Document Outline

- FEATURES

- APPLICATIONS

- DESCRIPTION

- PACKAGE/ORDERING INFORMATION

- ABSOLUTE MAXIMUM RATINGS

- PIN CONFIGURATIONS

- ELECTRICAL CHARACTERISTICS: V S =+2.7V to +5.5V Single-Supply

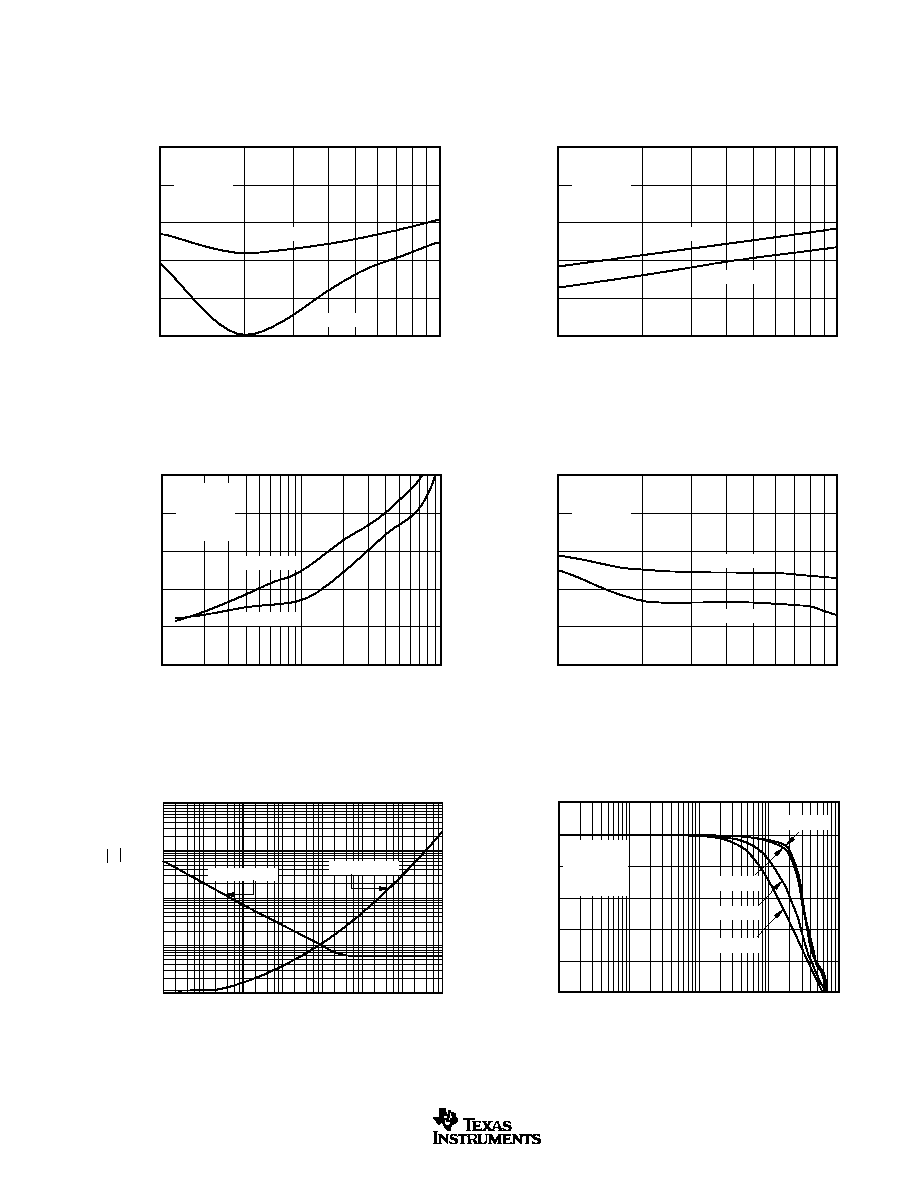

- TYPICAL CHARACTERISTICS

- APPLICATIONS INFORMATION

- OPERATING VOLTAGE

- RAIL-TO-RAIL INPUT

- RAIL-TO-RAIL OUTPUT

- OUTPUT DRIVE

- VIDEO

- DRIVING ANALOG- TO- DIGITAL CONVERTERS

- CAPACITIVE LOAD AND STABILITY

- WIDEBAND TRANSIMPEDANCE AMPLIFIER

- PCB LAYOUT

- POWER DISSIPATION

- PowerPAD THERMALLY ENHANCED PACKAGE

- PowerPAD ASSEMBLY PROCESS

- PACKAGE DRAWINGS

- DDA (S ÖPDSO ÖG8) Power PAD PLASTIC SMALL-OUTLINE

- DBV (R-PDSO-G5) PLASTIC SMALL-OUTLINE

- DGK (R-PDSO-G8) PLASTIC SMALL-OUTLINE PACKAGE

- D (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

- PW (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

www.ti.com

Copyright © 2002, Texas Instruments Incorporated

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

OPA354

OPA2354

OPA4354

SBOS233B ≠ FEBRUARY 2002 ≠ REVISED NOVEMBER 2002

DESCRIPTION

The OPA354 series of high-speed, voltage-feedback CMOS op-

erational amplifiers are designed for video and other applications

requiring wide bandwidth. They are unity-gain stable and can drive

large output currents. Differential gain is 0.02% and differential

phase is 0.09

∞

. Quiescent current is only 4.9mA per channel.

The OPA354 series op amps are optimized for operation on

single or dual supplies as low as 2.5V (

±

1.25V) and up to 5.5V

(

±

2.75V). Common-mode input range extends beyond the sup-

plies. The output swing is within 100mV of the rails, supporting

wide dynamic range.

For applications requiring the full 100mA continuous output

current, single and dual SO-8 PowerPAD versions are avail-

able.

The single version (OPA354) is available in the tiny SOT23-5 and

SO-8 PowerPAD packages. The dual version (OPA2354) comes

in the miniature MSOP-8 and SO-8 PowerPAD packages. The

quad version (OPA4354) is offered in TSSOP-14 and SO-14

packages.

Multichannel versions feature completely independent circuitry for

lowest crosstalk and freedom from interaction. All are specified

over the extended ≠40

∞

C to +125

∞

C temperature range.

FEATURES

q

UNITY-GAIN BANDWIDTH: 250MHz

q

WIDE BANDWIDTH: 100MHz GBW

q

HIGH SLEW RATE: 150V/

µ

s

q

LOW NOISE: 6.5nV/

Hz

q

RAIL-TO-RAIL I/O

q

HIGH OUTPUT CURRENT: > 100mA

q

EXCELLENT VIDEO PERFORMANCE:

Diff Gain: 0.02%, Diff Phase: 0.09

∞

0.1dB Gain Flatness: 40MHz

q

LOW INPUT BIAS CURRENT: 3pA

q

QUIESCENT CURRENT: 4.9mA

q

THERMAL SHUTDOWN

q

SUPPLY RANGE: 2.5V to 5.5V

q

MicroSIZE AND PowerPAD

TM

PACKAGES

250MHz, Rail-to-Rail I/O, CMOS

OPERATIONAL AMPLIFIERS

APPLICATIONS

q

VIDEO PROCESSING

q

ULTRASOUND

q

OPTICAL NETWORKING, TUNABLE LASERS

q

PHOTODIODE TRANSIMPEDANCE AMPS

q

ACTIVE FILTERS

q

HIGH-SPEED INTEGRATORS

q

ANALOG-TO-DIGITAL (A/D) CONVERTER

INPUT BUFFERS

q

DIGITAL-TO-ANALOG (D/A) CONVERTER

OUTPUT AMPLIFIERS

q

BARCODE SCANNERS

q

COMMUNICATIONS

OPAx354 RELATED PRODUCTS

FEATURES

PRODUCT

Shutdown Version of the OPA354 Family

OPAx357

200MHz GBW, Rail-to-Rail Output, CMOS, Shutdown

OPAx355

200MHz GBW, Rail-to-Rail Output, CMOS

OPAx356

38MHz GBW, Rail-to-Rail Input/Output, CMOS

OPAx350/3

75MHz BW G = 2, Rail-to-Rail Output

OPAx631

150MHz BW G = 2, Rail-to-Rail Output

OPAx634

100MHz BW, Differential Input/Output, 3.3V Supply

THS412x

PowerPAD is a trademark of Texas Instruments.

