Multilayer Chip Inductors

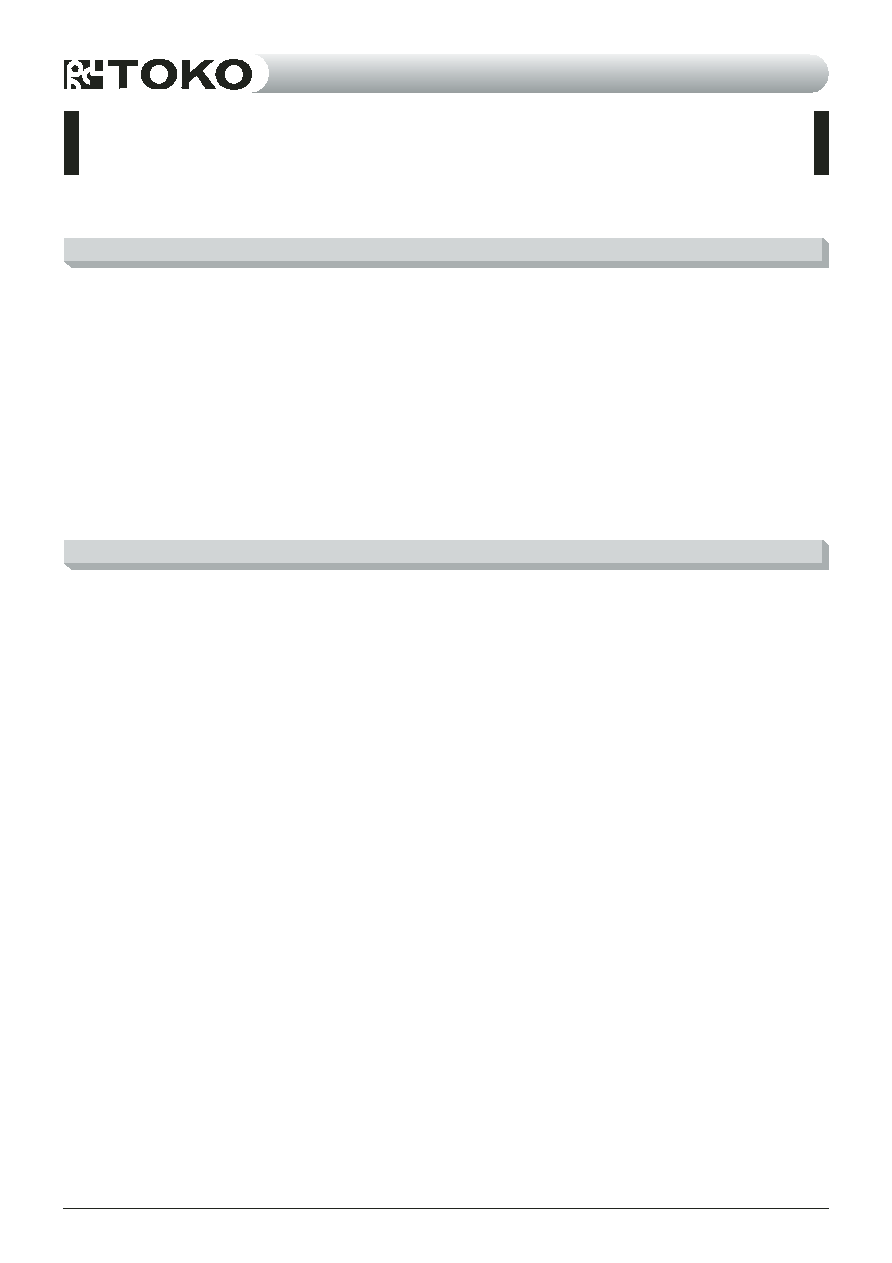

EXAMPLES OF CHARACTERISTICS

Inductance Range:

1.5~680nH (E-12)

Temperature Coefficient of L: + 250ppm/∞C (for reference only)

