Æ

OPA650

1

FEATURES

q

LOW POWER: 50mW

q

UNITY GAIN STABLE BANDWIDTH:

560MHz

q

LOW HARMONICS: ≠77dBc at 5MHz

q

FAST SETTLING TIME: 20ns to 0.01%

q

LOW INPUT BIAS CURRENT: 5

µ

A

q

DIFFERENTIAL GAIN/PHASE ERROR:

0.01%/0.03

∞

q

HIGH OUTPUT CURRENT: 85mA

DESCRIPTION

The OPA650 is a low power, wideband voltage feed-

back operational amplifier. It features a high band-

width of 560MHz as well as a 12-bit settling time of

only 20ns. The low distortion allows its use in commu-

nications applications, while the wide bandwidth and

true differential input stage make it suitable for use in

a variety of active filter applications. Its low distortion

gives exceptional performance for telecommunica-

tions, medical imaging and video applications.

The OPA650 is internally compensated for unity-gain

stability. This amplifier has a fully symmetrical differ-

ential input due to its "classical" operational amplifier

circuit architecture. Its unusual combination of speed,

accuracy and low power make it an outstanding choice

for many portable, multi-channel and other high speed

applications, where power is at a premium.

The OPA650 is also available in dual (OPA2650) and

quad (OPA4650) configurations.

Wideband, Low Power Voltage Feedback

OPERATIONAL AMPLIFIER

OPA650

Æ

APPLICATIONS

q

HIGH RESOLUTION VIDEO

q

BASEBAND AMPLIFIER

q

CCD IMAGING AMPLIFIER

q

ULTRASOUND SIGNAL PROCESSING

q

ADC/DAC GAIN AMPLIFIER

q

ACTIVE FILTERS

q

HIGH SPEED INTEGRATORS

q

DIFFERENTIAL AMPLIFIER

OPA650

OPA650

Current

Mirror

Output

Stage

C

C

Inverting

Input

Non-Inverting

Input

+V

S

Output

≠V

S

International Airport Industrial Park ∑ Mailing Address: PO Box 11400, Tucson, AZ 85734 ∑ Street Address: 6730 S. Tucson Blvd., Tucson, AZ 85706 ∑ Tel: (520) 746-1111 ∑ Twx: 910-952-1111

Internet: http://www.burr-brown.com/ ∑ FAXLine: (800) 548-6133 (US/Canada Only) ∑ Cable: BBRCORP ∑ Telex: 066-6491 ∑ FAX: (520) 889-1510 ∑ Immediate Product Info: (800) 548-6132

© 1994 Burr-Brown Corporation

PDS-1264F

Printed in U.S.A. March, 1998

SBOS041

2

Æ

OPA650

NOTES: (1) An asterisk (

T

) specifies the same value as the grade to the left. (2) Frequency response can be strongly influenced by PC board parasitics. The OPA650

is nominally compensated assuming 2pF parasitic load. The demonstration boards show low parasitic layouts for the different package styles.

SPECIFICATIONS

At T

A

= +25

∞

C, V

S

=

±

5V, R

L

= 100

, and R

FB

= 402

,

unless otherwise noted. R

FB

= 25

for a gain of +1.

OPA650P, U, N

OPA650UB, NB

PARAMETER

CONDITIONS

MIN

TYP

MAX

MIN

TYP

MAX

UNITS

FREQUENCY RESPONSE

Closed-Loop Bandwidth

(2)

G = +1

560

T

(1)

MHz

G = +2

140

T

MHz

G = +5

37

T

MHz

G = +10

18

T

MHz

Gain Bandwidth Product

180

T

MHz

Slew Rate

G = +1, 2V Step

240

T

V/

µ

s

Over Specified Temperature

220

T

V/

µ

s

Rise Time

0.2V Step

1

T

ns

Fall Time

0.2V Step

1

T

ns

Settling Time

0.01%

G = +1, 2V Step

19.6

T

ns

0.1%

G = +1, 2V Step

10.2

T

ns

1%

G = +1, 2V Step

6.3

T

ns

Spurious Free Dynamic Range

G = +1, f = 5.0 MHz, V

O

= 2Vp-p

R

L

= 100

73

T

dBc

R

L

= 200

77

T

dBc

Differential Gain

G = +1, NTSC, V

O

= 1.4Vp, R

L

= 150

0.01

T

%

Differential Phase

G = +1, NTSC, V

O

= 1.4Vp, R

L

= 150

0.03

T

Degrees

Bandwidth for 0.1dB Gain Flatness

G = +2

25

T

MHz

INPUT OFFSET VOLTAGE

Input Offset Voltage

±

1

±

5

0.6

±

2.5

mV

Average Drift

±

3

T

µ

V/

∞

C

Power Supply Rejection (+V

S

)

|V

S

| = 4.5V to 5.5V

60

76

70

T

dB

(≠V

S

)

47

53

50

T

dB

INPUT BIAS CURRENT

Input Bias Current

V

CM

= 0V

5

20

T

10

µ

A

Over Temperature

30

20

µ

A

Input Offset Current

V

CM

= 0V

0.5

1

0.2

0.5

µ

A

Over Temperature

3

2

µ

A

NOISE

Input Voltage Noise

Noise Density, f = 100Hz

43

T

nV/

Hz

f = 10kHz

9.4

T

nV/

Hz

f = 1MHz

8.4

T

nV/

Hz

f = 1MHz to 100MHz

8.4

T

nV/

Hz

Integrated Noise, BW = 10Hz to 100MHz

84

T

µ

Vrms

Input Bias Current Noise

Current Noise Density, f = 0.1MHz to 100MHz

1.2

T

pA/

Hz

Noise Figure (NF)

