a load-dump pulse, the output transistor is

switched to conductive condition to prevent destruction.

The short circuit detection is suppressed during the load-

dump.

Interference Voltages and Load-dump

The IC supply is protected by R

1

, C

1

and an integrated

21-V Z-diode. The inputs are protected by a series

resistor, integrated 21-V Z-diode and RF capacitor.

The RC-configuration stabilizes the supply of the circuit

during negative interference voltages to avoid power-on

reset ( POR ).

The relay output is protected against short interference

peaks by an integrated 28-V Z-diode. During load-dump,

the relay output is switched to conductive condition if the

battery voltage exceeds approximately 30 V. The output

transistor is dimensioned so that it can absorb the current

produced by the load-dump pulse.

Power-on Reset

When the operating voltage is switched on, an internal

power-on reset pulse ( POR ) is generated which sets the

logic of the circuits to defined initial condition. The relay

output is disabled, the short circuit buffer is reset.

Functional Description

Interval Function

The circuit is brought to its interval mode with the input

switch INT operated for more than 625 ms

( t > t

4

+ t

4D

+t

5

).

This time includes:

≠ 100 ms debounce time t

4

≠ 25 ms INT switch-on delay t

4D

≠ 500 ms relay activation time t

5

If the INT input is toggled for 125 ms < t < 625 ms, the

relay activation time t

5

lapses anyway and the wiper

performs one turn. To enable correct interval functioning,

the INT input has to be activated afterwards as described.

The beginning of the interval pause depends on the

application with or without wiper motor park switch ( see

figures 5, 6, 7 and 8 ).

U842B

TELEFUNKEN Semiconductors

Rev. A2, 03-Feb-97

5 (12)