Æ

OPA4

354

OPA3

54

OPA4

354

OPA354

V

OUT

V+

V≠

≠V

IN

+V

IN

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

OPA354, OPA2354, OPA4354

2

SBOS233B

www.ti.com

ABSOLUTE MAXIMUM RATINGS

(1)

Supply Voltage, V+ to V≠ ................................................................... 7.5V

Signal Input Terminals, Voltage

(2)

.................... (V≠) ≠ 0.5V to (V+) + 0.5V

Current

(2)

..................................................... 10mA

Output Short-Circuit

(3)

.............................................................. Continuous

Operating Temperature .................................................. ≠55

∞

C to +150

∞

C

Storage Temperature ...................................................... ≠65

∞

C to +150

∞

C

Junction Temperature .................................................................... +150

∞

C

Lead Temperature (soldering, 10s) ............................................... +300

∞

C

NOTES: (1) Stresses above these ratings may cause permanent damage.

Exposure to absolute maximum conditions for extended periods may degrade

device reliability. These are stress ratings only, and functional operation of the

device at these or any other conditions beyond those specified is not implied.

(2) Input terminals are diode-clamped to the power-supply rails. Input signals

that can swing more than 0.5V beyond the supply rails should be current limited

to 10mA or less. (3) Short-circuit to ground, one amplifier per package.

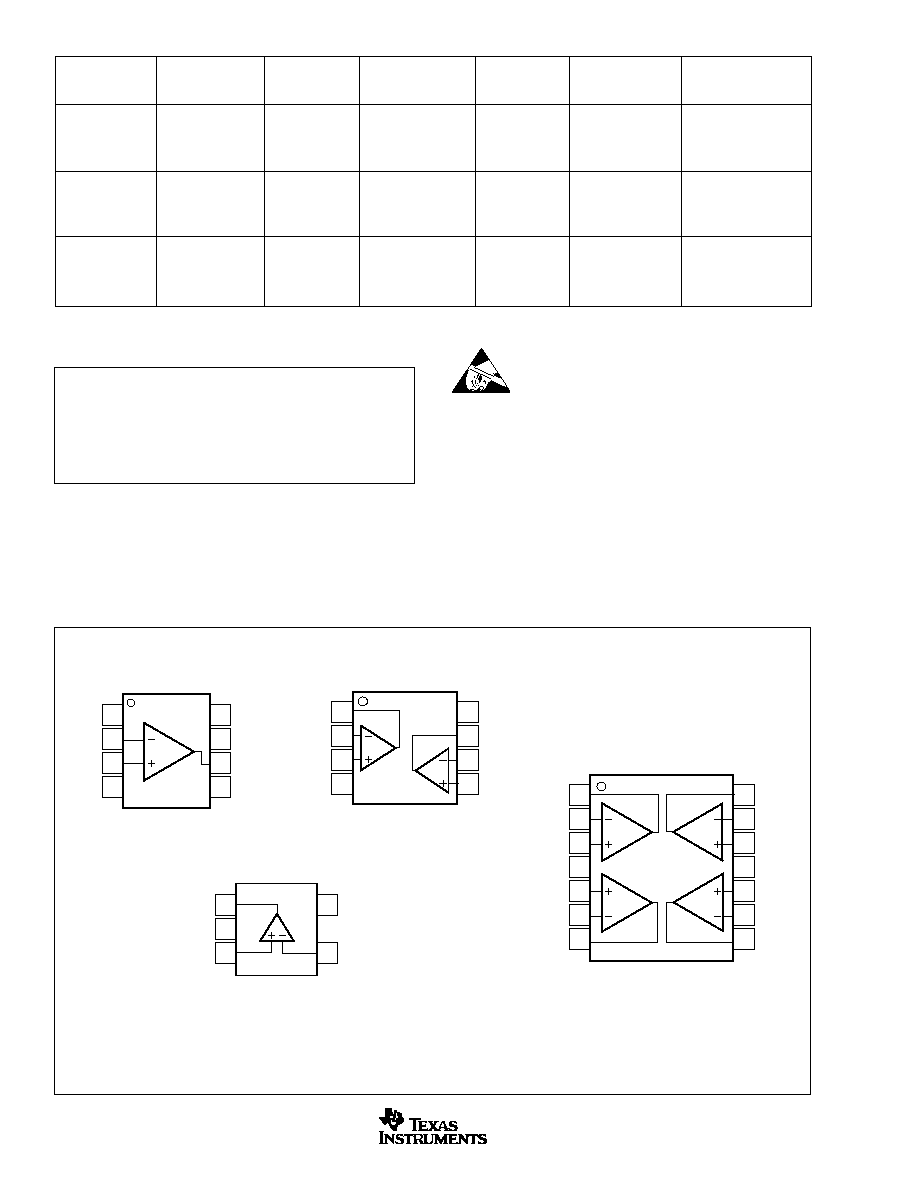

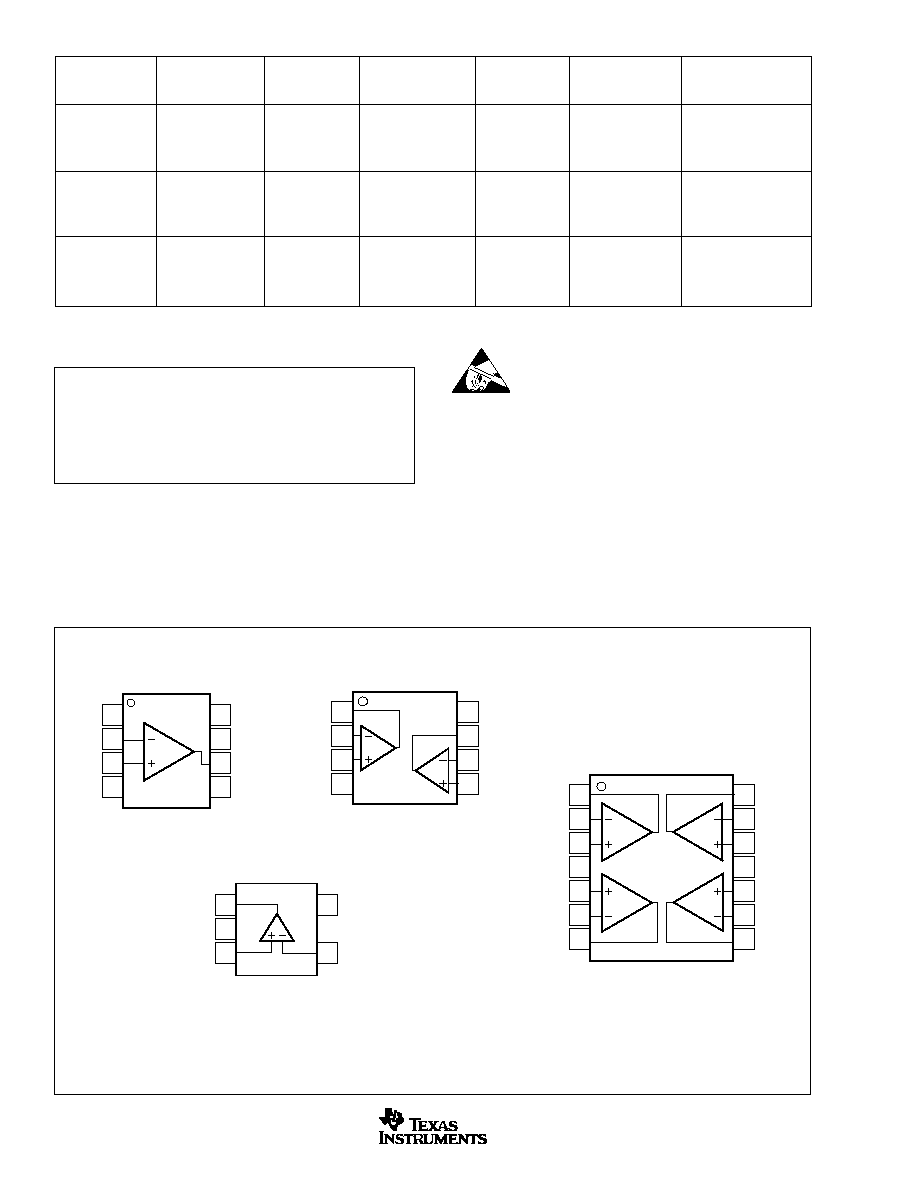

PACKAGE/ORDERING INFORMATION

PIN CONFIGURATIONS

Top View

ELECTROSTATIC

DISCHARGE SENSITIVITY

This integrated circuit can be damaged by ESD. Texas

Instruments recommends that all integrated circuits be handled

with appropriate precautions. Failure to observe proper han-

dling and installation procedures can cause damage.

