www.ti.com

FEATURES

APPLICATIONS

DESCRIPTION

ONET4201LD

SLLS677 ≠ NOVEMBER 2005

155 Mbps to 4.25 Gbps LASER DRIVER

∑

SONET/SDH Transmission Systems

∑

Multi-Rate Operation From 155 Mbps up to

4.25 Gbps

∑

Fibre Channel Optical Modules

∑

Fiber Optic Data Links

∑

Bias Current Programmable From 1 mA

to 100 mA

∑

Digital Cross-Connects

∑

Optical Transmitters

∑

Modulation Current Programmable From 5 mA

to 85 mA

∑

APC and Fault Detection

∑

Fault Mode Selection

The ONET4201LD is a laser driver for multiple fiber

optic applications up to 4.25 Gbps. The device

∑

Bias and Photodiode Current Monitors

accepts CML input data and provides bias and

∑

CML Data Inputs

modulation currents for driving a laser diode. Also

∑

Temperature Compensation of Modulation

provided

are

automatic

power

control

(APC),

temperature compensation of modulation current,

Current

fault detection, and current monitor features.

∑

Single 3.3-V Supply

The device is available in a small footprint 4 mm

◊

4

∑

Active Back-Termination at the Output

mm 24-pin QFN package. The circuit requires a

∑

Surface Mount Small Footprint 4 mm

◊

4 mm

single 3.3-V supply.

24-Lead QFN Package

This power efficient laser driver is characterized for

operation from ≠40

∞

C to 85

∞

C.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Copyright © 2005, Texas Instruments Incorporated