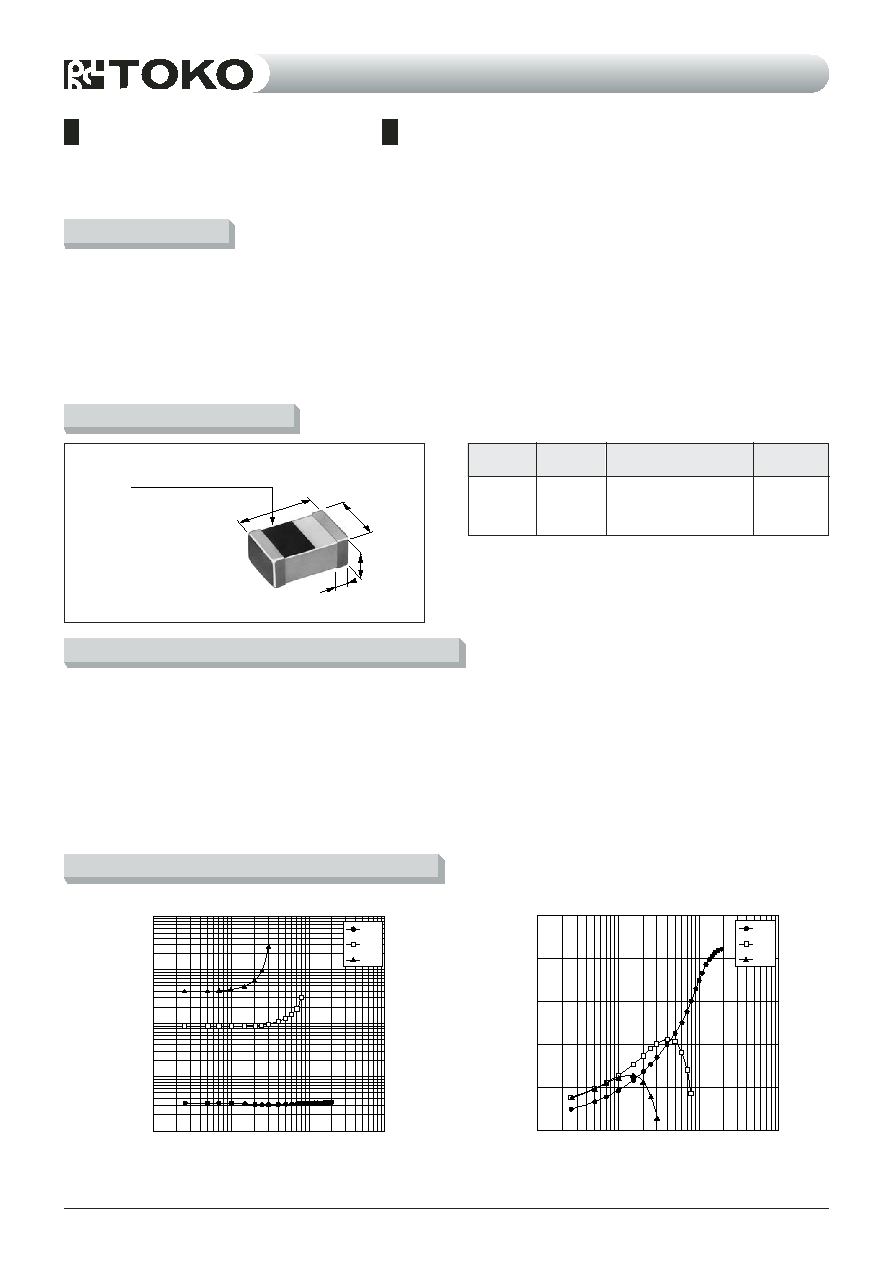

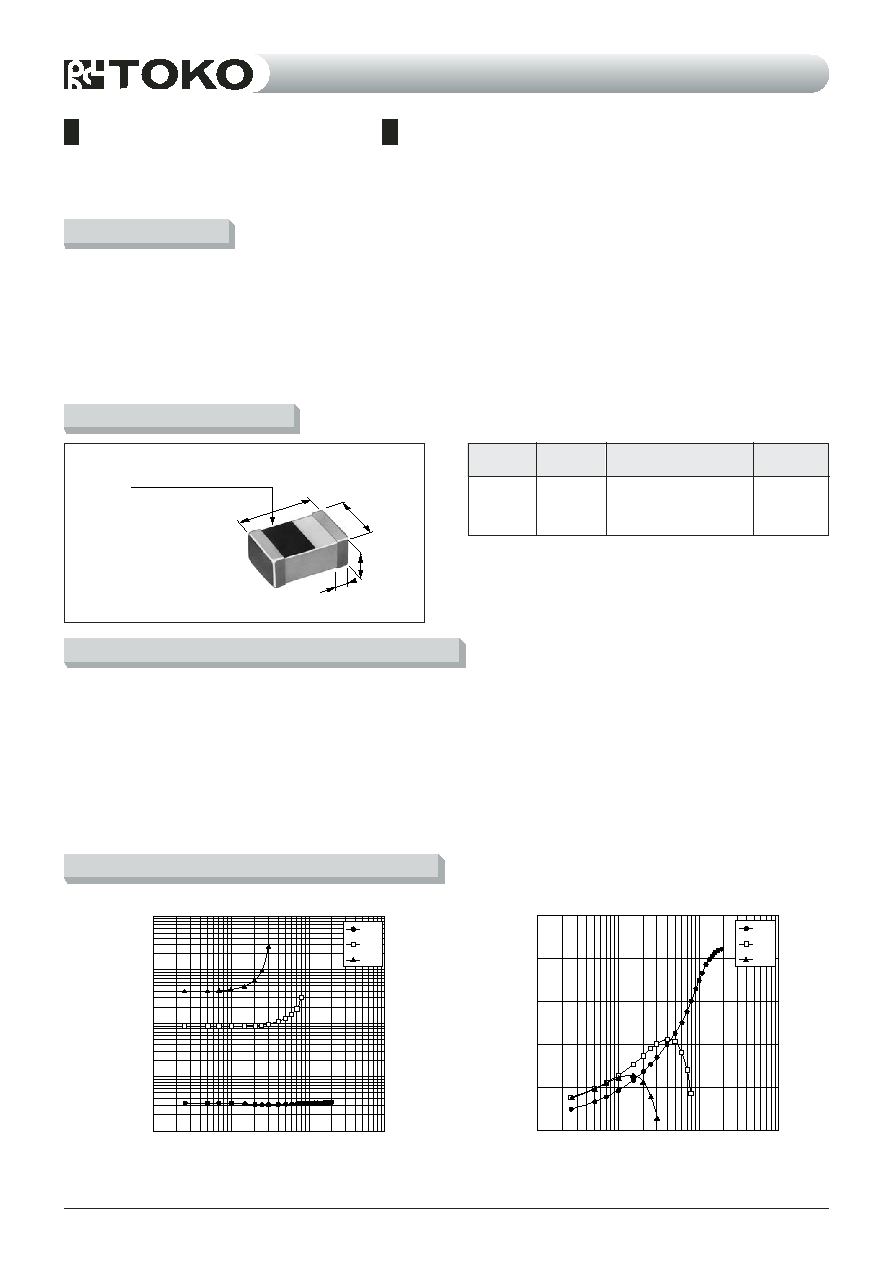

DIMENSIONS

FEATURES

ELECTRICAL CHARACTERISTICS

LL2012-FHL

Series

continued on next page

Electrode

widthA (mm)

Thickness

T (mm)

Width

W (mm)

Length

L (mm)

∑ Inductance Range

1.5~680nH (E-12 Series)

∑ Inductance Tolerance

S ;

±

0.3nH (1.5~5.6nH)

J ;

±

5% (6.8~680nH)

K ;

±

10%, (3.3~680nH)

∑ Q (Typical)

22 ~ 65 (at 800MHz)

∑ Rated Current

50~300mA

∑ L Temperature Coefficient

+ 250ppm/∞C

(for reference only)

∑ Operating Temperature Range

-

40~

+

100∞C

∑ Storage Temperature Range

-

40~

+

100∞C

∑

1.5680nH (E-12 Series

∑

S; ±0.3nH (1.55.6nH)

J ; ±% (6.8680nH)

K; ±10% (3.3680nH)

∑

Q (Typical)

2265 (at 800MHz)

∑

50300mA

∑

L ()

250ppm/

∑

-40100

∑

-40100

∑ Marking of polarity: Marking is on the upper surface of

the unit.

∑

:

2.0 ± 0.2

1.25 ± 0.2

0.6 ± 0.2 (1.5~8.2nH)

0.85 ± 0.3 (10.0~39.0nH)

1.0 ± 0.3 (47.0~100nH)

1.2 ± 0.3 (120.0~680nH)

0.5 ± 0.3

L

W

T

A

Marking of polarity (Black)

3N3

82N

R39

10,000

1,000

100

10

1

10

100

1,000

10,000

Inductance (nH)