R

S

= 10k

4

T

dB

R

S

= 50

19.5

T

dB

INPUT VOLTAGE RANGE

Common-Mode Input Range

±

2.8

T

V

Over Specified Temperature

±

2.2

T

V

Common-Mode Rejection

V

CM

=

±

0.5V

65

90

70

T

dB

INPUT IMPEDANCE

Differential

15 || 1

T

k

|| pF

Common-Mode

16 || 1

T

M

|| pF

OPEN-LOOP GAIN

Open-Loop Voltage Gain

V

O

=

±

2V, R

L

= 100

45

51

46

T

dB

Over Specified Temperature

V

O

=

±

2V, R

L

= 100

43

44

dB

OUTPUT

Voltage Output

Over Specified Temperature

No Load

±

2.2

±

3.0

±

2.4

T

V

R

L

= 250

±

2.2

±

2.5

±

2.4

T

V

R

L

= 100

±

2.0

±

2.3

±

2.2

T

V

Current Output, Sourcing

75

110

T

T

mA

Over Specified Temperature

65

T

mA

Current Output, Sinking

65

85

T

T

mA

Over Specified Temperature

35

T

mA

Short Circuit Current

150

T

mA

Output Resistance

0.1MHz, G = +1

0.08

T

POWER SUPPLY

Specified Operating Voltage

±

5

T

V

Derated Voltage Range

±

4.5

±

5.5

T

T

V

Quiescent Current

±

5.1

±

7.75

±

5.1

±

6.5

mA

Over Specified Temperature

±

8.75

±

7.5

mA

TEMPERATURE RANGE

Specification: P, U, N, UB, NB

≠40

+85

T

T

∞

C

Thermal Resistance,

JA

P

8-Pin DIP

100

T

∞

C/W

U

SO-8

125

T

∞

C/W

N

SOT23-5

150

T

∞

C/W

Æ

OPA650

3

1

2

3

5

4

+V

S

≠Input

Output

≠V

S

+Input

1

2

3

4

8

7

6

5

NC

+V

S

Output

NC

NC

≠Input

+Input

≠V

S

Supply ...............................................................................................

±

5.5V

Internal Power Dissipation .................................. See Thermal Conditions

Differential Input Voltage ..................................................................

±

1.2V

Input Voltage Range ............................................................................

±

V

S

Storage Temperature Range: P, U, UB, N, NB ............ ≠40

∞

C to +125

∞

C

Lead Temperature (soldering, 10s) .............................................. +300

∞

C

(soldering, SOIC 3s) ....................................... +260

∞

C

Junction Temperature (T

J

) ............................................................ +175

∞

C

ABSOLUTE MAXIMUM RATINGS

PIN CONFIGURATION

Top View

DIP/SO-8

SOT23-5

The information provided herein is believed to be reliable; however, BURR-BROWN assumes no responsibility for inaccuracies or omissions. BURR-BROWN assumes no responsibility

for the use of this information, and all use of such information shall be entirely at the user's own risk. Prices and specifications are subject to change without notice. No patent rights or

licenses to any of the circuits described herein are implied or granted to any third party. BURR-BROWN does not authorize or warrant any BURR-BROWN product for use in life support

devices and/or systems.

ELECTROSTATIC

DISCHARGE SENSITIVITY

Electrostatic discharge can cause damage ranging from per-

formance degradation to complete device failure. Burr-Brown

Corporation recommends that all integrated circuits be handled

and stored using appropriate ESD protection methods.

ESD damage can range from subtle performance degradation

to complete device failure. Precision integrated circuits may

be more susceptible to damage because very small parametric

changes could cause the device not to meet published speci-

fications.

PACKAGE

DRAWING

TEMPERATURE

PACKAGE

ORDERING

PRODUCT

PACKAGE

NUMBER

(1)

RANGE

MARKING

(2)

NUMBER

(3)

OPA650U

SO-8 Surface Mount

182

≠40

∞

C to +85

∞

C

OPA650U

OPA650U

OPA650UB

SO-8 Surface Mount

182

≠40

∞

C to +85

∞

C

OPA650UB

OPA650UB

OPA650N

5-pin SOT23-5

331

≠40

∞

C to +85

∞

C

A50

OPA650N-250

OPA650N-3k

OPA650NB

5-pin SOT23-5

331

≠40

∞

C to +85

∞

C

A50B

OPA650NB-250

OPA650NB-3k

OPA650P

8-Pin Plastic DIP

006

≠40

∞

C to +85

∞

C

OPA650P

OPA650P

NOTE: (1) For detailed drawing and dimension table, please see end of data sheet, or Appendix C of Burr-Brown IC Data Book. (2) The "B" grade of the SO-8 package

will be marked with a "B" by pin 8. The "B" grade of the SOT23-5 will be marked with a "B" near pins 3 and 4. (3) The SOT23-5 is only available on a 7" tape and reel

(e.g. ordering 250 pieces of "OPA650N-250" will get a single 250 piece tape and reel. Ordering 3000 pieces of "OPA650N-3k" will get a single 3000 piece tape and reel).