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

www.ti.com

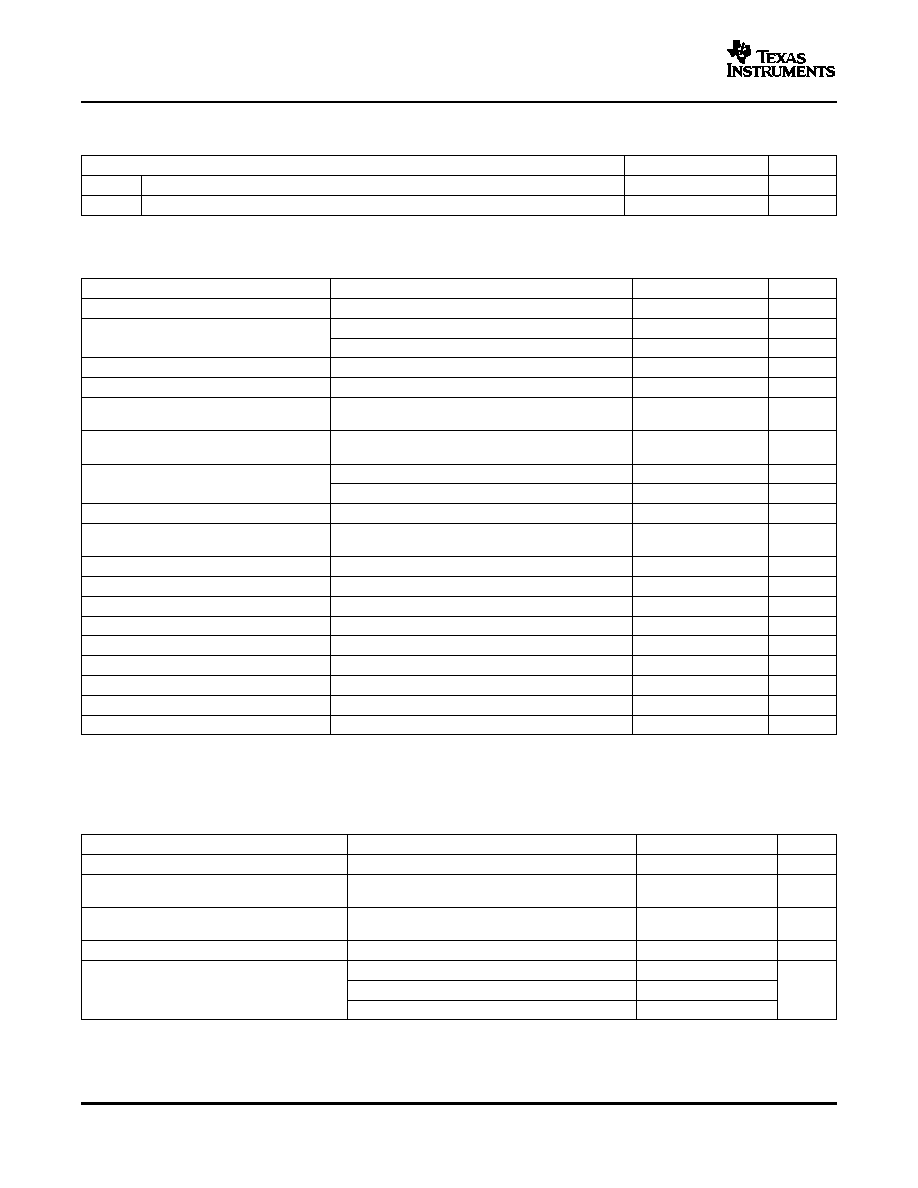

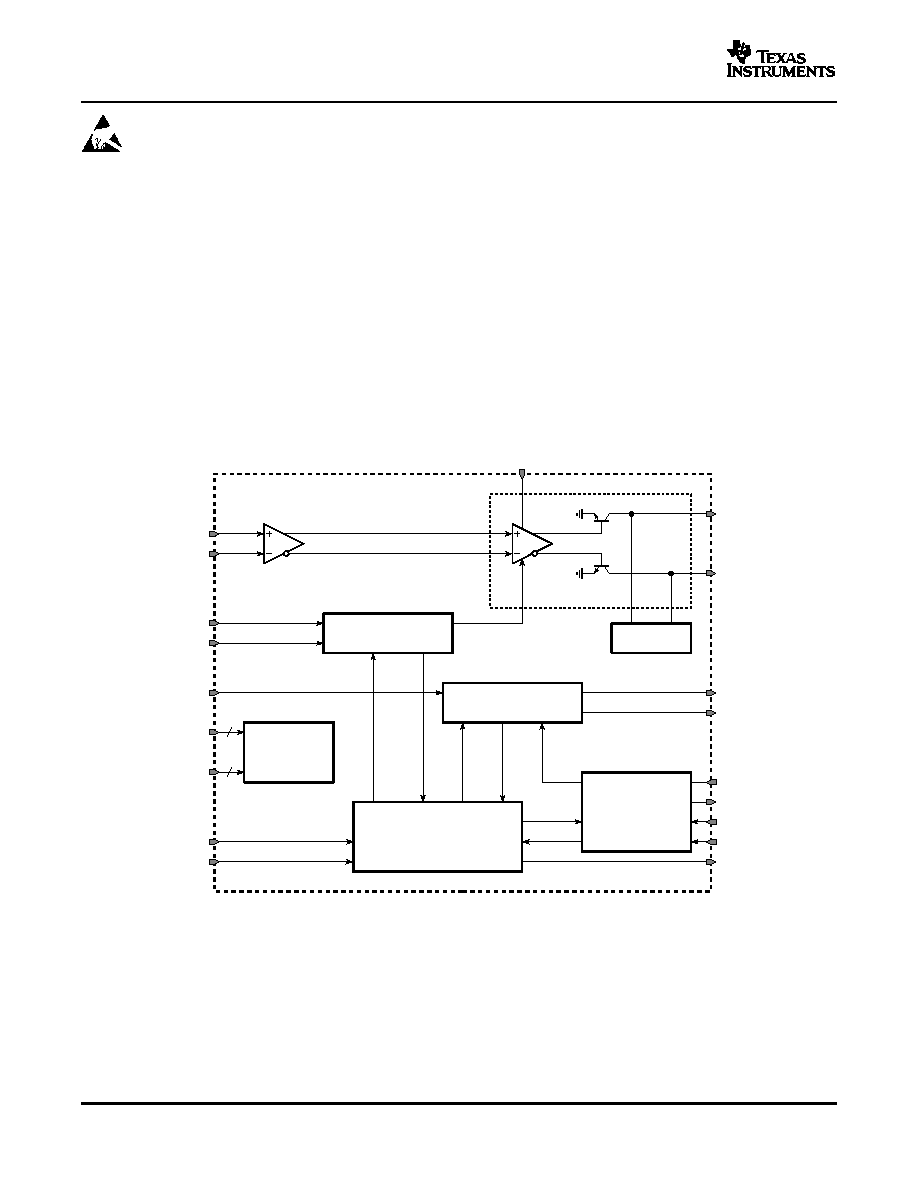

DETAILED DESCRIPTION

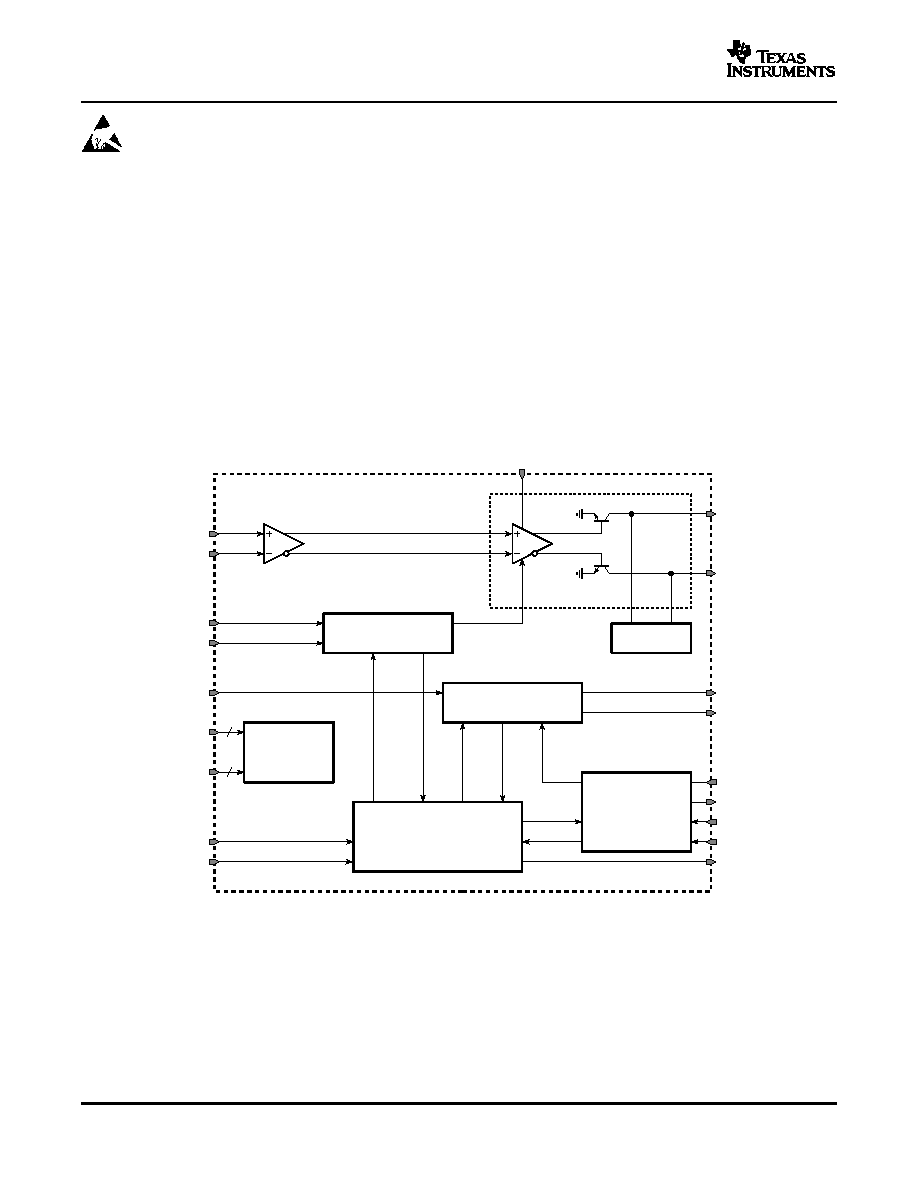

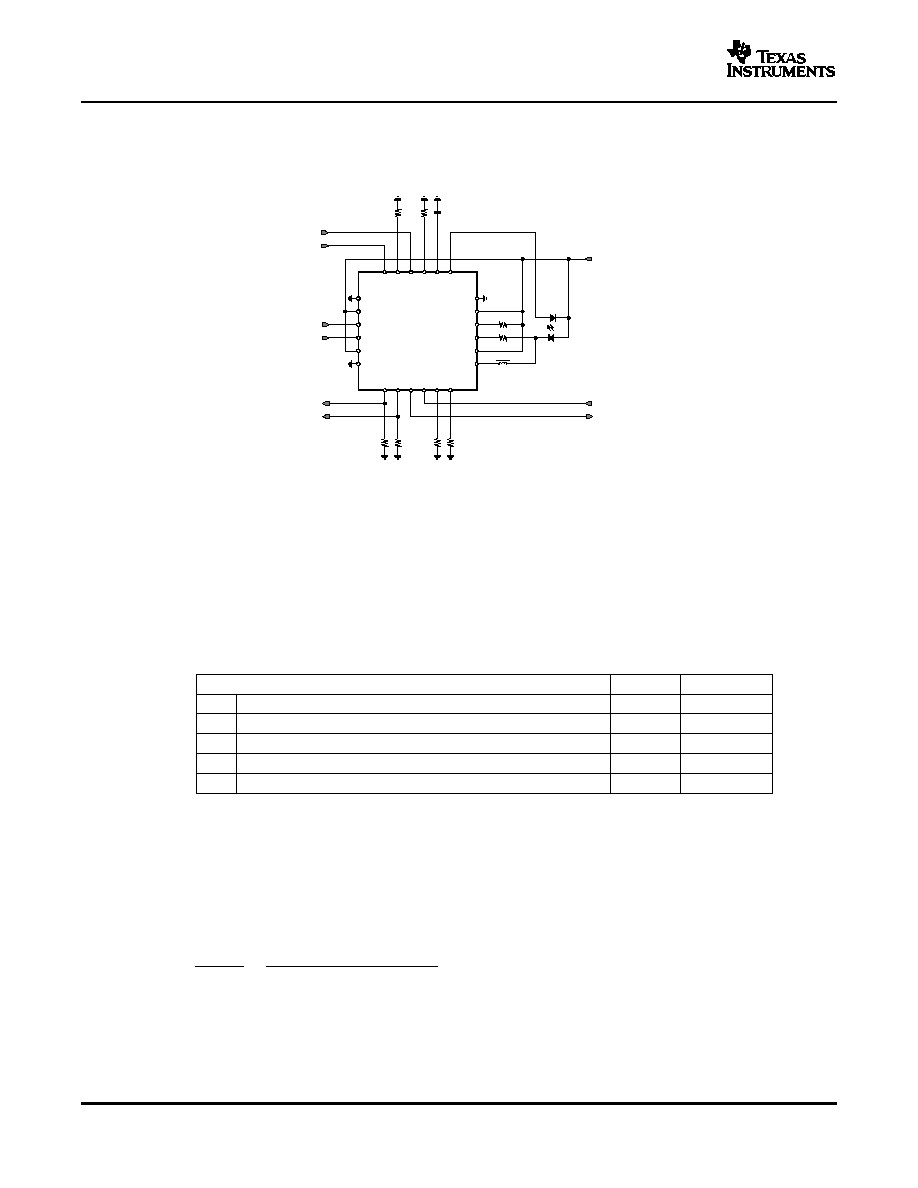

BLOCK DIAGRAM

VCC

GND

DIN+

DIN≠

MOD+

MOD≠

MODSET

current modulator

OUTPOL

MODTC

BIAS

MONB

IBMAX

MONP

PD

APCSET

SDOWN

DISABLE

CAPC

FLTMODE

active termination

OUT+

OUT≠

input buffer stage

modulation current generator

MODCTRL

MODSET

IMODEN

MODTC

IMODMON

reference

voltage

and bias

generation

VCC

GND

4

3

bias current generator

BIAS

IBMAX

IBEN

IBMON IBSET

MONB

control

IMODEN

IMODMON

IBEN

IBMON

DISABLE

SDOWN

APCCTRL

APCMON

FLTMODE

automatic power control

(APC)

IBSET

APCMON

APCCTRL

MONP

APCSET

PD

CAPC

HIGH SPEED DATA PATH

ONET4201LD

SLLS677 ≠ NOVEMBER 2005

These devices have limited built-in ESD protection. The leads should be shorted together or the device

placed in conductive foam during storage or handling to prevent electrostatic damage to the MOS gates.

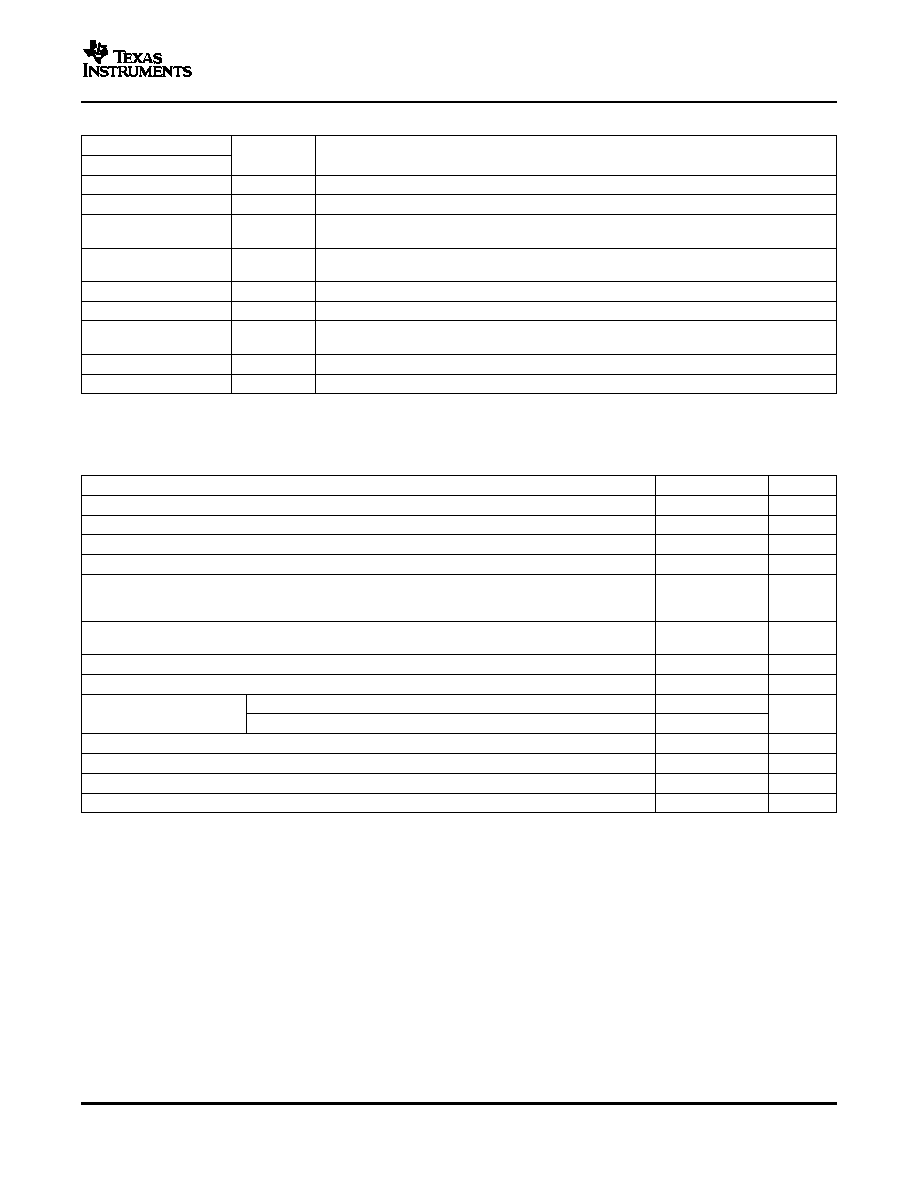

A simplified block diagram of the ONET4201LD is shown in

Figure 1

.

This compact, low power 4.25-Gbps laser driver circuit consists of a high-speed data path and a bias and control

block.

The function of the data path is to buffer the input data and then modulate the laser diode current according to

the input data stream.

The bias and control block generates the laser diode bias current, contains automatic power control (APC) to

maintain constant optical output power, generates a modulation current that can be temperature compensated

and controls power-on during start-up and shutdown after failure detection. The circuit design is optimized for

high-speed and low voltage operation (3.3 V).

The main circuit blocks are described in detail below.

Figure 1. Simplified Block Diagram of the ONET4201LD

The high-speed data path consists of an input buffer stage and a current modulator.

The input buffer stage takes CML compatible differential signals. It provides on-chip 50-

termination to VCC.

AC-coupling may be used at the DIN+ and DIN- inputs.

The laser diode current modulator mainly consists of two common-emitter output-transistors and the required

driver circuitry. According to the input data stream, the modulation current is sunk at the MOD+ or the MOD≠ pin,

respectively.

2

www.ti.com

BIAS AND CONTROL

BANDGAP VOLTAGE AND BIAS GENERATION

AUTOMATIC POWER CONTROL

I

PD

[A]

+

P

AVG

[W]

Ú

MON

[A W]

(1)

R

APCSET

[

W

]

+

4.69 V

I

PD

[A]

+

4.69 V

P

AVG

[W]

Ú

MON

[A W]

(2)

I

BIASMAX

[A]

+

343 V

R

BIASMAX

[

W

]

(3)

V

MONB

[V]

+

R

MONB

[

W

]

I

BIAS

[A]

68

(4)

V

MONP

[V]

+

R

MONP

[

W

]

I

PD

[A]

(5)

ONET4201LD

SLLS677 ≠ NOVEMBER 2005

DETAILED DESCRIPTION (continued)

Modulation current setting is performed by means of the modulation current generator block, which is supervised

by the control circuit block.

The laser diode can be either ac or dc coupled. In both cases, the maximum modulation current is 85 mA. The

modulation output is optimized for driving a 20-

load.

For optimum performance when driving a laser diode over a 20-

transmission line, the ONET4201LD provides

active 20-

back-termination, which minimizes jitter caused by reflections.

The bias and control circuitry consists of the bandgap voltage and bias generation block, the bias current

generator, the automatic power control block and the supervising control circuitry.

The bandgap voltage reference provides process and temperature independent reference voltages needed to set

bias current, modulation current, and photodiode reference current. Additionally, this block provides the biasing

for all internal circuits.

The ONET4201LD laser driver incorporates an APC loop to compensate for the changes in laser threshold

current over temperature and lifetime. The internal APC is enabled when resistors are connected to the IBMAX

and APCSET pins. A back-facet photodiode mounted in the laser package is used to detect the average laser

output power. The photodiode current I

PD

that is proportional to the average laser power, can be calculated by

using the laser to monitor transfer ratio,

MON

and the average power, P

AVG

:

In closed loop operation, the APC modifies the laser diode bias current by comparing I

PD

with a reference current

I

APCSET

and generates a bias compensation current. I

PD

can be programmed by selecting the external resistor

R

APCSET

according to:

The bias compensation current subtracts from the maximum bias current to maintain the monitor photodiode

current. The maximum bias current is programmed by the resistor connected to IBMAX:

this current limit establishes the maximum bias current available in closed loop mode, as well as in transient fault

conditions such as shorts at the PD pin to ground or delayed laser power up.

An external pin MONB is provided as a bias current monitor output. A fraction of the bias current (1/68) is

mirrored and develops a voltage drop across an external resistor to ground, R

MONB

. The voltage at MONB is

given as:

If the voltage at MONB is greater than the programmed threshold, a fault mode occurs.

The MONP is also provided as a photocurrent monitor output. The photodiode current, I

PD

, is mirrored and

develops a voltage across an external resistor to ground, R

MONP

. The voltage at MONP is given as:

If the voltage at MONP is greater than the programmed threshold, a fault mode occurs.

3

www.ti.com

MODULATION CURRENT GENERATOR

I

MOD

[A]

+

265 V

R

MODSET

[

W

]

1

)

24

W

R

MODTC

[

W

]

)

630 ppm

T[

o

C]

*

T

0

[

o

C]

(6)

CONTROL

FAULT DETECTION

ONET4201LD

SLLS677 ≠ NOVEMBER 2005

DETAILED DESCRIPTION (continued)

As with any negative feedback system design, care must be taken to assure stability of the loop. The loop

bandwidth must not be too high in order to minimize pattern-dependent jitter. The dominant pole is determined by

the capacitor C

APC

. The recommended value for C

APC

is 200 nF. The capacitance of the monitor photodiode C

PD

adds another pole to the system and thus it must be small enough to maintain stability. The recommended value

for this capacitance is C

PD

50 pF.

The internal APC loop can be disabled by connecting a 100-k

resistor from APCSET to VCC and leaving PD

open. In open loop operation, the laser diode current is set by I

BIASMAX

and I

MODSET

.