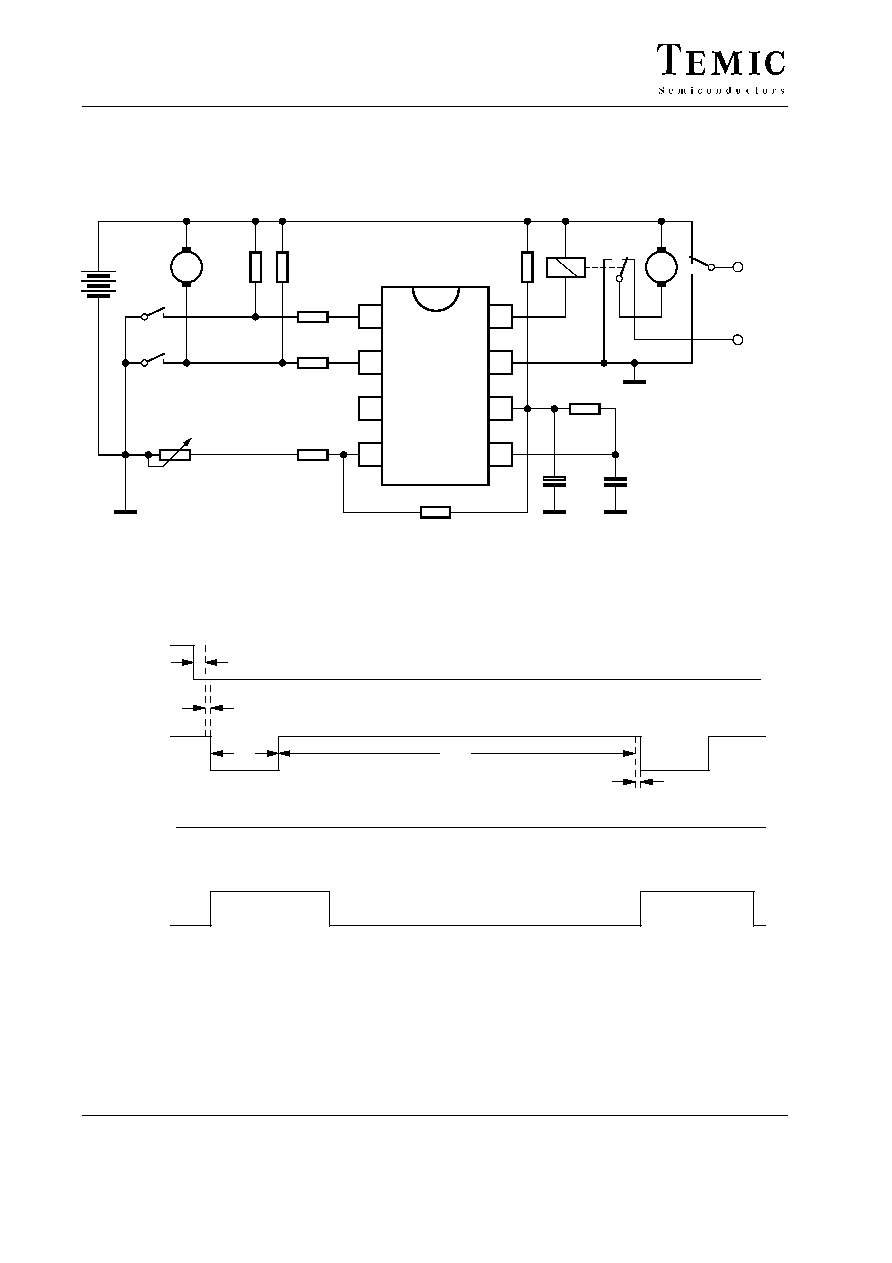

Interval Function with Park-Switch Feedback

During the relay activation time the wiper motor leaves

its park position and the park switch changes its potential

from V

Batt

to GND. After the relay is switched off the

wiper motor is supplied via the park switch until the park

position is reached again. The park switch changes its

potential from GND back to V

Batt

. With the park switch

connected to the park input (Pin 3) the interval pause t

6

starts after the 25 ms debounce time (t

7

) is over (see

figures 5 and 6).

13289

8

7

6

5

1

2

3

4

U842B

R

4

10 k

R

5

47 k

R

6

10 k

R

11

360

1.5 k

R

3

M

Wash

pump

1.5 k

R

2

INT

WASH

VR

1

1 k

SETINT

C

1

47

µ

F

180

R

1

R

7

1.5 k

R

9

220 k

C

2

100 nF

M

Wiper motor

Park

Run

Figure 5. Application circuit with park switch feedback

t

4D

V

0V

t

5

t

4

t

INT

8

OUT

PARK

MOTOR

ON

OFF

6

t

4D

t

Batt

V

0V

Batt

V

0V

Batt

13302

Figure 6. Intermittent circuit function with park position feedback

U842B

TELEFUNKEN Semiconductors

Rev. A2, 03-Feb-97

6 (12)

Interval Function without Park-Switch Feedback

If the park input of the circuit is not connected with the

park switch of the wiper motor (see figure 7), the interval

pause starts directly after the turn-on time of the relay is

over (see figure 8).

13290

8

7

6

5

1

2

3

4

U842B

R

4

10 k

R

5

47 k

R

11

1.5 k

R

3

M

Wash

pump

1.5 k

R

2

INT

WASH

VR

1

1 k

SETINT

C

1

47

µ

F

180

R

1

R

7

20 k

R

9

220 k

C

2

100 nF

M

Wiper motor

Park

Run

5.1 k

Figure 7. Application circuit without park position feedback

t

4D

6

t

OFF

ON

MOTOR

PARK

OUT

INT

t

4

t

5

0V

V

4D

t

Batt

0V

V

Batt

0V

V

Batt

13303

Figure 8. Intermittent circuit function without park position feedback

U842B

TELEFUNKEN Semiconductors

Rev. A2, 03-Feb-97

7 (12)

WASH

V

OFF

ON

MOTOR

OUT

PARK

<t

1

t

1R

wipe1

wipe2

wipe3

0V

t

1

t

7

Batt

V

0V

Batt

V

0V

Batt

13304

Figure 9. Wash operation with park switch signal

After operating the WASH switch, the relay is activated

after the debounce time, t

1

. As long as the switch is

pushed, water is sprayed on the windscreen by the wash

pump. When it is released, the dry wiping starts after 100

ms reverse debouncing (t

1R

).