Please refer to Appendix B of Burr-Brown IC Data Book for detailed Tape and Reel Mechanical information.

PACKAGE/ORDERING INFORMATION

4

Æ

OPA650

TYPICAL PERFORMANCE CURVES

At T

A

= +25

∞

C, V

S

=

±

5V, R

L

= 100

, and R

FB

= 402

,

unless otherwise noted. R

FB

= 25

for Gain of +1.

INPUT BIAS CURRENT AND OFFSET VOLTAGE

vs TEMPERATURE

7

6

5

4

2

1

0

≠1

≠50

≠25

0

25

50

75

100

Input Bias Current (mA)

Offset Voltage (mV)

Temperature (∞C)

V

OS

I

B

INPUT VOLTAGE AND CURRENT NOISE

vs FREQUENCY

Frequency (Hz)

100

1k

10k

100k

1M

100

10

1

Input Current Noise (pA/

Hz)

Input Voltage Noise (nV/

Hz)

Non-inverting and

Inverting Current Noise

Voltage Noise

SUPPLY CURRENT vs TEMPERATURE

7

6

5

4

3

≠60

≠40

≠20

0

20

40

60

80

100

Supply Current (±mA)

Temperature (∞C)

OUTPUT CURRENT vs TEMPERATURE

110

100

90

80

≠50

≠25

0

25

50

75

100

Output Current (±mA)

Temperature (∞C)

I

O

+

I

O

≠

COMMON-MODE REJECTION

vs INPUT COMMON-MODE VOLTAGE

100

90

80

70

60

≠4

≠3

≠2

≠1

0

1

2

3

4

Common Mode-Rejection (dB)

Common-Mode Voltage (V)

A

OL

, PSR AND CMRR vs TEMPERATURE

100

90

80

70

60

50

40

≠50

≠25

0

25

50

75

125

A

OL

, PSR and CMRR (dB)

Temperature (∞C)

A

OL

PSR≠

CMRR

PSR+

Æ

OPA650

5

TYPICAL PERFORMANCE CURVES

(CONT)

At T

A

= +25

∞

C, V

S

=

±

5V, R

L

= 100

, and R

FB

= 402

,

unless otherwise noted. R

FB

= 25

for Gain of +1.

LARGE SIGNAL TRANSIENT RESPONSE

(G = +1)

Time (5ns/div)

2.0

1.6

1.2

0.8

0.4

0

≠0.4

≠0.8

≠1.2

≠1.6

≠2.0

Output Voltage (V)

CLOSED-LOOP BANDWIDTH (G = +1)

Frequency (Hz)

6

3

0

≠3

≠6

≠9

1M

10M

100M

1G

Gain (dB)

DIP Bandwidth

= 520MHz

SO-8 Bandwidth

= 560MHz

CLOSED-LOOP BANDWIDTH (G = +5)

Frequency (Hz)

20

17

14

11

8

5

2

≠1

1M

10M

100M

1G

Gain (dB)

SO-8/DIP Bandwidth = 37MHz

CLOSED-LOOP BANDWIDTH (G = +2)

Frequency (Hz)

12

9

6

3

0

≠3

≠6

≠9

≠12

1M

10M

100M

1G

Gain (dB)

SO-8/DIP Bandwidth = 140MHz

RECOMMENDED ISOLATION RESISTANCE

vs CAPACITIVE LOAD

40

30

20

10

0

0

20

40

60

80

100

Isolation Resistance, R

ISO

(

)

Capacitive Load, C

L

(pF)

OPA650

C

L

1k

R

ISO

25

SMALL SIGNAL TRANSIENT RESPONSE

(G = +1)

Time (5ns/div)

200

160

120

80

40

0

≠40

≠80

≠120

≠160

≠200

Output Voltage (mV)

6

Æ

OPA650

TYPICAL PERFORMANCE CURVES

(CONT)

At T

A

= +25

∞

C, V

S

=

±

5V, R

L

= 100

, and R

FB

= 402

,

unless otherwise noted. R

FB

= 25

for Gain of +1.

HARMONIC DISTORTION vs FREQUENCY

(G = +1, V

O

= 2Vp-p, R

L

= 100

)

Frequency (Hz)

Harmonic Distortion (dBc)

≠40

≠50

≠60

≠70

≠80

≠90

100k

10M

1M

100M

3f

O

2f

O

HARMONIC DISTORTION vs TEMPERATURE

(f

O

= 5MHz, V

O

= 2Vp-p, G = +1)

≠50

≠60

≠70

≠80

≠90

≠60

≠40

≠20

0

20

40

60

80

3f

O

2f

O

100

Harmonic Distortion (dBc)

Temperature (∞C)

5MHz HARMONIC DISTORTION

vs OUTPUT SWING

Output Swing (Vp-p)

≠60

≠70

≠80

≠90

≠100

0.1

1

10

Harmonic Distortion (dBc)

3f

O

2f

O

G = +2

10MHz HARMONIC DISTORTION

vs OUTPUT SWING

Output Swing (Vp-p)

≠50

≠60

≠70

≠80

≠90

0.1

1

10

Harmonic Distortion (dBc)

3f

O

2f

O

OPEN-LOOP GAIN AND PHASE

vs FREQUENCY

60

50

40

30

20

10

0

+45

0

≠45

≠90

≠135

≠180

≠225

1k

10k

100k

1M

10M

100M

1G

Gain (dB)