The modulation current generator defines the tail current of the modulator, which is sunk from either MOD+ or

MOD- depending upon the data pattern. The modulation current consists of a modulation current I

MOD0

at a

reference temperature T

0

= 60

∞

C (set by the resistor R

MODSET

) and a temperature dependent modulation current

defined by the resistor R

MODTC

. The modulation current can be estimated as follows:

Note that the reference temperature, T

0

, and the temperature compensation set by R

MODTC

varies from

part-to-part. To reduce the variation, I

MOD

can be calibrated over temperature and set with a microcontroller DAC

or digital potentiometer.

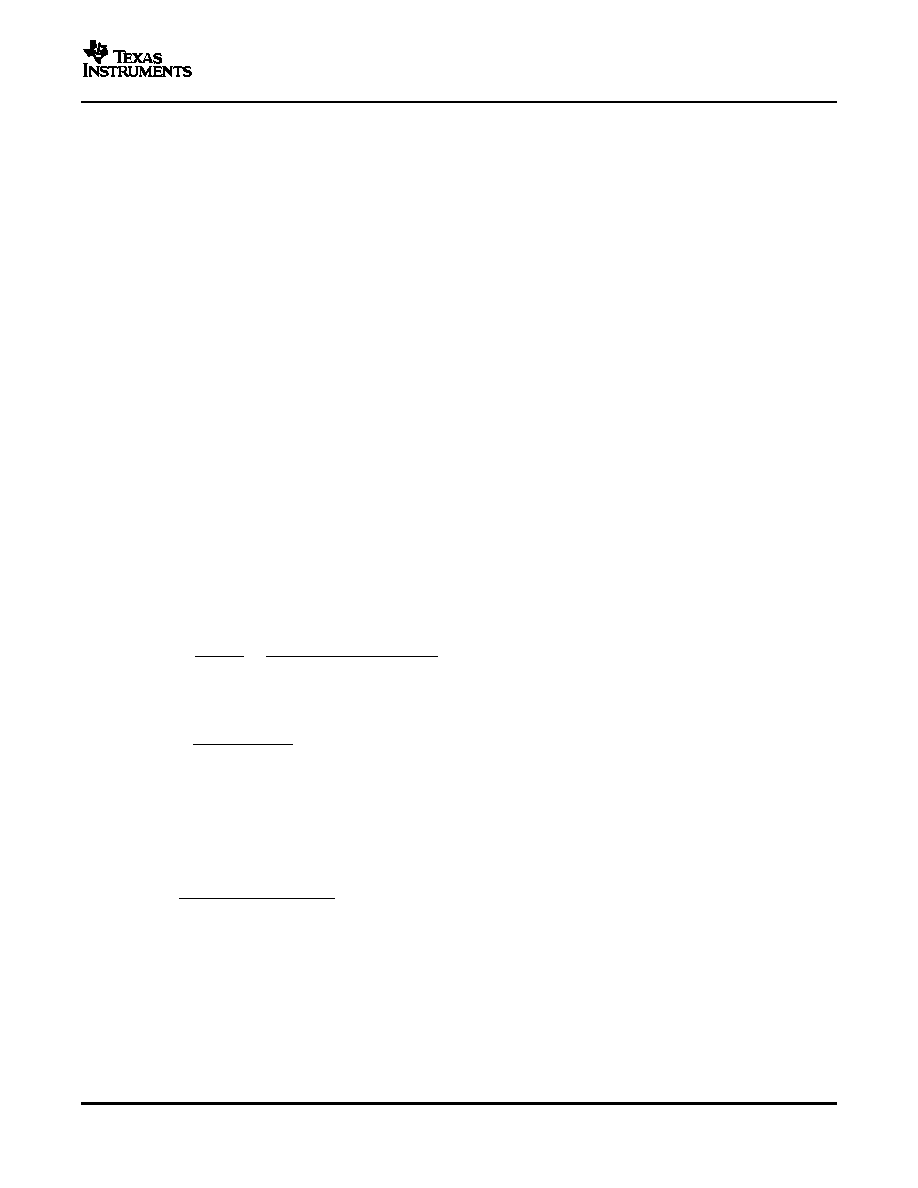

The function of this block is to control the start-up sequence, detect faults, detect tracking failure of the APC loop

and provide disable control. The laser driver has a controlled start-up sequence which helps prevent transient

glitches from being applied to the laser during power on. At start-up, the laser diode is off, SDOWN is low, and

the APC loop is open. Once V

CC

reaches ~2.8 V, the laser diode bias generator and modulation current

generator circuitry are activated (if DISABLE is low). The slow start circuitry gradually brings up the current

delivered to the laser diode. From the time that V

CC

reaches ~2.8 V to when the modulation current and bias

current reach 95% of their steady state value, is considered the initialization time. If DISABLE is asserted during

power on, the slow start circuitry will not activate until DISABLE is negated.

The fault detection circuitry monitors the operation of the ONET4201LD. If FLTMODE is set to a low level,

(hard-fault mode) this circuitry will disable the bias and modulation circuits and latch the SDOWN output upon

detection of a fault. The fault mode is reset by toggling DISABLE (for a minimum time of T

RES

) or by toggling V

CC

.

Once DISABLE is toggled, SDOWN is set low and the circuit is re-initialized.

If FLTMODE is set to a high level (soft-fault mode), a fault will be indicated at the SDOWN output, however the

bias and modulation circuits are not disabled. The SDOWN output is reset once the fault causing condition

disappears. Toggling DISABLE or VCC is not required.

