| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: THAT2180A | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

THAT Corporation; 45 Sumner Street; Milford, Massachusetts 01757-1656; USA

Tel: +1 508 478 9200; Fax: +1 508 478 0990; Web: www.thatcorp.com

BIAS CURRENT

COMPENSATION

Vbe

MULTI-

PLIER

Output

Sym

Iset

V-

Vcc

Ec+

Ec-

Iadj

Input

Gnd

7

2

3

8

4

5

1

6

2k

25

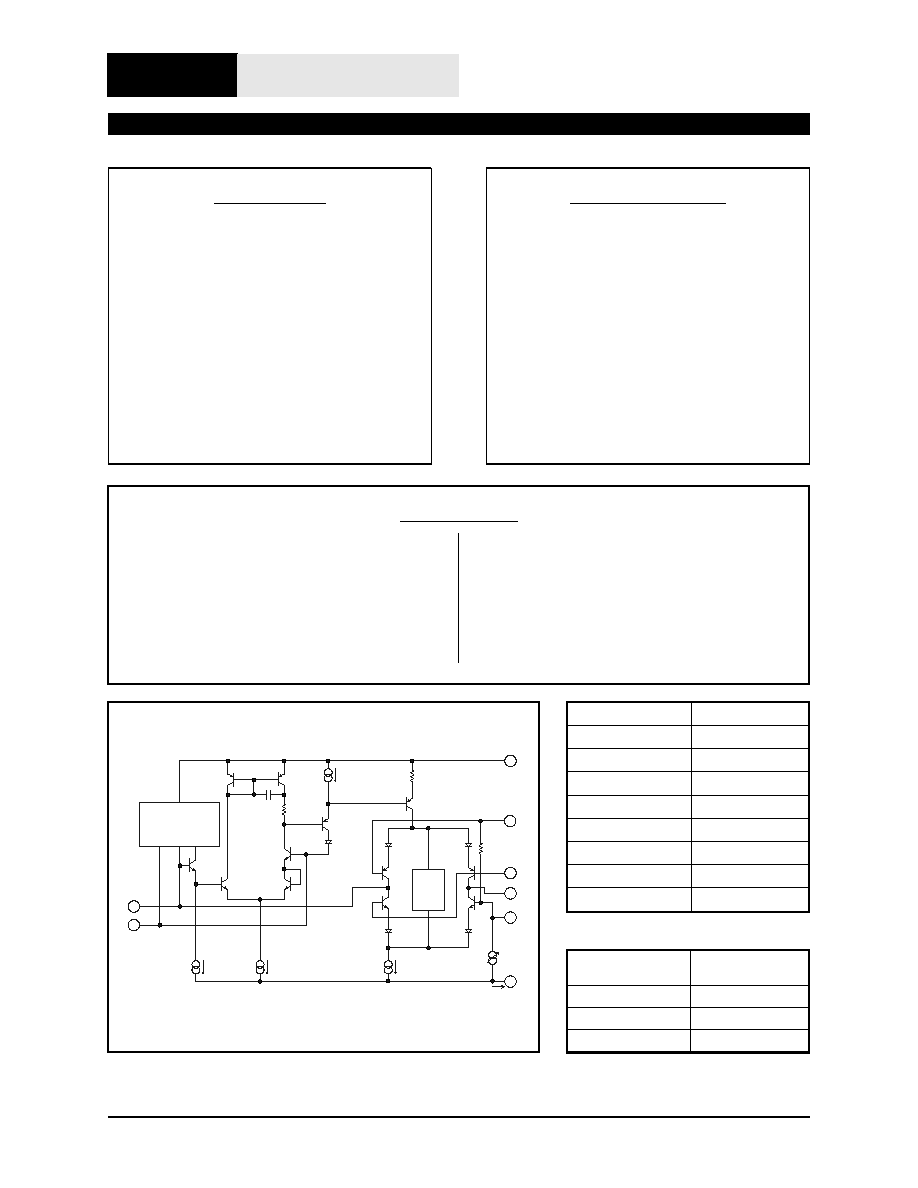

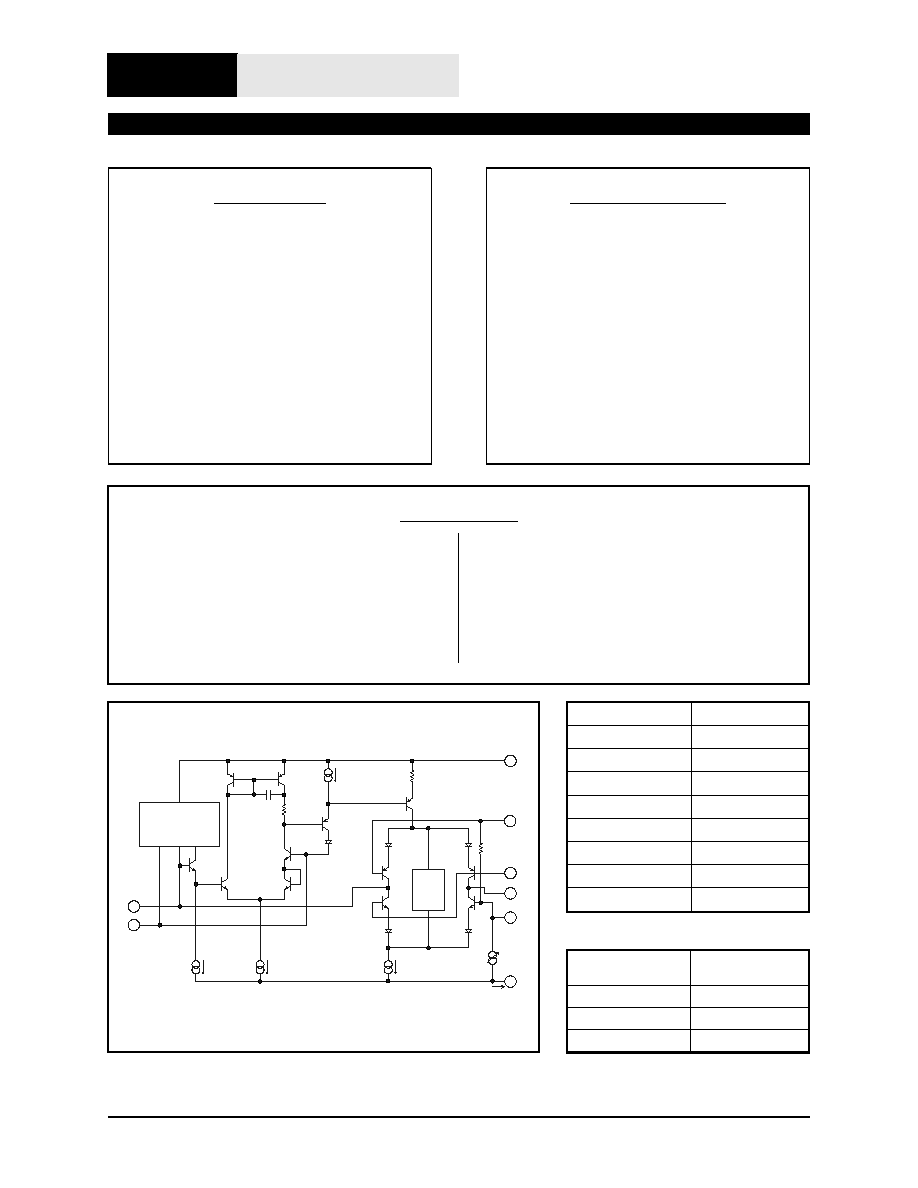

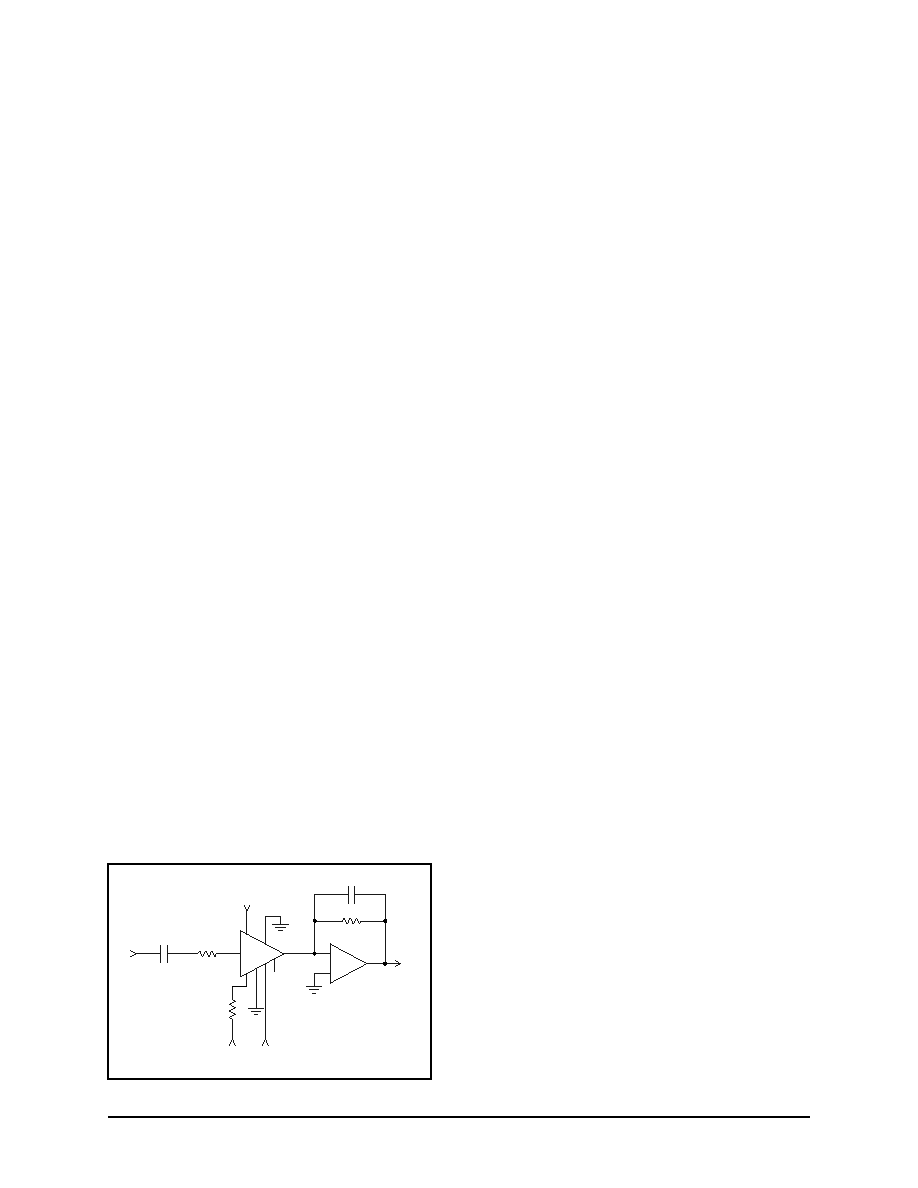

Figure 1. 2180 Series Equivalent Circuit Diagram

Pin Name

SIP Pin

Input

1

Ec+

2

Ec≠

3

Sym

4

V≠

5

Gnd

6

V+

7

Output

8

Table 1. 2180 Series Pin Assignments

FEATURES

∑

Wide Dynamic Range: >120 dB

∑

Wide Gain Range: >130 dB

∑

Exponential (dB) Gain Control

∑

Low Distortion: < 0.01 % (2180A)

∑

Wide Gain-Bandwidth: 20 MHz

∑

Dual Gain-Control Ports (pos/neg)

∑

Pin-Compatible with 2150-Series

APPLICATIONS

∑

Faders

∑

Panners

∑

Compressors

∑

Expanders

∑

Equalizers

∑

Filters

∑

Oscillators

∑

Automation System

Description

THAT 2180 Series integrated-circuit voltage con-

trolled amplifiers (VCAs) are very high-performance

current-in/current-out

devices

with

two

oppos-

ing-polarity, voltage-sensitive control ports. They offer

wide-range exponential control of gain and attenuation

with low signal distortion. The parts are trimmed at

wafer stage for low THD and control-voltage

feedthrough without further adjustment.

The VCA design takes advantage of a fully comple-

mentary dielectric isolation process which offers

closely matched NPN/PNP pairs, to deliver discrete

performance at IC prices. The parts are available in

three grades, selected for factory trimmed distortion,

alowing the user to optimize cost vs. performance. The

2180 Series is available in an 8-pin single-in-line (SIP)

package.

Max THD @1 V,

1 kHz, 0 dB

Plastic

SIP

0.01%

2180LA

0.02%

2180LB

0.05%

