| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: TA1317AN | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

TA1317AN

2002-09-06

1

TOSHIBA Bipolar Linear Integrated Circuit Silicon Monolithic

TA1317AN

Deflection Processor IC for TV

TA1317AN is a deflection processor IC for a large and wide

picture tube.

TA1317AN incorporates EW, vertical distortion correction

circuit and dynamic focus correction circuit. It can control various

functions via I

2

C BUS line.

Features

∑

Vertical drive (AC/DC-coupling)

∑

Picture height adjustment

∑

Vertical shift adjustment

∑

Vertical symmetry correction

∑

Vertical linearity correction

∑

Vertical S correction

∑

Vertical integral correction

∑

Vertical/Horizontal EHT compensation

∑

EW drive (parabola/PWM output)

∑

Picture width

∑

EW trapezium correction

∑

EW parabola correction

∑

EW corner correction (top only/bottom only/top&bottom)

∑

EW S correction

∑

Center curve correction (SAW/PAR)

∑

Parabola output for horizontal and vertical dynamic focus (H/V output independently)

∑

Horizontal and vertical dynamic focus phase adjustment

∑

Horizontal and vertical dynamic focus amplitude adjustment

∑

Horizontal dynamic focus curve characteristic adjustment

∑

V-ramp limiter circuit

∑

Analog blanking output

Weight: 1.22 g (typ.)