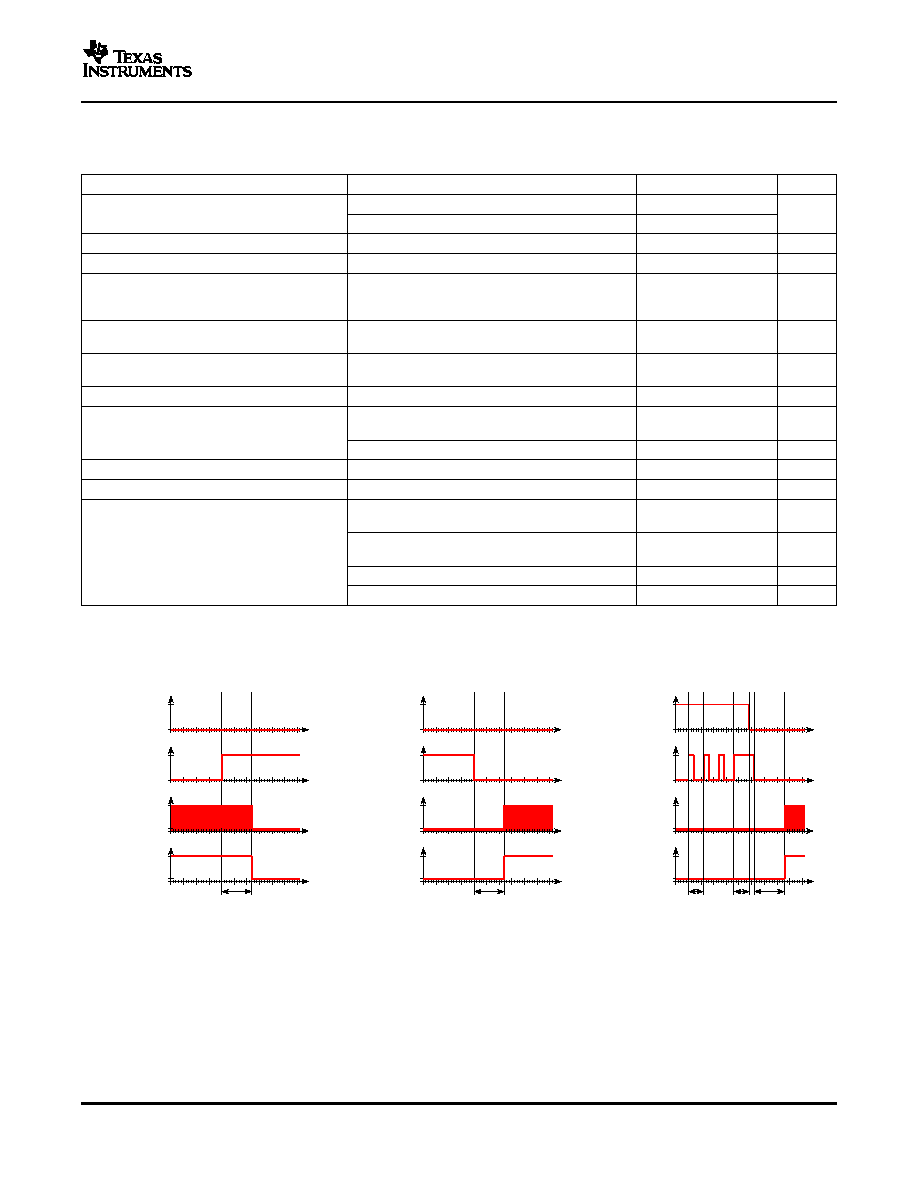

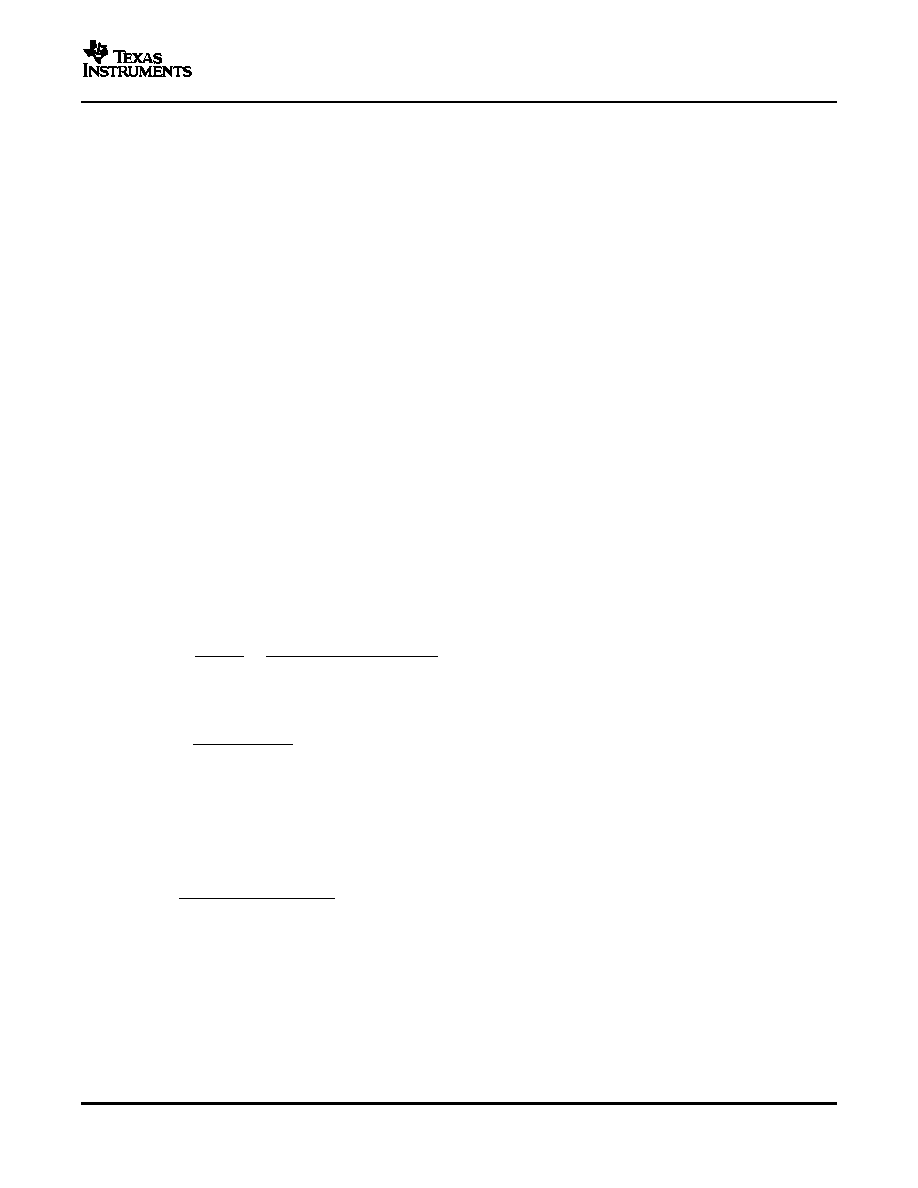

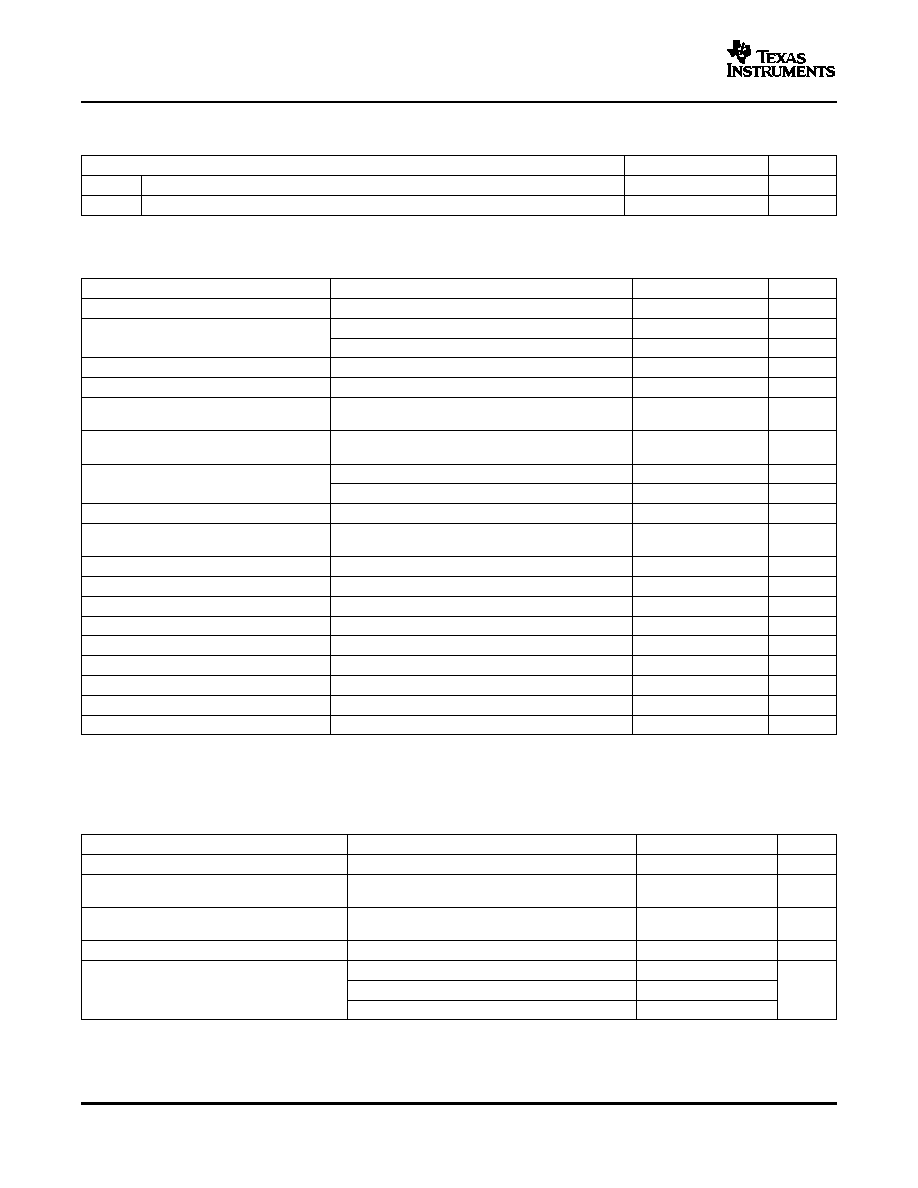

A functional representation of the fault detection circuitry is shown in

Figure 2

.

4

www.ti.com

MODTC

IBMAX

IBEN

SDOWN

IMODEN

VCC

2.8 V

MONB

MONP

IPD

IBIAS/68

MODSET

APCSET

DISABLE

R

Q

S

flipflop

START

TREScounter

RES

comparator

1.25 V

short circuit

to VCC or

GND detect

MODTC

IBMAX

APCSET

MODSET

SHORT

MUX

I0

I1

Q

CMOS buffer

FLTMODE

MUX

I1

I0

Q

inverter

inverter

ONET4201LD

SLLS677 ≠ NOVEMBER 2005

DETAILED DESCRIPTION (continued)

Figure 2. Functional Representation of the Fault Detection Circuitry

A fault mode will be produced if the laser cathode is grounded and the photocurrent causes MONP to exceed its

programmed threshold. Another fault mode can be produced if the laser diode end of life conditions causes

excessive bias current and photocurrent that results in monitor voltages (MONP, MONB) being greater than their

programmed threshold. Other fault modes can occur if there are any I/O pin single point failures (short to V

CC

or

GND) and the monitor voltages exceed their programmed threshold (see

Table 1

).