Inductance vs Frequency

f(MHz)

3N3

82N

R39

80

100

60

40

20

0

10

100

1,000

10,000

Q vs Frequency

f (MHz)

Q

∑ New specifications

∑ Dual frequency standard for inductance value

∑ Supports high temperature reflow soldering (260∞C,

3 times)

∑ Surface mounting applicability (Supports both reflow and

flow soldering)

∑ High reliability (ceramic integrated structure, and terminals

plated)

∑

∑

∑

260◊

∑

∑

Multilayer Chip Inductors

3

LL2012-FHL1N5S

LL2012-FHL1N8S

LL2012-FHL2N2S

LL2012-FHL2N7S

LL2012-FHL3N3S

LL2012-FHL3N9S

LL2012-FHL4N7S

LL2012-FHL5N6S

LL2012-FHL6N8J

LL2012-FHL8N2J

LL2012-FHL10NJ

LL2012-FHL12NJ

LL2012-FHL15NJ

LL2012-FHL18NJ

LL2012-FHL22NJ

LL2012-FHL27NJ

LL2012-FHL33NJ

LL2012-FHL39NJ

LL2012-FHL47NJ

LL2012-FHL56NJ

LL2012-FHL68NJ

LL2012-FHL82NJ

LL2012-FHLR10J

LL2012-FHLR12J

LL2012-FHLR15J

LL2012-FHLR18J

LL2012-FHLR22J

LL2012-FHLR27J

LL2012-FHLR33J

LL2012-FHLR39J

LL2012-FHLR47J

LL2012-FHLR56J

LL2012-FHLR68J

continued from previous page

TOKO STANDARD PART NUMBERS

TYPE LL2012-FHLSeries

(Quantity/reel; ~39nH [4,000 PCS], 47nH~ [3,000 PCS])