2180LC

Table 2. Ordering Information

T H A T

C o r p o r a t i o n

THAT 2180A, 2180B, 2180C

Pre-Trimmed IC

Voltage Controlled Amplifiers

THAT Corporation; 45 Sumner Street; Milford, Massachusetts 01757-1656; USA

Tel: +1 508 478 9200; Fax: +1 508 478 0990; Web: www.thatcorp.com

Page 2

THAT2180 Series IC VCAs

SPECIFICATIONS

1

Absolute-Maximum Ratings (T

A

= 25∞C)

Positive Supply Voltage (V

CC

)

+20 V

Negative Supply Voltage (V

EE

)

-20 V

Supply Current (I

CC

)

10 mA

Max DE

C

E

C+

- (E

C-

)

± 1V

Power Dissipation (P

D

) (T

A

= 75∞C)

330 mW

Operating Temperature Range (T

OP

)

0 to +70∞C

Storage Temperature Range (T

ST

)

-40 to +125∞C

Recommended Operating Conditions

2180A

2180B

2180C

Parameter

Symbol

Conditions

Min Typ

Max

Min Typ

Max

Min Typ

Max Units

Positive Supply Voltage V

CC

+4 +15 +18

+4 +15 +18

+4 +15 +18

V

Negative Supply Voltage V

EE

-4

-15 -18

-4

-15 -18

-4

-15 -18

V

Bias Current

I

SET

V

CC

- V

EE

= 30 V

1

2.4

5

1

2.4

5

1

2.4

5

mA

Signal Current

I

IN

+I

OUT

I

SET

= 2.4mA

-- 0.35 1.5

-- 0.35 1.5

-- 0.35 1.5

mA

rms

Electrical Characteristics≤

2180A

2180B

2180C

Parameter

Symbol

Conditions

Min Typ

Max

Min Typ

Max

Min Typ

Max Units

Supply Current

I

CC

No Signal

--

2.4

4

--

2.4

4

--

2.4

4

mA

Equiv. Input Bias Current I

B

No Signal

--

2

10

--

2

12

--

2

15

nA

Input Offset Voltage

V

OFF(IN)

No Signal

--

±5

--

--

±5

--

--

±5

--

mV

Output Offset Voltage V

OFF(OUT)

R

out

= 20 kW

0 dB gain

--

0.5

1

--

1

2

--

1.5

3

mV

+15 dB gain

--

1

3

--

1.5

4

--

3

10

mV

+30 dB gain

--

3

12

--

5

15

--

9

30

mV

Gain Cell Idling Current I

IDLE

--

20

--

--

20

--

--

20

--

mA

Gain-Control Constant

T

A

=25∞C (T

CHIP

@35∞C)

-60 dB < gain < +40 dB

E

C+

/Gain (dB)

Pin 2 (Fig. 14)

6.0

6.1

6.2

6.0

6.1

6.2

6.0

6.1

6.2

mV/dB

E

C-

/Gain (dB)