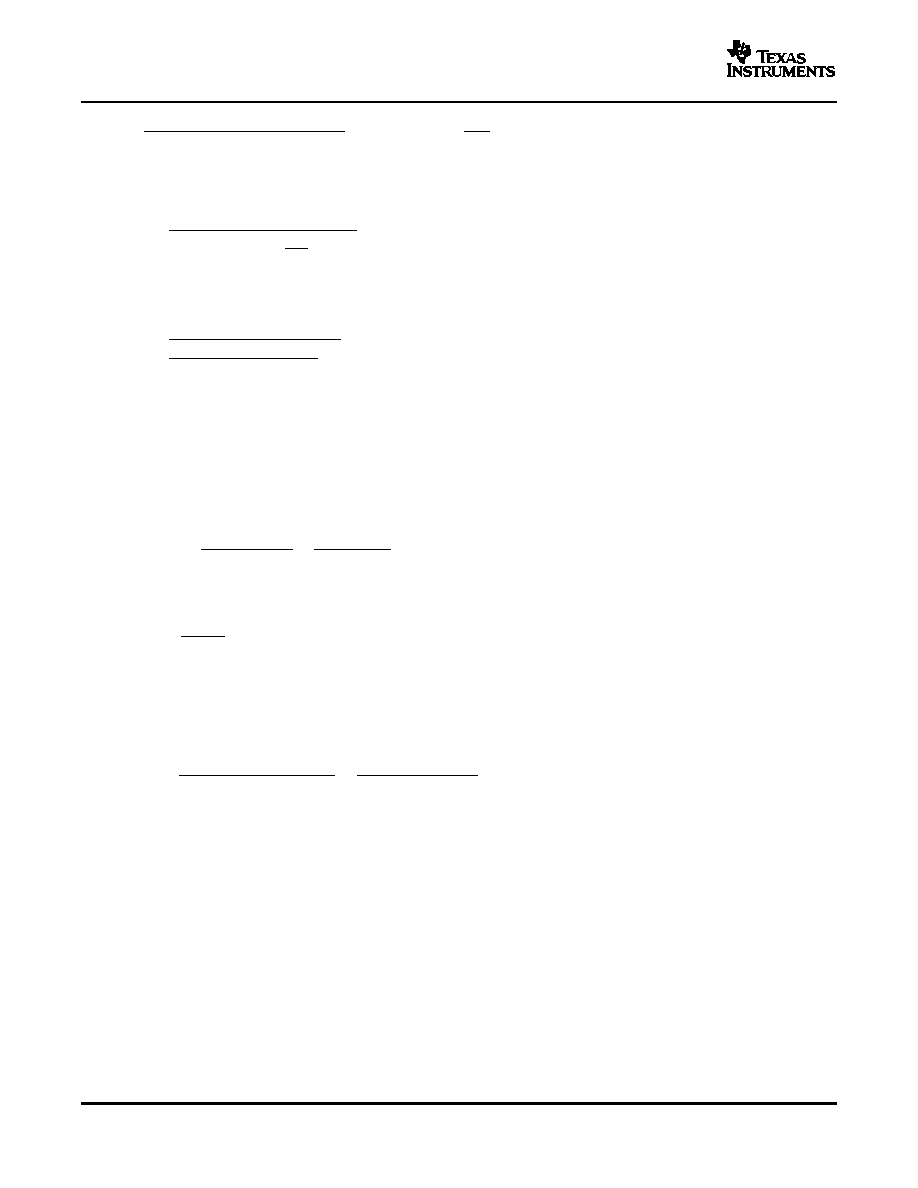

Table 1. Response to I/O-Pin Shorts to VCC or GND

FLTMODE = LOW

FLTMODE = HIGH

PIN

Response to Short to GND

Response to Short to V

CC

Response to Short to GND

Response to Short to V

CC

DIN+

No fault, I

MOD

disabled

No fault

No fault, I

MOD

disabled

No fault

DIN≠

No fault, I

MOD

disabled

No fault

No fault, I

MOD

disabled

No fault

MONP

No fault

SDOWN latched high, I

BIAS

No fault

SDOWN high, I

BIAS

and I

MOD

and I

MOD

disabled

unaffected

MONB

No fault

SDOWN latched high, I

BIAS

No fault

SDOWN high, I

BIAS

and I

MOD

and I

MOD

disabled

unaffected

DISABLE

Normal circuit operation

Normal circuit operation

Normal circuit operation

Normal circuit operation

SDOWN

No fault

No fault

No fault

No fault

OUTPOL

No fault, polarity reverses

No fault

No fault, polarity reverses

No fault

BIAS

SDOWN latched high, I

MOD

No fault, I

BIAS

goes to zero

SDOWN high, I

MOD

No fault, I

MOD

unaffected

disabled

unaffected

MOD+

SDOWN latched high, I

BIAS

and

No fault

SDOWN high, I

BIAS

No fault

I

MOD

disabled

unaffected

MOD≠

SDOWN latched high, I

BIAS

and

No fault

SDOWN high, I

BIAS

No fault

I

MOD

disabled

unaffected

PD

No fault, I

MOD

unaffected

No fault, I

BIAS

goes to zero

No fault, I

MOD

unaffected

No fault, I

BIAS

goes to zero

CAPC

No fault

No fault, I

BIAS

goes to zero

No fault, I

MOD

unaffected

No fault, I

BIAS

goes to zero

MODTC

SDOWN latched high, I

BIAS

and

No fault

SDOWN high, I

BIAS

and I

MOD

No fault

I

MOD

disabled

unaffected

5

www.ti.com

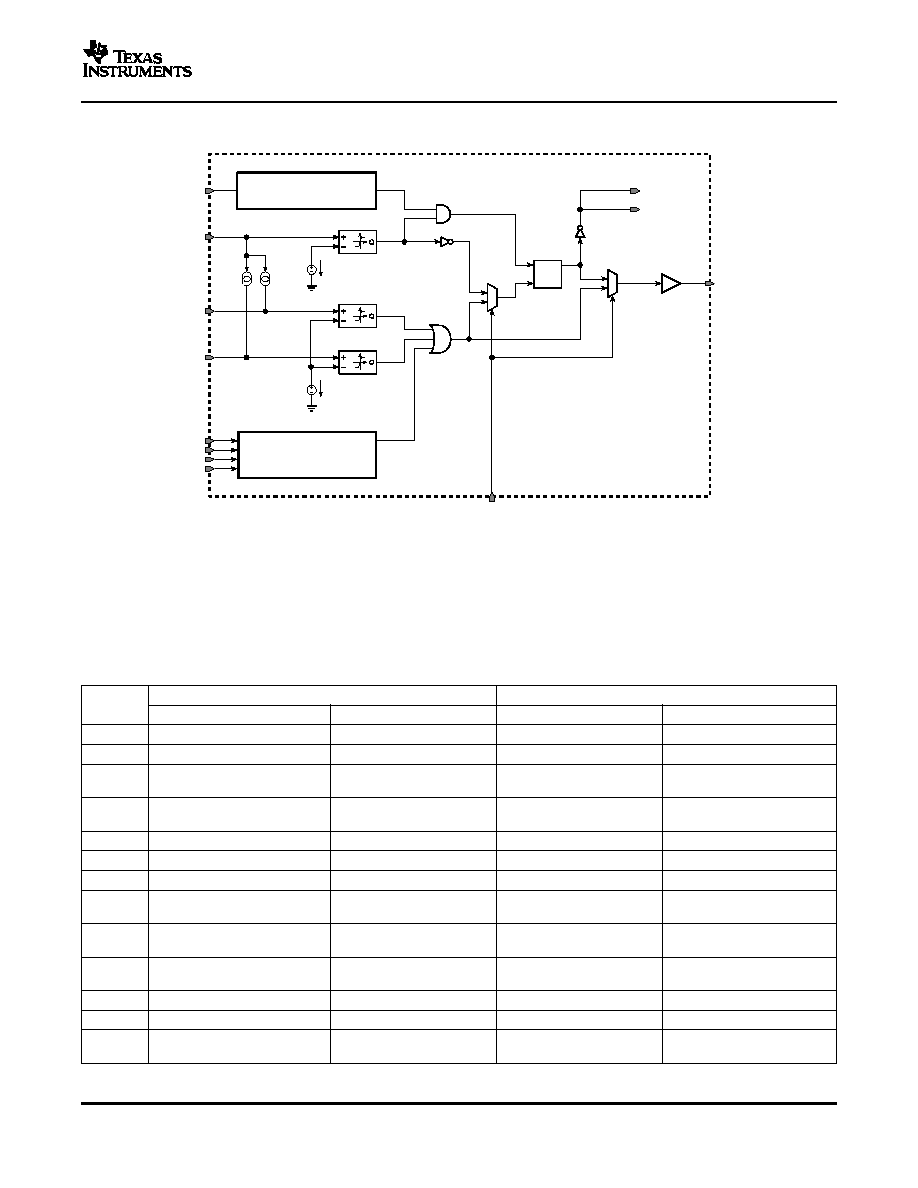

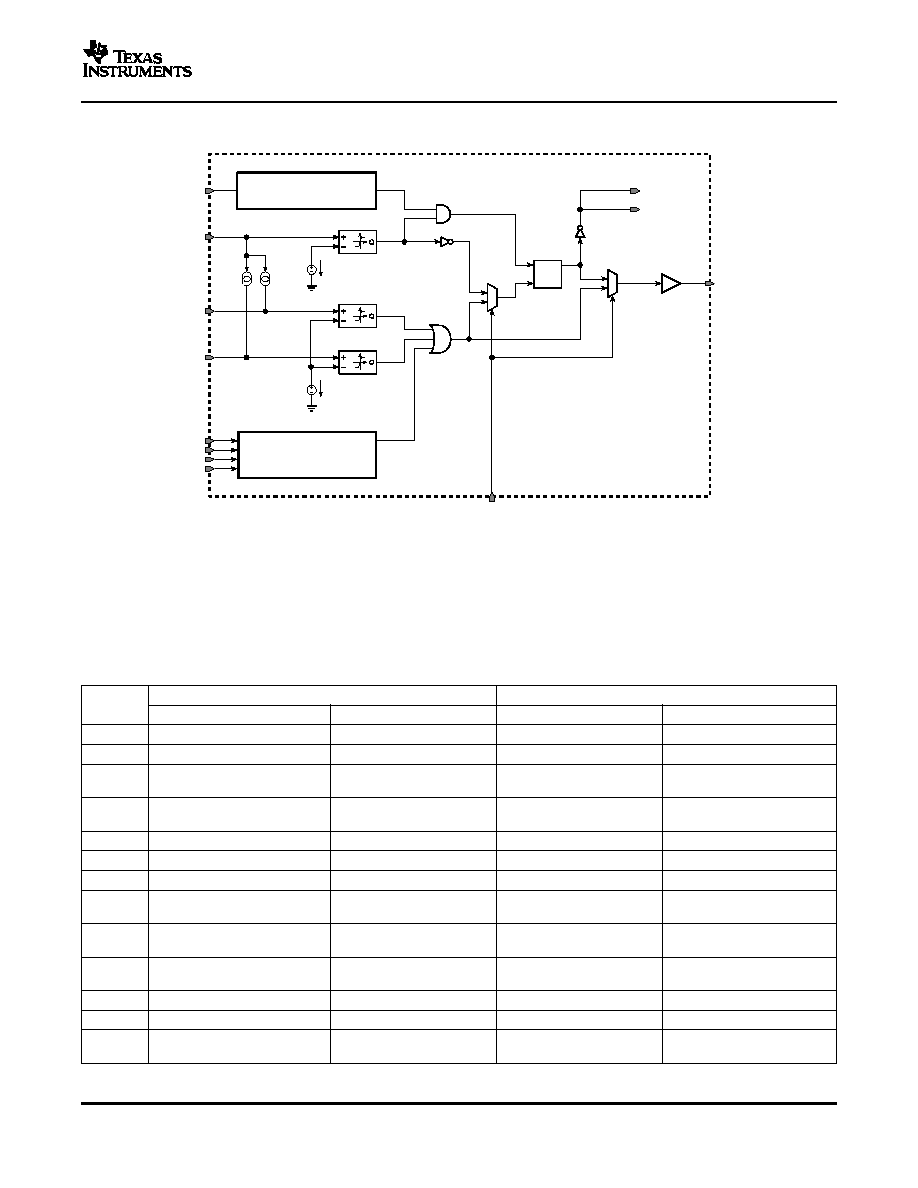

PACKAGE

GND

VCC

DIN+

DIN≠

GND

VCC

VCC

GND

MOD≠

MOD+

VCC

BIAS

ONET4201LD

24 Lead QFN

APCSET

DISABLE

OUTPOL

IBMAX

CAPC

PD

MONB

MONP

SDOWN

MODSET

MODTC

FL

TMODE

2

1

3

4

5

6

17

18

16

15

14

13

8

7

9

10 11 12

23

24

22 21 20 19

ONET4201LD

SLLS677 ≠ NOVEMBER 2005

DETAILED DESCRIPTION (continued)

Table 1. Response to I/O-Pin Shorts to VCC or GND (continued)

FLTMODE = LOW

FLTMODE = HIGH

PIN

Response to Short to GND

Response to Short to V

CC

Response to Short to GND

Response to Short to V

CC

APCSET

SDOWN latched high, I

BIAS

and

No fault, I

MOD

unaffected

SDOWN high, I

BIAS

and I

MOD

No fault

I

MOD

disabled

unaffected

MODSET

SDOWN latched high, I

BIAS

and

No fault, disables I

MOD

SDOWN high, I

BIAS

No fault, disables I

MOD

I

MOD

disabled

unaffected

IBMAX

SDOWN latched high, I

BIAS

and

SDOWN latched high, I

BIAS

SDOWN high, I

MOD

SDOWN high, I

MOD

unaffected

I

MOD

disabled

and I

MOD

disabled

unaffected

For the ONET4201LD, a small footprint 4 mm

◊

4 mm 24-lead QFN package is used, with a lead pitch of 0,5

mm. The pin out is shown in

Figure 3

.

In order to achieve the required low thermal resistance of about 38 K/W, which keeps the maximum junction

temperature below 115

∞

C, a good thermal connection of the exposed die pad is mandatory.

Figure 3. Pinout of the ONET4201LD in a 4 mm

◊

4 mm 24-Lead QFN Package (Top View)

TERMINAL FUNCTIONS

TERMINAL

I/O

DESCRIPTION

NO.

NAME

1, 6, 18, EP

GND

Supply

Circuit ground. The exposed die pad (EP) must be grounded.

2, 5, 14, 17

VCC

Supply

3.3 V

±

10% supply voltage

3

DIN+

CML-in

Non-inverted data input. On-chip 50-

terminated to VCC.

4

DIN≠

CML-in

Inverted data input. On-chip 50-

terminated to VCC.

7

MONP

Analog-out

Photodiode current monitor sources a current identical to the photodiode current

8

MONB

Analog-out

Bias current monitor sources 1/68 of the bias current

9

SDOWN

LVTTL-out

Fault detection flag

10

FLTMODE

CMOS-in

Fault mode selection input. If a low level is applied to this pin, any fault event is latched and the

bias and modulation currents are disabled in a fault condition. Toggling of DISABLE or VCC

resets the fault condition. If pin is set to a high level, fault events are flagged at the SDOWN

output but not latched. The bias and modulation currents are not disabled. SDOWN is reset

once the fault condition disappears.

11

MODSET

Analog-in

Set temperature independent modulation current with resistor to GND.

12

MODTC

Analog-in

Set modulation current temperature compensation with resistor to GND.

6

www.ti.com

ABSOLUTE MAXIMUM RATINGS

ONET4201LD

SLLS677 ≠ NOVEMBER 2005

TERMINAL FUNCTIONS (continued)

TERMINAL

I/O

DESCRIPTION

NO.

NAME

13

BIAS

Analog-out

Laser diode bias current sink. Connect to laser cathode.

15

MOD+

Analog-out

Laser modulation current output. Connect to laser cathode. Avoid usage of vias on board.

16

MOD≠

Analog-out

Complementary laser modulation current output. Connect to VCC adjacent to anode of laser

diode. Avoid usage of vias on board.

19

PD

Analog-in

Monitor photodiode input. Connect to photodiode anode for APC. Sinks the photodiode current

to GND.

20

CAPC

Analog

APC loop capacitor

21

IBMAX

Analog-in

Set maximum laser diode current with resistor to GND.

22

OUTPOL

LVTTL-in

Alters modulation current output polarity. Open or high: normal polarity, low: inverted polarity.

OUTPOL is pulled up internally. Normal polarity: when DIN+ is high current is sunk into MOD+.

23

APCSET

Analog-in

Set photodiode reference current with resistor to GND.

24

DISABLE

LVTTL-in

Disable modulation and bias current outputs.

over operating free-air temperature range (unless otherwise noted)

(1)

VALUE

UNIT

V

CC

Supply voltage

(2)

≠0.3 to 4

V

I

IBIAS

Current into BIAS

≠20 to 120

mA

I

IMOD+

, I

IMOD≠

Current into MOD+, MOD≠

≠ 20 to 120

mA

I

PD

Current into PD

≠5 to 5

mA

V

DIN+

, V

DIN≠,

V

DISABLE

,

Voltage at DIN+, DIN≠, DISABLE, MONB, MONP, FLTMODE, SDOWN

(2)

≠0.3 to 4

V

V

MONB

, V

MONP

, V

FLTMODE

,

V

SDOWN

V

CAPC

, V

IBMAX

, V

MODSET

,

Voltage at CAPC, IBMAX, MODSET, APCSET, MODTC

(2)

≠0.3 to 3

V

V

APCSET

, V

MODTC

V

MOD+

, V

MOD-

Voltage at MOD+, MOD≠

(2)

0.6 to VCC+1.5

V

V

BIAS

Voltage at BIAS

(2)

1 to 3.5

V

ESD rating at all pins except MOD+, MOD≠

2

ESD

kV (HBM)

ESD rating at MOD+, MOD-

1

T

J,max

Maximum junction temperature

150

∞

C

T

STG

Storage temperature range

≠65 to 150

∞

C

T

A

Characterized free-air operating temperature range

≠40 to 85

∞

C

T

LEAD

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds

260

∞

C

(1)

Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under recommended operating

conditions is not implied. Exposure to absolute≠maximum≠rated conditions for extended periods may affect device reliability.

(2)

All voltage values are with respect to network ground terminal.

7

www.ti.com

RECOMMENDED OPERATING CONDITIONS

DC ELECTRICAL CHARACTERISTICS

AC ELECTRICAL CHARACTERISTICS

ONET4201LD

SLLS677 ≠ NOVEMBER 2005

over operating free-air temperature range (unless otherwise noted)

MIN

NOM

MAX

UNIT

V

CC

Supply voltage

3

3.3

3.6

V

T

A

Operating free-air temperature

≠40

85

∞

C

over recommended operating conditions (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

V

CC

Supply voltage

3

3.3

3.6

V

I

MOD

= 30 mA, I

BIAS

= 20 mA (excluding I

MOD

, I

BIAS

)

32

mA

I

VCC

Supply current

I

MOD

= 60 mA, I

BIAS

= 100 mA (excluding I

MOD

, I

BIAS

)

55

mA

I

BIAS

Bias current range

100

mA

I

BIAS-OFF

Bias off-current

DISABLE = high or hard-fault mode; V

BIAS

3.5 V

25

µ

A

Bias overshoot

During module hot plugging. V

CC

turn on time must be

10%

0.8 s

Bias current temperature

APC open loop

≠480

480

ppm/

∞

C

stability

Bias current absolute

I

BIAS

1 mA

≠15%

15%

accuracy

(1)

I

BIAS

= 1 mA, T

A

= 25

∞

C

±

15%

Bias current monitor gain

I

BIAS

/I

MONB

68

mA/ mA

MONB and MONP threshold

A fault is never detected for V

MONB/P

1 V and a fault

1

1.25

1.35

V

range

always occurs for V

MONB/P

1.35 V

PD current monitor gain

I

PD

/I

MONP

1

mA/mA

V

ID

Differential input signal

200

1600

mVp-p

SDOWN output high voltage

I

OH

= 100

µ

A sourcing

2.4

V

SDOWN output low voltage

I

OL

= 1 mA sinking

0.4

V

DISABLE input impedance

4.7

7.4

10

k

DISABLE input high voltage

2

V

DISABLE input low voltage

0.8

V

V

PD

Monitor diode voltage

1.6

V

Monitor diode dc current range

18

1500

µ

A

(1)

Absolute accuracy refers to part-to-part variation.

Typical operating condition is at V

CC

= 3.3 V, I

MOD

= 30 mA, I

BIAS

= 20 mA and T

A

= 25

∞

C,

over recommended operating conditions (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

Data Rate

4.25

Gbps

I

MOD

Modulation current range

Current into MOD+/MOD≠ pin;

5

85

mA

V

MOD+

, V

MOD≠

0.6 V

I

MOD-

Modulation off-current

DISABLE = high or hard-fault occurred

25

µ

A

OFF

Modulation current stability

≠600

600

ppm/

∞

C

I

MOD

= 10 mA

±

40%

Modulation current absolute

I

MOD

= 50 mA

±

25%

accuracy

(1)

I

MOD

= 80 mA

±

20%

(1)

Absolute accuracy refers to part-to-part variation.