1.5

1.8

2.2

2.7

3.3

3.9

4.7

5.6

6.8

8.2

10

12

15

18

22

27

33

39

47

56

68

82

100

120*

150*

180*

220*

270**

330**

390**

470**

560**

680**

4000

0.10

0.02

300

4000

0.10

0.02

300

3800

0.10

0.03

300

3600

0.10

0.03

300

3400

0.10

0.04

300

3200

0.10

0.04

300

2800

0.12

0.03

300

2800

0.15

0.05

300

2100

0.15

0.06

300

2000

0.18

0.05

300

1600

0.20

0.06

300

1350

0.22

0.07

300

1350

0.24

0.11

300

1200

0.26

0.10

300

1100

0.28

0.09

300

1100

0.30

0.12

300

1000

0.40

0.13

300

900

0.50

0.13

300

800

0.55

0.21

300

750

0.60

0.23

300

700

0.65

0.24

300

600

0.70

0.28

300

550

0.80

0.33

300

500

0.85

0.32

250

450

0.90

0.44

250

400

1.00

0.51

250

360

3.00

2.15

200

330

3.50

3.22

200

300

4.00

2.86

150

270

4.50

3.82

150

240

5.00

2.58

50

210

5.50

2.69

50

180

6.00

3.14

50

11

12

12

12

12

12

12

12

12

15

15

16

16

16

16

16

16

16

17

17

17

20

20

16*

16*

10**

10**

11**

11**

11**

11**

11**

11**

1.5 ±0.5nH

800

1.7 ±0.5nH

800

2.1 ±0.5nH

800

2.42 ±0.5nH

800

3.0 ±0.5nH

800

3.7 ±0.5nH

800

4.6 ±0.5nH

800

5.7 ±0.5nH

800

6.7

±10%

800

8.2

±10%

800

10.2

±10%

800

12.7

±10%

800

15.8

±10%

800

19.5

±10%

800

24.5

±10%

800

31.2

±10%

800

38.5

±10%

800

50.7

±10%

800

63.9

±10%

800

62.7

±10%

500

80.3

±10%

500

103

±10%

500

142

±10%

500

139

±10%

300

173

±10%

300

194

±10%

200

234

±10%

200

303

±10%

200

382

±10%

200

500

±10%

200

≠

≠

≠

≠

≠

≠

≠

≠

≠

15.3

27.5

37.5

52.0

61.5

79.3

14.0

25.0

33.9

46.6

54.0

78.4

16.7

29.5

39.9

55.0

62.6

96.4

15.5

27.5

36.8

50.8

57.8

89.0

15.4

29.0

39.2

52.6

59.2

96.4

16.0

29.7

39.7

53.4

59.7

76.8

16.5

30.4

40.9

54.3

61.0

81.0

17.0

31.3

42.1

55.2

61.0

76.9

18.7

33.3

44.6

58.1

63.9

89.7

18.5

32.2

42.4

54.8

59.5

73.2

18.9

33.7

44.4

56.9

61.5

75.7

20.5

36.5

47.5

60.8

65.9

79.8

22.1

39.5

51.5

64.2

68.2

67.9

22.9

40.7

52.9

64.9

68.4

49.3

21.6

38.0

48.6

56.8

57.4

≠

22.8

39.6

49.4

57.4

57.3

≠

23.0

39.9

49.9

55.6

54.4

≠

24.6

41.4

50.0

50.9

45.5

≠

24.8

41.8

49.5

47.4

39.4

≠

26.1

43.3

50.0

44.5

34.5

≠

25.7

41.8

46.2

33.6

18.1

≠

26.5

41.4

43.1

21.5

≠

≠

27.7

43.3

41.4

≠

≠

≠

26.4

38.2

31.0

≠

≠

≠

29.2

40.3

29.6

≠

≠

≠

28.2

33.2

≠

≠

≠

≠

25.1

32.8

≠

≠

≠

≠

23.6

28.8

≠

≠

≠

≠

26.0

28.6

≠

≠

≠

≠

25.0

21.1

≠

≠

≠

≠

25.5

≠

≠

≠

≠

≠

24.5

≠

≠

≠

≠

≠

26.5

≠

≠

≠

≠

≠

S

S

S

S

S

S

S

S

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

TOKO

part number

1800

MHz

1000

MHz

800

MHz

500

MHz

300

MHz

100

MHz

Freq.

(MHz)

Inductance & Tolerance

at 100MHz

at 800(500, 300, 200)MHz

Q Typ.

Q

Min.

100

MHz

S.R.F

(MHz)

Min.

R

DC

()

Max.

I

DC

(mA)

Max.

R

DC

()

Typ.

L

(nH)

Toler-

ance

L

(nH)

Toler-

ance

*

at 50MHz,

**

at 25MHz

∑Test Equipment & note

() ∑ L, Q

: RF Impedance Analyzer 4291A/B (Agilent), Test Fixture 16192A (Agilent)

∑ S.R.F.

: Network Analyzer 8719D (Agilent), 8720D (Agilent)

∑ RDC

: Milliohmmeter 4338A/B (Agilent)

∑ Inductance tolerance : S=

±

0.3nH, J=

±

5%

∑ Operating temperature range : -40∞C~+100∞C

∑ Storage temperature range

: -40∞C~+100∞C

Multilayer and Thick FilmChip Inductors

PRECAUTIONS

FEATURES

LL2012-FHL∑ LLP1005-FH

Series

∑

Lineup of shape series expanded from 0603 size to 2012

size.

∑

Expanded inductance range covering 1.0 nH~680 nH.

∑

Realization of product lineup that includes the addition of

B class tolerance, aiming at narrow tolerance.

∑

High frequency characteristics: Can be used over the

range 400 MHz~10 GHz.

∑

Lineup of a series that can be soldered with lead-less

solder.

∑

Lineup of a non-polarity series.

∑

Lineup of a series that has an expanded working

temperature

range of -55∞C~+125∞C.

∑

Improved L value reliability: Lineup of a series whose L

value is controlled by two frequencies (100 MHz and 800

MHz).

∑ 06032012

∑ 1.0nH680nH

∑ B±0.1nH

∑ 400MHz10GHz

∑

∑

∑ -55125

∑ 100MHz800MHzL

1. Precaution for application

1.1 The part must be pre-heated before soldering if reflow or flow

solder is applied.