Wipe/ Wash Mode with Park Position Feedback

If the park input of the circuit is connected to the park

switch, the dry wiping lasts three full wipe cycles (see

figure 9). During the third cycle, the wiper motor is sup-

plied via the park switch because the relay driver is

switched off after the second cycle.

Wipe/ Wash Mode without Park Position Feedback

If U842B is used without the wiper motor's park switch,

Pin 3 stays at high potential via its integrated pull-up

resistor. Therefore, the driver stage switches off after the

fixed dry wiping time t

2

.

t

1

WASH

V

OFF

ON

0V

MOTOR

OUT

PARK

<t

1

t

2

t

1R

Batt

V

0V

Batt

V

0V

Batt

13305

Figure 10. Wash operation without park signal report

U842B

TELEFUNKEN Semiconductors

Rev. A2, 03-Feb-97

8 (12)

Wipe/ Wash Mode Priority

The wipe/wash mode has priority over the interval mode

≠ therefore the interval function is interrupted as soon as

the WASH switch is operated longer than the debounce

time t

1

. With or without park switch feedback, after relay

activation time is over (no park switch feedback), or after

the third wipe (park switch feedback), the interval mode

is continued with an interval pause t

6

(see figures 11

and 12).

6

t

0V

5

PARK

OUT

ON

OFF

WASH

INT

V

t

MOTOR

t

4D

Batt

0V

V

Batt

0V

V

Batt

0V

V

Batt

13306

Figure 11. Wipe/ wash priority with park position feedback

4D

t

MOTOR

t

V

INT

WASH

OFF

ON

OUT

PARK

5

t

2

0V

t

6

Batt

V

0V

Batt

V

0V

Batt

V

0V

Batt

13307

Figure 12. Wash/ wipe priority without park position feedback

U842B

TELEFUNKEN Semiconductors

Rev. A2, 03-Feb-97

9 (12)