8

www.ti.com

V

HIGH

t

V

LOW

DISABLE

I

MOD

I

MOD-OFF

I

MOD

I

BIAS

I

BIAS-OFF

I

BIAS

t

t

T

OFF

t

V

HIGH

V

LOW

SDOWN

V

HIGH

t

V

LOW

DISABLE

I

MOD

I

MOD-OFF

I

MOD

I

BIAS

I

BIAS-OFF

I

BIAS

t

t

T

ON

t

V

HIGH

V

LOW

SDOWN

V

HIGH

t

V

LOW

DISABLE

I

MOD

I

MOD-OFF

I

MOD

I

BIAS

I

BIAS-OFF

I

BIAS

t

t

T

ON

t

V

HIGH

V

LOW

SDOWN

T

RESET

T

RESET

ONET4201LD

SLLS677 ≠ NOVEMBER 2005

AC ELECTRICAL CHARACTERISTICS (continued)

Typical operating condition is at V

CC

= 3.3 V, I

MOD

= 30 mA, I

BIAS

= 20 mA and T

A

= 25

∞

C,

over recommended operating conditions (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

R

MODTC

= 3.125 k

8300

Modulation current

ppm/

∞

C

temperature compensation

(2)

R

MODTC

= Open

630

t

r

Output rise time (20% to 80%)

V

MOD+

1 V, V

MOD≠

1 V, I

MOD

= 30 mA

55

75

ps

t

f

Output fall time (20% to 80%)

V

MOD+

1 V, V

MOD≠

1 V, I

MOD

= 30 mA

55

75

ps

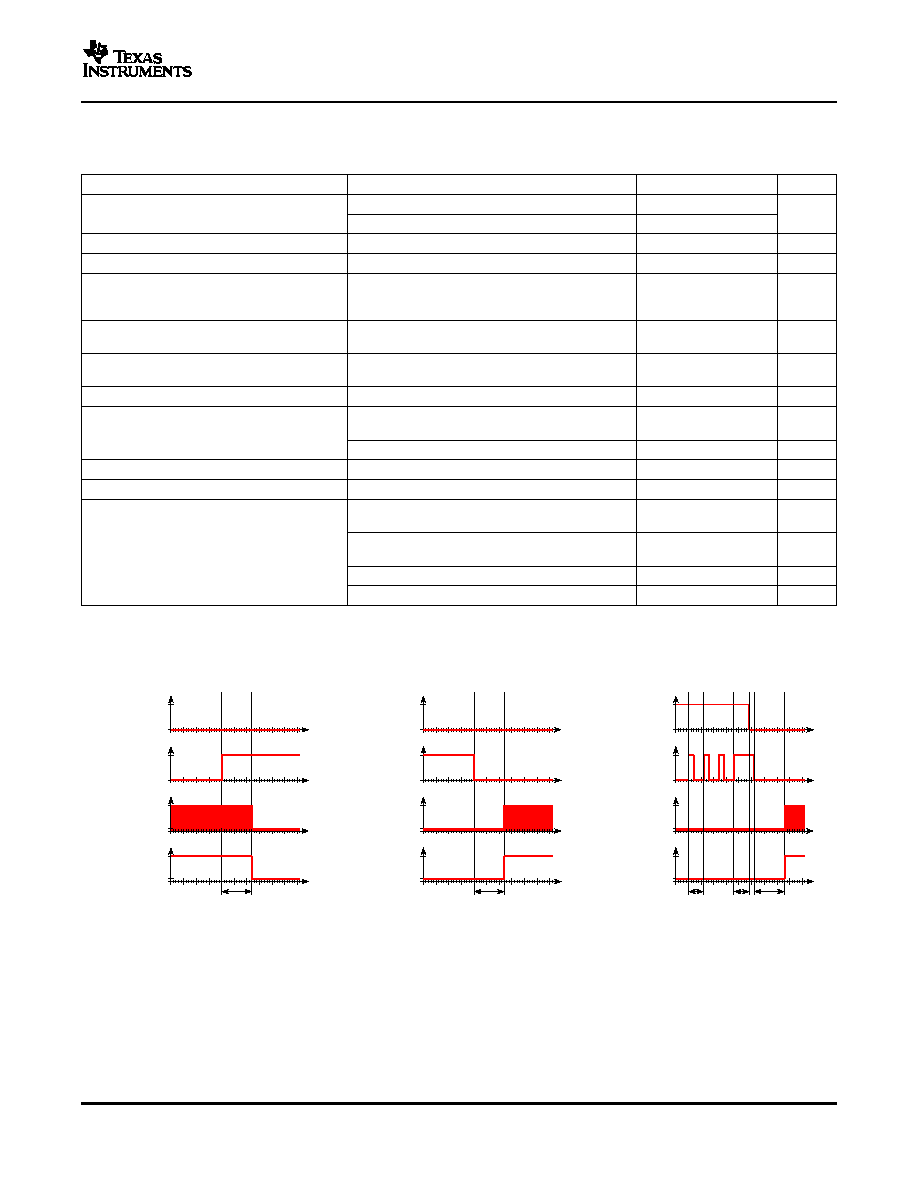

T

OFF

Disable assert time (see

Figure 4

)

Time from rising edge of DISABLE to when output

0.06

5

µ

s

currents fall below the max limits of I

MOD-OFF

and

I

BIAS-OFF

T

ON

Disable negate time (see

Figure 5

)

Time from falling edge of DISABLE to when output

200

µ

s

is 90% of nominal

T

INIT

Time to initialize

From power on or negation of SDOWN using

200

µ

s

DISABLE

T

FAULT

Fault assert time

Time from fault to SDOWN rising edge

3.3

50

µ

s

Maximum spike pulse length at DISABLE being

10

µ

s

ignored

T

RESET

DISABLE reset (see

Figure 6

)

Time DISABLE needs to be high to reset SDOWN

20

µ

s

Output overshoot/undershoot

≠13.5%

13.5%

Random jitter

I

MOD

= 60 mA

0.6

0.9

ps

RMS

10 mA

I

MOD

60 mA, with K28.5 pattern

15

30

ps

p-p

at 4.25 Gbps

10 mA

I

MOD

60 mA, with 2

23

≠1 PRBS or

13

32

ps

p-p

DJ

Deterministic jitter

(3)

equivalent pattern at 2.67 Gbps

K28.5 pattern at 1.06 Gbps

5

ps

p-p

2

23

≠ 1 PRBS or equivalent pattern at 155 Mbps

10

ps

p-p

(2)

For a given external resistor connected to the MODTC pin, the modulation current temperature compensation will vary due to

part-to-part variations.

(3)

Jitter measured at positive edge and negative edge crossing of eye diagram.

Figure 4. DISABLE Assert Time

Figure 5. DISABLE Negate Time

Figure 6. SDOWN Reset Time

TOFF

TON

TRESET

9

www.ti.com

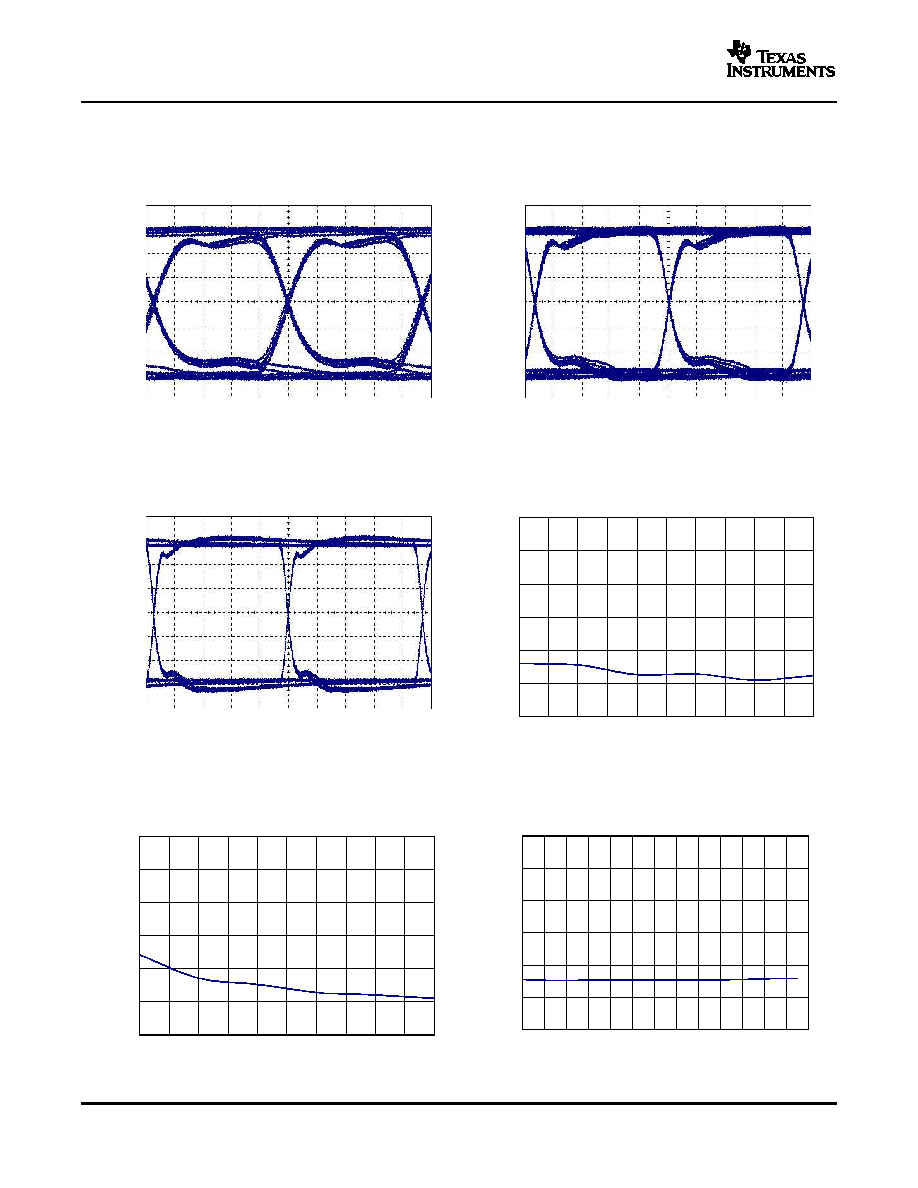

TYPICAL CHARACTERISTICS

Time [50ps/Div]

Single-Ended Output V

oltage

[50mV/Div]

Time [100ps/Div]

Single-Ended Output V

oltage

[50mV/Div]

Time [100ps/Div]

Single-Ended Output V

oltage

[50mV/Div]

Time [200ps/Div]

Single-Ended Output V

oltage

[50mV/Div]

Time [200ps/Div]

Single-Ended Output V

oltage

[50mV/Div]

Deterministic Jitter including PWD [ps

p-p

]

0

30

60

50

40

20

10

55

60

10

15

20

25

30

40

45

50

55

Modulation Current [mA]

0

1.5

3.0

2.5

2.0

1.0

0.5

10

90

-40

-30

-20

-10

0

50

60

70

80

40

30

20

Random Jitter [ps

RMS

]

0

1.5

3.0

2.5

2.0

1.0

0.5

10

90

-40

-30

-20

-10

0

50

60

70

80

40

30

20

Temperature [

5

C]

0

1.5

3.0

2.5

2.0

1.0

0.5

55

60

10

15

20

25

30

40

45

50

55

Random Jitter [ps

RMS

]

0

1.5

3.0

2.5

2.0

1.0

0.5

55

60

10

15

20

25

30

40

45

50

55

Modulation Current [mA]

ONET4201LD

SLLS677 ≠ NOVEMBER 2005

Typical operating condition is at V

CC

= 3.3 V, I

MOD

= 30 mA, I

BIAS

= 20 mA and T

A

= 25

∞

C (unless otherwise noted)