The difference between pre-heat temperature and soldering

temperature must be within 150∞C.

1.2 If a solder iron is applied, the soldering process must be

completed within 3 seconds at the soldering temperature lower

than 260∞C.

The tip of the solder iron must not touch the terminal electrode

in this process.

1.3 Soldering by using an iron must be only once for the same part.

1.4 PCB mounted this part must be handled with a care to minimize

any physical stress to the part at the board assembly process.

1.5 To minimize the influence to the part, the thickness of PCB,

land dimension, and the amount of solder must be evaluated

carefully by individual application.

1.6 CFC, triethance, and isopropil used for the washing process will

not affect the part performance.

2. Precaution of storage

Storage condition is critical to maintain an optimum soldering

performance.

2.1 Environmental requirements:

Control ambient temperature at or under 40∞C and 70%RH.

Recommended use of the products within 6 months.

2.2 Influence of harmful gas:

Store the products in a place isolated from harmful gases like

sulfer and chlorine.

1.

1.1

150

1.2 260

3

1.3 11

1.4

1.5

1.6

2.

2.1

4070RH

6

2.2

LLV0603-FB ∑ LLV0603-F ∑ LL1005-FHL ∑ LL1608-FSL

Multilayer and Thick FilmChip Inductors

3

Tolerance

± 0.1nH

± 0.2nH

± 0.3nH

± 2%

± 3%

± 5%

± 10%

± 20%

Mark

B

C

S

G

T

J

K

M

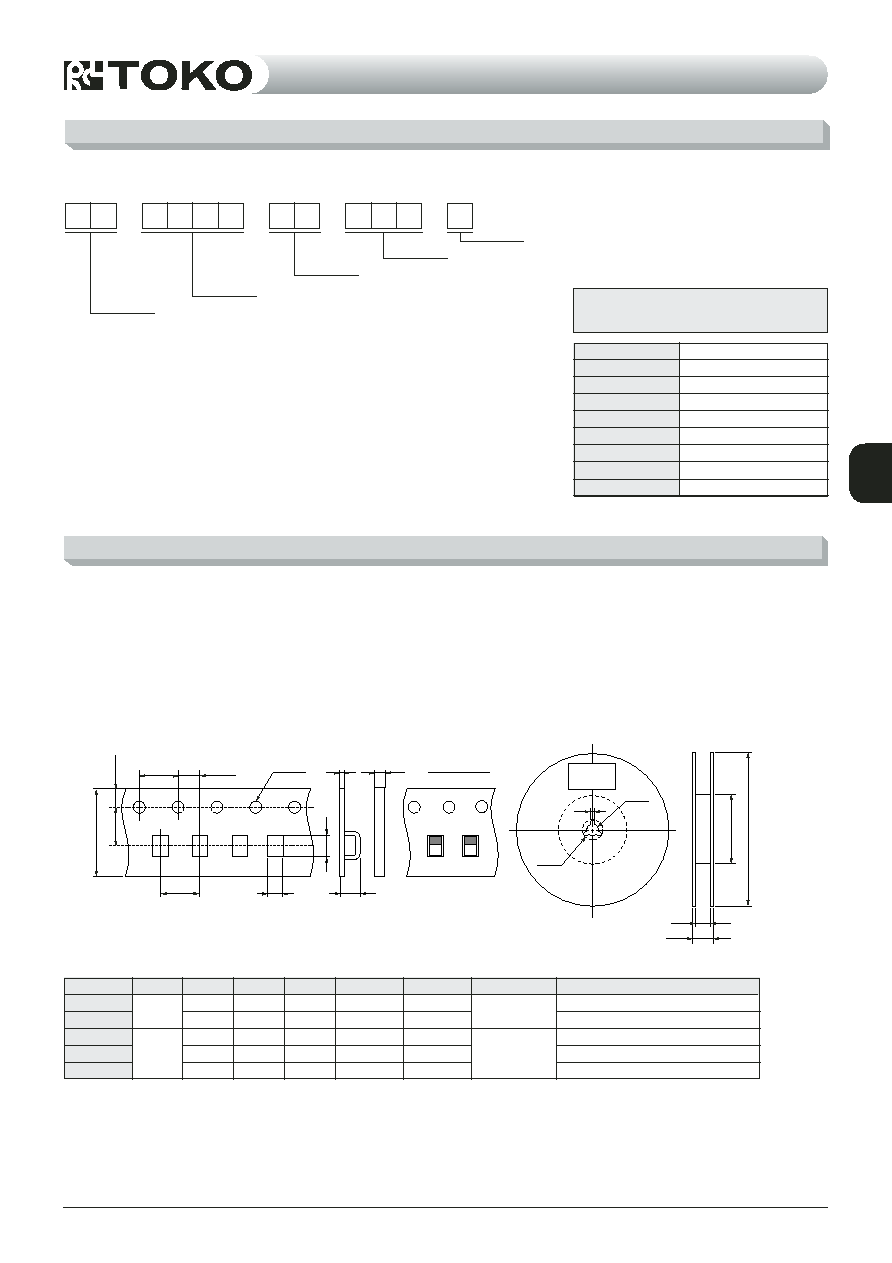

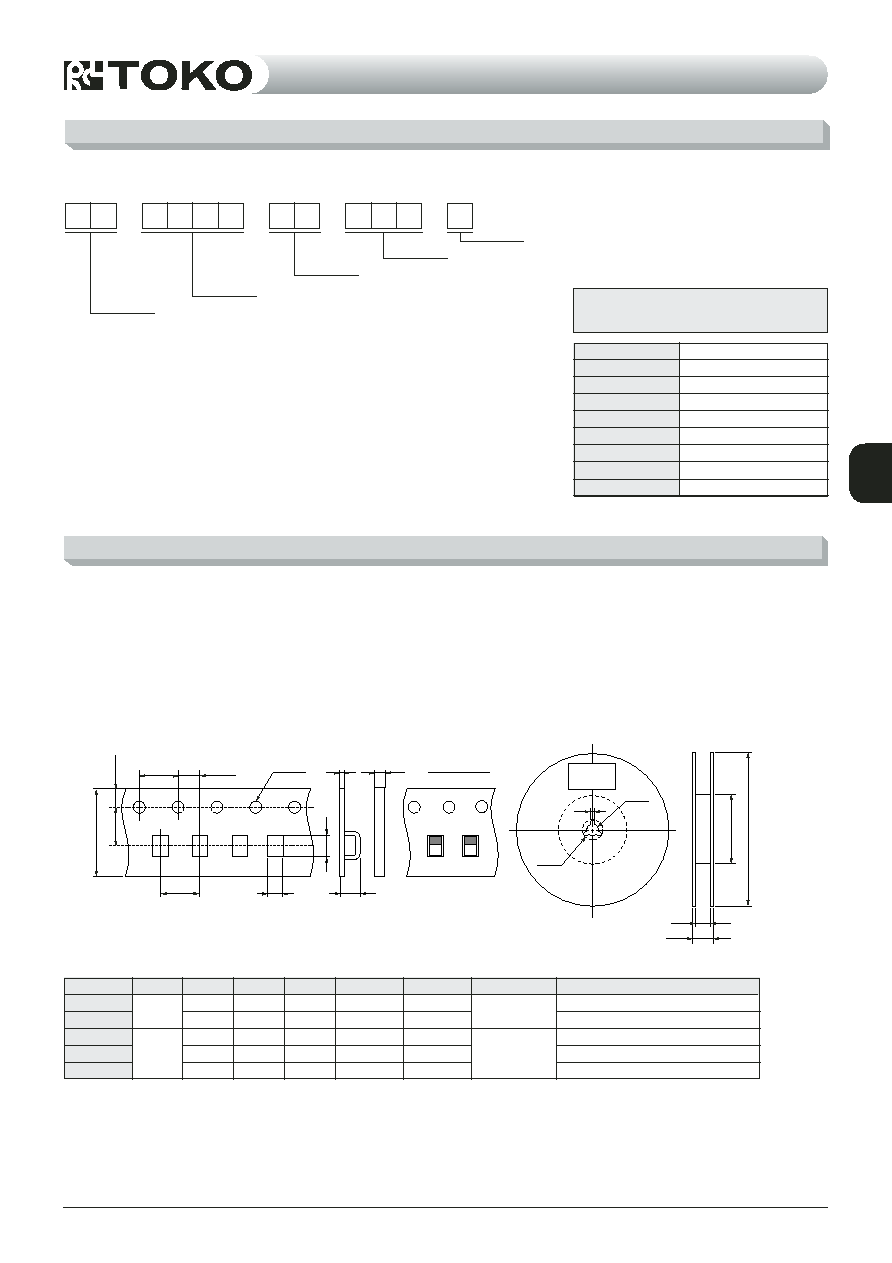

REEL PACKAGING

PART NUMBERING SYSTEM

Example

L L

1 6 0 8

F S

Tolerance

Inductance

Material

Physical Dimensions

TOKO's Type name

Unit is nH and 3 digits are used.

The value is indicated as shown below.

3nH

Example 4N7...4.7nH

33N...33nH

R27...270nH

Inductance

Tolerance for the Inductance

A

B

C

T

1

T

2

T

3

Material (Tape)

QTY (ÿ180)

Type

LL2012

LL1608

LL1005

LLP1005

LLV0603

(1) Chip's placing

Chip Inductors are packaged into 8mm width, 4 or 2mm

pitch plastic or paper tape then enclosed by cover tape.

(2) Carriage hole position

Carriage hole position is right side of tape when sealing tape

is up side.

∑ Tape dimensions (Unit: mm) (mm)

∑ Reel dimensions (Unit: mm) (mm)

(1)

8mm42mm

(2)

4

2

1.5

1.0

0.62

0.67

0.35

2.3

1.8

1.12

1.15

0.65

0.3

0.2

--

--

--

Max. 2.0

Max. 1.4

--

--

--

--

--

Max. 0.8

Max. 0.8

Max. 0.8

~39nH:4000, 47nH~3000PCS/reel

4000PCS/reel

10,000PCS/reel

10,000PCS/reel

15,000PCS/reel

Plastic

Paper

∑ Label: Customer's P/N, Q'ty, TOKO P/N, TOKO, INC.