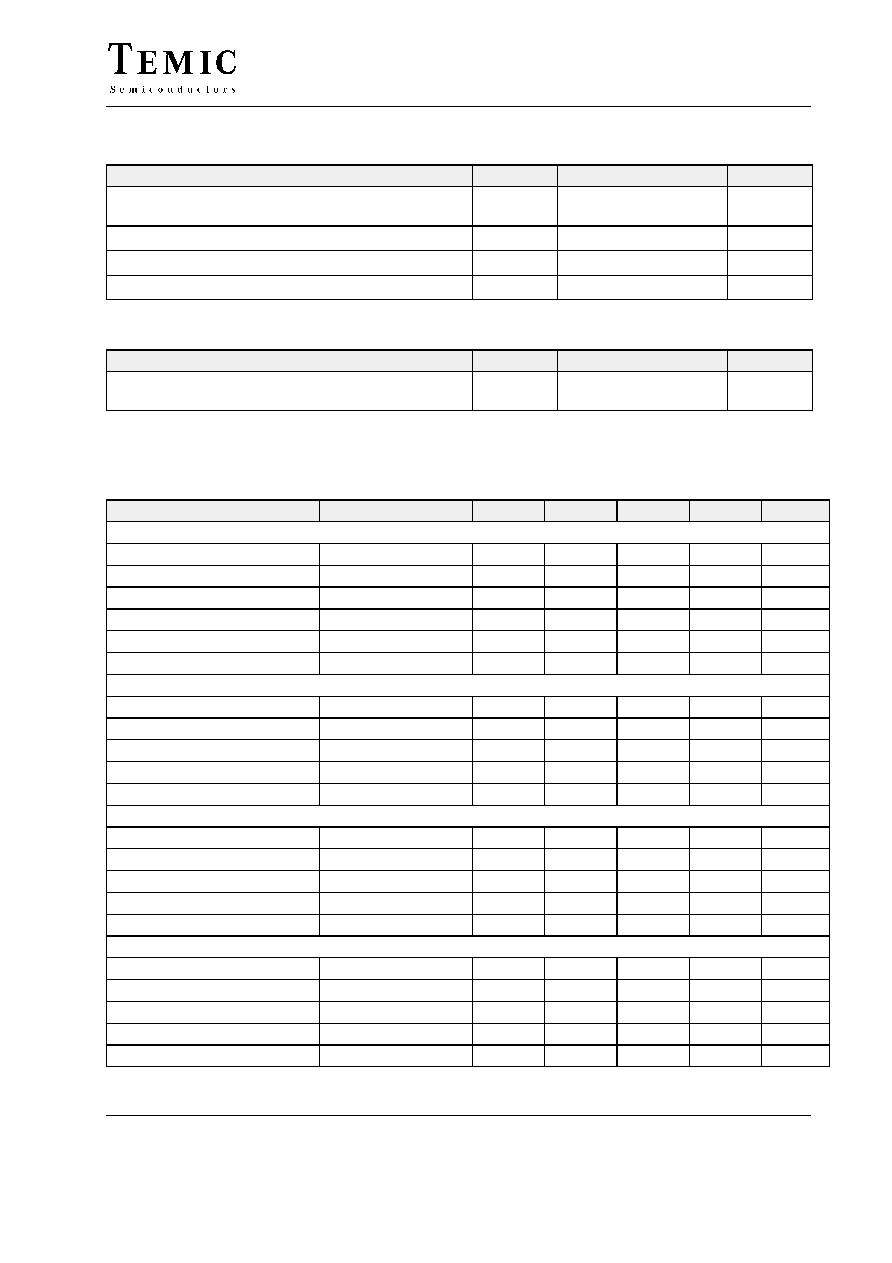

Absolute Maximum Ratings

Parameters

Symbol

Value

Unit

¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡

Supply voltage

t = 60 s

t = 600 s

¡¡¡¡¡

¡¡¡¡¡

V

Batt

V

Batt

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

24

18

¡¡¡¡¡

¡¡¡¡¡

V

V

¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡

Ambient temperature range

¡¡¡¡¡

¡¡¡¡¡

T

amb

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

≠30 to +100

¡¡¡¡¡

¡¡¡¡¡

∞

C

¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡

¡

¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡

¡

Storage temperature range

¡¡¡¡¡

¡

¡¡¡

¡

T

stg

¡¡¡¡¡¡¡¡

¡

¡¡¡¡¡¡

¡

≠40 to +100

¡¡¡¡¡

¡

¡¡¡

¡

∞

C

¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡

¡

¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡

¡

¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡

Maximum junction temperature

¡¡¡¡¡

¡

¡¡¡

¡

¡¡¡¡¡

T

j

¡¡¡¡¡¡¡¡

¡

¡¡¡¡¡¡

¡

¡¡¡¡¡¡¡¡

150

¡¡¡¡¡

¡

¡¡¡

¡

¡¡¡¡¡

∞

C

Thermal Resistance

Parameters

Symbol

Maximum

Unit

¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡

Thermal resistance

DIP8

SO8

¡¡¡¡¡

¡¡¡¡¡

R

thja

R

thja

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

110

160

¡¡¡¡¡

¡¡¡¡¡

K/W

K/W

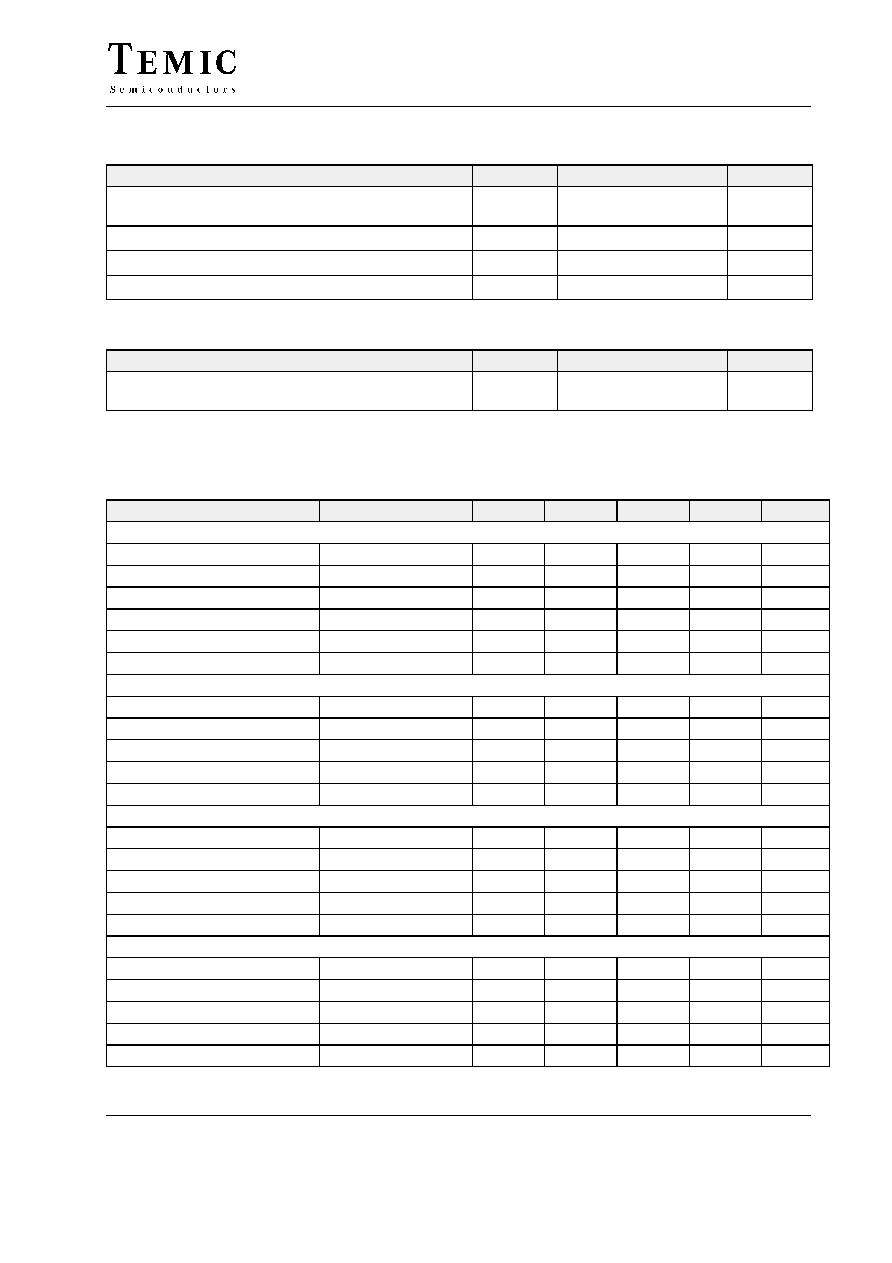

Electrical Characteristics

V

Batt

= 13.5 V, T

amb

= 25

∞

C, reference point ground (Pin 7), circuit with recommended external circuitry

(see figure 2)