ESD damage can range from subtle performance degrada-

tion to complete device failure. Precision integrated circuits

may be more susceptible to damage because very small

parametric changes could cause the device not to meet its

published specifications.

1

2

3

4

8

7

6

5

NC

(1)

V+

Out

NC

(1)

NC

(1)

≠In

+In

V≠

OPA354

SO PowerPAD

(2)

1

2

3

5

4

V+

≠In

Out

V≠

+In

OPA354

SOT23

1

2

3

4

8

7

6

5

V+

Out B

≠In B

+In B

Out A

≠In A

+In A

V≠

OPA2354

SO PowerPAD

(2)

MSOP

A

B

1

2

3

4

5

6

7

14

13

12

11

10

9

8

Out D

≠In D

+In D

V≠

+In C

≠In C

Out C

Out A

≠In A

+In A

V+

+In B

≠In B

Out B

OPA4354

SO

TSSOP

B

C

D

A

NOTES: (1) NC means no internal connection. (2) PowerPAD should be connected to V≠ or left floating.

SPECIFIED

PACKAGE

TEMPERATURE

PACKAGE

ORDERING

TRANSPORT

PRODUCT

PACKAGE-LEAD

DESIGNATOR

(1)

RANGE

MARKING

NUMBER

MEDIA, QUANTITY

OPA354

SO-8 PowerPAD

DDA

≠40

∞

C to +125

∞

C

OPA354A

OPA354AIDDA

Rails, 97

"

"

"

"

"

OPA354AIDDAR

Tape and Reel, 2500

OPA354

SOT23-5

DBV

≠40

∞

C to +125

∞

C

OABI

OPA354AIDBVT

Tape and Reel, 250

"

"

"

"

"

OPA354AIDBVR

Tape and Reel, 3000

OPA2354

SO-8 PowerPAD

DDA

≠40

∞

C to +125

∞

C

OPA2354A

OPA2354AIDDA

Rails, 97

"

"

"

"

"

OPA2354AIDDAR

Tape and Reel, 2500

OPA2354

MSOP-8

DGK

≠40

∞

C to +125

∞

C

OACI

OPA2354AIDGKT

Tape and Reel, 250

"

"

"

"

"

OPA2354AIDGKR

Tape and Reel, 2500

OPA4354

SO-14

D

≠40

∞

C to +125

∞

C

OPA4354A

OPA4354AID

Rails, 58

"

"

"

"

"

OPA4354AIDR

Tape and Reel, 2500

OPA4354

TSSOP-14

PW

≠40

∞

C to +125

∞

C

OPA4354A

OPA4354AIPWT

Tape and Reel, 250

"

"

"

"

"

OPA4354AIPWR

Tape and Reel, 2500

NOTE: (1) For the most current specifications and package information, refer to our web site at www.ti.com.

OPA354, OPA2354, OPA4354

3

SBOS233B

www.ti.com

OPA354AI,

OPA2354AI, OPA4354AI

PARAMETER

CONDITION

MIN

TYP

MAX

UNITS

OFFSET VOLTAGE

Input Offset Voltage

V

OS

V

S

= +5V

±

2

±

8

mV

Specified Temperature Range

±

10

mV

vs Temperature

dV

OS

/dT

Specified Temperature Range

±

4

µ

V/

∞

C

vs Power Supply

PSRR

V

S

= +2.7V to +5.5V, V

CM

= (V

S

/2) ≠ 0.15V

±

200

±

800

µ

V/V

Specified Temperature Range

±

900

µ

V/V

INPUT BIAS CURRENT

Input Bias Current

I

B

3

±

50

pA

Input Offset Current

I

OS

±

1

±

50

pA

NOISE

Input Noise Voltage Density

e

n

f = 1MHz

6.5

nV/

Hz

Current Noise Density

i

n

f = 1MHz

50

fA/

Hz

INPUT VOLTAGE RANGE

Common-Mode Voltage Range

V

CM

(V≠) ≠ 0.1V

(V+) + 0.1V

V

Common-Mode Rejection Ratio

CMRR

V

S

= +5.5V, ≠0.1V < V

CM

< +3.5V

66

80

dB

Specified Temperature Range

64

dB

V

S

= +5.5V, ≠0.1V < V

CM

< +5.6V

56

68

dB

Specified Temperature Range

55

dB

INPUT IMPEDANCE

Differential

10

13

|| 2

|| pF

Common-Mode

10

13

|| 2

|| pF

OPEN-LOOP GAIN

A

OL

V

S

= +5V, +0.3V < V

O

< +4.7V

94

110

dB

Specified Temperature Range

V

S

= +5V, +0.4V < V

O

< +4.6V

90

dB

FREQUENCY RESPONSE

Small-Signal Bandwidth

f

≠3dB

G = +1, V

O

= 100mVp-p, R

F

= 25

250

MHz

f

≠3dB

G = +2, V

O

= 100mVp-p

90

MHz

Gain-Bandwidth Product

GBW

G = +10

100

MHz

Bandwidth for 0.1dB Gain Flatness

f

0.1dB

G = +2, V

O

= 100mVp-p

40

MHz

Slew Rate

SR

V

S

= +5V, G = +1, 4V Step

150

V/

µ

s

V

S

= +5V, G = +1, 2V Step

130

V/

µ

s

V

S

= +3V, G = +1, 2V Step

110

V/

µ

s

Rise-and-Fall Time

G = +1, V

O

= 200mVp-p, 10% to 90%

2

ns

G = +1, V

O

= 2Vp-p, 10% to 90%

11

ns

Settling Time, 0.1%

V

S

= +5V, G = +1, 2V Output Step

30

ns

0.01%

60

ns

Overload Recovery Time

V

IN

∑ Gain = V

S

5

ns

Harmonic Distortion

2nd-Harmonic

G = +1, f = 1MHz, V

O

= 2Vp-p, R

L

= 200

, V

CM

= 1.5V

≠75

dBc

3rd-Harmonic

G = +1, f = 1MHz, V

O

= 2Vp-p, R

L

= 200

, V

CM

= 1.5V

≠83

dBc

Differential Gain Error

NTSC, R

L

= 150

0.02

%

Differential Phase Error

NTSC, R

L

= 150

0.09

degrees

Channel-to-Channel Crosstalk, OPA2354

f = 5MHz

≠100

dB

OPA4354

≠84

dB

OUTPUT

Voltage Output Swing from Rail

V

S

= +5V, R

L

= 1k

, A

OL

> 94dB

0.1

0.3

V

Specified Temperature Range

V

S

= +5V, R

L

= 1k

, A

OL

> 90dB

0.4

V

Output Current

(1)(2)

, Single, Dual, Quad

I

O

V

S

= +5V

100

mA

V

S

= +3V

50

mA

Closed-Loop Output Impedance

f < 100kHz

0.05

POWER SUPPLY

Specified Voltage Range

V

S

2.7

5.5

V

Operating Voltage Range

2.5 to 5.5

V

Quiescent Current (per amplifier)

I

Q

V

S

= +5V, Enabled, I

O

= 0

4.9

6

mA

Specified Temperature Range

7.5

mA

THERMAL SHUTDOWN

Junction Temperature

Shutdown

160

∞

C

Reset from Shutdown

140

∞

C

TEMPERATURE RANGE

Specified Range

≠40

125

∞

C

Operating Range

≠55

150

∞

C

Storage Range

≠65

150

∞

C

Thermal Resistance

JA

∞

C/W

SOT23-5, MSOP-8

150

∞

C/W

TSSOP-14

100

∞

C/W

SO-14

100

∞

C/W

SO-8 PowerPAD

65

∞

C/W

ELECTRICAL CHARACTERISTICS:

V

S

= +2.7V to +5.5V Single-Supply

Boldface limits apply over the specified temperature range, T

A

= ≠40

∞

C to +125

∞

C.

At T

A

= +25

∞

C, R

F

= 0

, R

L

= 1k

, and connected to V

S

/2, unless otherwise noted.

NOTES: (1) See typical characteristic "Output Voltage Swing vs Output Current." (2) Specified by design.