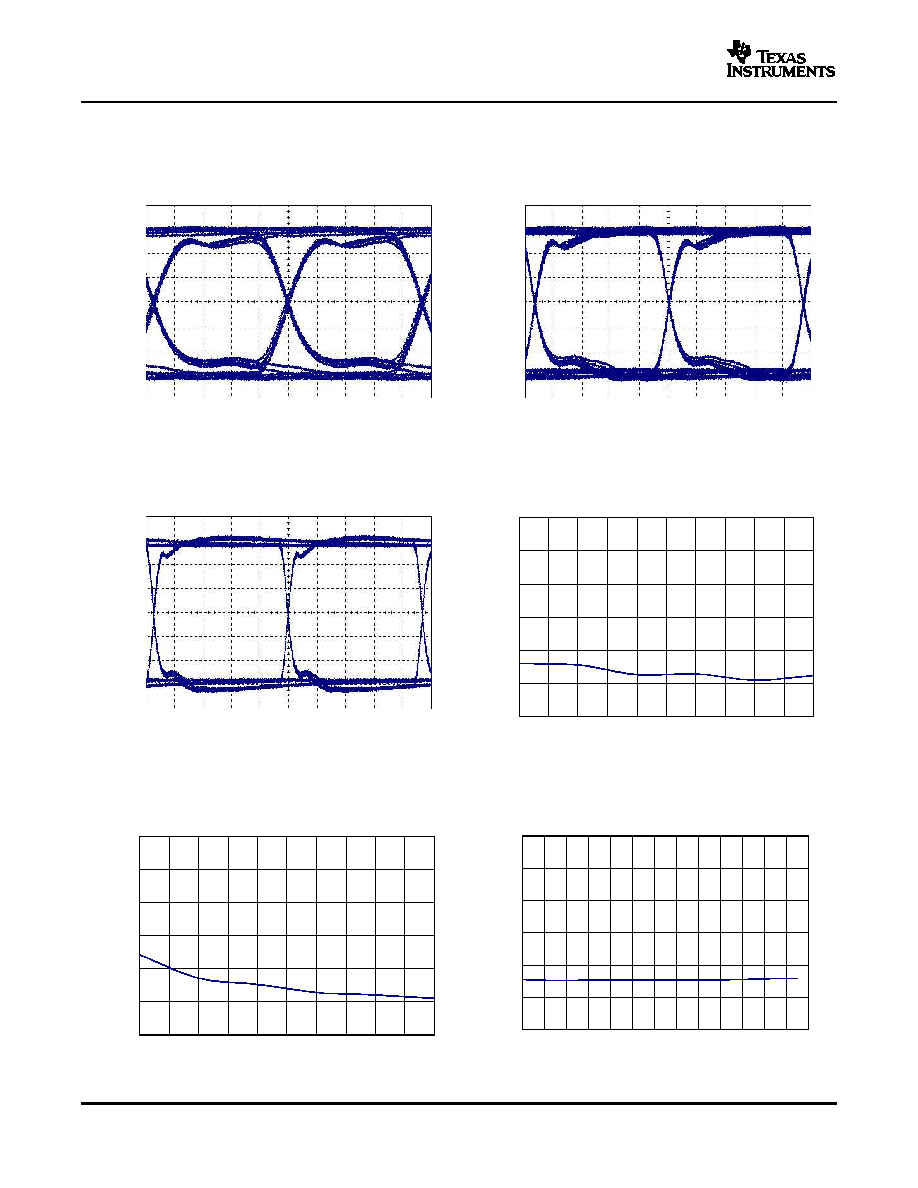

ELECTRICAL EYE-DIAGRAM AT 4.25 Gbps

ELECTRICAL EYE-DIAGRAM AT 2.125 Gbps

WITH K28.5 PATTERN, I

MOD

= 30 mA

WITH K28.5 PATTERN, I

MOD

= 30 mA

Figure 7.

Figure 8.

ELECTRICAL EYE-DIAGRAM AT 1.0625 Gbps

DETERMINISTIC JITTER

WITH K28.5 PATTERN, I

MOD

= 30 mA

vs

MODULATION CURRENT

Figure 9.

Figure 10.

RANDOM JITTER

RANDOM JITTER

vs

vs

MODULATION CURRENT

TEMPERATURE

Figure 11.

Figure 12.

10

www.ti.com

20

50

80

70

60

40

30

55

60

10

15

20

25

30

40

45

50

55

Rise Time

Fall Time

Rise Time and Fall Time [ps]

20

50

80

70

60

40

30

55

60

10

15

20

25

30

40

45

50

55

Modulation Current [mA]

Rise Time

Fall Time

10

13

20

15

14

12

11

16

17

18

19

55

60

10

15

20

25

30

40

45

50

55

Bias Monitor Current Gain [mA/A]

10

13

20

15

14

12

11

16

17

18

19

55

60

10

15

20

25

30

40

45

50

55

Bias Current [mA]

0

60

120

100

80

40

20

50

100

0

10

20

30

40

60

70

80

90

I

BIAS

[mA]

0

60

120

100

80

40

20

50

100

0

10

20

30

40

60

70

80

90

R

BIASMAX

[k

]

0

60

100

90

80

40

20

50

70

30

10

50

100

0

10

20

30

40

60

70

80

90

I

MOD

[mA]

0

60

100

90

80

40

20

50

70

30

10

50

100

0

10

20

30

40

60

70

80

90

R

MODSET

[k

]

ONET4201LD

SLLS677 ≠ NOVEMBER 2005

TYPICAL CHARACTERISTICS (continued)

Typical operating condition is at V

CC

= 3.3 V, I

MOD

= 30 mA, I

BIAS

= 20 mA and T

A

= 25

∞

C (unless otherwise noted)

RISE TIME AND FALL TIME

BIAS-MONITOR CURRENT GAIN I

MONB

/I

BIAS

vs

vs

MODULATION CURRENT

BIAS CURRENT I

BIAS

Figure 13.

Figure 14.

BIAS CURRENT I

BIAS

IN OPEN LOOP MODE

MODULATION CURRENT I

MOD

vs

vs

EXTERNAL RESISTOR R

BIASMAX

EXTERNAL RESISTOR R

MODSET

Figure 15.

Figure 16.

11

www.ti.com

Photodiode Monitor Gain [mA/mA]

0

1.5

3.0

2.5

2.0

1.0

0.5

10

90

-40

-30

-20

-10

0

50

60

70

80

40

30

20

Temperature [

5

C]

I

PD

[mA]

0.0

1.2

1.8

1.6

1.4

0.8

0.4

1.0

0.6

0.2

50

100

0

10

20

30

40

60

70

80

90

R

APCSET

[k

]

Bias Current Monitor Gain [mA/A]

10

14

20

18

16

12

10

90

-40

-30

-20

-10

0

50

60

70

80

40

30

20

Temperature [

5

C]

Supply Current [mA]

10

30

80

70

50

20

60

40

10

90

-40

-30

-20

-10

0

50

60

70

80

40

30

20

Temperature [

5

C]

Time [500ns/Div]

V

SDOWN

V

DISABLE

I

MOD+

I

BIAS

t = 2.21

µ

s

Time [100

m

s/Div]

V

SDOWN

V

DISABLE

I

MOD+

I

BIAS

t = 240

µ

s

Time [100

m

s/Div]

V

SDOWN

V

DISABLE

I

MOD+

I

BIAS

t = 240

µ

s

ONET4201LD

SLLS677 ≠ NOVEMBER 2005

TYPICAL CHARACTERISTICS (continued)

Typical operating condition is at V

CC

= 3.3 V, I

MOD

= 30 mA, I

BIAS

= 20 mA and T

A

= 25

∞

C (unless otherwise noted)

MONITOR DIODE CURRENT I

PD

PHOTO DIODE MONITOR GAIN I

MONP

/I

PD

vs

vs

EXTERNAL RESISTOR R

APCSET

TEMPERATURE

Figure 17.

Figure 18.

BIAS CURRENT MONITOR GAIN I

MONB

/I

BIAS

SUPPLY CURRENT (excl. I

MOD

and I

BIAS

)

vs

vs

TEMPERATURE

TEMPERATURE

Figure 19.

Figure 20.

DISABLE ASSERT TIME T

OFF

DISABLE NEGATE TIME T

ON

Figure 21.

Figure 22.

12

www.ti.com

Time [5

m

s/Div]

V

SDOWN

V

DISABLE

I

MOD+

I

BIAS

t = 12.8

µ

s

ONET4201LD

SLLS677 ≠ NOVEMBER 2005

TYPICAL CHARACTERISTICS (continued)

Typical operating condition is at V

CC

= 3.3 V, I

MOD

= 30 mA, I

BIAS

= 20 mA and T

A

= 25

∞

C (unless otherwise noted)

SHUTDOWN RESET TIME T

RESET

Figure 23.

13

www.ti.com

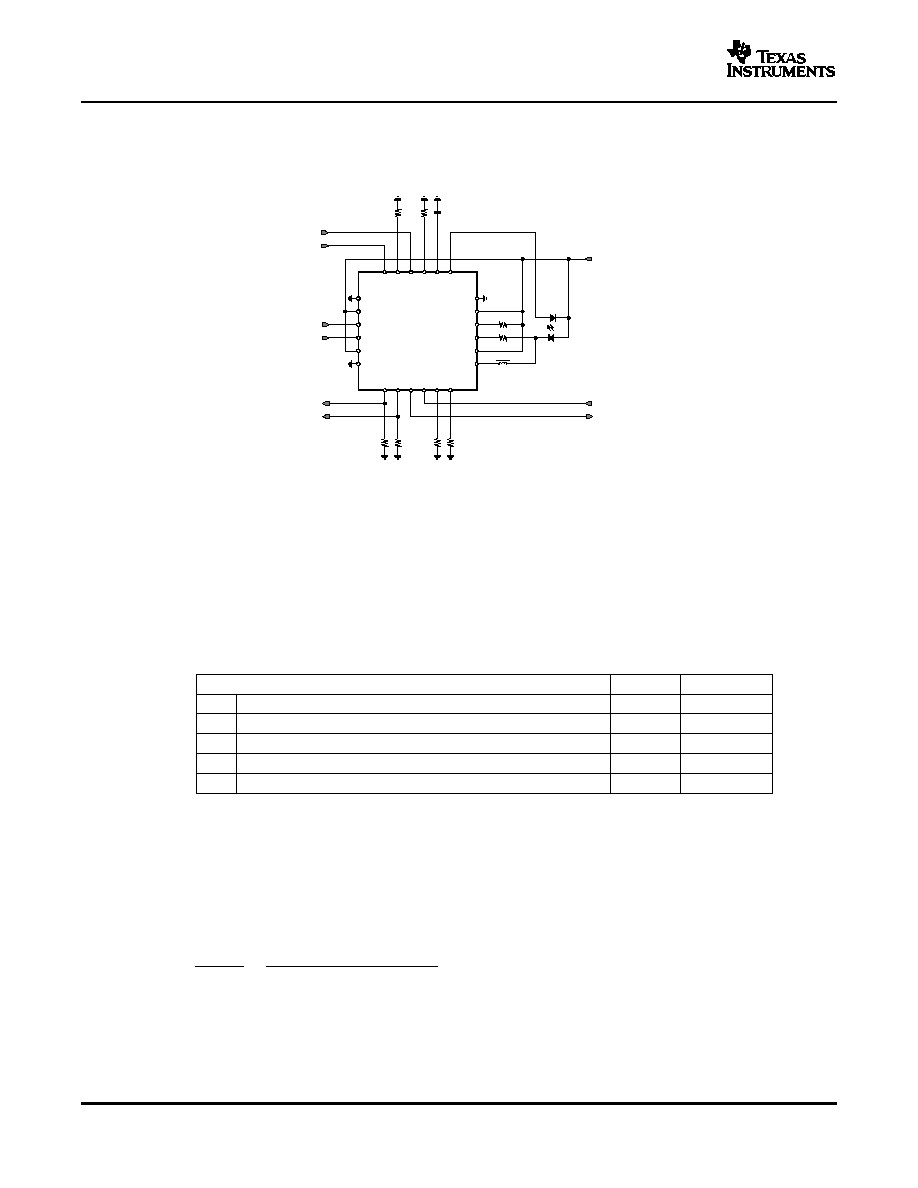

APPLICATION INFORMATION

VCC

DIN+

DIN≠

OUTPOL

MONP

FLTMODE

DISABLE

SDOWN

MONB

R

MONP

R

MONB

R

MODSET

R

MONTC

R

APCSET

R

BIASMAX

20

W

R

D

Laser-

diode

Monitor

Photodiode

C

APC

MONB

DIN+

DIN≠

MONP

MOD+

MOD≠

BIAS

PD

CAPC

OUTPOL

APCSET

DISABLE

VCC

GND

VCC

VCC

GND

VCC

GND

IBMAX

MODTC

MODSET

FL

TMODE

SDOWN

ONET4201LD

24 Lead QFN

SELECT A LASER

SELECT APCSET RESISTOR

I

PD

[A]

+

P

AVG

[W]

Ú

MON

[A W]

(7)

R

APCSET

[

W

]

+

4.69 V

I

PD

[A]

+

4.69 V

P

AVG

[W]