TA1317AN

2002-09-06

2

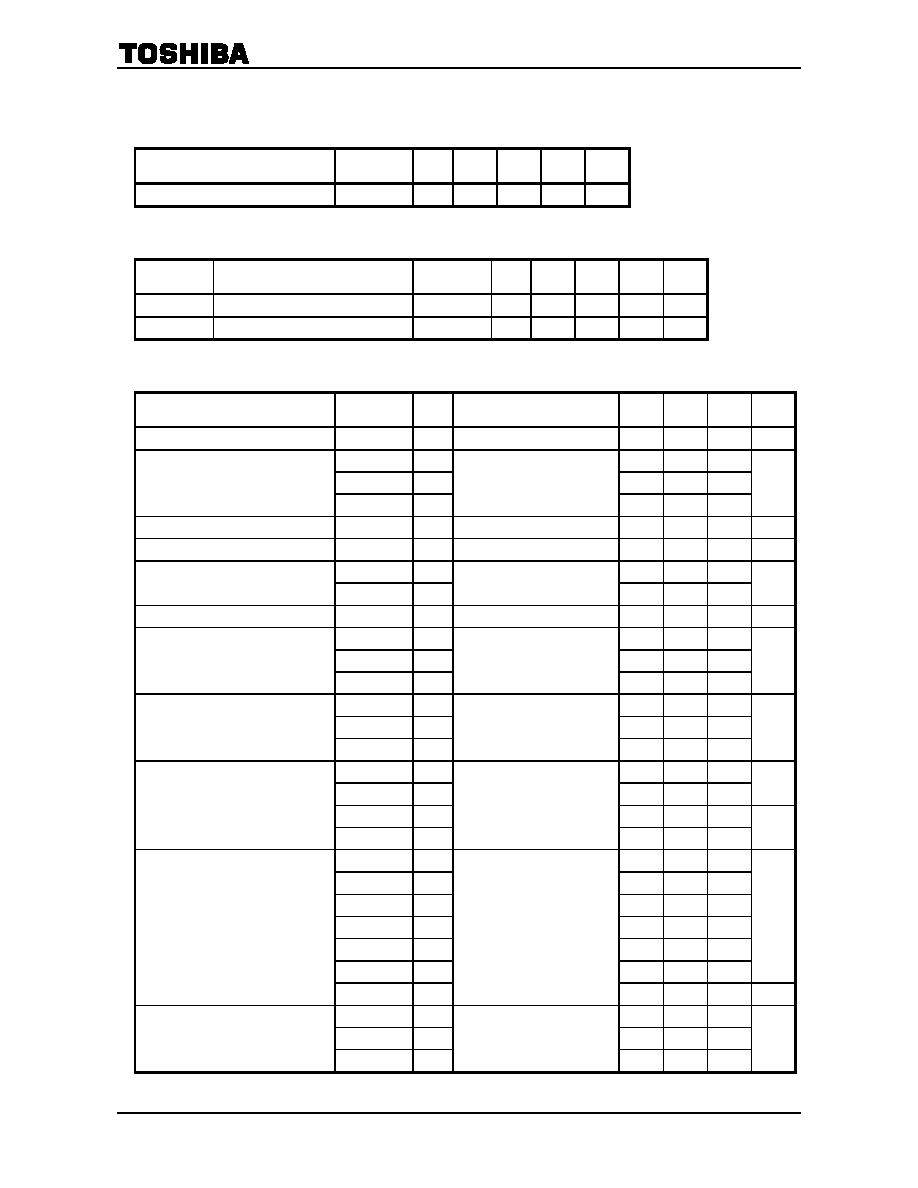

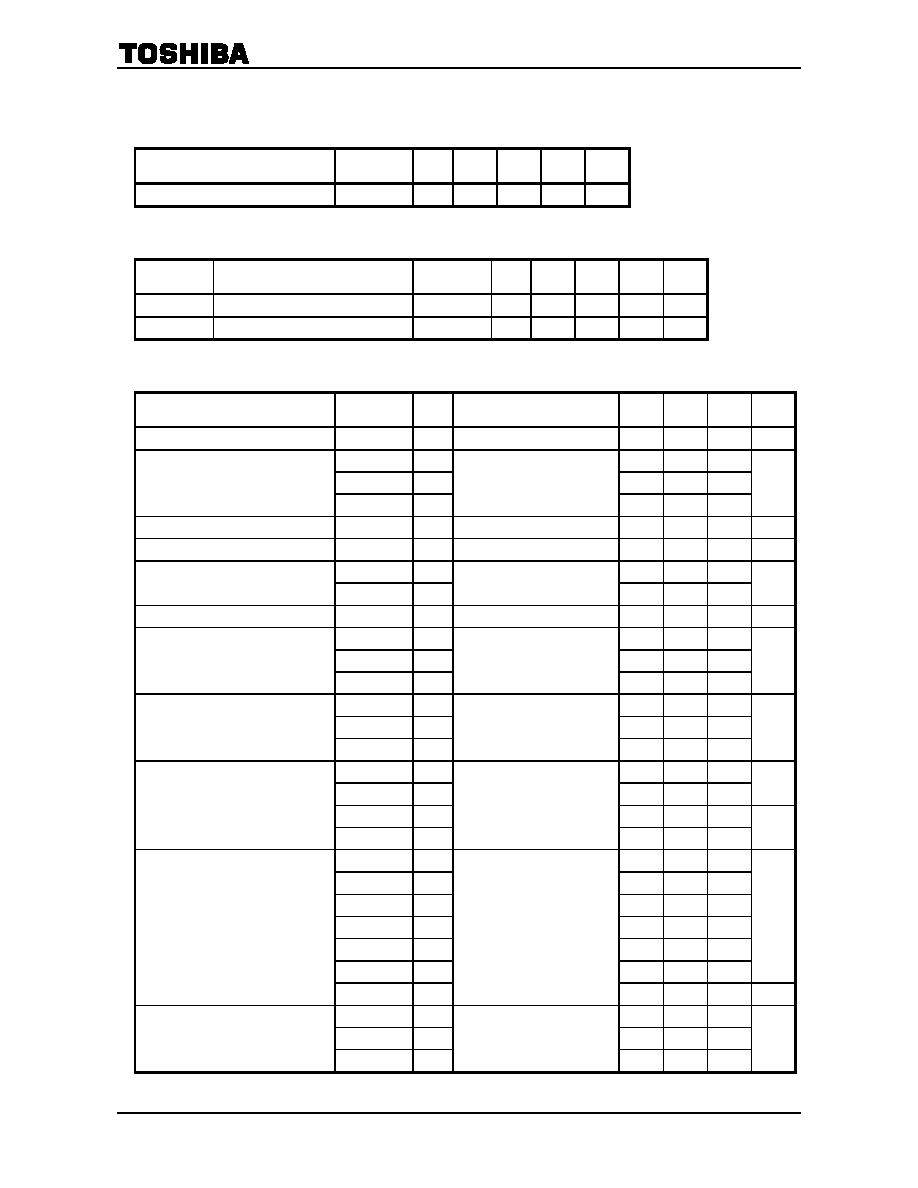

Block Diagram

12

11

1

2

3

5

4

6

7

8

9

10

13

14

24

23

22

20

21

15

19

18

17

16

V-

R

A

M

P

F

I

L

T

ER

AG

C

F

I

L

T

ER

V

REF

V

LINEARITY

V

I

EW

CORNER

AGC

PULSE

GENE

CENTER

PARABOLA

ANALOG

BLK

CENTER

SAW

V-DF

PHASE

LVP

DETECT

H-DF

PHASE

H-DF

OUT

V

SYMMETRY

EW

TRAPEZIUM

V

I

V-DF

OUT

V-DF

AMP

EW-S

CORRECTION

H-RAMP

H-DF

BATHTUB

I

2

CBUS

DECODER

V

I

CENTER

OUT

EW PWM

EW WIDTH

H EHT

EW AMP

DAC

TC

FIL

T

ER

V

IN

BL

K O

U

T

CE

NT

E

R

OUT

V-

D

F

O

U

T

L

VP IN

H-DF

OUT

DI

GI

T

A

L GND

SC

L

SD

A

V N

F

V

-

DC RE

F

CE

NT

E

R

DA

C

V

CC

EW

PW

M

EH

T IN

A

N

A

L

OG

GND

EW

F

D

V D

R

I

V

E

EW

F

I

L

T

E

R

FBP

IN

V

I

BAND-GAP

V-RAMP

+

+

+

+

V

I

V-S

CORRECTION

V-

CORRECTION

V EHT

V AMP

V PHASE

V-RAMP

LIMITER

V GUARD

DETECT

TA1317AN

2002-09-06

3

Pin Functions

Pin

No.

Pin Name

Function

Interface Circuit

Input/Output Signal

1 V

REF

Internal reference

voltage adjustment pin.

If CRT DY has

temperature coefficient,

it can be cancelled in

TV by applying inverse

temperature coefficient

to this pin. In case of

not using, connect 0.01

µ

F capacitor between

this pin and GND.

2 CENTER

DAC

DAC output pin.

When bus write function

VD

=

0, 2 bit DAC

output; VD

=

1, 7 bit

DAC output.

In case of not using, it

should be open.

DC

3 EHT

IN

EHT input pin.

In case of not using,

connect 0.01

µ

F

capacitor between this

pin and GND.

DC

4

V DRIVE

Vertical output pin

1

9

7

1 k

10 k

1 k

10.

3 k

40 k

2

9

7

50

5 k

3

7

9

4.

5 V

11 k

10 k

4

7

9

4.

5 k

100

30 k

TA1317AN

2002-09-06

4

Pin

No.

Pin Name

Function

Interface Circuit

Input/Output Signal

5 V-DC

REF

DC reference voltage

output pin when V is DC

coupling.

In case of not using, it

should be open.

DC

6 V

NF

Vertical negative

feedback input pin.

When VD

=

0, if pin is

1.2 V (typ.) or below, or

3.7 V (typ.) or higher,

returns abnormal

detection result to BUS

read function (V guard),

forcibly setting pin 20 to

High. When VD

=

1, if

pin is 2.4 V (typ.) or

below, or 7.4 V (typ.) or

higher, abnormality is

detected.

7 V

CC

V

CC

pin.

Connect 9 V (typ.).

8 EW

PWM

EW D drive (PWM)

output pin. Open

collector output.

In case of not using, it

should be open.

9 ANALOG

GND

GND pin for analog

block

10 EW

FD

EW

feedback

pin

5

9

7

5 k

30 k

40 k

1 k

6

9

7

12.5 k

50

8

9

7

10

7

60 k

9

TA1317AN

2002-09-06

5

Pin

No.

Pin Name

Function

Interface Circuit

Input/Output Signal

11 EW

FILTER

Connect phase

compensation filter for

EW output. EW

parabola waveform can

be extracted from this

pin.

12 FBP

IN

FBP input pin.

In case of not using

H-DF and EW-PWM

outputs, it should be

open.

13

SDA

SDA pin for I

2

C bus

14

SCL

SCL pin for I

2

C bus

15

DIGITAL GND

GND pin for digital block

11

7

100

9

100

500

12

9

7

500

5.

0 V

15

2.

25 V

13

7

15

3 V

50

ACK

20 k

SDA

14

7

15

3 V

20 k

SCL

Th: 2.25 V

Th: 2.25 V

Th: 2.25 V

Input frequency:

28 k~45 kHz

TA1317AN

2002-09-06

6

Pin

No.

Pin Name

Function

Interface Circuit

Input/Output Signal

16 H-DF

OUT

Outputs parabola

waveform for horizontal

dynamic focus.

Mask the pulse in

horizontal blanking if it

is not needed.

In case of not using, it

should be open.

17 LVP

IN

LVP detection pin.

Connect reference

voltage used to protect

deflection circuit against

low supply voltage. If

this pin is 5.0 V (typ.) or

below, returns abnormal

detection result to bus

read function.

In case of not using

LVP detection, it should

be open.

DC

18 V-DF

OUT

Outputs parabola

waveform for vertical

dynamic focus.

In case of not using, it

should be open.

19 CENTER

OUT

Outputs center curve

correction waveform.

Connect this pin to

curve correction input

pin of horizontal sync

IC.

In case of not using, it

should be open.

16

9

7

1 k

100

15

200

22.

5 k

18

9

7

2 k

100

1 m

A

19

9

7

1 k

100

22.

5 k

or

or composite of above

two waveforms

5 V

17

9

7

3 k

H-BLK

H-DF OUT

TA1317AN

2002-09-06

7

Pin

No.

Pin Name

Function

Interface Circuit

Input/Output Signal

20 BLK

OUT

Analog blanking output

pin. Open collector

output.

In case of not using, it

should be open.