Pin 3

-6.2 -6.1 -6.0

-6.2 -6.1 -6.0

-6.2 -6.1 -6.0 mV/dB

Gain-Control TempCo DE

C

/ DT

CHIP

Ref T

CHIP

= 27∞C

-- +0.33 --

-- +0.33 --

-- +0.33 --

%/∞C

Gain-Control Linearity

-60 to +40 dB gain

--

0.5

2

--

0.5

2

--

0.5

2

%

1 kHz Off Isolation

E

C+

= -360 mV, E

C-

= +360 mV 110 115

--

110 115

110 115

--

dB

Output Noise

e

n(OUT)

20 Hz ~ 20 kHz

R

out

= 20kW

0 dB gain

--

-98 -97

--

-98 -96

--

-98 -95

dBV

+15 dB gain

--

-88 -86

--

-88 -85

--

-88 -84

dBV

Voltage at V-

V

V-

No Signal

-3.1 -2.85 -2.6

-3.1 -2.85 -2.5

-3.1 -2.85 -2.6

V

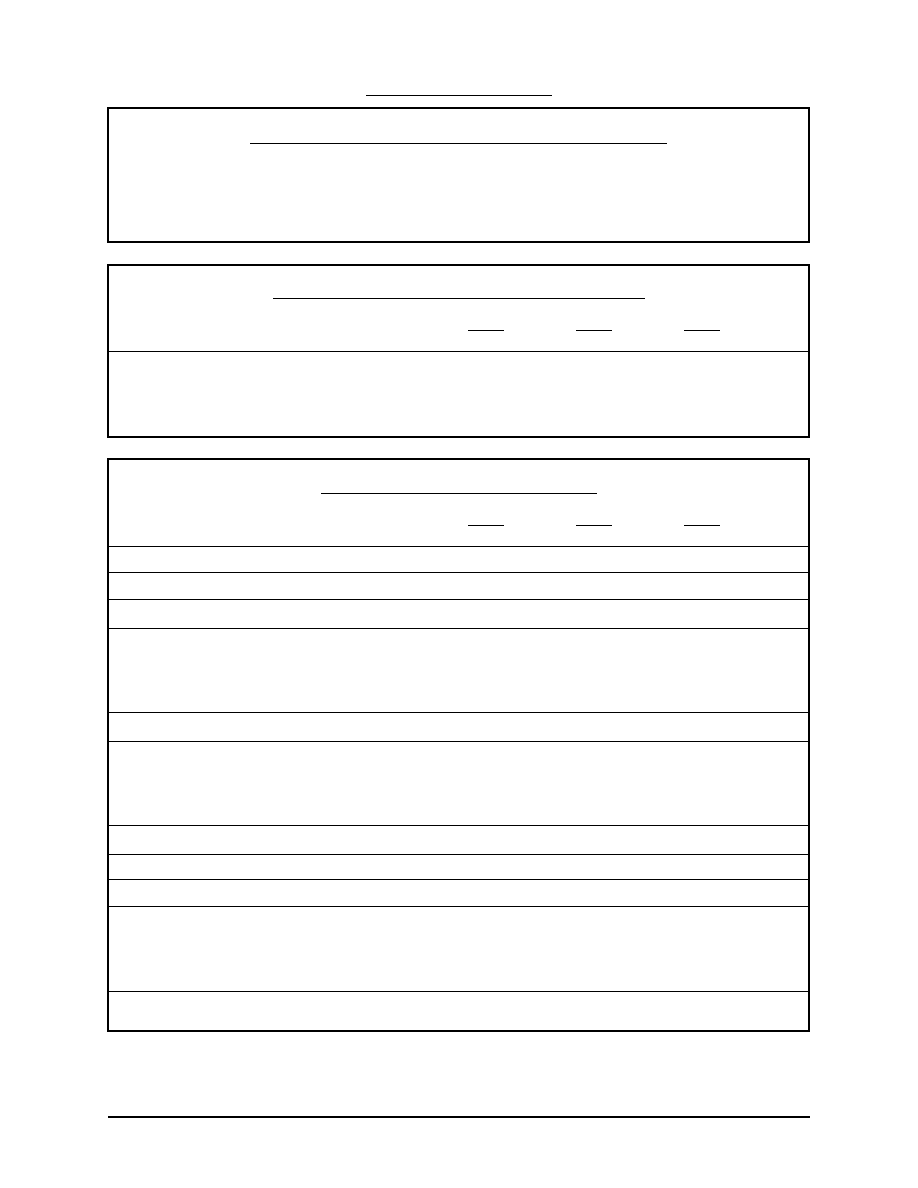

1. All specifications subject to change without notice.

2. Unless otherwise noted, T

A

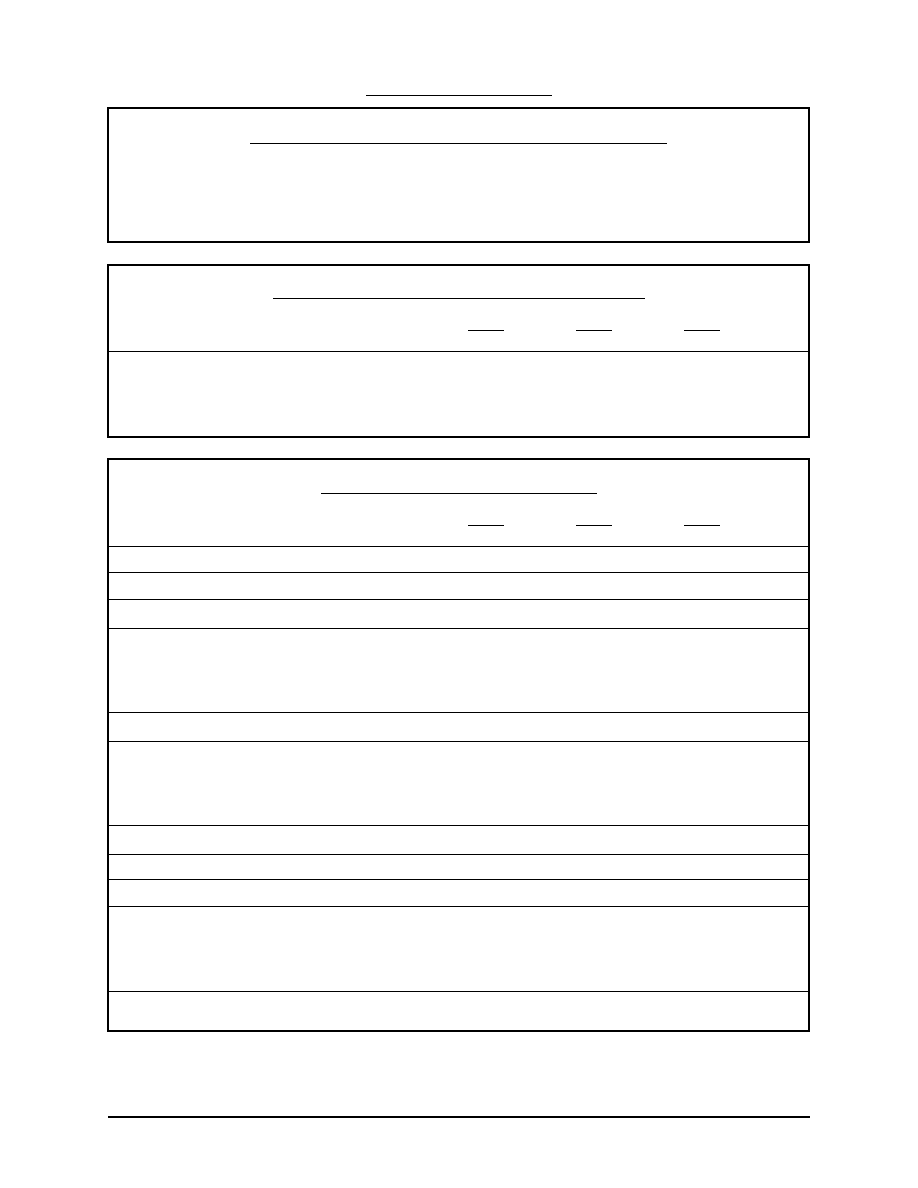

=25∞C, V

CC

= +15V, V

EE

= ≠15V. Test circuit is as shown in Figure 2.