∑

9.0 (9.5)

11.4 (13.5)

P=4.0±0.1

2.0±0.05

1.55±0.05

13

60 (100)

180 (330)

21

T

1

T

3

T

2

B

A

C

8.0

±

0.2

3.5

±

0.05

1.75

±

0.1

2

Label

( ) ¯330

Multilayer and Thick FilmChip Inductors

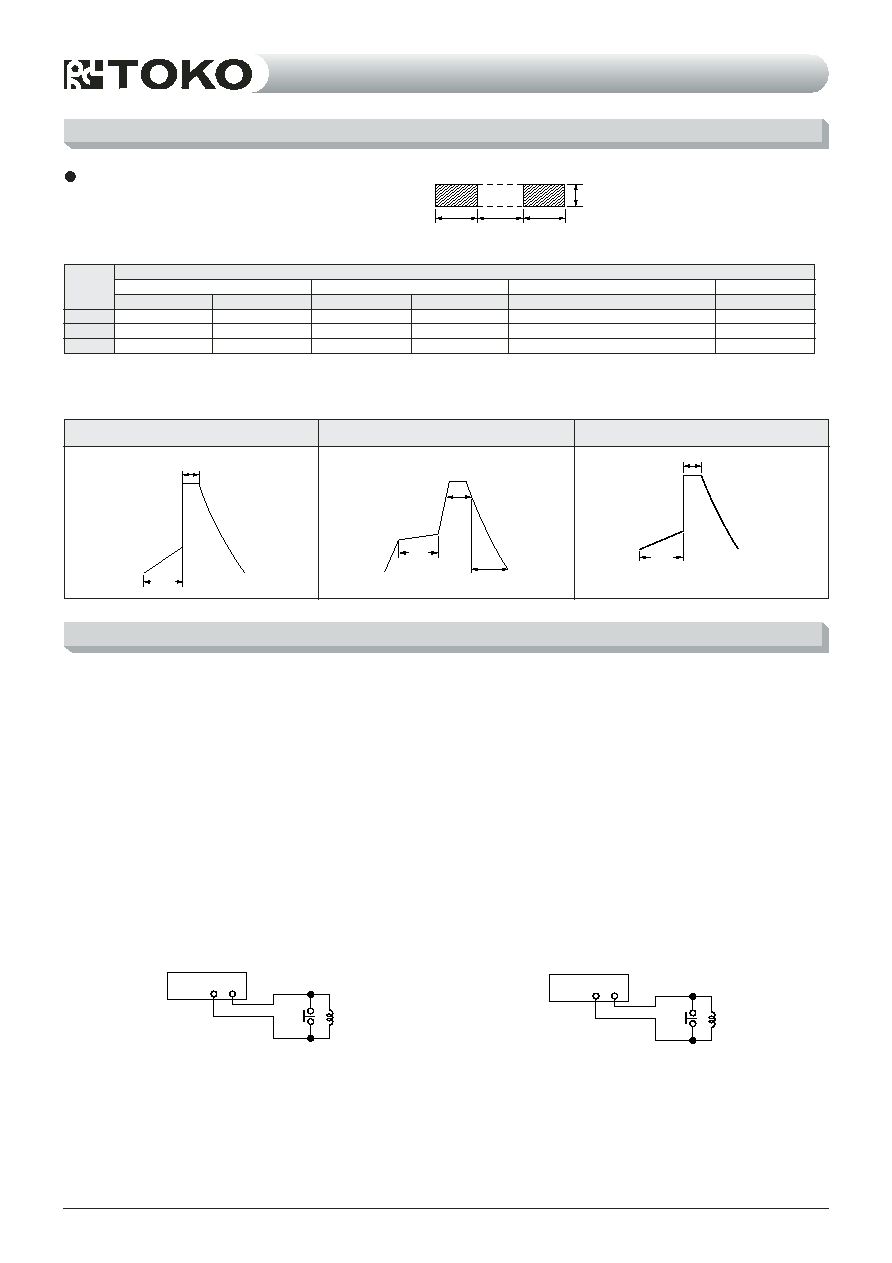

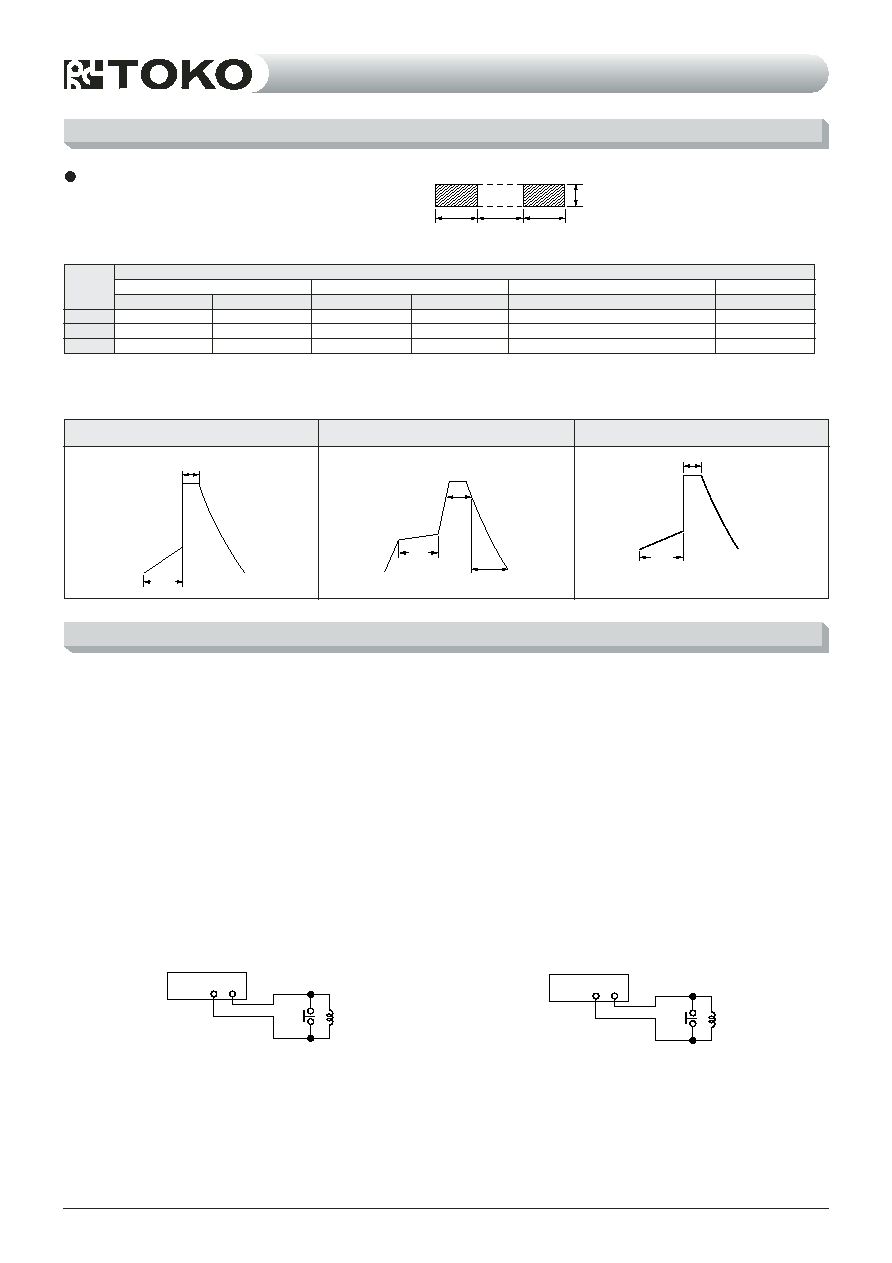

SOLDERING CONDITIONS

Recommended Pattern

∑ Conditions for soldering temperatures are determined as per figures below after prior confirmation that abnormalities are not

evident.

∑

b

b

c

a

2s.

250±10∞C

150±10∞C

2min.

Solder iron power

18W

Flow Soldering

Reflow Soldering

Soldering Iron

7s.

230±5∞C

80±20∞C

2min.

20s.

140~170∞C

240∞C

225∞C

2min.

80s.

Reflow soldering

a

b

c

Pattern dimensions (unit; mm)

LL2012 series

Flow soldering

1.0~1.4

0.8~1.2

0.8~1.0

1.0~1.2

0.6~1.0

0.8~1.2

0.8~1.0

0.8~1.0

0.6~0.8

0.7

0.6~0.8

0.6~0.8

0.4

0.4~0.5

0.45~0.55

0.25

0.18~0.22

0.30~0.35

Reflow soldering

Flow soldering

Reflow soldering

Reflow soldering

LL1608 series

LL1005 & LLP1005 series

LLV0603 series

ELECTRICAL CHARACTERISTICS TEST METHOD

Test Circuit

DC RESISTANCE

TESTER

SW

INDUCTOR

SAMPLE

SW

1. INDUCTANCE, Q