21 V

IN

Inputs vertical trigger

pulse. Notifies

subsequent circuit of

input fall as trigger.

22 TC

FILTER

Connects filter for

generating internal

pulse.

23 V-RAMP

FILTER

Connects filter for

generating vertical ramp

signal.

200

20

9

7

1 k

200

21

9

7

2 k

22

9

7

100

10 k

Th: 1.5 V

23

9

7

1 k

100

1 k

TA1317AN

2002-09-06

8

Pin

No.

Pin Name

Function

Interface Circuit

Input/Output Signal

24 AGC

FILTER

Connects filter used to

automatically adjust

oscillation amplitude of

vertical ramp signal.

Can switch AGC

sensitivity by BUS write

function.

3.

2 V

24

9

7

1 k

2.

25 V

500

500

TA1317AN

2002-09-06

9

Bus Control Map

Write Mode

Slave Address: 8CH

(10001100)

Sub-Address

D7

MSB

D6

D5

D4

D3

D2

D1

D0

LSB

Preset

MSB LSB

00

PICTURE HEIGHT

VD

1000

0000

01

PICTURE WIDTH1

V SHIFT

1000

0000

02

V LINEARITY

V-EHT COMPENSATION

1000

0000

03

ANALOG V-BLK STOP PHASE

H-EHT COMPENSATION

1000

0000

04

ANALOG V-BLK START PHASE

V-RAMP LIMIT2

1000

0000

05

V CENTERING

V-RAMP LIMIT1

1000 0000

06

V-DF PHASE

V-DF AMPLITUDE

1000

1000

07

H-DF PHASE

H-DF AMPLITUDE

1000

1000

08

H-DF CURVE

V INTEGRAL CORRECTION

1000

0000

09

V AGC

V S CORRECTION

1000

0000

0A

*

*

EW PARABOLA

1000

0000

0B

EW TRAPEZIUM

V STOP

1000

0000

0C

EW TOP CORNER

*

*

PICTURE

WIDTH2

1000

0000

0D

EW BOTTOM CORNER

*

*

*

1000

0000

0E

EW S CORRECTION

*

*

*

1000

0000

0F

EW CORNER

*

*

*

1000

0000

10

CENTER PARABOLA

CENTER SAW

1000

1000

11

V SYMMETRY

0000 0000

Read Mode

Slave Address: 8DH

(10001101)

D7

MSB

D6

D5

D4

D3

D2

D1

D0

LSB

0

V DF

H DF

LVP

V NF

V GUARD

EW OUT

V OUT

POR

TA1317AN

2002-09-06

10

Bus Control Function

Write Mode

Register Name/Number of Bits

Function Explanation

Output Change

Picture Change

Preset

PICTURE HEIGHT/7

Adjusts the picture height.

0000000: min

1000000: center

1111111: max

center

(1000000)

VD/1 Changes

V-DRIVE

mode

0: DC-coupling

1: AC-coupling

DC-coupling

(0)

PICTURE WIDTH/7

Adjusts the picture width.

0000000: max

1000000: center

1111111: min

Sub-address 0C-D0 bit comes LSB.

center

(1000000)

V SHIFT/2

Where VD

=

0, sets DAC output level of pin 2 is set. Where

VD

=

1, sets DC level of V-DRIVE is adjusted.

00: min

11: max

min

(00)

V LINEARITY/5

Corrects the vertical linearity.

00000: min

10000: center

11111: max

center

(10000)

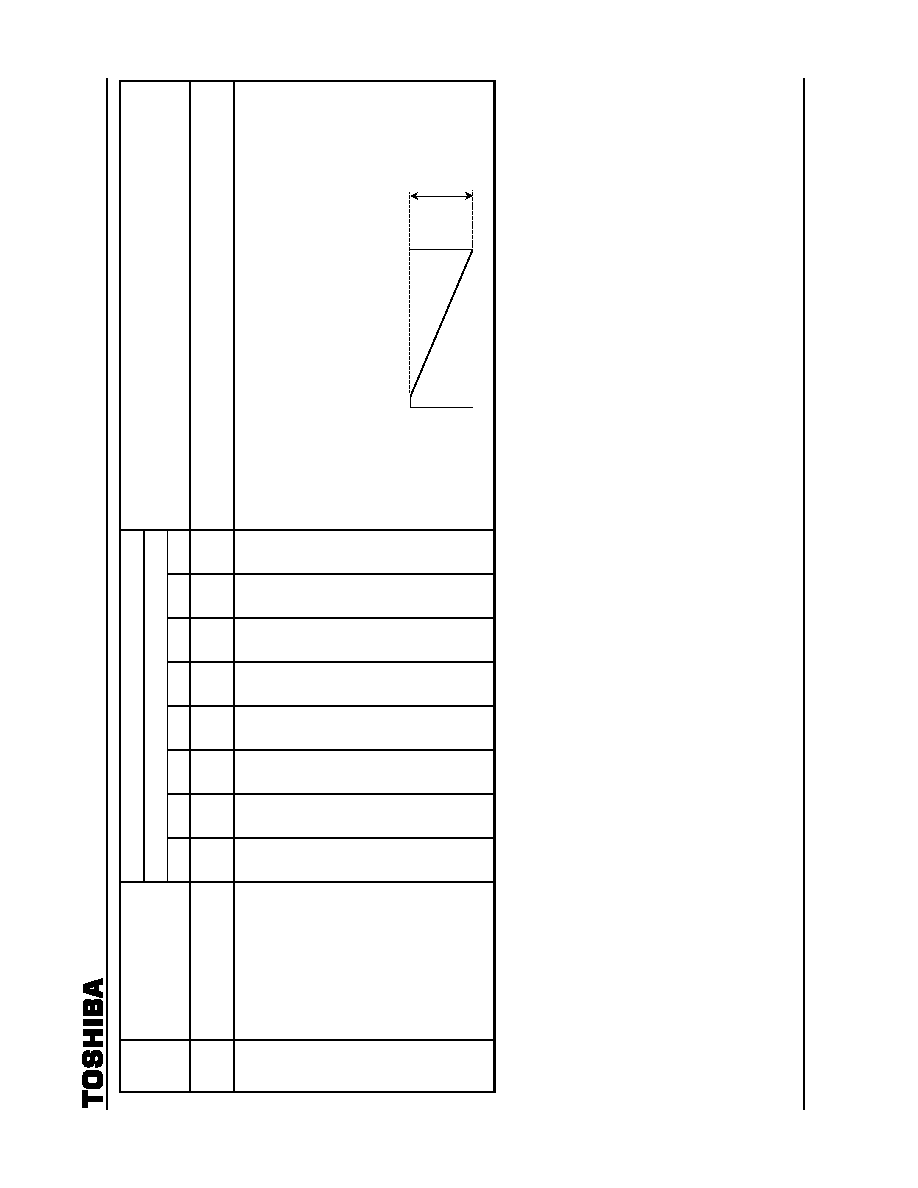

Pin 6

Pin 6 (VD

=

1)

Pin 6

Pin 11

Solid line Dashed line

Solid line Dashed line

VD

=

1

Solid line Dashed line

Solid line Dashed line

TA1317AN

2002-09-06

11

Register Name/Number of Bits

Function Explanation

Output Change

Picture Change

Preset

V-EHT COMPENSATION/3

Adjusts the compensated rate for the V-DRIVE by EHT-IN

(pin 3).