Parameters

Test Conditions / Pin

Symbol

Min

Typ

Max

Unit

¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡

Supply

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Supply-voltage range

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

V

S

¡¡¡¡

¡¡¡¡

9

¡¡¡¡

¡¡¡¡

¡¡¡¡¡

¡¡¡¡¡

16

¡¡¡

¡¡¡

V

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Supply currrent

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

I

6

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡¡

¡¡¡¡¡

3

¡¡¡

¡¡¡

mA

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Undervoltage threshold POR

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

V

6

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

3.5

¡¡¡¡¡

¡¡¡¡¡

¡¡¡

¡¡¡

V

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Series resistance

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

R

1

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

180

¡¡¡¡¡

¡¡¡¡¡

¡¡¡

¡¡¡

W

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Filter capacitance

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

C

1

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

47

¡¡¡¡¡

¡¡¡¡¡

¡¡¡

¡¡¡

mF

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Internal Z-diode

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

V

6

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

21

¡¡¡¡¡

¡¡¡¡¡

¡¡¡

¡¡¡

V

INT input

Pin 1

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Protective diode

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

V

1

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

21

¡¡¡¡¡

¡¡¡¡¡

¡¡¡

¡¡¡

V

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Internal capacitance

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

C

1

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

25

¡¡¡¡¡

¡¡¡¡¡

¡¡¡

¡¡¡

pF

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Threshold

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

V

1

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

0.5 V

6

¡¡¡¡¡

¡¡¡¡¡

¡¡¡

¡¡¡

W

¡¡¡¡¡¡¡¡¡¡

¡

¡¡¡¡¡¡¡¡

¡

Pull-up resistance

¡¡¡¡¡¡¡¡

¡

¡¡¡¡¡¡

¡

¡¡¡¡

¡

¡¡

¡

R

1

¡¡¡¡

¡

¡¡

¡

¡¡¡¡

¡

¡¡

¡

20

¡¡¡¡¡

¡

¡¡¡

¡

¡¡¡

¡¡¡

k

W

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

External series resistance

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

R

S

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

10

¡¡¡¡¡

¡¡¡¡¡

¡¡¡

¡¡¡

k

W

PARK input

Pin 3

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Protective diode

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

V

3

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

21

¡¡¡¡¡

¡¡¡¡¡

¡¡¡

¡¡¡

V

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Internal capacitance

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

C

3

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

25

¡¡¡¡¡

¡¡¡¡¡

¡¡¡

¡¡¡

pF

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Threshold

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

V

3

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

0.5 V

6

¡¡¡¡¡

¡¡¡¡¡

¡¡¡

¡¡¡

W

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Pull-up resistance

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

R

3

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

20

¡¡¡¡¡

¡¡¡¡¡

¡¡¡

¡¡¡

k

W

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

External series resistance

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

R

S

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

10

¡¡¡¡¡

¡¡¡¡¡

¡¡¡

¡¡¡

k

W

WASH input

Pin 2

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Protective diode

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

V

2

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

21

¡¡¡¡¡

¡¡¡¡¡

¡¡¡

¡¡¡

V

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Internal capacitance

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

C

2

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

25

¡¡¡¡¡

¡¡¡¡¡

¡¡¡

¡¡¡

pF

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Threshold

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

V

2

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

0.5 V

6

¡¡¡¡¡

¡¡¡¡¡

¡¡¡

¡¡¡

W

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Pull-up resistance

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

R

2

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

100

¡¡¡¡¡

¡¡¡¡¡

¡¡¡

¡¡¡

k

W

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

External series resistance

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

R

S

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

47

¡¡¡¡¡

¡¡¡¡¡

¡¡¡

¡¡¡

k

W

U842B

TELEFUNKEN Semiconductors

Rev. A2, 03-Feb-97

10 (12)