THAT Corporation; 45 Sumner Street; Milford, Massachusetts 01757-1656; USA

Tel: +1 508 478 9200; Fax: +1 508 478 0990; Web: www.thatcorp.com

600029 Rev 01

Page 3

Electrical Characteristics (Cont'd.)

2180A

2180B

2180C

Parameter

Symbol

Conditions

Min Typ

Max

Min Typ

Max

Min Typ

Max Units

Total Harmonic Distortion

THD

1 kHz, No External Trim

V

IN

= 0 dBV, 0 dB gain

-- 0.005 0.010

-- 0.010 0.020

-- 0.030 0.050

%

V

IN

= +10 dBV, -15 dB gain -- 0.020 0.030

-- 0.030 0.040

-- 0.040 0.070

%

V

IN

= -5 dBV, +15 dB gain

-- 0.020 0.030

-- 0.030 0.040

-- 0.040 0.070

%

Slew Rate

R

in

= R

out

= 20 kW

--

12

--

--

12

--

--

12

--

V/ms

Gain at 0 V Control Voltage

E

C-

= 0 mV

-0.1 0.0

+0.1 -0.15 0.0 +0.15 -0.2 0.0

+0.2

dB

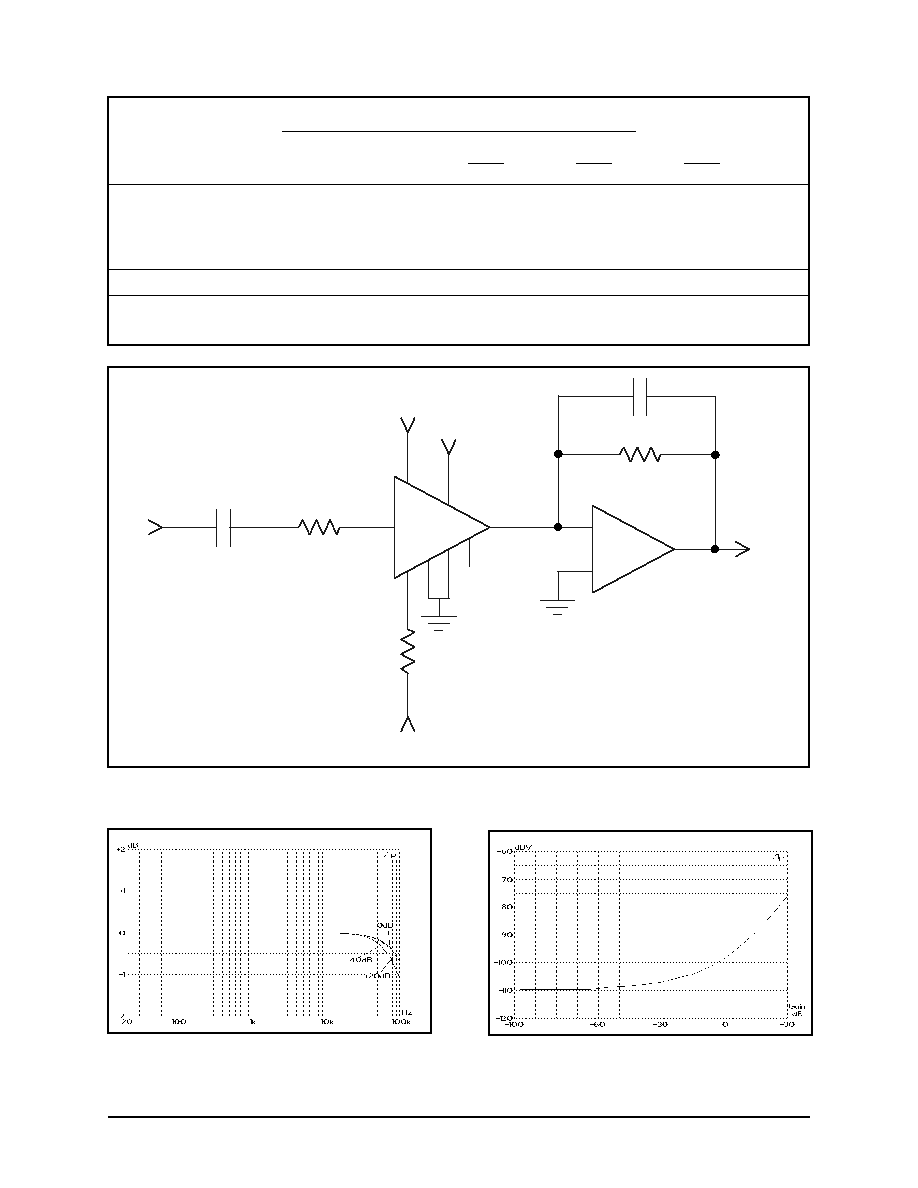

Figure 3. 2180 Series Frequency Response Vs. Gain

Figure 4. 2180 Series Noise (20kHz NBW) Vs. Gain

Vcc

Ec-

IN

10u

20k

5.1k

Vee

OUT

22p

20k

OUT

OP275

7

3

8

4

2

6

5

1

V+

-IN

Ec-

Ec+

SYM

GND

V-

2180

Series

VCA

Power Supplies

Vcc = +15 V

Vee = -15 V

-

+

NC

Figure 2. Typical Application Circuit

THAT Corporation; 45 Sumner Street; Milford, Massachusetts 01757-1656; USA

Tel: +1 508 478 9200; Fax: +1 508 478 0990; Web: www.thatcorp.com

Theory of Operation

3

The THAT 2180 Series VCAs are designed for high

performance in audio-frequency applications requiring

exponential gain control, low distortion, wide dynamic

range and low control-voltage feedthrough. These parts

control gain by converting an input current signal to a

bipolar logged voltage, adding a dc control voltage, and

re-converting the summed voltage back to a current

through a bipolar antilog circuit.