000: min

111: max

min

(000)

ANALOG V-BLK STOP PHASE/5

Sets the analog blanking stop phase on pin 20. Inputs the

output from pin 20 to an external BLK-IN of synchronization

IC.

00000: min

10000: center

11111: max

center

(10000)

H-EHT COMPENSATION/3

Adjusts the compensated rate for the EW output by EHT-IN

(pin 3).

000: min

111: max

min

(000)

ANALOG V-BLK START PHASE/5

Sets the analog blanking start phase on pin 20. Inputs the

output from pin 20 to external BLK-IN of synchronization IC.

00000: min

10000: center

11111: max

center

(10000)

V-RAMP LIMIT LEVEL/4

Sets the V-ramp slice level.

0000: OFF

0001: min

1111: max

Sub-address 05-D0 bit comes MSB.

OFF

(0000)

Pin 6

Solid line Dashed line

Solid line Dashed line

Solid line Dashed line

Pin 6

Solid line Dashed line

Pin 11

TA1317AN

2002-09-06

12

Register Name/Number of Bits

Function Explanation

Output Change

Picture Change

Preset

V CENTERING/7

Where VD

=

0, DC level of V-DRIVE is adjusted. Where VD

=

1, DAC output level of pin 2 is set.

0000000: min

1000000: center

1111111: max

min

(0000000)

V-DF PHASE/4

Adjusts the phase of vertical dynamic focus output.

0000: min

1000: center

1111: max

center

(1000)

V-DF AMPLITUDE/4

Adjusts the amplitude of vertical dynamic focus output.

0000: min

1000: center

1111: max

center

(1000)

H-DF PHASE/4

Adjusts the phase of horizontal dynamic focus output.

0000: min

1000: center

1111: max

center

(1000)

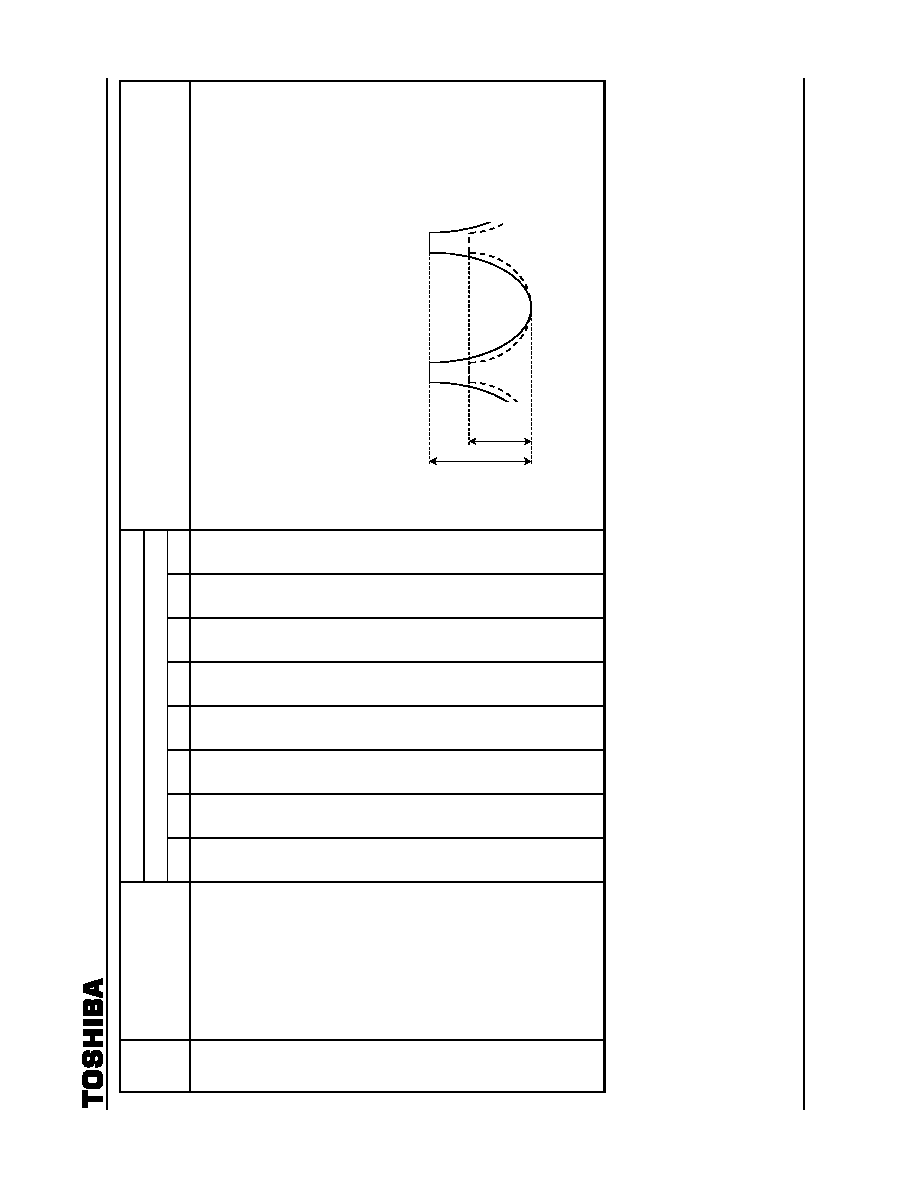

Pin 18

Pin 6 (VD

=

0)

Solid line

Dashed line

VD

=

0

Pin 16

Pin 18

TA1317AN

2002-09-06

13

Register Name/Number of Bits

Function Explanation

Output Change

Picture Change

Preset

H-DF AMPLITUDE/4

Adjusts the amplitude of horizontal dynamic focus output.

0000: min

1000: center

1111: max

center

(1000)

H-DF CURVE/4

Adjusts the curve characteristic of horizontal dynamic focus

output.

0000: max

1111: min

max

(0000)

V INTEGRAL CORRECTION/4

Adjusts the vertical integral correction.

0000: min

1111: max

min

(0000)

V AGC/2

Sets the AGC gain for V-ramp.

00: LOW

11: HIGH

LOW

(00)

V S CORRECTION/6

Adjusts the vertical S correction.

000000: min

100000: center

111111: max

min

(000000)

EW PARABOLA/6

Adjusts the amplitude of EW output.

000000: min

111111: max

min

(000000)

Pin 16

Pin 6

Pin 11

Solid line Dashed line

Solid line Dashed line

Pin 16

Solid line Dashed line

Pin 6

TA1317AN

2002-09-06

14

Register Name/Number of Bits

Function Explanation

Output Change

Picture Change

Preset

EW TRAPEZIUM/7

Adjusts the EW trapezium correction.

0000000: min

1000000: center

1111111: max

Note: When this data will be changed, V symmetry

characteristic will be also changed.

center

(1000000)

V STOP/1

Switches over the V-stop mode.