OPA354, OPA2354, OPA4354

4

SBOS233B

www.ti.com

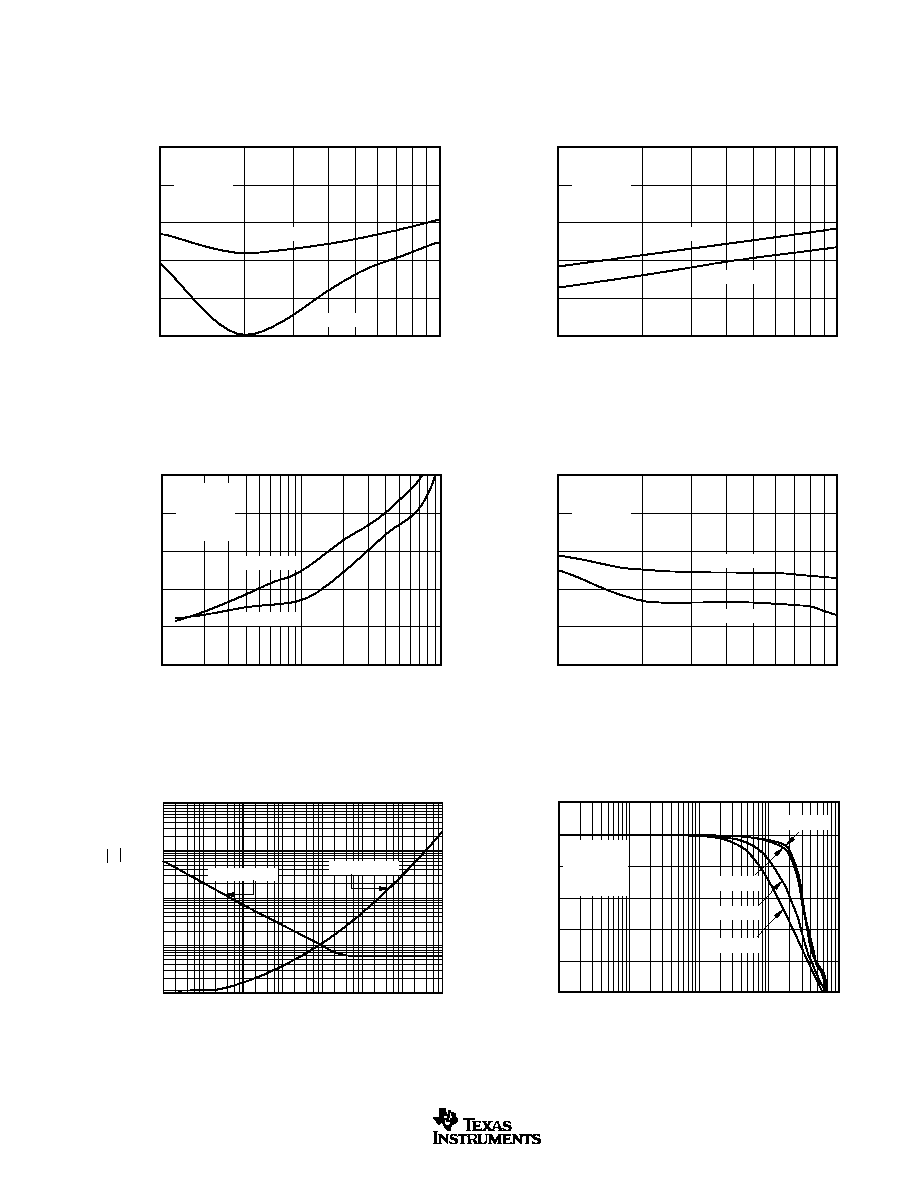

TYPICAL CHARACTERISTICS

At T

A

= +25

∞

C, V

S

= 5V, G = +1, R

F

= 0

, R

L

= 1k

, and connected to V

S

/2, unless otherwise noted.

NONINVERTING SMALL-SIGNAL

FREQUENCY RESPONSE

Frequency (Hz)

Normalized Gain (dB)

10M

1M

100M

1G

100k

3

0

≠3

≠6

≠9

≠12

≠15

V

O

= 0.1Vp-p

G = +2, R

F

= 604

G = +1

R

F

= 25

G = +5, R

F

= 604

G = +10, R

F

= 604

INVERTING SMALL-SIGNAL

FREQUENCY RESPONSE

Frequency (Hz)

Normalized Gain (dB)

10M

1M

100M

1G

100k

3

0

≠3

≠6

≠9

≠12

≠15

V

O

= 0.1Vp-p, R

F

= 604

G = ≠1

G = ≠5

G = ≠10

G = ≠2

NONINVERTING SMALL-SIGNAL STEP RESPONSE

Time (20ns/div)

Output V

oltage (40mV/div)

NONINVERTING LARGE-SIGNAL STEP RESPONSE

Time (20ns/div)

Output V

oltage (500mV/div)

0.1dB GAIN FLATNESS

Frequency (Hz)

Normalized Gain (dB)

10M

1M

100M

1G

100k

0.5

0.4

0.3

0.2

0.1

0

≠0.1

≠0.2

≠0.3

≠0.4

≠0.5

V

O

= 0.1Vp-p

G = +1

R

F

= 25

G = +2

R

F

= 604

HARMONIC DISTORTION vs OUTPUT VOLTAGE

Output Voltage (Vp-p)

Harmonic Distortion (dBc)

2

1

3

4

0

≠50

≠60

≠70

≠80

≠90

≠100

G = ≠1

f = 1MHz

R

L

= 200

3rd-Harmonic

2nd-Harmonic

OPA354, OPA2354, OPA4354

5

SBOS233B

www.ti.com

TYPICAL CHARACTERISTICS

(Cont.)

At T

A

= +25

∞

C, V

S

= 5V, G = +1, R

F

= 0

, R

L

= 1k

, and connected to V

S

/2, unless otherwise noted.

HARMONIC DISTORTION vs NONINVERTING GAIN

Gain (V/V)

Harmonic Distortion (dBc)

10

1

≠50

≠60

≠70

≠80

≠90

≠100

V

O

= 2Vp-p

f = 1MHz

R

L

= 200

3rd-Harmonic

2nd-Harmonic

HARMONIC DISTORTION vs INVERTING GAIN

Gain (V/V)

Harmonic Distortion (dBc)

10

1

≠50

≠60

≠70

≠80

≠90

≠100

V

O

= 2Vp-p

f = 1MHz

R

L

= 200

3rd-Harmonic

2nd-Harmonic

HARMONIC DISTORTION vs FREQUENCY

Frequency (Hz)

Harmonic Distortion (dBc)

10M

1M

100k

≠50

≠60

≠70

≠80

≠90

≠100

G = +1

V

O

= 2Vp-p

R

L

= 200

V

CM

= 1.5V

3rd-Harmonic

2nd-Harmonic

HARMONIC DISTORTION vs LOAD RESISTANCE

R

L

(

)

Harmonic Distortion (dBc)

1k

100

≠50

≠60

≠70

≠80

≠90

≠100

G = +1

V

O

= 2Vp-p

f = 1MHz

V

CM

= 1.5V

3rd-Harmonic

2nd-Harmonic

FREQUENCY RESPONSE FOR VARIOUS R

L

Frequency (Hz)

Normalized Gain (dB)

10M

1M

100M

1G

100k

3

0

≠3

≠6

≠9

≠12

≠15

R

L

= 10k

R

L

= 100

R

L

= 1k

R

L

= 50

G = +1

R

F

= 0

V

O

= 0.1Vp-p

C

L

= 0pF

INPUT VOLTAGE AND CURRENT NOISE

SPECTRAL DENSITY vs FREQUENCY

Frequency (Hz)

V

oltage Noise (nV/

Hz),

Current Noise (fA/

Hz)

100M

10

100

1k

10k

100k

1M

10M

10k

1k

100

10

1

Current Noise

Voltage Noise

OPA354, OPA2354, OPA4354

6

SBOS233B

www.ti.com

TYPICAL CHARACTERISTICS

(Cont.)

At T

A

= +25

∞

C, V

S

= 5V, G = +1, R

F

= 0

, R

L

= 1k

, and connected to V

S

/2, unless otherwise noted.