Ú

MON

[A W]

(8)

ONET4201LD

SLLS677 ≠ NOVEMBER 2005

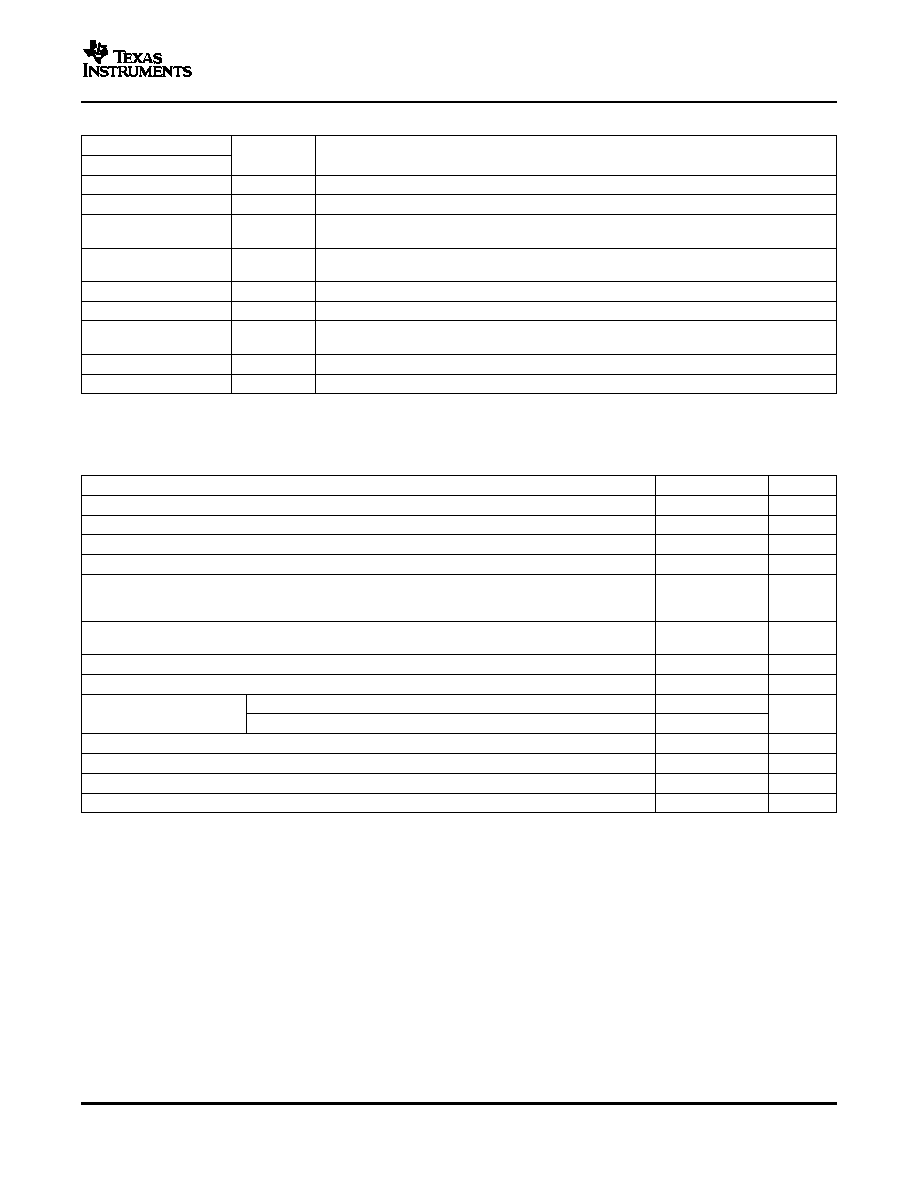

Figure 24

shows the ONET4201LD connected with a dc-coupled interface to the laser diode, alternatively the

ONET4201LD laser driver can be ac-coupled.

Figure 24. Basic Application Circuit With DC-Coupled Interface Between

the ONET4201LD and the Laser Diode

APC loop instability may occur with large inductive loading on the BIAS pin. To ensure loop stability in this case,

it is recommended to connect a 1-nF capacitor to ground at the BIAS pin.

In the design example according to

Figure 24

, the ONET4201LD is dc coupled to a typical communication-grade

laser diode capable of operating at 4.25 Gb/s with the following specifications shown in

Table 2

.

Table 2. Laser Diode Specifications

PARAMETER

VALUE

UNITS

Wavelength

1310

nm

P

AVG

Average Optical Output Power

5

mW

I

TH

Threshold current

10

mA

MON

Laser to Monitor Transfer

0.05

mA/mW

Laser Slope Efficiency

0.2

mW/mA

When the APC loop is activated, the desired average optical output power P

AVG

is defined by characteristics of

the monitor diode and by the APCSET resistor R

APCSET

. The relation between the monitor photodiode current IPD

and the average optical output power P

AVG

is given by

Equation 7

:

The R

APCSET

resistor is calculated by

Equation 8

:

14

www.ti.com

R

APCSET

[

W

]

+

4.69 V

P

AVG

[W]

Ú

MON

[A W]

+

4.69 V

5 mW

0.05 mA mW

+

18.75 k

W

(9)

SELECT MODSET RESISTOR

I

MOD

[A]

+

Pp

*

p[W]

h

[W A]

+

2

P

AVG

[W]

re

*

1

re

)

1

h

[W A]

(10)

I

MOD

+

2

5 mW

6.3

*

1

6.3

)

1

0.2 mW mA

+

36.3 mA

(11)

I

MOD

[A]

+

I

MOD0

[A]

1

)

TC

T[

o

C]

*

T

0

[

o

C]

(12)

R

MODSET

[

W

]

+

265 V

I

MOD

[A]

1

)

TC

T[

o

C]

*

T

0

[

o

C]

(13)

R

MODSET

[

W

]

+

265 V

36.3 mA

1

)

4000 ppm

o

C

(25

o

C

*

60

o

C)

+

6.3 k

W

(14)

SELECT MODTC RESISTOR

TC

LD

1

o

C

+

h

2

[W A]

* h

1

[W A]

h

1

[W A]

T

2

[

o

C]

*

T

1

[

o

C]

10

6

(15)

ONET4201LD

SLLS677 ≠ NOVEMBER 2005

For the laser diode specified in

Table 2

and the desired average optical output power of 5 mW, R

APCSET

is

calculated as seen in

Equation 9

:

Note that the monitor photodiode current I

PD

must not exceed 1.5 mA corresponding to a minimum APCSET

resistor R

APCSET,MIN

= 3.1 k

.

In dependence of the required optical output peak-to-peak power P

p-p

, or the average optical power P

AVG

the

necessary modulation current I

MOD

can be calculated using the laser slope efficiency

and the desired extinction

ratio r

e

:

Using the laser diode parameters from

Table 2

and assuming an extinction ratio r

e

= 8 dB (

6.3) for an average

optical power P

AVG

= 5 mW the required modulation current results as:

The modulation current is adjustable with a selectable temperature coefficient TC according to the relation:

Where T is the ambient temperature in

∞

C and T

0

is the reference temperature (T

0

= 60

∞

C).

The temperature coefficient of the modulation current TC is typically adjustable between 630 ppm/

∞

C and 8300

ppm/

∞

C.

For calculation of the required external resistor R

MODSET

for a given modulation current and a given temperature,

the formula can be modified as follows:

If 4000 ppm/

∞

C is the desired temperature coefficient and the modulation current from the example above, 36.3

mA, is required at a temperature of 25

∞

C, the MODSET resistor R

MODSET

is given by

Equation 14

.

Note that the modulation current I

MOD

must not exceed 85 mA over the complete temperature range

corresponding to a minimum MODSET resistor R

MODSET,MIN

= 3.1 k

.

The R

MODTC

resistor is used to program a modulation temperature coefficient that can be used to compensate for

the decreased slope efficiency of the laser at a higher temperature. The temperature coefficient TC

LD

of the laser

can be calculated using the slope efficiency

1

at temperature T

1

and

2

at temperature T

2

as shown in

Equation 15

:

As an example, for the laser in

Table 2

, the slope efficiency at temperature T

1

= 25

∞

C is

1

= 0.2 mW/mA. At

temperature T

2

= 85

∞

C the slope efficiency is

2

= 0.15 mW/mA. The corresponding temperature coefficient TC

LD

laser can be calculated:

15

www.ti.com

TC

LD

+

0.15 mW mA

*

0.2 mW mA

0.2 mW mA

(85

o

C

*

25

o

C)

10

6

+ *

4167 1

o

C

(16)

R

MODTC

+

24

W

(TC

*

630 ppm) 1

o

C

o

C

(17)

R

MODTC

+

24

W

4167 ppm

*

630 ppm

o

C

o

C

+

6.8 k

W

(18)

SELECT BIASMAX RESISTOR

I

BIASMAX

[A]

+

I

THMAX

[A]

(19)

R

BIASMAX

[

W

]

+

343 V

I

BIASMAX

[A]

+

343 V

I

THMAX

[A]

(20)

R

BIASMAX

+

343 V

40 mA

+

8.6 k

W

(21)

SELECT V

MONB

AND V

MONP

RANGE

V

MONB

[V]

+

R

MONB

[

W

]

I

BIAS

[A]

68

+

768

W

I

BIAS

[A]

68

+

11.29

W

I

BIAS

[A]

(22)

V

MONP

[V]

+

R

MONP

[

W

]

I

PD

[A]

+

200

W

I

PD

[A]

(23)

LASER DIODE INTERFACE

ONET4201LD

SLLS677 ≠ NOVEMBER 2005

The MODTC resistor R

MODTC

can be used to compensate the laser temperature coefficient TC

LD

in order to

maintain the same optical output swing within a range of 630 ppm up to 8300 ppm. For this, R

MODTC

may be

programmed as follows:

To compensate for the decreased slope efficiency of the laser in

Table 2

, T

C

needs to be 4167 ppm/

∞

C.

This leads to the following MODTC resistor R

MODTC

:

The BIASMAX resistor R

BIASMAX

is used to limit the bias current applied to the laser diode.

To calculate R

BIASMAX

, the maximum threshold current at 85

∞

C and end of life must be determined. The

maximum bias current for the dc-coupled interface can be approximated by

Equation 19

.

R

BIASMAX

can be set by the

Equation 20

.

For the example laser diode, the maximum threshold current is 40 mA at 85

∞

C. Therefore, R

BIASMAX

can be

approximated by

Equation 21

.

Monitoring the bias current is achieved by taking the fractional (1/68) bias current and developing a voltage

across an external resistor to ground.

Equation 22

provides the value for V

MONB

for a resistor value equal to

768

.

Monitoring of the photo current is achieved by taking a mirror of I

PD

and developing a voltage across an external

resistor to ground.

Equation 23

provides the value for V

MONP

for a resistor equal to 200

.

The output stage of the ONET4201LD is optimized for driving a 20-

load. The combination of a dampening

resistor, R

D

, along with the resistance of the laser diode needs to be 20

for impedance matching. The

suggested typical values for R

D

is 6

to 15

. A bypass capacitor of 10 nF placed close to the laser anode will

also help to optimize performance.

16

PACKAGING INFORMATION

Orderable Device

Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

(2)

Lead/Ball Finish

MSL Peak Temp

(3)

ONET4201LDRGER

ACTIVE

QFN

RGE

24

3000 Green (RoHS &

no Sb/Br)

CU NIPDAU

Level-2-260C-1 YEAR

ONET4201LDRGET

ACTIVE

QFN

RGE

24

250

Green (RoHS &

no Sb/Br)

CU NIPDAU

Level-2-260C-1 YEAR

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco

Plan

-

The

planned

eco-friendly

classification:

Pb-Free

(RoHS)

or

Green

(RoHS

&

no

Sb/Br)

-

please

check

http://www.ti.com/productcontent

for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

PACKAGE OPTION ADDENDUM

www.ti.com

21-Nov-2005

Addendum-Page 1

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI's terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI's standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty. Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products

Applications

Amplifiers

amplifier.ti.com

Audio

www.ti.com/audio

Data Converters

dataconverter.ti.com

Automotive

www.ti.com/automotive

DSP

dsp.ti.com

Broadband

www.ti.com/broadband

Interface

interface.ti.com

Digital Control

www.ti.com/digitalcontrol

Logic

logic.ti.com

Military

www.ti.com/military

Power Mgmt

power.ti.com

Optical Networking

www.ti.com/opticalnetwork

Microcontrollers

microcontroller.ti.com

Security

www.ti.com/security

Telephony

www.ti.com/telephony

Video & Imaging

www.ti.com/video

Wireless

www.ti.com/wireless

Mailing Address:

Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright

2005, Texas Instruments Incorporated