0: Normal

1: V stop/BLK stop

Normal

(0)

EW TOP CORNER/5

Adjusts the EW top corner correction.

00000: max

10000: center

11111: min

center

(10000)

EW BOTTOM CORNER/5

Adjusts the EW bottom corner correction.

00000: max

10000: center

11111: min

center

(10000)

EW S CORRECTION/5

Adjusts the EW S correction.

00000: max

10000: center

11111: min

center

(10000)

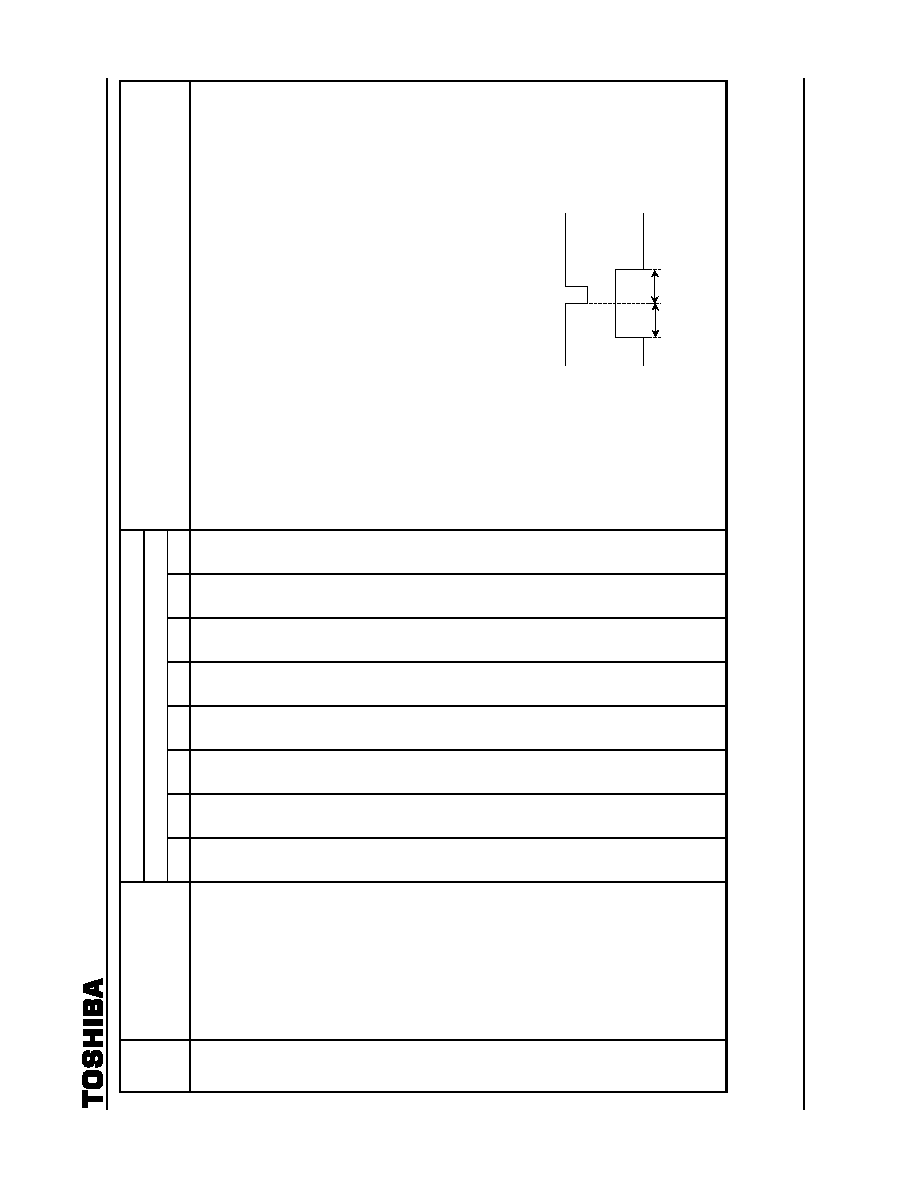

Pin 6

Pin 11

Solid line Dashed line

Solid line Dashed line

Pin 11

Pin 11

Solid line Dashed line

Solid line

Dashed line

Pin 11

TA1317AN

2002-09-06

15

Register Name/Number of Bits

Function Explanation

Output Change

Picture Change

Preset

EW CORNER/5

Adjusts the EW corner correction.

00000: max

10000: center

11111: min

center

(10000)

CENTER PARABOLA/4

Adjusts the parabola-component amplitude.

0000: max

1000: center

1111: min

center

(1000)

CENTER SAW/4

Adjusts the saw-component amplitude.

0000: min

1000: center

1111: max

center

(1000)

V SYMMETRY/8

Corrects the vertical symmetry.

00000000: min

10000000: center

11111111: max

Note: When this data will be changed, EW trapezium

characteristic will be also changed.

center

(10000000)

Pin 11

Solid line Dashed line

Solid line Dashed line

Solid line Dashed line

Pin 19

Pin 19

Solid line

Dashed line

Pin 6

TA1317AN

2002-09-06

16

Read Mode

Register Name/Number of Bits

Function Explanation

V DF/1

Vertical dynamic focus output self-check.

0: NG (no)

1: OK (yes)

H DF/1

Horizontal dynamic focus output self-check.

0: NG (no)

1: OK (yes)

LVP/1

LVP (low voltage protection) is detected.

0: OFF (pin 17 is high)

1: ON (pin 17 is low)

V NF/1

V-NF input self-check.

0: NG (no)

1: OK (yes)

V GUARD/1

Detects abnormality on V-NF input. If abnormal, Pin 20 goes high.

0: OFF (normal)

1: ON (abnormal)

EW OUT/1

EW output self-check.

0: NG (no)

1: OK (yes)

V OUT/1

V-DRIVE output self-check.

0: NG (no)

1: OK (yes)

POR/1 Power-on

reset.

Responds 0 at first reading after power-on, 1 at second reading.

0: Resister preset

1: Normal

TA1317AN

2002-09-06

17

Data Transfer Formats via I

2

C Bus

Slave address

A6 A5 A4 A3 A2 A1 A0 W/R

1 0 0 0 1 1 0 0/1

Start and Stop Condition

Bit Transfer

Acknowledge

SDA

SCL

S

Start condition

P

Stop condition

SDA

SCL

SDA stable

Change of SDA allowed

SDA by transmitter

Only bit 9: Low impedance

Clock pulse for acknowledge

S

1 8

9

SDA by receiver

SCL from master

Bit 9: High impedance

TA1317AN

2002-09-06

18

Data Transmit Format 1

Data Transmit Format 2

Data Receive Format

At the moment of the first acknowledge, the master transmitter becomes a master receiver and the slave

transmitter. This acknowledge is still generated by this slave.

The Stop condition is generated by the master.

Details are provided in the Philips I

2

C specifications.

Optional Data Transmit Format: Automatic Increment Mode

In this transmission method, data is set on automatically incremented sub-address from the specified

sub-address.

Purchase of TOSHIBA I

2

C components conveys a license under the Philips I

2

C Patent Rights to use these

components in an I

2

C system, provided that the system conforms to the I

2

C Standard Specification as defined by

Philips.