FREQUENCY RESPONSE FOR VARIOUS C

L

Frequency (Hz)

Normalized Gain (dB)

10M

1M

100M

1G

100k

9

6

3

0

≠3

≠6

≠9

≠12

≠15

C

L

= 100pF

C

L

= 47pF

C

L

= 5.6pF

G = +1

V

O

= 0.1Vp-p

R

S

= 0

RECOMMENDED R

S

vs CAPACITIVE LOAD

Capacitive Load (pF)

R

S

(

)

100

10

1k

1

160

140

120

100

80

60

40

20

0

OPA354

C

L

R

S

V

IN

V

O

1k

For 0.1dB

Flatness

FREQUENCY RESPONSE vs CAPACITIVE LOAD

Frequency (Hz)

Normalized Gain (dB)

100M

10M

1M

1G

100k

3

0

≠3

≠6

≠9

≠12

≠15

OPA354

C

L

R

S

V

IN

V

O

1k

C

L

= 47pF, R

S

= 140

C

L

= 100pF, R

S

= 120

C

L

= 5.6pF, R

S

= 0

G = +1,

V

O

= 0.1Vp-p

COMMON-MODE REJECTION RATIO AND

POWER-SUPPLY REJECTION RATIO vs FREQUENCY

Frequency (Hz)

CMRR, PSRR (dB)

10k

100k

1M

10M

100M

1G

100

80

60

40

20

0

PSRR≠

PSRR+

CMRR

OPEN-LOOP GAIN AND PHASE

Frequency (Hz)

Open-Loop Phase (degrees)

Open-Loop Gain (dB)

10

100

1k

100k

10k

1M

10M

1G

100M

180

160

140

120

100

80

60

40

20

0

≠20

≠40

Phase

Gain

COMPOSITE VIDEO

DIFFERENTIAL GAIN AND PHASE

Number of 150

Loads

dG/dP

(%/degrees)

3

2

4

1

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

dP

dG

OPA354, OPA2354, OPA4354

7

SBOS233B

www.ti.com

TYPICAL CHARACTERISTICS

(Cont.)

At T

A

= +25

∞

C, V

S

= 5V, G = +1, R

F

= 0

, R

L

= 1k

, and connected to V

S

/2, unless otherwise noted.

MAXIMUM OUTPUT VOLTAGE vs FREQUENCY

Frequency (MHz)

Output V

oltage (Vp-p)

10

100

1

6

5

4

3

2

1

0

V

S

= 5.5V

V

S

= 2.7V

Maximum Output

Voltage without

Slew-Rate

Induced Distortion

CLOSED-LOOP OUTPUT IMPEDANCE vs FREQUENCY

Frequency (Hz)

Output Impedance (

)

10M

100M

1M

1G

100k

100

10

1

0.1

0.01

OPA354

Z

O

OUTPUT VOLTAGE SWING vs OUTPUT CURRENT

FOR V

S

= 5V

Output Current (mA)

Output V

oltage (V)

75

50

25

125

100

150

175

200

0

5

4

3

2

1

0

125

∞

C

25

∞

C

≠55

∞

C

SUPPLY CURRENT vs TEMPERATURE

Temperature (

∞

C)

Supply Current (mA)

65

85

105

5

25

45

135

125

≠55

≠35

≠15

7

6

5

4

3

2

1

0

V

S

= 5V

V

S

= 2.5V

OUTPUT VOLTAGE SWING vs OUTPUT CURRENT

FOR V

S

= 3V

Output Current (mA)

Output V

o

ltage (V)

60

40

20

80

100

120

0

3

2

1

0

125

∞

C

25

∞

C

≠55

∞

C

INPUT BIAS CURRENT vs TEMPERATURE

Temperature (

∞

C)

Input Bias Current (pA)

65

85

105

5

25

45

135

125

≠55

≠35

≠15

10k

1k

100

10

1

OPA354, OPA2354, OPA4354

8

SBOS233B

www.ti.com

TYPICAL CHARACTERISTICS

(Cont.)

At T

A

= +25

∞

C, V

S

= 5V, G = +1, R

F

= 0

, R

L

= 1k

, and connected to V

S

/2, unless otherwise noted.

CHANNEL-TO-CHANNEL CROSSTALK

Frequency (Hz)

Crosstalk, Input-Referred (dB)

10M

1M

1G

100M

100k

0

≠20

≠40

≠60

≠80

≠100

≠120

OPA4354

OPA2354

COMMON-MODE REJECTION RATIO AND

POWER-SUPPLY REJECTION RATIO vs TEMPERATURE

Temperature (

∞

C)

CMRR, PSRR (dB)

65

85

105

5

25

45

135

125

≠55

≠35

≠15

100

90

80

70

60

50

Power-Supply Rejection Ratio

Common-Mode Rejection Ratio

OFFSET VOLTAGE PRODUCTION DISTRIBUTION

Offset Voltage (mV)

Population

≠6

≠7

≠8

≠5 ≠4 ≠3 ≠2 ≠1

0 1

2

3

4

5

6

7 8

OPEN-LOOP GAIN vs TEMPERATURE

Temperature (

∞

C)

Open-Loop Gain (dB)

65

85

105

5

25

45

135

125

≠55

≠35

≠15

120

110

100

90

80

70

R

L

= 1k

OUTPUT SETTLING TIME TO 0.1%

Time (ns)

Output Error (%)

30

40

10

20

100

50

60

70

80

90

0

0.5

0.4

0.3

0.2

0.1

0

≠0.1

≠0.2

≠0.3

≠0.4

≠0.5

V

O

= 2Vp-p

OPA354, OPA2354, OPA4354

9

SBOS233B

www.ti.com

APPLICATIONS INFORMATION

The OPA354 is a CMOS, rail-to-rail I/O, high-speed, voltage-

feedback operational amplifier designed for video, high-

speed, and other applications. It is available as a single, dual,

or quad op amp.

The amplifier features a 100MHz gain bandwidth and 150V/

µ

s

slew rate, but it is unity-gain stable and can be operated as a

+1V/V voltage follower.

OPERATING VOLTAGE

The OPA354 is specified over a power-supply range of +2.7V

to +5.5V (

±

1.35V to

±

2.75V). However, the supply voltage

may range from +2.5V to +5.5V (

±

1.25V to

±

2.75V). Supply

voltages higher than 7.5V (absolute maximum) can perma-

nently damage the amplifier.

Parameters that vary over supply voltage or temperature are

shown in the Typical Characteristics section of this data

sheet.