Phase (∞)

Frequency (Hz)

Phase

Gain

CLOSED LOOP BANDWIDTH (G = +10)

Frequency (Hz)

1M

10M

100M

1G

SO-8/DIP Bandwidth = 18MHz

26

23

20

17

14

11

8

5

2

Gain (dB)

Æ

OPA650

7

the ground and power plane layout should not be in close

proximity to the signal I/O pins. Avoid narrow power and

ground traces to minimize inductance between the pins and

the decoupling capacitors. Larger (2.2

µ

F to 6.8

µ

F) decoupling

capacitors, effective at lower frequencies, should also be

used. These may be placed somewhat farther from the

device and may be shared among several devices in the same

area of the PC board.

c) Careful selection and placement of external compo-

nents will preserve the high frequency performance of the

OPA650. Resistors should be a very low reactance type.

Surface mount resistors work best and allow a tighter overall

layout. Metal film or carbon composition axially-leaded

resistors can also provide good high frequency performance.

Again, keep their leads as short as possible. Never use

wirewound type resistors in a high frequency application.

Since the output pin and the inverting input pin are most

sensitive to parasitic capacitance, always position the feed-

back and series output resistor, if any, as close as possible to

the package pins. Other network components, such as non-

inverting input termination resistors, should also be placed

close to the package.

Even with a low parasitic capacitance shunting external

resistors, excessively high resistor values can create signifi-

cant time constants and degrade performance. Good metal

film or surface mount resistors have approximately 0.2pF in

shunt with the resistor. For resistor values > 1.5k

, this adds

a pole and/or zero below 500MHz that can affect circuit

operation. Keep resistor values as low as possible consistent

with output loading considerations. The 402

feedback

used for the Typical Performance Plots is a good starting

point for design. Note that a 25

feedback resistor, rather

than a direct short, is suggested for a unity gain follower.

This effectively reduces the Q of what would otherwise be

a parasitic inductance (the feedback wire) into the parasitic

capacitance at the inverting input.

TYPICAL PERFORMANCE CURVES

(CONT)

At T

A

= +25

∞

C, V

S

=

±

5V, R

L

= 100

, and R

FB

= 402

,

unless otherwise noted. R

FB

= 25

for Gain of +1.

HARMONIC DISTORTION vs GAIN

(f

O

= 5MHz, V

O

= 2Vp-p)

≠40

≠50

≠60

≠70

≠80

1

2

3

4

5

6

7

8

9

10

Harmonic Distortion (dBc)

Non-Inverting Gain (V/V)

3f

O

2f

O

DISCUSSION OF

PERFORMANCE

The OPA650 is a low power, wideband voltage feedback

operational amplifier. Each channel is internally compen-

sated to provide unity gain stability. The OPA650's voltage

feedback architecture features true differential and fully sym-

metrical inputs. This minimizes offset errors, making the

OPA650 well suited for implementing filter and instrumen-

tation designs. The OPA650's AC performance is optimized

to provide a gain bandwidth product of 180MHz and a fast

0.1% settling time of 10.2ns, which is an important consid-

eration in high speed data conversion applications. Along

with its excellent settling characteristics, the low DC input

offset of

±

1mV and drift of

±

3

µ

V/

∞

C support high accuracy

requirements. In applications requiring a higher slew rate and

wider bandwidth, such as video and high bit rate digital

communications, consider the current feedback OPA658.

CIRCUIT LAYOUT AND BASIC OPERATION

Achieving optimum performance with a high frequency am-

plifier like the OPA650 requires careful attention to layout

parasitics and selection of external components. Recommen-

dations for PC board layout and component selection include:

a) Minimize parasitic capacitance to any ac ground for all

of the signal I/O pins. Parasitic capacitance on the output

and inverting input pins can cause instability; on the non-

inverting input it can react with the source impedance to

cause unintentional bandlimiting. To reduce unwanted ca-

pacitance, a window around the signal I/O pins should be

opened in all of the ground and power planes. Otherwise,

ground and power planes should be unbroken elsewhere on

the board.

b) Minimize the distance (< 0.25") from the two power pins

to high frequency 0.1

µ

F decoupling capacitors. At the pins,

8

Æ

OPA650

d) Connections to other wideband devices on the board

may be made with short direct traces or through on-board

transmission lines. For short connections, consider the trace

and the input to the next device as a lumped capacitive load.

Relatively wide traces (50 to 100 mils) should be used,

preferably with ground and power planes opened up around

them. Estimate the total capacitive load and set R

ISO

from

the plot of recommended R

ISO

vs capacitive load. Low

parasitic loads may not need an R

ISO

since the OPA650 is

nominally compensated to operate with a 2pF parasitic load.

If a long trace is required and the 6dB signal loss intrinsic to

doubly terminated transmission lines is acceptable, imple-

ment a matched impedance transmission line using microstrip

or stripline techniques (consult an ECL design handbook for

microstrip and stripline layout techniques). A 50

environ-

ment is not necessary on board, and in fact a higher imped-

ance environment will improve distortion as shown in the

distortion vs load plot. With a characteristic impedance

defined based on board material and desired trace dimen-

sions, a matching series resistor into the trace from the

output of the amplifier is used as well as a terminating shunt

resistor at the input of the destination device. Remember

also that the terminating impedance will be the parallel

combination of the shunt resistor and the input impedance of

the destination device; the total effective impedance should

match the trace impedance. Multiple destination devices are

best handled as separate transmission lines, each with their

own series and shunt terminations.