S

Slave address

0 A

Transmit data

A

Sub address

A P

7 bit

MSB

S: Start condition

8 bit

MSB

A: Acknowledge

9 bit

MSB

P: Stop condition

S

Slave address

0 A

Transmit data

A

Sub address

A

Transmit data n

A

Sub address

A P

S

Slave address

1 A

Transmit data 2

A

Transmit data 1

A P

7 bit

MSB

8 bit

MSB

S

Slave address

A

Transmit data 2

Transmit data 1

A P

7 bit

MSB

8 bit

MSB

0

Sub address

7 bit

MSB

A 1

8 bit

MSB

TA1317AN

2002-09-06

19

Maximum Ratings

(Ta

=

=

=

=

25∞C)

Characteristics Symbol Rating Unit

Power Supply voltage

V

CCmax

12

Input pin signal voltage

e

inmax

9

p-p

Power dissipation

P

D

(*) 1250

mW

Power dissipation reduction rate

1/

ja

-

10 mW/∞C

Operating temperature

T

opr

-

20~65 ∞C

Storage temperature

T

stg

-

55~150 ∞C

*: See the figure below.

Recommended Operating Conditions

Characteristics Description

Min

Typ.

Max

Unit

Supply voltage (V

CC

)

Pin

7

8.5 9.0 9.5 V

EHT input voltage

Pin 3

0.0

9.0 V

FBP input amplitude

Pin 12

4.0

9.0 V

FBP input frequency

Pin 12

28

45 kHz

FBP input width

Pin 12

2.5

µ

s

SCL/SDA pull-up voltage

Pins 13 & 14

3.0

5.0

9.0

V

LVP input voltage

Pin 17

0.0

9.0 V

V input amplitude

Pin 21

3.0

9.0 V

V input frequency

Pin 21

50

120 Hz

V input width

Pin 21

2.5

µ

s

EW PWM input current

Pin 8

5 mA

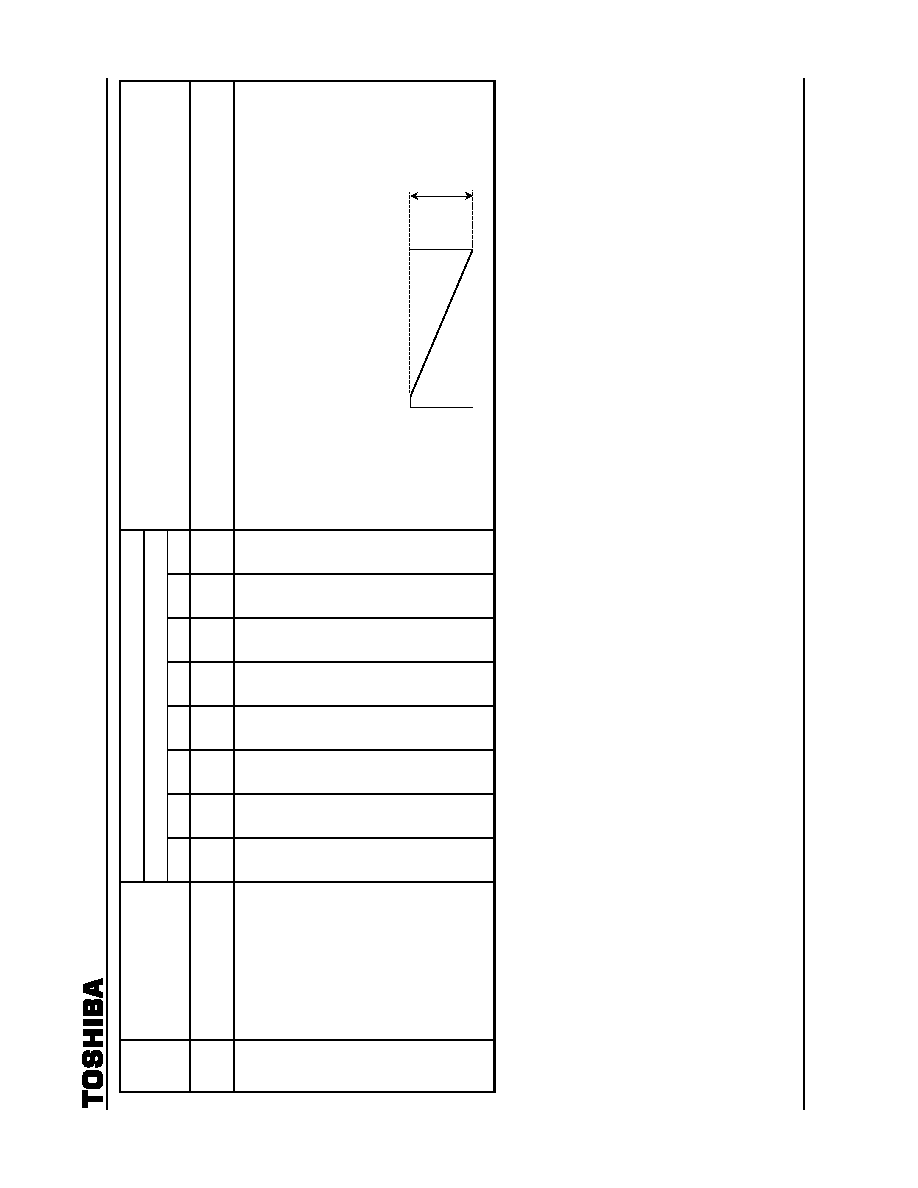

Figure 1 P

D

≠ Ta Curve

Ambient temperature Ta (∞C)

P

o

wer

dissi

pati

on P

D

(mW

)

1250

0

0

150

25 65

850

TA1317AN

2002-09-06

20

Electrical Characteristics

(unless otherwise specified,

V

CC

=

=

=

=

9 V, Ta

=

=

=

=

25∞C)

Current dissipation

Pin Name

Symbol

Test

Circuit

Min Typ. Max Unit

V

CC

I

CC

40 50.8 62 mA

Pin voltages

Pin No.

Pin Name

Symbol

Test

Circuit

Min Typ. Max Unit

1 V

REF

V

1

4.60 4.88 5.10 V

5 V

-DC

REF V

5

4.60 4.88 5.10 V

AC Characteristics

Characteristics Symbol

Test

Circuit

Test Condition

Min

Typ.