Parameters

Test Conditions / Pin

Symbol

Min

Typ

Max

Unit

PAUS input

Pin 4

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Protective diode

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

V

4

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

21

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

V

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Internal capacitance

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

C

4

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

25

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

pF

Relay output

Pin 8

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Saturation voltage 100 mA

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

V

8

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

1.0

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

V

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Saturation voltage 200 mA

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

V

8

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

1.2

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

V

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Relay coil resistance

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

R

Rel

¡¡¡¡

¡¡¡¡

60

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

W

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Output current

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

I

8

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

300

¡¡¡¡

¡¡¡¡

mA

¡¡¡¡¡¡¡¡¡¡

¡

¡¡¡¡¡¡¡¡

¡

¡¡¡¡¡¡¡¡¡¡

Normal operation

¡¡¡¡¡¡¡¡

¡

¡¡¡¡¡¡

¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡

¡¡

¡

¡¡¡¡

¡¡¡¡

¡

¡¡

¡

¡¡¡¡

¡¡¡¡

¡

¡¡

¡

¡¡¡¡

¡¡¡¡

¡

¡¡¡

¡¡¡¡

¡¡¡¡

¡

¡¡

¡

¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

¡

¡¡¡¡¡¡¡¡

¡

Output pulse current

¡¡¡¡¡¡¡¡

¡

¡¡¡¡¡¡

¡

¡¡¡¡

¡

¡¡

¡

I

8

¡¡¡¡

¡

¡¡

¡

¡¡¡¡

¡

¡¡

¡

¡¡¡¡

¡

¡¡¡

1.5

¡¡¡¡

¡

¡¡

¡

A

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Load-dump

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Internal Z-diode

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

V

8

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

28

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

V

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Short circuit threshold

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

I

8

¡¡¡¡

¡¡¡¡

500

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

mA

Oscillator input

Pin 5

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Oscillator capacitor

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

Pin 5

¡¡¡¡

¡¡¡¡

C

2

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

100

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

nF

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Oscillator resistor

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

Pins 5 and 6

¡¡¡¡

¡¡¡¡

R

8

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

220

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

k

W

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Basic frequency

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

f

0

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

320

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

Hz

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Lower switching point

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

V

5

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

0.07 V

6

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Upper switching point

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

External 1 k

W pot.

¡¡¡¡

¡¡¡¡

V

5

¡¡¡¡

¡¡¡¡

0.2 V

6

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

0.5 V

6

¡¡¡¡

¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Internal discharge resistance

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

R

5

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

2

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

k

W

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Protective diode

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

V

F

= forward voltage

¡¡¡¡

¡¡¡¡

V

5

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

V

S

+ V

F

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

V

Times

External circuitry ≠ see oscillator input (figure 3)

¡¡¡¡¡¡¡¡¡¡

¡

¡¡¡¡¡¡¡¡

¡

¡

¡¡¡¡¡¡¡¡

¡

¡

¡¡¡¡¡¡¡¡

¡

¡

¡¡¡¡¡¡¡¡

¡

¡

¡¡¡¡¡¡¡¡

¡

¡¡¡¡¡¡¡¡¡¡

Debouncing times:

INT input

WASH input

Pre-wash delay

Reverse delay

Park

Short circuit

¡¡¡¡¡¡¡¡

¡

¡¡¡¡¡¡

¡

¡

¡¡¡¡¡¡

¡

¡

¡¡¡¡¡¡

¡

¡

¡¡¡¡¡¡

¡

¡

¡¡¡¡¡¡

¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡

¡¡

¡

¡

¡¡

¡

¡

¡¡

¡

¡

¡¡

¡

¡

¡¡

¡

¡¡¡¡

t

4

t

1

t

1,R

t

8

t

7

¡¡¡¡

¡

¡¡

¡

¡

¡¡

¡

¡

¡¡

¡

¡

¡¡

¡

¡

¡¡

¡

¡¡¡¡

50

260

50

14

5

¡¡¡¡

¡

¡¡

¡

¡

¡¡

¡

¡

¡¡

¡

¡

¡¡

¡

¡

¡¡

¡

¡¡¡¡

¡¡¡¡

¡

¡¡¡

¡

¡¡¡

¡

¡¡¡

¡

¡¡¡

¡

¡¡¡

¡¡¡¡

125

540

125

37

12

¡¡¡¡

¡

¡¡

¡

¡

¡¡

¡

¡

¡¡

¡

¡

¡¡

¡

¡

¡¡

¡

¡¡¡¡

ms

ms

ms

ms

ms

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Switch-on delay (interval mode)