If the 6dB attenuation loss of a doubly terminated line is

unacceptable, a long trace can be series-terminated at the

source end only. This will help isolate the line capacitance

from the op amp output, but will not preserve signal integrity

as well as a doubly terminated line. If the shunt impedance

at the destination end is finite, there will be some signal

attenuation due to the voltage divider formed by the series

and shunt impedances.

e) Socketing a high speed part like the OPA650 is not

recommended. The additional lead length and pin-to-pin

capacitance introduced by the socket creates an extremely

troublesome parasitic network which can make it almost

impossible to achieve a smooth, stable response. Best results

are obtained by soldering the part onto the board. If socket-

ing for the DIP package is desired, high frequency flush

mount pins (e.g., McKenzie Technology #710C) can give

good results.

The OPA650 is nominally specified for operation using

±

5V

power supplies. A 10% tolerance on the supplies, or an ECL

≠5.2V for the negative supply, is within the maximum speci-

fied total supply voltage of 11V. Higher supply voltages can

break down internal junctions possibly leading to catastrophic

failure. Single supply operation is possible as long as com-

mon mode voltage constraints are observed. The common

mode input and output voltage specifications can be inter-

preted as a required headroom to the supply voltage. Observ-

ing this input and output headroom requirement will allow

non-standard or single supply operation. Figure 1 shows one

approach to single-supply operation.

402

OPA650

V

AC

402

R

L

+V

S

+V

S

V

S

2

R

OUT

V

S

2

V

OUT

= + 2∑V

AC

FIGURE 1. Single Supply Operation.

OFFSET VOLTAGE ADJUSTMENT

If additional offset adjustment is needed, the circuit in

Figure 2 can be used without degrading offset drift with

temperature. Avoid external adjustment whenever possible

since extraneous noise, such as power supply noise, can be

inadvertently coupled into the amplifier's inverting input

terminal. Remember that additional offset errors can be

created by the amplifier's input bias currents. Whenever

possible, match the impedance seen by both inputs as is

shown with R

3

. This will reduce input bias current errors to

the amplifier's offset current.

R

2

OPA650

(1)

R

3

= R

1

|| R

2

R

1

R

Trim

+V

S

≠V

S

20k

V

IN

or Ground

Output Trim Range +V

S

to ≠V

S

R

Trim

47k

R

2

R

2

R

Trim

0.1µF

NOTE: (1) R

3

is

optional and can

be used to cancel

offset errors due

to input bias currents.

ESD PROTECTION

ESD damage has been well recognized for MOSFET de-

vices, but any semiconductor device is vulnerable to this

potentially damaging source. This is particularly true for

very high speed, fine geometry processes.

ESD damage can cause subtle changes in amplifier input

characteristics without necessarily destroying the device. In

precision operational amplifiers, this may cause a noticeable

degradation of offset voltage and drift. Therefore, ESD

handling precautions are strongly recommended when han-

dling the OPA650.

FIGURE 2. Offset Voltage Trim.

Æ

OPA650

9

DRIVING CAPACITIVE LOADS

The OPA650's output stage has been optimized to drive low

resistive loads. Capacitive loads, however, will decrease the

amplifier's phase margin which may cause high frequency

peaking or oscillations. Capacitive loads greater than 10pF

should be isolated by connecting a small resistance, usually

15

to 30

, in series with the output as shown in Figure 4.

This is particularly important when driving high capacitance

loads such as flash A/D converters. Increasing the gain from

+1 will improve the capacitive load drive due to increased

phase margin.

In general, capacitive loads should be minimized for opti-

mum high frequency performance. Coax lines can be driven

if the cable is properly terminated. The capacitance of coax

cable (29pF/foot for RG-58) will not load the amplifier

when the coaxial cable or transmission line is terminated in

its characteristic impedance.

THERMAL CONSIDERATIONS

The OPA650 will not require heatsinking under most oper-

ating conditions. Maximum desired junction temperature

will limit the maximum allowed internal power dissipation

as described below. In no case should the maximum junction

temperature be allowed to exceed +175

∞

C.

Operating junction temperature (T

J

) is given by T

A

+

P

D

JA

. The total internal power dissipation (P

D

) is a com-

bination of the total quiescent power (P

DQ

) and the power

dissipated in of the output stage (P

DL

) to deliver load

power. Quiescent power is simply the specified no-load

supply current times the total supply voltage across the

part. P

DL

will depend on the required output signal and load

but would, for a grounded resistive load, be at a maximum

when the output is a fixed DC voltage equal to 1/2 of either

supply voltage (assuming equal bipolar supplies). Under

this condition, P

DL

= V

S

2

/(4∑R

L

) where R

L

includes feed-

back network loading. Note that it is the power dissipated

in the output stage and not in the load that determines

internal power dissipation. As an example, compute the

maximum T

J

for an OPA650N at A

V

= +2, R

L

= 100

, R

FB

= 402

,

±

V

S

=

±

5V, with the output at |V

S

/2|, and the

specified maximum T

A

= +85

∞

C. P

D

= 10V∑8.75mA + (5

2

)/

(4∑(100

||804

)) = 158mW. Maximum T

J

= +85

∞

C +

0.158W∑150

∞

C/W = 109

∞

C.