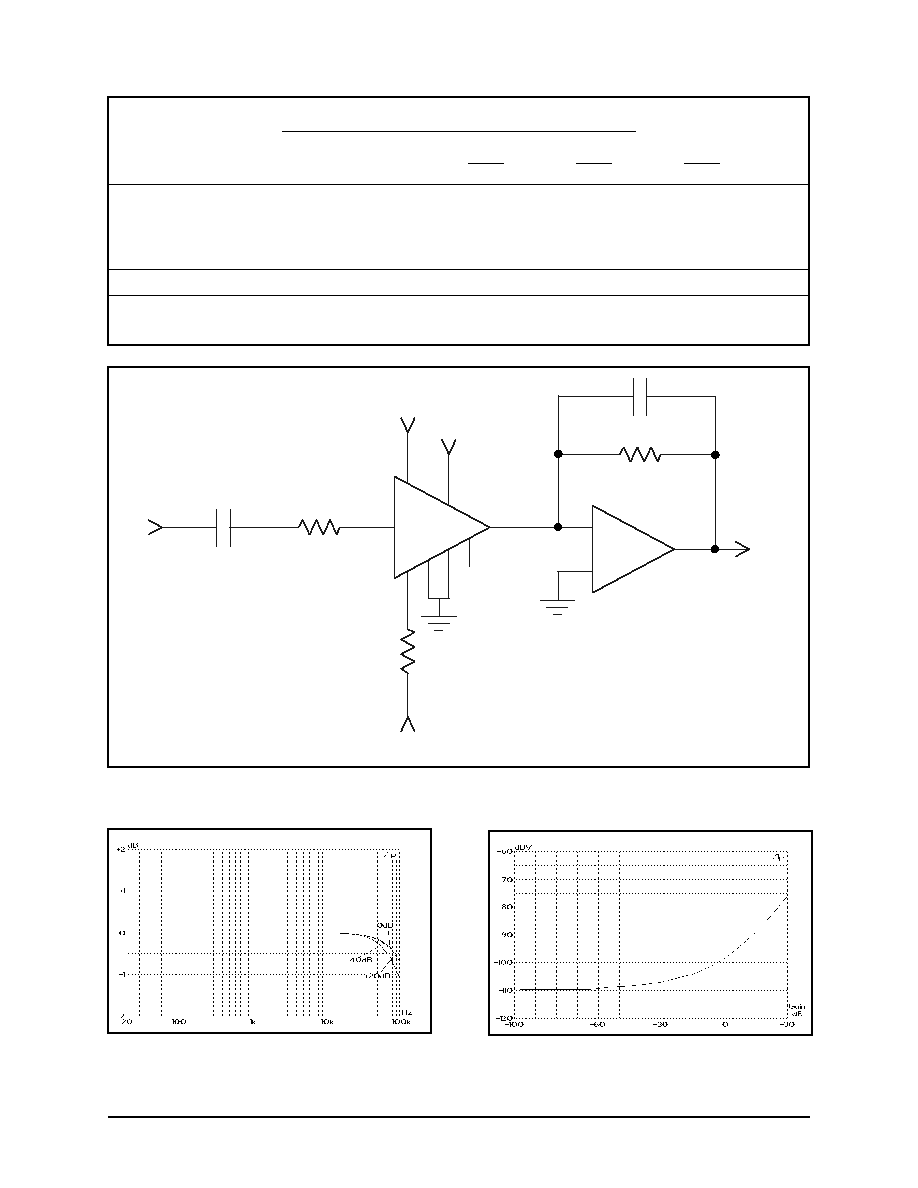

Figure 5 presents a considerably simplified internal

circuit diagram of the IC. The ac input signal current

flows in pin1, the input pin. An internal operational

transconductance amplifier (OTA) works to maintain

pin 1 at a virtual ground potential by driving the emitters

of Q1 and (through the Voltage Bias Generator) Q3.

Q3/D3 and Q1/D1 act to log the input current, producing

a voltage, V3, which represents the bipolar logarithm of

the input current. (The voltage at the junction of D1 and

D2 is the same as V3, but shifted by four forward V

be

drops.)

Gain Control

Since pin 8, the output, is usually connected to a vir-

tual ground, Q2/D2 and Q4/D4 take the bipolar antilog

of V3, creating an output current which is a precise rep-

lica of the input current. If pin 2 (Ec+) and pin 3 (Ec-)

are held at ground, the output current will equal the in-

put current. For pin 2 positive or pin 3 negative, the out-

put current will be scaled larger than the input current.

For pin 2 negative or pin 3 positive, the output current is

scaled smaller than the input.

The scale factor between the output and input cur-

rents is the gain of the VCA. Either pin 2 (Ec+) or pin 3

(Ec-), or both, may be used to control gain. Gain is expo-

nentially proportional to the voltage at pin 2, and expo-

nentially proportional to the negative of the voltage at

pin 3. Therefore, pin 2 (Ec+) is the positive control port,

while pin 3 (Ec-) is the negative control port. Because of

the exponential characteristic, the control voltage sets

gain linearly in decibels. Figure 6 shows the decibel cur-

rent gain of a 2180 versus the voltage at Ec+, while Fig-

ure 7 shows gain versus the Ec-.

Temperature Effects

The logging and antilogging in the VCA depends on

the logarithmic relationship between voltage and current

in a semiconductor junction (in particular, between a

transistor's V

be

and I

c

). As is well known, this relation-

ship is temperature dependent. Therefore, the gain of

any log-antilog VCA depends on its temperature.

Page 4

THAT2180 Series IC VCAs

3. For more details about the internal workings of the 2180 Series of VCAs, see An Improved Monolithic Volt-

age-Controlled Amplifier, by Gary K. Hebert (Vice-President, Engineering, for THAT Corporation), presented at the 99th

convention of the Audio Engineering Society, New York, Preprint number 4055.

Figure 6. Gain vs. Control Voltage (E

C+

, Pin 2) at 25∞C

Figure 7. Gain vs. Control Voltage (Ec-, Pin 3) at 25∞C

Figure 8. Gain vs. Control Voltage (Ec-) with Temp (∞C)

D1

IN

OUT

SYM

Ec-

D4

D3

Ec+

25

V-

+

Voltage

Bias

Generator

V

3

I

IN

Q1

Q4

Q3

Q2

Icell

Iadj

5

4

8

3

1

2

D2

Figure 5. Simplified Internal Circuit Diagram

Figure 8 shows the effect of temperature on the nega-

tive control port. (The positive control port behaves in the

same manner.) Note that the gain at Ec = 0 V is 0 dB, re-

gardless of temperature. Changing temperature changes

the scale factor of the gain by 0.33%/∞C, which pivots the

curve about the 0 dB point.

Mathematically, the 2180's gain characteristic is

Gain

E

E

(0.0061)(1 0.0033DT)

C

C

=

-

+

+

-

,

Eq. 1

where DT is the difference between room temperature

(25∞C) and the actual temperature, and Gain is the

gain in decibels. At room temperature, this reduces to

Gain

E

E

0.0061

C

C

=

-

+

-

,

Eq. 2

If only the positive control port is used, this becomes

Gain

E

0.0061

C

=

+

,

Eq. 3

If only the negative control port is used, this becomes

Gain

E

0.0061

C

=

-

-

,

Eq. 4

DC Bias Currents

The 2180 current consumption is determined by the

resistor between pin 5 (V-) and the negative supply voltage

(V

EE

). Typically, with 15V supplies, the resistor is 5.1 kW,

which provides approximately 2.4 mA. This current is

split into two paths: 570 mA is used for biasing the IC,

and the remainder becomes Icell as shown in Figure 5.

Icell is further split in two parts: about 20 mA biases the

core transistors (Q1 through Q4), the rest is available for

input and output signal current

DC Feedthrough

Normally, a small dc error term flows in pin 8 (the

output). When the gain is changed, the dc term changes.

This control-voltage feedthrough is more pronounced

with gain; the ≠A version of the part produces the least

feedthrough, the ≠C version the most. See Figure 9 for

typical curves for dc offset vs. gain

Audio Performance

The 2180-Series VCA design, fabrication and testing

ensure extremely good audio performance when used as

recommended. In particular, the 2180 maintains low

distortion over a wide range of gain, cut and signal lev-

els. Figures 10 through 12 show typical distortion per-

formance for representative samples of each grade of the

part. Figure 13 shows the harmonic content of the dis-

tortion in a typical B-grade part.

THAT Corporation; 45 Sumner Street; Milford, Massachusetts 01757-1656; USA

Tel: +1 508 478 9200; Fax: +1 508 478 0990; Web: www.thatcorp.com

600029 Rev 01

Page 5

Figure 11. 1 kHz THD+Noise Vs. Input Level,

+15 dB Gain

Figure 12. 1 kHz THD+Noise Vs. Input Level,

-15 dB Gain

Figure 9. Representative DC Offset Vs. Gain

Figure 13. FFT of THD, 0dB gain, 1kHz, 0dBV,

Typical 2180B

Figure 10. 1 kHz THD+Noise Vs. Input Level, 0 dB Gain

Applications

Input

As mentioned above, input and output signals are

currents, not voltages. While this often causes some con-

ceptual difficulty for designers first exposed to this con-

vention, the current input/output mode provides great

flexibility in application.

The Input pin (pin 1) is a virtual ground with nega-

tive feedback provided internally (see Figure 5, Page 4).

The input resistor (shown as 20 kW in Figure 2, Page 3)

should be scaled to convert the available ac input voltage

to a current within the linear range of the device. Gen-

erally, peak input currents should be kept under 1 mA

for best distortion performance.

Figures 10 through 12 show distortion vs. Signal

level for the three parts in the 2180 Series for 0 dB,

+15 dB and -15 dB gain. The circuit of Figure 2, Page 3

was used to generate these curves.

For a specific application, the acceptable distortion

will usually determine the maximum signal current level

which may be used. Note that, with 20 kW cur-

rent-to-voltage converting resistors, distortion remains

low even at 10 V rms input at 0 dB or -15 dB gain, and

at 1.7 V rms input at +15 dB gain (~10 V rms output).