Max

Unit

Vertical trigger input shaped voltage

V

TH

(Note

1)

1.2 1.5 1.7 V

V

TCH

3.90 4.10 4.30

V

TCM

2.95 3.15 3.35

Timing pulse output voltage

V

TCL

(Note 2)

0.97 1.07 1.17

V

Vertical ramp wave amplitude

V

RMP

(Note

3)

1.65 1.75 1.85 V

p-p

Vertical drive amplification

GV

(Note

4)

21 24 27 dB

V

4H

2.5 3.3 4.1

Vertical drive output voltage

V

4L

(Note 5)

0.00 0.00 0.30

V

Vertical NF signal amplitude

V

NFM

(Note

6)

1.65 1.85 2.05 V

p-p

V

DC

(80)

3.00 3.55 4.10

V

DC

(83)

5.65 6.20 6.75

Vertical phase adjustment 1 (V shift)

change amount

V

DC

(Note 7)

2.30 2.65 3.00

V

V

DD

(00)

1.64 1.82 2.00

V

DD

(FE)

2.87 3.16 3.45

Vertical phase adjustment 2

(V centering) change amount

V

DD

(Note 8)

1.30 1.45 1.60

V

V

NFL

0.85 1.00 1.15

V

NFH

2.55 2.75 2.95

V

p-p

V

NFP

43 48 53

Vertical amplitude adjustment

(picture height) change amount

V

NFN

(Note 9)

-

53

-

48

-

43

%

V

1

(00)

0.90 1.06 1.22

V

2

(00)

0.69 0.81 0.93

V

1

(80)

0.82 0.96 1.10

V

2

(80)

0.77 0.91 1.05

V

1

(F8)

0.73 0.86 0.99

V

2

(F8)

0.85 1.00 1.15

V

p-p

Vertical linearity correction

(V linearity) change amount

V

LIN

(Note 10)

9.5 10.5 12.5 %

V

VT

(00)

4.60 4.95 5.20

V

VT

(FF)

5.40 5.70 6.00

Vertical symmetry (V symmetry)

change amount

V

VT

(Note 11)

0.67 0.76 0.85

V

TA1317AN

2002-09-06

21

Characteristics Symbol

Test

Circuit

Test Condition

Min

Typ.

Max

Unit

V

S

(80)

1.92 2.26 2.60

V

S

(BF)

1.27 1.50 1.73

V

p-p

Vertical S correction (V S correction)

change amount

V

S

(Note 12)

17 21 25 %

V

(80)

1.54 1.82 2.10

V

(8F)

1.62 1.90 2.18

V

p-p

Vertical integral correction

(V

correction) change amount

V

(Note 13)

3.0 4.0 5.2 %

V

E

(80)

1.58 1.86 2.14

V

E

(87)

1.44 1.69 1.94

V

p-p

Vertical EHT compensation (V EHT

compensation) change amount

V

EHT

(Note 14)

8.5 10.0 11.5 %

V

EHL

1.9 2.4 2.9

EHT input dynamic range

V

EHH

(Note 15)

5.9 6.4 6.9

V

V

EV

(00)

5.20 6.15 7.10

V

EV

(FC)

1.30 1.55 1.80

Horizontal amplitude adjustment

(picture width) change amount

V

EV

(Note 16)

4.20 4.60 5.00

V

V

PB

(00)

0.00 0.02 0.06

V

PB

(20)

1.6 2.0 2.3

V

PB

(3F)

2.8 3.3 3.8

Parabola amplitude adjustment

(EW parabola) change amount

V

PB

(Note 17)

2.8 3.3 3.8

V

p-p

V

TC

(00)

2.3 2.8 3.2

V

TC

(F8)

0.9 1.2 1.4

V

p-p

V

TCP

32 40 46

EW top corner correction

(EW top corner) change amount

V

TCN

(Note 18)

-

46

-

40

-

32

%

V

BC

(00)

2.4 2.8 3.2

V

BC

(F8)

0.9 1.2 1.4

V

p-p

V

BCP

32 45 55

EW bottom corner correction

(EW bottom corner) change amount

V

BCN

(Note 19)

-

52

-

40

-

35

%

V

M

(00)

2.4 2.8 3.2

V

M

(F8)

0.8 1.1 1.4

V

p-p

V

MP

40 47 57

EW corner correction change amount

V

MN

(Note 20)

-

52

-

42

-

32

%

V

S

(00)

2.2 2.6 3.0

V

S

(F8)

1.0 1.4 1.6

V

p-p

V

SP

28 35 40

EW S correction change amount

V

SN

(Note 21)

-

40

-

32

-

27

%

V

ET

(00)

2.4 2.7 3.0

V

ET

(FE)

-

3.0

-

2.7

-

2.4

ms

V

ETP

11.0 13.5 16.0

EW trapezium correction change

amount

V

ETN

(Note 22)

-

16.0

-

13.5

-

11.0

%

V

HC

(80)

3.0 3.6 4.2

V

HC

(87)

4.0 4.7 5.4

Horizontal EHT compensation (H-EHT

compensation) DC change amount

V

HC

(Note 23)

1.0 1.2 1.4

V

EHT (1)

1.55 1.90 2.20

EHT (7)

1.65 2.00 2.30

V

p-p

Parabola amplitude EHT

compensation

EHT

(Note 24)

2.7 4.0 5.3 %

TA1317AN

2002-09-06

22

Characteristics Symbol

Test

Circuit

Test Condition

Min

Typ.

Max

Unit

V

X

(00)

20 35 50

V

X

(40)

45 65 85

V

X

(80)

250 340 430

AGC operating current

V

X

(C0)

(Note 25)

535 715 895

µ

A

V

N

(8F)

4.3 5.0 5.7

Sawtooth correction (cent saw)

maximum amplitude

V

N

(80)

(Note 26)

4.3 5.0 5.7

V

p-p

V

P

(F8)

1.9 2.2 2.5

Parabola correction (cent par)

maximum amplitude

V

P

(08)

(Note 27)

1.9 2.2 2.5

V

p-p

V

HD

(80)

2.1 2.8 3.3

V

HD

(88)

2.4 3.1 4.0

V

HD

(8F)

2.6 3.4 4.3

V

p-p

V

HDP

7

10

13

Horizontal DF amplitude adjustment

(H DF amp)

V

HDN

(Note 28)

-

15

-

12

-

7

%

T

HD

(08)

-

6.0

-

4.4

-

2.0

T

HD

(F8)

2.0 4.4 6.0

Horizontal DF phase adjustment

(H DF phase)

T

HD

(Note 29)

6.5 8.8 10.0

V

p-p

T

HB

(00)

32.0 42.0 52.0

T

HB

(F0)

21.0 31.0 41.0

Horizontal DF bathtub (H DF curve)

adjustment

T

HB

(Note 30)

2.5 4.5 6.5

µ

s

V

VD

(80)

2.05 2.40 2.75

V

VD

(88)

2.30 2.70 3.10

V

VD

(8F)

2.55 3.00 3.45

V

p-p

V

VDP

7

10

13

Vertical DF amplitude adjustment

(V DF amp)

V

VDN

(Note 31)

-

15

-

10

-

7

%

T

VD

(08)

-

2.5

-

2.0

-

1.5

T

VD

(F8)

1.5 2.0 2.5

Vertical DF phase adjustment

(V DF phase)

T

VD

(Note 32)

3.4 4.0 4.6

ms

LVP detection voltage

V

LVP

(Note

33)

4.7 5.0 5.3 V

V

VGH

7.0 7.3 7.6

Vertical guard detection voltage

V

VGL

(Note 34)

2.1 2.4 2.7

V

Vertical guard detection output current

(BLK-OUT output current)

I

20

(Note

35)

450 630 750

µ

A

V

CA

(00)

0.20 0.50 0.55

Vertical centering DAC output voltage

1 (V centering)

V

CA

(FE)

(Note 36)

4.7 5.0 5.3

V

V

CD

(80)

0.20 0.60 0.80

Vertical centering DAC output voltage

2 (V shift)

V

CD

(83)

(Note 37)

4.7 5.0 5.3

V

V

Y

(00)

1.7 1.9 2.1

V

Y

(80)

2.25 2.50 2.75

Vertical centering change amount in V

STOP mode

V

Y

(FE)

(Note 38)

2.7 3.0 3.3

V

Vertical NF signal amplitude at DC

coupling

V

DFB

(Note

39)

0.85 0.95 1.05 V

p-p

Vertical NF center voltage at DC

coupling

V

C

(Note

40)

2.25 2.50 2.75 V

TA1317AN

2002-09-06

23

Characteristics Symbol

Test

Circuit

Test Condition

Min

Typ.