OUTPUT DRIVE CAPABILITY

The OPA650 has been optimized to drive 75

and 100

resistive loads. The device can drive a 2Vp-p into a 75

load.

This high-output drive capability makes the OPA650 an ideal

choice for a wide range of RF, IF, and video applications. In

many cases, additional buffer amplifiers are unneeded.

Many demanding high-speed applications such as driving

A/D converters require op amps with low wideband output

impedance. For example, low output impedance is essential

when driving the signal-dependent capacitances at the inputs

of flash A/D converters. As shown in Figure 3, the OPA650

maintains very low-closed loop output impedance over fre-

quency. Closed-loop output impedance increases with fre-

quency since loop gain is decreasing.

FIGURE 3. Small-Signal Output Impedance vs Frequency.

SMALL-SIGNAL OUTPUT IMPEDANCE

vs FREQUENCY

Frequency (Hz)

1k

100

10

1

0.1

0.01

10k

100k

1M

100M

10M

Output Impedance (

)

G = +1

OPA650

C

L

R

L

R

ISO

(R

ISO

typically 15

to 30

)

25

FIGURE 4. Driving Capacitive Loads.

FREQUENCY RESPONSE COMPENSATION

The OPA650 is internally compensated and is stable in unity

gain with a phase margin of approximately 60

∞

. However,

the unity gain buffer is the most demanding circuit configu-

ration for loop stability and oscillations are most likely to

occur in this gain. If possible, use the device in a noise gain

greater than one to improve phase margin and reduce the

susceptibility to oscillation. (Note that, from a stability

standpoint, an inverting gain of ≠1V/V is equivalent to a

noise gain of 2.) Frequency response for other gains are

shown in the Typical Performance Curves.

The high frequency response of the OPA650 in a good

layout is very flat with frequency. However, some circuit

configurations such as those where large feedback resis-

tances are used, can produce high-frequency gain peaking.

This peaking can be minimized by connecting a small

capacitor in parallel with the feedback resistor. This capaci-

tor compensates for the closed-loop, high-frequency, trans-

fer function zero that results from the time constant formed

by the input capacitance of the amplifier (typically 2pF after

PC board mounting), and the input and feedback resistors.

The selected compensation capacitor may be a trimmer, a

fixed capacitor, or a planned PC board capacitance. The

capacitance value is strongly dependent on circuit layout and

closed-loop gain. Using small resistor values will preserve

10

Æ

OPA650

Load Resistance (

)

Harmonic Distortion (dBc)

≠60

≠70

≠80

≠90

10

100

1k

3f

O

2f

O

the phase margin and avoid peaking by keeping the break

frequency of this zero sufficiently high. When high closed-

loop gains are required, a three-resistor attenuator (tee-

network) is recommended to avoid using large value resis-

tors with large time constants.

PULSE SETTLING TIME

High speed amplifiers like the OPA650 are capable of

extremely fast settling time with a pulse input. Excellent

frequency response flatness and phase linearity are required

to get the best settling times. As shown in the specifications

table, settling time for a

±

1V step at a gain of +1 for the

OPA650 is extremely fast. The specification is defined as

the time required, after the input transition, for the output to

settle within a specified error band around its final value. For

a 2V step, 1% settling corresponds to an error band of

±

20mV, 0.1% to an error band of

±

2mV, and 0.01% to an

error band of

±

0.2mV. For the best settling times, particu-

larly into an ADC capacitive load, little or no peaking in the

frequency response can be allowed. Using the recommended

R

ISO

for capacitive loads will limit this peaking and reduce

the settling times. Fast, extremely fine scale settling (0.01%)

requires close attention to ground return currents in the

supply decoupling capacitors. For highest performance, con-

sider the OPA642 which isolates the output stage decoupling

from the rest of the amplifier.

DIFFERENTIAL GAIN AND PHASE

Differential Gain (DG) and Differential Phase (DP) are

among the more important specifications for video applica-

tions. The percentage change in closed-loop gain over a

specified change in output voltage level is defined as DG.

DP is defined as the change in degrees of the closed-loop

phase over the same output voltage change. DG and DP are

both specified at the NTSC sub-carrier frequency of 3.58MHz.

DG and DP increase closed-loop gain and output voltage

transition. All measurements were performed using a

Tektronix model VM700 Video Measurement Set.

DISTORTION

The OPA650's harmonic distortion characteristics into a

100

load are shown versus frequency and power output in

the typical performance curves. Distortion can be signifi-

cantly improved by increasing the load resistance as illus-

trated in Figure 5. Remember to include the contribution of

the feedback network when calculating the effective load

resistance seen by the amplifier.

NOISE FIGURE

The OPA650 voltage noise spectral density is specified in

the Typical Performance Curves. For RF applications, how-

ever, Noise Figure (NF) is often the preferred noise specifi-

cation since it allows system noise performance to be more

easily calculated. The OPA650's Noise Figure vs Source

Resistance is shown in Figure 6.

SPICE MODELS AND EVALUATION BOARD

Computer simulation of circuit performance using SPICE is

often useful when analyzing the performance of analog

circuits and systems. This is particularly true for Video and

RF amplifier circuits where parasitic capacitance and induc-

tance can have a major effect on circuit performance. SPICE

models are available on a disk from the Burr-Brown Appli-

cations Department.