∑ Test equipment

∑ Impedance analyzer:

4291A/B(Agilent):LL1005-FHL, LL1608-FSL, LL2012-FHL,

LLP1005-FH, LLV0603-FB, LLV0603-F,

∑Test fixture: 16192A(Agilent): LL1005-FHL, LL1608-FSL,

LL2012-FHL

16196B(Agilent): LLP1005-FH

16196C(Agilent): LLV0603-FB, LLV0603-F

∑ Test method

∑ Set measuring frequency read inductance and Q value.

2. RDC (DC Resistance)

∑ Test equipment

∑ 4338A/B(Agilent) or equivalent

∑ Test method

(1) Place the sample in the test terminals.

(2)

Do not place in or pull out the sample while pushing SW.

1. Q

∑

∑ 4291A/B(Agilent): LL1005-FHL, LL1608-FSL,

LL2012-FHL, LLP1005-FH,

LLV0603-FB, LLV0603-F

∑ 16192A(Agilent): LL1005-FHL, LL1608-FSL,

LL2012-FHL

16196B(Agilent): LLP1005-FH

16196C(Agilent): LLV0603-FB, LLV0603-F

∑

∑ Q

2. R

DC

()

∑

∑ 4338A/B(Agilent)

∑

(1)

(2) SW

3. Self resonance frequency (S.R.F.)

∑ Test equipment

∑ Network Analyzer: 8719D(Agilent):0.5GHz13.5GHz

8720D(Agilent):13.6GHz20.0GHz

∑ Test Method

∑ Measure the frequency at which the phase of inductive

reactance and capacitive reactance is 0.

3. S.R.F.()

∑

∑ 8719D(Agilent):0.5GHz13.5GHz

8720D(Agilent):13.6GHz20.0GHz

∑

∑

0