This is especially true in the ≠A and ≠B grades of the

part.

Distortion vs. Noise

A designer may trade off noise for distortion by de-

creasing the 20 kW current-to-voltage converting resis-

tors used at the input and output in Figure 2, Page 3. For

every dB these resistor values are decreased, the voltage

noise at the output of the OP275 is reduced by one dB.

For example, with 10 kW resistors, the output noise floor

drops to ≠104 dBV (typical) at 0 dB gain -- a 6 dB re-

duction in noise because 10 kW is 1/2 of (6 dB lower

than) 20 kW.

Conversely, if THD is more important than noise per-

formance, increasing these resistors to 40 kW will in-

crease the noise level by 6 dB, while reducing distortion

at maximum voltage levels. Furthermore, if maximum

signal levels are higher (or lower) than the traditional

10 V rms, these resistors should be scaled to accommo-

date the actual voltages prevalent in the circuit. Since the

2180 handles signals as currents, these ICs can even op-

erate with signal levels far exceeding the 2180's supply

rails, provided appropriately large resistors are used.

High-Frequency Distortion

The choice of input resistor has an additional, subtle

effect on distortion. Since the feedback impedances

around the internal opamp (essentially Q1/D1 and

Q3/D3) are fixed, low values for the input resistor will

require more closed-loop gain from the opamp. Since

the open-loop gain naturally falls off at high frequencies,

asking for too much gain will lead to increased

high-frequency distortion. For best results, this resistor

should be kept to 10 kW or above.

Stability

An additional consideration is stability: the internal

op amp is intended for operation with source imped-

ances of less than 60 kW at high frequencies. For most

audio applications, this will present no problem

DC Coupling

The quiescent dc voltage level at the input (the input

offset voltage) is approximately +0 mV, but, as in many

general-purpose opamps, this is not well controlled. Any

dc input currents will cause dc in the output which will

be modulated by gain; this may cause audible thumps. If

the input is dc coupled, dc input currents may be gener-

ated due to the input offset voltage of the 2180 itself, or

due to offsets in stages preceeding the 2180. Therefore,

capacitive coupling is almost mandatory for quality au-

dio applications. Choose a capacitor which will give ac-

ceptable low frequency performance for the application.

Summing Multiple Input Signals

Multiple signals may be summed via multiple resis-

tors, just as with an inverting opamp configuration. In

such a case, a single coupling capacitor may be located

next to pin 1 rather than multiple capacitors at the

driven ends of the summing resistors. However, take

care that the capacitor does not pick up stray signals.

Output

The Output pin (pin 8) is intended to be connected

to a virtual ground node, so that current flowing in it

may be converted to a voltage (see Figures 2 & 14).

Choose the external opamp for good audio performance.

The feedback resistor should be chosen based on the de-

sired current-to-voltage conversion constant. Since the

input resistor determines the voltage-to-current conver-

sion at the input, the familiar ratio of R

f

/R

i

for an invert-

ing opamp will determine the overall voltage gain when

the 2180 is set for 0 dB current gain. Since the VCA per-

forms best at settings near unity gain, use the input and

feedback resistors to provide design-center gain or loss,

if necessary.

A small feedback capacitor around the output

opamp is needed to cancel the output capacitance of the

VCA. Without it, this capacitance will destabilize most

opamps. The capacitance at pin 8 is typically 15 pf.

Power Supplies

Positive

The positive supply is connected directly to V+

(pin 7). No special bypassing is necessary, but it is good

practice to include a small (~1 mf) electrolytic or

(~0.1 mf) ceramic capacitor close to the VCA IC on the

PCB. Performance is not particularly dependent on sup-

THAT Corporation; 45 Sumner Street; Milford, Massachusetts 01757-1656; USA

Tel: +1 508 478 9200; Fax: +1 508 478 0990; Web: www.thatcorp.com

Page 6

THAT2180 Series IC VCAs

ply voltage. The lowest permissible supply voltage is de-

termined by the sum of the input and output currents

plus I

SET

, which must be supplied through the output

of the internal transconductance amplifier and down

through the core and voltage bias generator. Reducing

signal currents may help accommodate low supply volt-

ages. THAT Corporation intends to publish an applica-

tion note covering operation on low supply voltages.

Please inquire for its availability.

The highest permissible supply voltage is fixed by the

process characteristics and internal power consumption.

+18 V is the nominal limit.

Negative

The negative supply terminal is V- (pin 5). Unlike

normal negative supply pins, this point is intended to be

connected to a current source I

set

(usually simply a re-

sistor to V

EE

), which determines the current available

for the device. As mentioned before, this source must

supply the sum of the input and output signal currents,

plus the bias to run the rest) of the IC. The minimum

value for this current is 570 mA over the sum of the re-

quired signal currents. Usually, I

set

should equal 2.4 mA

for most pro audio applications with ±15 V supplies.

Higher bias levels are of limited value, largely because

the core transistors become ineffective at logging and

antilogging at currents over 1 mA.

Mathematically, this can be expressed as

I

cell

≥ Peak (I

in

) + Peak (I

out

) + 220 mA; and

I

cell

= I

set

- 350 mA. Therefore,

I

set

≥ Peak (I

in

) + Peak (I

out

) + 570 mA.

The voltage at V- (pin 5) is four diode drops below

ground, which, for the 2180, is approximately -2.85 V.

Since this pin connects to a (high impedance) current

supply, not a voltage supply, bypassing at pin 5 is not

normally necessary.

Ground

The GND pin (pin 6) is used as a ground reference

for the VCA. The non-inverting input of the internal

opamp is connected here, as are various portions of the

internal bias network. It may not be used as an addi-

tional input pin.

Voltage Control

Negative Sense

E

C-

(pin 3) is the negative voltage control port. This

point controls gain inversely with applied voltage: posi-

tive voltage causes loss, negative voltage causes gain. As

described on Page 5, the current gain of the VCA is unity

when pin 3 is at 0 V with respect to pin 2, and varies

with voltage at approximately -6.1 mV/dB, at room tem-

perature.