Demonstration boards are available for each OPA650 pack-

age style. These boards implement a very low parasitic

layout that will produce the excellent frequency and pulse

responses shown in the Typical Performance Curves. For

each package style, the recommended demonstration board

is:

Contact your local Burr-Brown sales office or distributor to

order demonstration boards.

DEM-OPA65xP

8-Pin DIP for the OPA650P

DEM-OPA65xU

SO-8 for the OPA650U

DEM-OPA6xxN

SOT23 for the OPA650N

FIGURE 6. Noise Figure vs Source Resistance.

NOISE FIGURE vs SOURCE RESISTANCE

Source Resistance (

)

30

25

20

15

10

5

0

10

100

1k

100k

10k

Noise Figure (dB)

NF = 10 LOG 1 +

e

n

2

+ (I

n

R

S

)

2

4KTR

S

FIGURE 5. 5MHz Harmonic Distortion vs Load Resistance.

Æ

OPA650

11

TYPICAL APPLICATION

FIGURE 7. Low Distortion Video Amplifier.

OPA650

V

OUT

402

402

Video

Input

75

75

75

Transmission Line

75

FIGURE 8. Layout Detail For DEM-OPA65xP Demonstration Board.

R

6

R

1

OPA650

Out

J

1

1

2

GND

≠5V

P2

R

7

R

5

+In

R

3

R

4

R

2

≠In

J

1

J

2

2

7

4

6

3

C

2

0.1µF

C

4

2.2µF

402

C

1

2.2µF

C

3

0.1µF

1

2

GND

+5V

P1

R

8

+

+

NOTE: Values for R

1

, R

3

, R

5

, R

6

, and R

7

are chosen according to desired gain.

12

Æ

OPA650

(C)

(D)

(A)

(B)