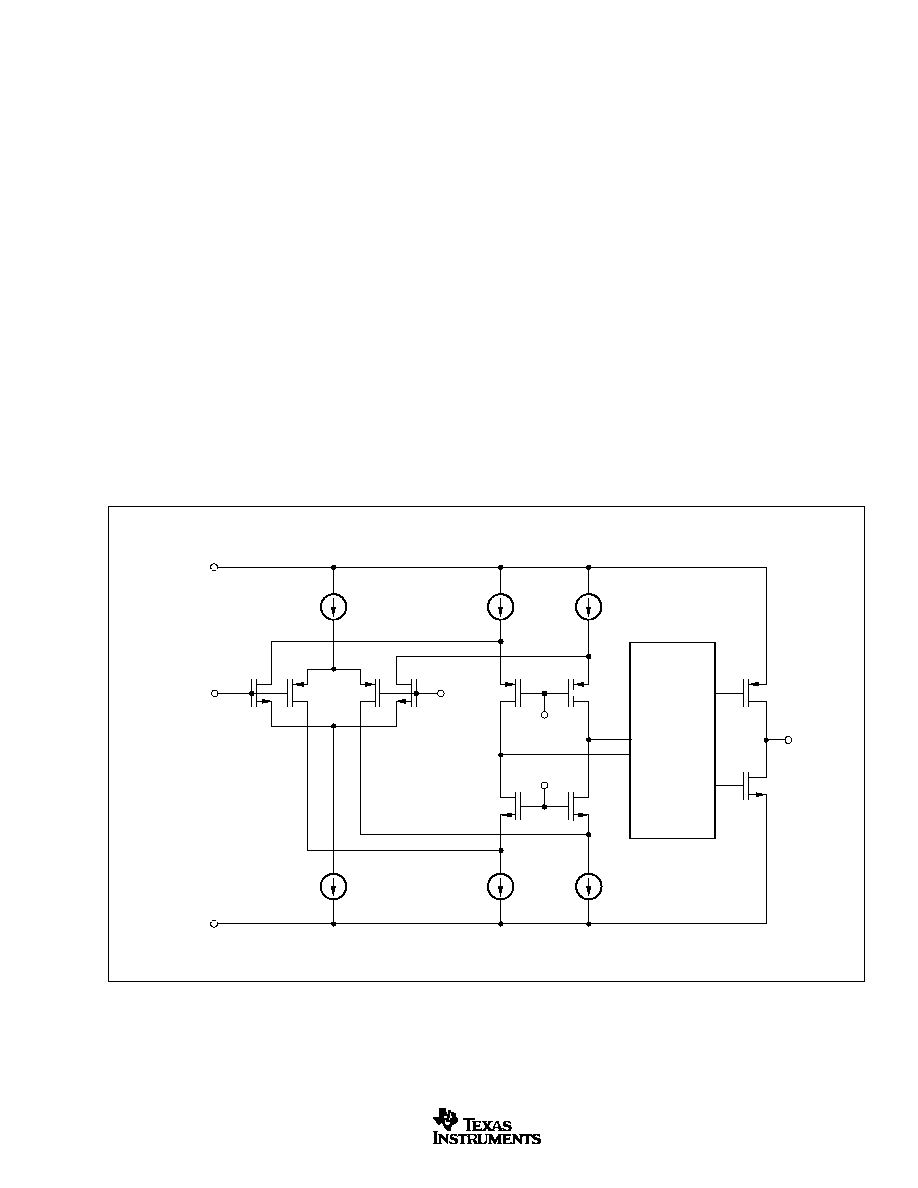

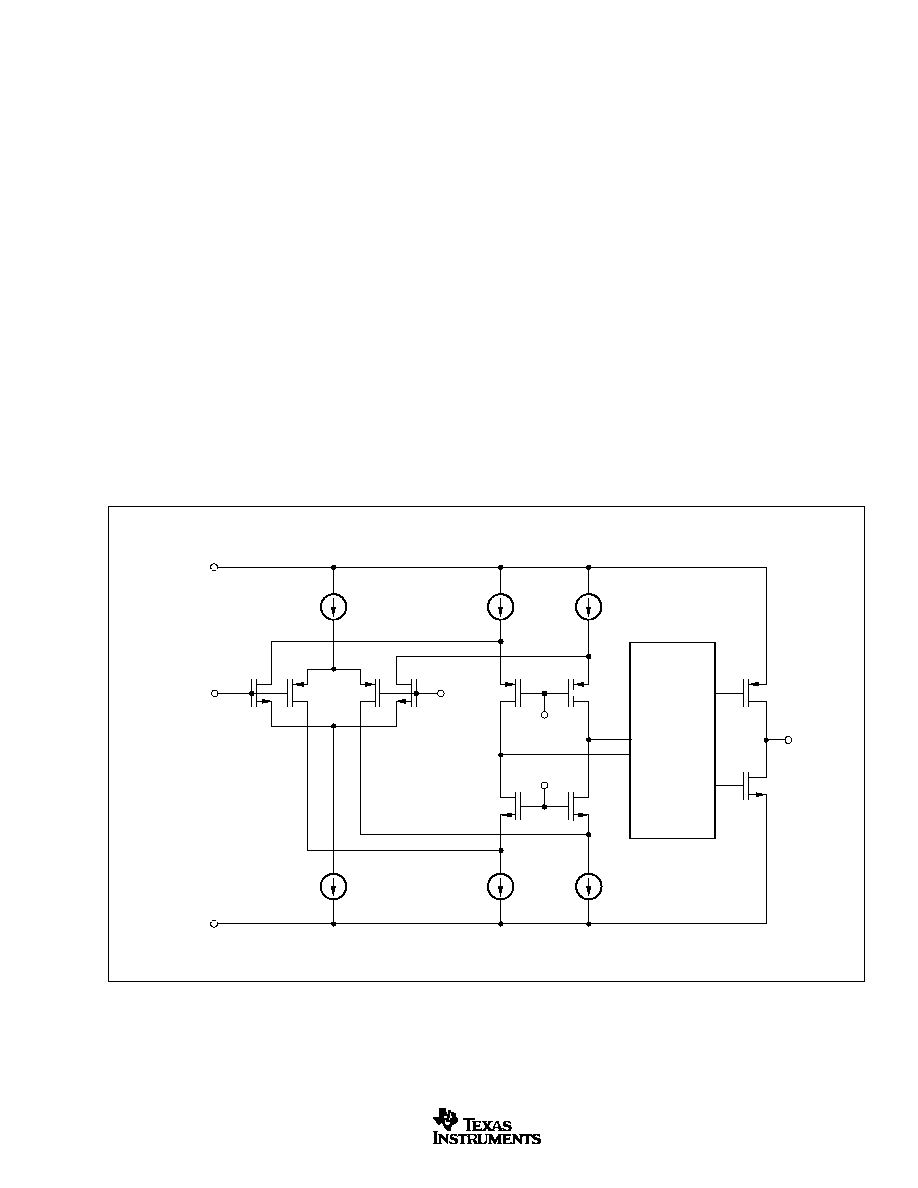

RAIL-TO-RAIL INPUT

The specified input common-mode voltage range of the OPA354

extends 100mV beyond the supply rails. This is achieved with

a complementary input stage--an N-channel input differential

pair in parallel with a P-channel differential pair, as shown in

Figure 1. The N-channel pair is active for input voltages close

to the positive rail, typically (V+) ≠ 1.2V to 100mV above the

positive supply, while the P-channel pair is on for inputs from

100mV below the negative supply to approximately (V+) ≠

1.2V. There is a small transition region, typically (V+) ≠ 1.5V

to (V+) ≠ 0.9V, in which both pairs are on. This 600mV

transition region can vary

±

500mV with process variation.

Thus, the transition region (both input stages on) can range

from (V+) ≠ 2.0V to (V+) ≠ 1.5V on the low end, up to (V+) ≠

0.9V to (V+) ≠ 0.4V on the high end.

A double-folded cascode adds the signal from the two input pairs

and presents a differential signal to the class AB output stage.

RAIL-TO-RAIL OUTPUT

A class AB output stage with common-source transistors is

used to achieve rail-to-rail output. For high-impedance loads

(> 200

), the output voltage swing is typically 100mV from

the supply rails. With 10

loads, a useful output swing can

be achieved while maintaining high open-loop gain. See

typical characteristics "Output Voltage Swing vs Output Current."

FIGURE 1. Simplified Schematic.

V

BIAS1

V

BIAS2

V

IN

+

V

IN

≠

Class AB

Control

Circuitry

V

O

V≠

(Ground)

V+

Reference

Current

OPA354, OPA2354, OPA4354

10

SBOS233B

www.ti.com

FIGURE 2. Laser Diode Driver.

OUTPUT DRIVE

The OPA354's output stage can supply a continuous output

current of

±

100mA and still provide approximately 2.7V of

output swing on a 5V supply (shown in Figure 2). For

maximum reliability, it is not recommended to run a continuous

DC current in excess of

±

100mA. Refer to the typical character-

istics "Output Voltage Swing vs Output Current." For supplying

continuous output currents greater than

±

100mA, the OPA354

may be operated in parallel, shown in Figure 3.

V

IN

V

1

5V

R

SHUNT

1

Laser Diode

OPA354

C

1

50pF

R

1

10k

R

3

10k

R

4

1k

R

2

1k

1

µ

F

+

≠

+

≠

V+

V≠

1V In = 100mA

Out, as Shown

R

SHUNT

1

Laser Diode

OPA2354

C

1

200pF

R

1

100k

R

5

1k

R

6

1

R

3

100k

R

4

10k

R

2

10k

1

µ

F

+

≠

2V In = 200mA

Out, as Shown

OPA2354

+5V

FIGURE 4. Single-Supply Video Line Driver.

Video

In

Video

Output

+2.5V

+5V

+2.5V

604

75

604

75

OPA354

FIGURE 3. Parallel Operation.

The OPA354 will provide peak currents up to 200mA, which

corresponds to the typical short-circuit current. Therefore, an

on-chip thermal shutdown circuit is provided to protect the

OPA354 from dangerously high junction temperatures. At

160

∞

C, the protection circuit will shut down the amplifier.

Normal operation will resume when the junction temperature

cools to below 140

∞

C.

VIDEO

The OPA354 output stage is capable of driving standard

back-terminated 75

video cables, shown in Figure 4. By

back-terminating a transmission line, it does not exhibit a

capacitive load to its driver. A properly back-terminated 75

cable does not appear as capacitance; it presents only a

150

resistive load to the OPA354 output.