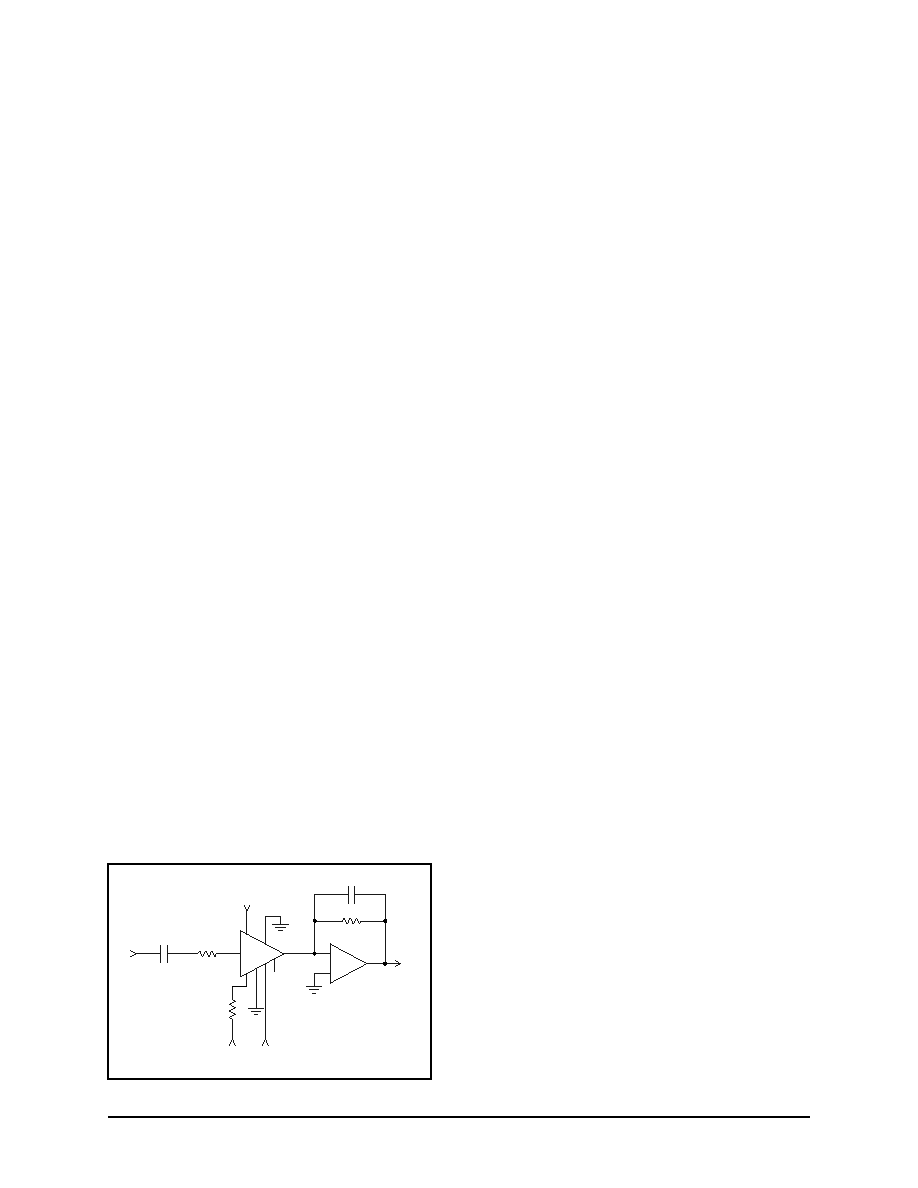

Positive Sense

As mentioned earlier, E

C+

(pin 2) is the posi-

tive-sense voltage control port. A typical circuit using

this approach is shown in Figure 14. E

C-

(Pin 3) should

be grounded, and E

C+

(pin 2) driven from a

low-impedance voltage source. Using the opposite sense

of control can sometimes save an inverter in the control

path. In order to maintain the wafer level adjustment

which minimizes THD, leave pin 4 open.

Positive and Negative

It is also possible (and sometimes advantageous) to

drive both control ports, either with differential drive (in

which case, the control sensitivities of each port are

summed), or through two different control signals.

There is no reason why both control ports cannot be

used simultaneously.

Control Port Drive Impedance

The control ports (pins 2 through 4) are connected

directly to the bases of the logging and/or antilogging

transistors. The accuracy of the logging and antilogging

is dependent on the E

C+

and E

C-

voltages being exactly

as desired to control gain. The base current in the core

transistors will follow the collector currents, of course.

Since the collector currents are signal-related, the base

currents are therefore also signal-related. Should the

source impedance of the control voltage(s) be large, the

signal-related base currents will cause signal-related

voltages to appear at the control ports, which will inter-

fere with precise logging and antilogging, in turn causing

distortion.

The 2180 Series VCAs are designed to be operated

with zero source impedance at pins 2 and 3, and an

infinite source impedance at pin 4. (Pin 4 should be left

open.) To realize all the performance designed into a

2180, keep the source impedance of the control voltage

driver well under 50 W.

This often suggests driving the control port directly

with an opamp. However, the closed-loop output imped-

ance of an opamp typically rises at high frequencies be-

cause open loop gain falls off as frequency increases. A

typical opamp's output impedance is therefore inductive

at high frequencies. Excessive inductance in the control

port source impedance can cause the VCA to oscillate in-

ternally. In such cases, a 100 W resistor in series with a

1.5 nf capacitor from the control port to ground will

usually suffice to prevent the instability.

THAT Corporation; 45 Sumner Street; Milford, Massachusetts 01757-1656; USA

Tel: +1 508 478 9200; Fax: +1 508 478 0990; Web: www.thatcorp.com

600029 Rev 01

Page 7

Vcc

Ec+

IN

10u

20k

5.1k

Vee

OUT

22p

20k

OUT

OP275

7

3

8

4

2

6

5

1

V+

-IN

Ec-

Ec+

SYM

GND

V-

2180

Series

VCA

Power Supplies

Vcc = +15 V

Vee = -15 V

-

+

NC

Figure 14. Positive Control Port Using Pin 2 (Ec+)

THAT Corporation; 45 Sumner Street; Milford, Massachusetts 01757-1656; USA

Tel: +1 508 478 9200; Fax: +1 508 478 0990; Web: www.thatcorp.com

Page 8

THAT2180 Series IC VCAs

Noise Considerations

It is second nature among good audio designers to con-

sider the effects of noisy devices on the signal path. As is

well known, this includes not only active devices such as

opamps and transistors, but extends to the choice of im-

pedance levels as well. High value resistors have higher in-

herent thermal noise, and the noise performance of an

otherwise quiet circuit can be easily spoiled by the wrong

choice of impedance levels.

Less well known, however, is the effect of noisy circuitry

and high impedance levels in the control path of volt-

age-control circuitry. The 2180 Series VCAs act like multi-

pliers: when no signal is present at the signal input, noise at

the control input is rejected. So, when measuring noise (in

the absence of signal ≠ as most everyone does), even very

noisy control circuitry often goes unnoticed. However, noise

at the control port of these parts will cause noise modula-

tion of the signal. This can become significant if care is not

taken to drive the control ports with quiet signals.

The 2180 Series VCAs have a small amount of inherent

noise modulation because of its class AB biasing scheme,

where the shot noise in the core transistors reaches a mini-

mum with no signal, and increases with the square root of

the instantaneous signal current. However, in an optimum

circuit, the noise floor rises only to -94 dBV with a

50 mA rms signal at unity gain -- 4 dB of noise modulation.

By contrast, if a unity-gain connected, non-inverting 5534

opamp is used to directly drive the control port, the noise

floor will rise to 92 dBV -- 6 dB of noise modulation.

To avoid excessive noise, one must take care to use

quiet electronics throughout the control-voltage circuitry.

One useful technique is to process control voltages at a

multiple of the eventual control constant (e.g., 61 mV/dB

-- ten times higher than the VCA requires), and then at-

tenuate the control signal just before the final drive am-

plifier. With careful attention to impedance levels,

relatively noisy opamps may be used for all but the final

stage.

Stray Signal Pickup

It is also common practice among audio designers to

design circuit boards to minimize the pickup of stray

signals within the signal path. As with noise in the con-

trol path, signal pickup in the control path can ad-

versely effect the performance of an otherwise good VCA.

Because it is a multiplier, the 2180 produces second

harmonic distortion if the audio signal itself is present at

the control port. Only a small voltage at the control port

is required: as little as 10 mV of signal can increase dis-

tortion to over 0.01%. This can frequently be seen at

high frequencies, where capacitive coupling between the

signal and control paths can cause stray signal pickup.

Because the signal levels involved are very small, this

problem can be difficult to diagnose. One useful tech-

nique is to temporarily bypass the control port to

ground via a modest-sized capacitor (e.g., 10 mF). If the

distortion diminishes, signal pickup in the control path

is the likely cause.

Temperature Sensitivity

As shown by the equation for A

V

(Page 5), the gain of

a 2180 VCA is sensitive to temperature in proportion to

the amount of gain or loss commanded. The constant of

proportionality is 0.33% of the decibel gain commanded,

per degree Celsius, referenced to 27∞C (300∞K). This

means that at 0 dB gain, there is no change in gain with

temperature. However, at -122 mV, the gain will be

+20 dB at room temperature, but will be 20.66 dB at a

temperature 10∞C lower.

For most audio applications, this change with tem-

perature is of little consequence. However, if necessary, it

may be compensated by a resistor embedded in the con-

trol voltage path whose value varies with temperature at

the same rate of 0.33%/∞C. Such parts are available from

RCD Components, Inc, 3301 Bedford St., Manchester,

NH, USA [(603) 669-0054], and KOA/Speer Electronics,

PO Box 547, Bradford, PA, 16701 USA [(814)362-5536].

Closing Thoughts

THAT Corporation welcomes comments, questions

and suggestions regarding these devices, their design

and application. Our engineering staff includes designers

who have decades of experience in applying our parts.