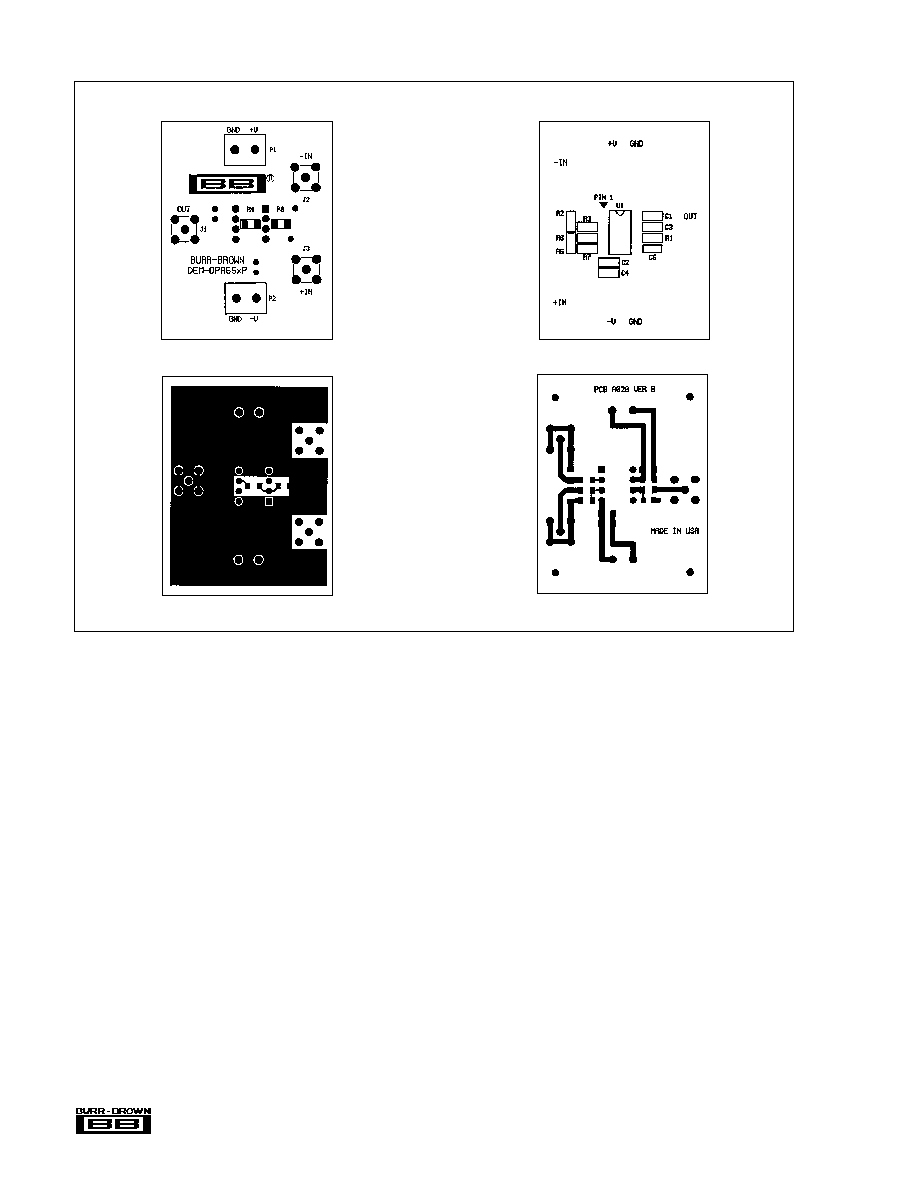

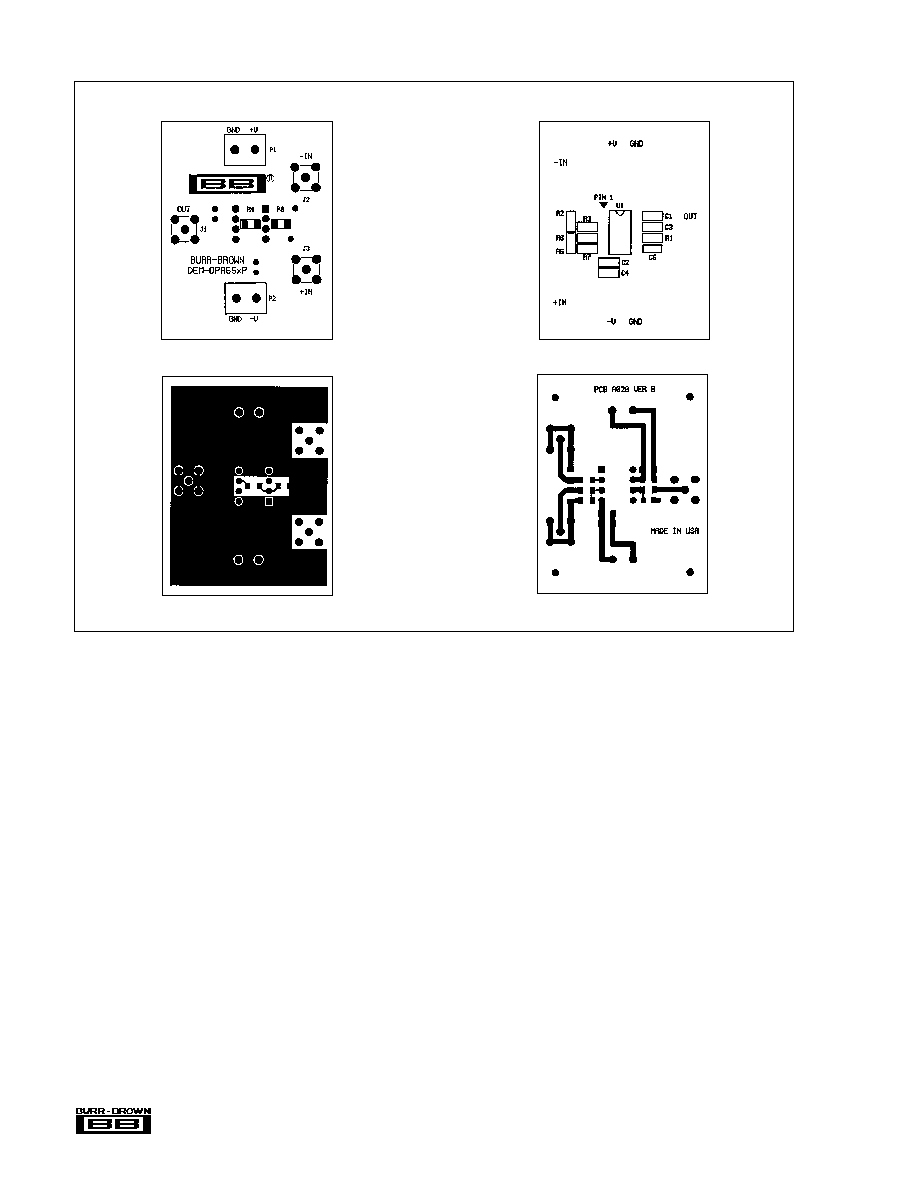

DEM-OPA65xP Demonstration Board Layout

FIGURE 9a. Evaluation Board Silkscreen (Bottom). 9b. Evaluation Board Silkscreen (Top). 9c. Evaluation Board Layout

(Solder Side). 9d. Evaluation Board Layout (Layout Side).

PACKAGING INFORMATION

ORDERABLE DEVICE

STATUS(1)

PACKAGE TYPE

PACKAGE DRAWING

PINS

PACKAGE QTY

OPA650N/250

ACTIVE

SOP

DBV

5

250

OPA650N/3K

ACTIVE

SOP

DBV

5

3000

OPA650P

OBSOLETE

PDIP

P

8

OPA650U

ACTIVE

SOIC

D

8

100

OPA650U/2K5

ACTIVE

SOIC

D

8

2500

(1) The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

PACKAGE OPTION ADDENDUM

www.ti.com

3-Oct-2003

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI's terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI's standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty. Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products

Applications

Amplifiers

amplifier.ti.com

Audio

www.ti.com/audio

Data Converters

dataconverter.ti.com

Automotive

www.ti.com/automotive

DSP

dsp.ti.com

Broadband

www.ti.com/broadband

Interface

interface.ti.com

Digital Control

www.ti.com/digitalcontrol

Logic

logic.ti.com

Military

www.ti.com/military

Power Mgmt

power.ti.com

Optical Networking

www.ti.com/opticalnetwork

Microcontrollers

microcontroller.ti.com

Security

www.ti.com/security

Telephony

www.ti.com/telephony

Video & Imaging

www.ti.com/video

Wireless

www.ti.com/wireless

Mailing Address:

Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright

2003, Texas Instruments Incorporated