The OPA354's rail-to-rail input and output capabilities make

possible its use as an amplifier for RGB graphic signals,

which have a voltage of zero at the video black level, see

Figure 5.

DRIVING ANALOG-TO-DIGITAL CONVERTERS

The OPA354 series op amps offer 60ns of settling time to

0.01%, making them a good choice for driving high- and

medium-speed sampling A/D converters and reference cir-

cuits. The OPA354 series provide an effective means of

buffering the A/D converter's input capacitance and resulting

charge injection while providing signal gain. For applications

requiring high DC accuracy, the OPA350 series is recom-

mended.

Figure 6 illustrates the OPA354 driving an A/D converter.

With the OPA354 in an inverting configuration, a capacitor

across the feedback resistor can be used to filter high-

frequency noise in the signal.

OPA354, OPA2354, OPA4354

11

SBOS233B

www.ti.com

FIGURE 5. RGB Cable Driver.

1/2

OPA2354

604

1

µ

F

75

10nF

+3V

75

Red

Green

Blue

604

Red

D/A

Converter

Green

D/A

Converter

Blue

D/A

Converter

75

OPA354

604

1

µ

F

10nF

+3V

75

75

1/2

OPA2354

604

75

604

75

604

75

75

+

+

ADS7816, ADS7861,

or ADS7864

12-Bit A/D Converter

OPA354

+5V

V

IN

V+

+In

≠In

V

REF

GND

NOTE: A/D Converter Input = 0V to V

REF

+2.5V

5k

5k

330pF

V

IN

= 0V to ≠5V for 0V to 5V output.

FIGURE 6. The OPA354 in Inverting Configuration Driving the ADS7816.

OPA354, OPA2354, OPA4354

12

SBOS233B

www.ti.com

CAPACITIVE LOAD AND STABILITY

The OPA354 series op amps can drive a wide range of

capacitive loads. However, all op amps under certain conditions

may become unstable. Op amp configuration, gain, and load

value are just a few of the factors to consider when determining

stability. An op amp in unity-gain configuration is the most

susceptible to the effects of capacitive load. The capacitive load

reacts with the op amp's output resistance, along with any

additional load resistance, to create a pole in the small-signal

response that degrades the phase margin. Refer to typical

characteristic "Frequency Response for Various C

L

" for detail.

The OPA354's topology enhances its ability to drive capaci-

tive loads. In unity gain, these op amps perform well with

large capacitive loads. Refer to typical characteristics "Rec-

ommended R

S

vs Capacitive Load" and "Frequency Re-

sponse vs Capacitive Load" for detail.

One method of improving capacitive load drive in the unity-

gain configuration is to insert a 10

to 20

resistor in series

with the output, as shown in Figure 7. This significantly

reduces ringing with large capacitive loads--see typical

characteristic "Frequency Response vs Capacitive Load."

However, if there is a resistive load in parallel with the

capacitive load, R

S

creates a voltage divider. This introduces

a DC error at the output and slightly reduces output swing.

This error may be insignificant. For instance, with R

L

= 10k

and R

S

= 20

, there is only about a 0.2% error at the output.

FIGURE 7. Series Resistor in Unity-Gain Configuration Im-

proves Capacitive Load Drive.

To achieve a maximally flat 2nd-order Butterworth frequency

response, the feedback pole should be set to:

1

2

4

R C

GBP

R C

F F

F D

=

Typical surface-mount resistors have a parasitic capacitance

of around 0.2pF that must be deducted from the calculated

feedback capacitance value.

Bandwidth is calculated by:

f

GBP

R C

Hz

dB

F D

-

=

3

2

For even higher transimpedance bandwidth, the high-speed

CMOS OPA355 (200MHz GBW) or the OPA655 (400MHz

GBW) may be used.

PCB LAYOUT

Good high-frequency Printed Circuit Board (PCB) layout tech-

niques should be employed for the OPA354. Generous use of

ground planes, short, direct signal traces, and a suitable

bypass capacitor located at the V+ pin will assure clean, stable

operation. Large areas of copper also provide a means of

dissipating heat that is generated in normal operation.

Sockets are definitely not recommended for use with any

high-speed amplifier.

A 10nF ceramic bypass capacitor is the minimum recom-

mended value; adding a 1

µ

F or larger tantalum capacitor in

parallel can be beneficial when driving a low-resistance load.

Providing adequate bypass capacitance is essential to achiev-

ing very low harmonic and intermodulation distortion.

POWER DISSIPATION

Power dissipation depends on power-supply voltage, signal

and load conditions. With DC signals, power dissipation is

equal to the product of output current times the voltage

across the conducting output transistor, V

S

≠ V

O

. Power

dissipation can be minimized by using the lowest possible

WIDEBAND TRANSIMPEDANCE AMPLIFIER

Wide bandwidth, low input bias current, and low input voltage

and current noise make the OPA354 an ideal wideband

photodiode transimpedance amplifier for low-voltage single-

supply applications. Low-voltage noise is important because

photodiode capacitance causes the effective noise gain of

the circuit to increase at high frequency.

The key elements to a transimpedance design (as shown in

Figure 8) are the expected diode capacitance (including the

parasitic input common-mode and differential-mode input

capacitance (2 + 2)pF for the OPA354), the desired transim-

pedance gain (R

F

), and the Gain Bandwidth Product (GBP)

for the OPA354 (100MHz). With these 3 variables set, the

feedback capacitor value (C

F

) may be set to control the

frequency response.

FIGURE 8. Transimpedance Amplifier.

OPA354

V+

V

IN

V

OUT

C

L

R

L

R

S

OPA354

V

OUT

R

F

10M

C

F

< 1pF

(prevents gain peaking)

+V

C

D

OPA354, OPA2354, OPA4354

13

SBOS233B

www.ti.com

power-supply voltage necessary to assure the required out-

put voltage swing.

For resistive loads, the maximum power dissipation occurs at

a DC output voltage of one half the power-supply voltage.

Dissipation with AC signals is lower. Application Bulletin

AB-039 (SBOA022), "Power Amplifier Stress and Power

Handling Limitations," explains how to calculate or measure

power dissipation with unusual signals and loads, and can be

found at www.ti.com.

Any tendency to activate the thermal protection circuit indi-

cates excessive power dissipation or an inadequate heat

sink. For reliable operation, junction temperature should be

limited to 150

∞

C, maximum. To estimate the margin of safety

in a complete design, increase the ambient temperature until

the thermal protection is triggered at 160

∞

C. The thermal

protection should trigger more than 35

∞

C above the maxi-

mum expected ambient condition of your application.

PowerPAD THERMALLY ENHANCED PACKAGE

Besides the regular SOT23-5 and MSOP-8, the single and

dual versions of the OPA354 also come in SO-8 PowerPAD.

The SO-8 PowerPAD is a standard-size SO-8 package

where the exposed leadframe on the bottom of the package

can be soldered directly to the PCB to create an extremely

low thermal resistance. This will enhance the OPA354's

power dissipation capability significantly and eliminates the

use of bulky heatsinks and slugs traditionally used in thermal

packages. This package can be easily mounted using stan-

dard PCB assembly techniques. NOTE: Since the SO-8

PowerPAD is pin-compatible with standard SO-8 packages,

the OPA354 and OPA2354 can directly replace operational

amplifiers in existing sockets. If the application does not

require the higher power dissipation capability, the PowerPAD

does not have to be soldered to the PCB.

The PowerPAD package is designed so that the leadframe

die pad (or thermal pad) is exposed on the bottom of the IC,

as shown in Figure 9. This provides an extremely low thermal

resistance (

JC

) path between the die and the exterior of the

package. The thermal pad on the bottom of the IC can then

be soldered directly to the PCB, using the PCB as a heatsink.

In addition, plated-through holes (vias) provide a low thermal

resistance heat flow path to the back side of the PCB.

PowerPAD ASSEMBLY PROCESS

1. The PowerPAD must be connected to the device's most

negative supply voltage, which will be ground in single-

supply applications, and V≠ in split-supply applications.

2. Prepare the PCB with a top-side etch pattern, as shown in

Figure 10. There should be etch for the leads as well as etch

for the thermal land.

FIGURE 10. 8-Pin PowerPAD PCB Etch and Via Pattern.

3. Place the recommended number of plated-through holes

(or thermal vias) in the area of the thermal pad. These holes

should be 13 mils in diameter. They are kept small so that

solder wicking through the holes is not a problem during

reflow. The minimum recommended number of holes for the

SO-8 PowerPAD package is 5, as shown in Figure 10.