Please feel free to contact us to discuss your applications

in detail.

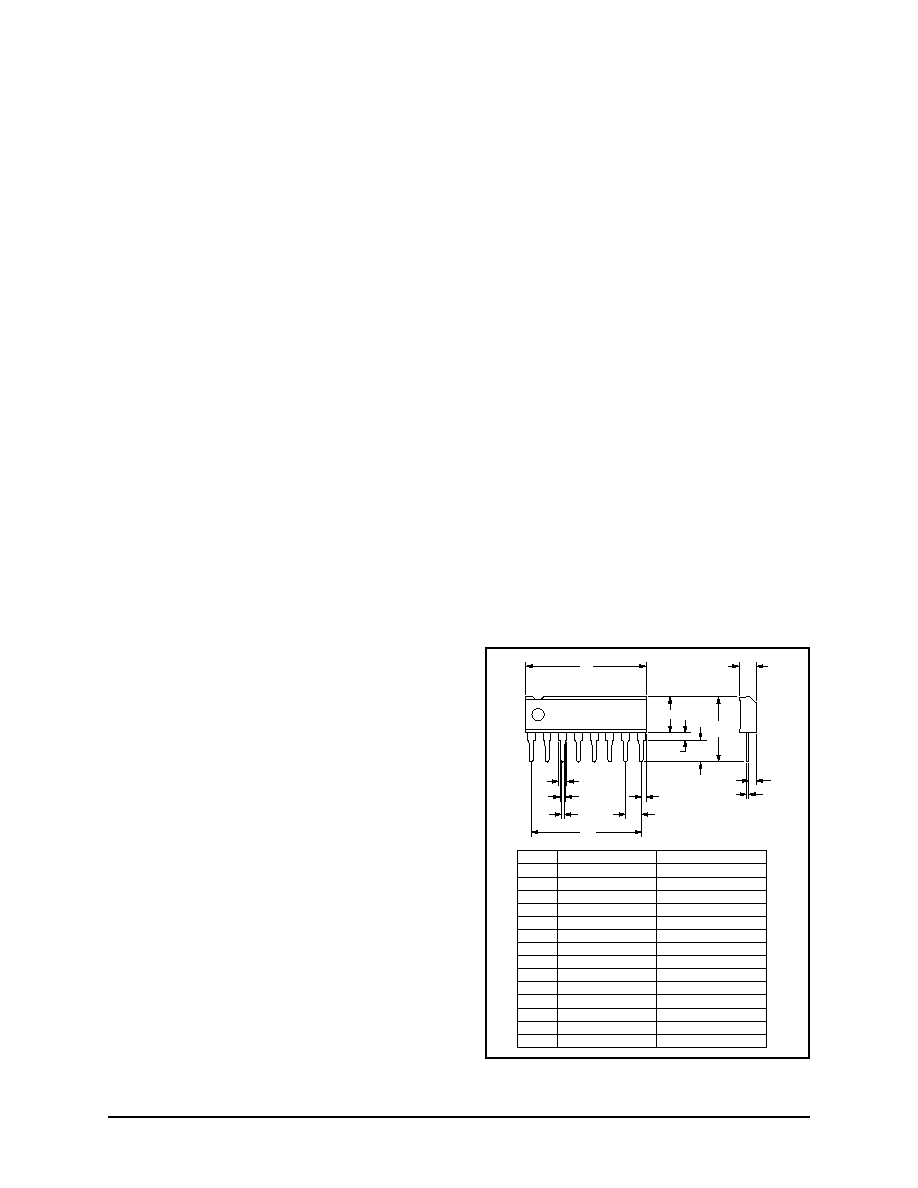

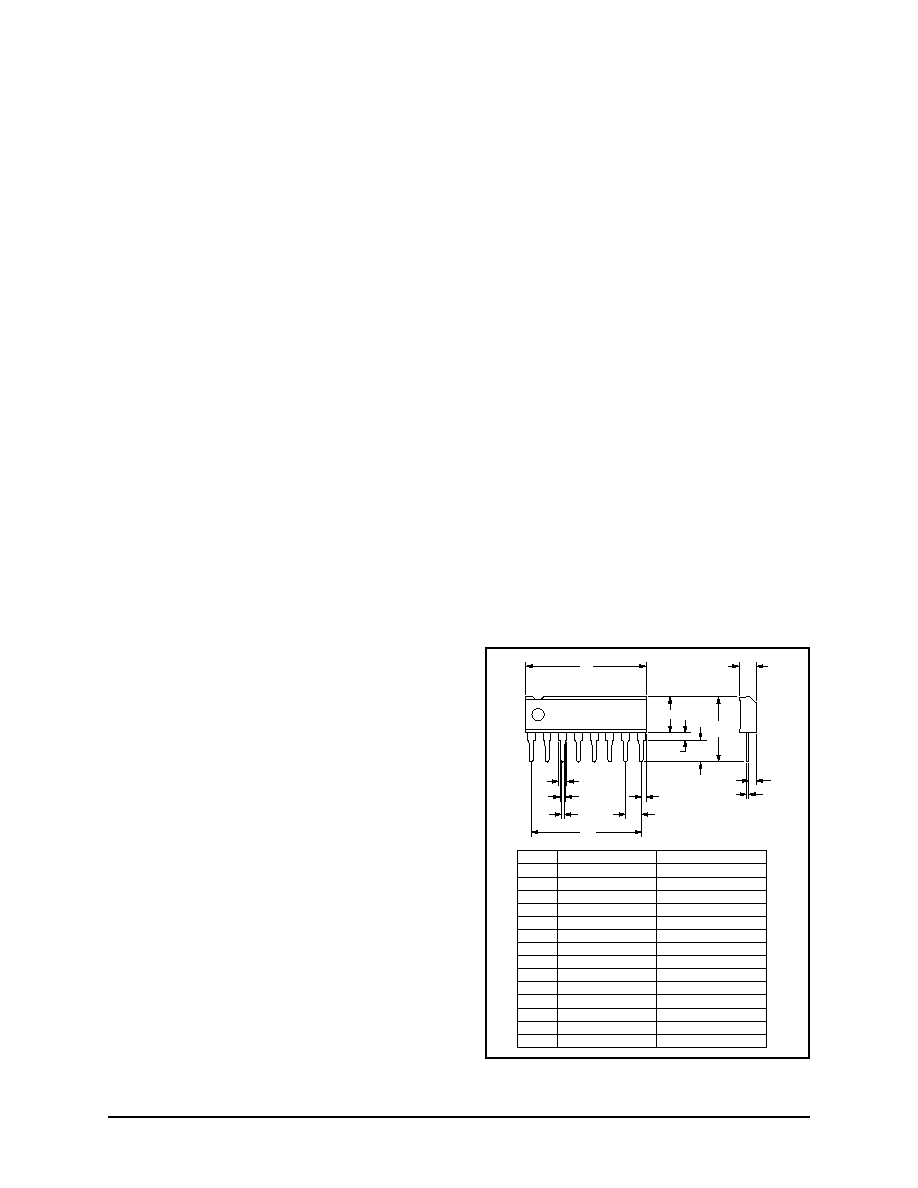

I

K

L

G

E TYP.

F

B

D

C

1

A

N

M

H

N

17.78 ±0.3

0.700 ±0.012

J

MILLIMETERS

19.5 +0.2/-0

1.25

0.65

0.85

2.54 ±0.2

0.9

1.2

5.8 +0.2/-0

2.8 +0.1/-0

10.5 ±0.5

1.3

0.3

3.5 ±0.5

INCHES

0.77 +0.008/-0

0.049

0.026

0.033

0.100 ±0.008

0.04

0.05

0.23 +0.008/-0

0.11 +0.004/-0

0.413 ±0.02

0.05

0.012

0.14 ±0.02

ITEM

A

B

C

D

E

F

G

H

I

J

K

L

M

Figure 16. -L (SIP) Version Package Outline Drawing