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

t

4D

¡¡¡¡

¡¡¡¡

18

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

31

¡¡¡¡

¡¡¡¡

ms

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Relay activation time

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

t

5

¡¡¡¡

¡¡¡¡

400

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

625

¡¡¡¡

¡¡¡¡

ms

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Interval pause

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

t

6

¡¡¡¡

¡¡¡¡

2.25

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

13.75

¡¡¡¡

¡¡¡¡

s

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Dry wiping

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

Without park switch feedback

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

t

2

¡¡¡¡

¡¡¡¡

2.1

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

3.5

¡¡¡¡

¡¡¡¡

s

¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡

With park switch feedback

¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

3

¡¡¡¡

¡¡¡¡

¡¡¡¡

¡¡¡¡

wipes

U842B

TELEFUNKEN Semiconductors

Rev. A2, 03-Feb-97

11 (12)

Package Information

13021

9.8

9.5

Package DIP8

Dimensions in mm

1.64

1.44

4.8 max

0.5 min

3.3

0.58

0.48

7.62

2.54

6.4 max

0.36 max

9.8

8.2

7.77

7.47

8

5

1

4

technical drawings

according to DIN

specifications

13034

technical drawings

according to DIN

specifications

Package SO8

Dimensions in mm

5.00

4.85

0.4

1.27

3.81

1.4

0.25

0.10

5.2

4.8

3.7

3.8

6.15

5.85

0.2

8

5

8

5

U842B

TELEFUNKEN Semiconductors

Rev. A2, 03-Feb-97

12 (12)

Ozone Depleting Substances Policy Statement

It is the policy of TEMIC TELEFUNKEN microelectronic GmbH to

1. Meet all present and future national and international statutory requirements.

2. Regularly and continuously improve the performance of our products, processes, distribution and operating systems

with respect to their impact on the health and safety of our employees and the public, as well as their impact on

the environment.

It is particular concern to control or eliminate releases of those substances into the atmosphere which are known as

ozone depleting substances ( ODSs ).

The Montreal Protocol ( 1987 ) and its London Amendments ( 1990 ) intend to severely restrict the use of ODSs and

forbid their use within the next ten years. Various national and international initiatives are pressing for an earlier ban

on these substances.

TEMIC TELEFUNKEN microelectronic GmbH semiconductor division has been able to use its policy of

continuous improvements to eliminate the use of ODSs listed in the following documents.

1. Annex A, B and list of transitional substances of the Montreal Protocol and the London Amendments respectively

2 . Class I and II ozone depleting substances in the Clean Air Act Amendments of 1990 by the Environmental

Protection Agency ( EPA ) in the USA

3. Council Decision 88/540/EEC and 91/690/EEC Annex A, B and C ( transitional substances ) respectively.

TEMIC can certify that our semiconductors are not manufactured with ozone depleting substances and do not contain

such substances.

We reserve the right to make changes to improve technical design and may do so without further notice.

Parameters can vary in different applications. All operating parameters must be validated for each customer

application by the customer. Should the buyer use TEMIC products for any unintended or unauthorized

application, the buyer shall indemnify TEMIC against all claims, costs, damages, and expenses, arising out of,

directly or indirectly, any claim of personal damage, injury or death associated with such unintended or

unauthorized use.

TEMIC TELEFUNKEN microelectronic GmbH, P.O.B. 3535, D-74025 Heilbronn, Germany

Telephone: 49 ( 0 ) 7131 67 2831, Fax number: 49 ( 0 ) 7131 67 2423