4. It is recommended, but not required, to place a small

number of additional holes under the package and outside

the thermal pad area. These holes provide additional heat

paths between the copper thermal land and the ground

plane. They may be larger because they are not in the area

to be soldered, so wicking is not a problem. This is illustrated

in Figure 10.

5. Connect all holes, including those within the thermal pad

area and outside the pad area, to the internal ground plane

or other internal copper plane for single-supply applications,

and V≠ for split-supply applications.

6. When laying out these holes, do not use the typical web

or spoke via connection methodology, as shown in Figure 11.

Web connections have a high thermal resistance connection

that is useful for slowing the heat transfer during soldering

operations. This makes soldering the vias that have ground

FIGURE 9. Section View of a PowerPAD Package.

Mold Compound (Plastic)

Leadframe Die Pad

Exposed at Base of the Package

(Copper Alloy)

Leadframe (Copper Alloy)

IC (Silicon)

Die Attach (Epoxy)

OPTIONAL:

Additional 4 vias outside

of thermal pad area but

under the package.

REQUIRED:

Thermal pad area 2.286mm x 2.286mm

(90 mils x 90 mils) with 5 vias

(via diameter = 13 mils)

Thermal Land

(Copper)

Minimum Size

4.8mm x 3.8mm

(189 mils x 150 mils)

Web or Spoke Via

Solid Via

NOT RECOMMENDED

(due to poor heat conduction)

RECOMMENDED

FIGURE 11. Via Connection.

OPA354, OPA2354, OPA4354

14

SBOS233B

www.ti.com

plane connections easier. However, in this application, low

thermal resistance is desired for the most efficient heat

transfer. Therefore, the holes under the PowerPAD package

should make their connection to the internal ground plane

with a complete connection around the entire circumference

of the plated-through hole.

7. The top-side solder mask should leave the pad connec-

tions and the thermal pad area exposed. The thermal pad

area should leave the 13 mil holes exposed. The larger holes

outside the thermal pad area may be covered with solder

mask.

8. Apply solder paste to the exposed thermal pad area and

all of the package terminals.

9. With these preparatory steps in place, the PowerPAD IC

is simply placed in position and run through the solder reflow

operation as any standard surface-mount component. This

results in a part that is properly installed.

For detailed information on the PowerPAD package including

thermal modeling considerations and repair procedures,

please see technical Brief SLMA002, "PowerPAD Thermally

Enhanced Package," located at www.ti.com.

OPA354, OPA2354, OPA4354

15

SBOS233B

www.ti.com

PACKAGE DRAWINGS

DDA (S≠PDSO≠G8)

Power PAD

PLASTIC SMALL-OUTLINE

6,20

5,84

3,81

3,99

4202561/A 02/01

8

5

1

4

1,68 MAX

0,13

4,98

4,80

0

∞

≠8

∞

0,41

0,89

0,25

0,20 NOM

Seating Plane

0,49

0,35

0,03

1,40

1,55

Thermal Pad

(See Note D)

M

0,10

0,10

1,27

Gage Plane

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion not to exceed 0,15.

D. The package thermal performance may be enhanced by bonding the thermal pad to an external thermal plane.

This pad is electrically and thermally connected to the backside of the die and possibly selected leads.

OPA354, OPA2354, OPA4354

16

SBOS233B

www.ti.com

PACKAGE DRAWINGS (Cont.)

DBV (R-PDSO-G5)

PLASTIC SMALL-OUTLINE

0,10

M

0,20

0,95

0

∞

≠ 8

∞

0,25

0,35

0,55

Gage Plane

0,15 NOM

4073253-4/G 01/02

2,60

3,00

0,50

0,30

1,50

1,70

4

5

3

1

2,80

3,00

0,95

1,45

0,05 MIN

Seating Plane

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion.

D. Falls within JEDEC MO-178

OPA354, OPA2354, OPA4354

17

SBOS233B

www.ti.com

PACKAGE DRAWINGS (Cont.)

DGK (R-PDSO-G8)

PLASTIC SMALL-OUTLINE PACKAGE

0,69

0,41

0,25

0,15 NOM

Gage Plane

4073329/C 08/01

4,98

0,25

5

3,05

4,78

2,95

8

4

3,05

2,95

1

0,38

1,07 MAX

Seating Plane

0,65

M

0,08

0

∞

≠ 6

∞

0,10

0,15

0,05

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion.

D. Falls within JEDEC MO-187

OPA354, OPA2354, OPA4354

18

SBOS233B

www.ti.com

PACKAGE DRAWINGS (Cont.)

D (R-PDSO-G**)

PLASTIC SMALL-OUTLINE PACKAGE

8 PINS SHOWN

8

0.197

(5,00)

A MAX

A MIN

(4,80)

0.189

0.337

(8,55)

(8,75)

0.344

14

0.386

(9,80)

(10,00)

0.394

16

DIM

PINS **

4040047/E 09/01

0.069 (1,75) MAX

Seating Plane

0.004 (0,10)

0.010 (0,25)

0.010 (0,25)

0.016 (0,40)

0.044 (1,12)

0.244 (6,20)

0.228 (5,80)

0.020 (0,51)

0.014 (0,35)

1

4

8

5

0.150 (3,81)

0.157 (4,00)

0.008 (0,20) NOM

0

∞

≠ 8

∞

Gage Plane

A

0.004 (0,10)

0.010 (0,25)

0.050 (1,27)

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion, not to exceed 0.006 (0,15).

D. Falls within JEDEC MS-012

OPA354, OPA2354, OPA4354

19

SBOS233B

www.ti.com

PACKAGE DRAWINGS (Cont.)

PW (R-PDSO-G**)

PLASTIC SMALL-OUTLINE PACKAGE

14 PINS SHOWN

0,65

M

0,10

0,10

0,25

0,50

0,75

0,15 NOM

Gage Plane

28

9,80

9,60

24

7,90

7,70

20

16

6,60

6,40

4040064/F 01/97

0,30

6,60

6,20

8

0,19

4,30

4,50

7

0,15

14

A

1

1,20 MAX

14

5,10

4,90

8

3,10

2,90

A MAX

A MIN

DIM

PINS **

0,05

4,90

5,10

Seating Plane

0

∞

≠ 8

∞

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion not to exceed 0,15.

D. Falls within JEDEC MO-153

PACKAGING INFORMATION

ORDERABLE DEVICE

STATUS(1)

PACKAGE TYPE

PACKAGE DRAWING

PINS

PACKAGE QTY

OPA2354AIDDA

ACTIVE

HSOP

DDA

8

100

OPA2354AIDDAR

ACTIVE

HSOP

DDA

8

2500

OPA2354AIDGKR

ACTIVE

VSSOP

DGK

8

2500

OPA2354AIDGKT

ACTIVE

VSSOP

DGK

8

250

OPA354AIDBVR

ACTIVE

SOP

DBV

5

3000

OPA354AIDBVT

ACTIVE

SOP

DBV

5

250

OPA354AIDDA

ACTIVE

HSOP

DDA

8

100

OPA354AIDDAR

ACTIVE

HSOP

DDA

8

2500

OPA4354AID

ACTIVE

SOIC

D

14

58

OPA4354AIDR

ACTIVE

SOIC

D

14

2500

OPA4354AIPWR

ACTIVE

TSSOP

PW

14

2500

OPA4354AIPWT

ACTIVE

TSSOP

PW

14

250

(1) The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

PACKAGE OPTION ADDENDUM

www.ti.com

3-Oct-2003

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI's terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI's standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty. Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products

Applications

Amplifiers

amplifier.ti.com

Audio

www.ti.com/audio

Data Converters

dataconverter.ti.com

Automotive

www.ti.com/automotive

DSP

dsp.ti.com

Broadband

www.ti.com/broadband

Interface

interface.ti.com

Digital Control

www.ti.com/digitalcontrol

Logic

logic.ti.com

Military

www.ti.com/military

Power Mgmt

power.ti.com

Optical Networking

www.ti.com/opticalnetwork

Microcontrollers

microcontroller.ti.com

Security

www.ti.com/security

Telephony

www.ti.com/telephony

Video & Imaging

www.ti.com/video

Wireless

www.ti.com/wireless

Mailing Address:

Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright

2003, Texas Instruments Incorporated