Max

Unit

V

CHH

20.0 26.0 32.0

Vertical ramp cut level

V

CLH

(Note 41)

26.0 32.1 38.0

%

BLHL

5.05 5.90 6.75

BLHM

2.30 2.70 3.10

BLHH

0.00

0.10

BLLL

5.10 6.00 6.90

BLLM

2.05 2.40 3.00

Analog blanking phase

BLLH

(Note 42)

0.00

0.10

ms

V

PP

(00)

0.00 0.02 0.06

V

PP

(20)

1.6 2.00 2.30

V

PP

(3F)

2.80 3.30 3.80

Parabola amplitude adjustment (EW

parabola) change amount at PWM

V

PP

(Note 43)

2.80 3.30 3.80

V

p-p

TA1317AN

2002-09-06

24

Test Condition

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

1

Vertical trigger input shaped

voltage

OFF

B

ON

OFF

B

ON

A

A

(1) Input vertical trigger pulse (figure below) to pin V

IN

.

(2) Increase vertical trigger pulse level (VT) from 0 V

P-P

. When timing pulse is output to

pin 22 (TC FILTER), measure vertical trigger pulse level V

TH

.

2

Timing pulse output voltage

OFF

B

ON

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Measure pin 22 (TC FILTER) voltages (V

TCH

, V

TCM

, V

TCL

) as shown in the figure

below.

Pin 22

(TC FILTER) waveform

Pin 23

(V-RAMP FILTER) waveform

V

TCH

V

TCM

V

TCL

640

µ

s

Vertical cycle

=

20

Vertical trigger pulse

Pulse level (VT)

0 V

TA1317AN

2002-09-06

25

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

3

Vertical ramp wave amplitude

OFF

B

ON

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Measure pin 23 (V-RAMP FILTER) amplitude V

RMP

as shown in the figure below.

4

Vertical drive amplification

OFF

C

ON

OFF

B

ON

A

A

(1) No signal input to pin V

IN

.

(2) Set VD (V-DRIVE mode switch) (sub-address: 00) to AC-Coupling mode (data: 81).

(3) Connect external power supply (V

6

) to TP6 (V fb).

(4) Change external power supply (V

6

) until pin 4 (V DRIVE) voltage is 0.8 V.

The voltage is made V

6A

.

(5) Measure pin 4 voltage (V

4A

) when the external power supply voltage is V

6A

+

0.2 V.

(6) Calculate the drive amplification (GV) using the following formula.

V

4A

-

0.8

GV

=

20 og

0.2

V

RMP

Pin 23

(V-RAMP FILTER) waveform

P

i

n 4

(V

DR

I

V

E

)

vol

t

age

(V

4

)

Pin 6 (V NF) external supply voltage (V

6

)

V

4H

V

4L

V

4A

0.8 V

V

6A

V

6A

+

0.2 V

TA1317AN

2002-09-06

26

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

5

Vertical drive output voltage

OFF

C

ON

OFF

B

ON

A

A

(1) Measure V

4H

using the figure for Note 4.

(2) Measure V

4L

using the figure for Note 4.

6

Vertical NF signal amplitude

OFF

C

ON

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Set VD (sub-address: 00) to AC-Coupling mode (data: 81).

(3) Set V INTEGRAL CORRECTION (sub-address: 08) to center (data: 88).

(4) Set V S CORRECTION (sub-address: 09) to center (data: A0).

(5) Set V SHIFT (sub-address: 01) data to 82.

(6) Measure Pin 6 (V NF) vertical sawtooth amplitude V

NFM

.

V

NFM

Pin 6

(V NF) waveform

TA1317AN

2002-09-06

27

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

7

Vertical phase adjustment 1

(V shift) change amount

OFF

B

ON

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Set VD (sub-address: 00) to AC-Coupling mode (data: 81).

(3) Set V INTEGRAL CORRECTION (sub-address: 08) to center (data: 88).

(4) Set V S CORRECTION (sub-address: 09) to center (data: A0).

(5) Set V SHIFT (sub-address: 01) to minimum (data: 80) and measure V

DC

(80) as

shown in the figure below.

(6) Set V SHIFT (sub-address: 01) to maximum (data: 83) and measure V

DC

(83) as

shown in the figure below.

(7) Calculate change amount V

DC

using the following formula.

V

DC

=

V

DC

(83)

-

V

DC

(80)

V

DC

(83)

V

DC

(80)

10 ms

Pin 6

(V NF) waveform

10 ms

TA1317AN

2002-09-06

28

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

8

Vertical phase adjustment 2

(V centering) change amount

ON

A

OFF

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Set VD (sub-address: 00) to DC-Coupling mode (data: 80).

(3) Set V INTEGRAL CORRECTION (sub-address: 08) to center (data: 88).

(4) Set V S CORRECTION (sub-address: 09) to center (data: A0).

(5) Set V CENTERING (sub-address: 05) to minimum (data: 00) and measure V

DD

(00)

as shown in the figure below.

(6) Set V CENTERING (sub-address: 05) to maximum (data: FE) and measure V

DD

(FE) as shown in the figure below.

(7) Calculate change amount V

DD

using the following formula.

V

DD

=

V

DD

(FE)

-

V

DD

(00)

V

DD

(FE)

V

DD

(00)

10 ms

Pin 6

(V NF) waveform

10 ms

TA1317AN

2002-09-06

29

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

9

Vertical amplitude adjustment

(picture height) change

amount

OFF

B

ON

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Set VD (sub-address: 00) to AC-Coupling mode (data: 81).

(3) Set V INTEGRAL CORRECTION (sub-address: 08) to center (data: 88).

(4) Set V S CORRECTION (sub-address: 09) to center (data: A0).

(5) Set V SHIFT (sub-address: 01) data to 82.

(6) Set PICTURE HEIGHT (sub-address: 00) to minimum (data: 01) and measure Pin 6

(V NF) amplitude (V

NFL

).

(7) Set PICTURE HEIGHT (sub-address: 00) to maximum (data: FF) and measure Pin

6 (V NF) amplitude (V

NFH

).

(8) Determine variable ranges (V

NFP

, V

NFN

) using the following formulas.

V

NFH

-

V

NFM

V

NFL

-

V

NFM

V

NFP

=

V

NFM

◊

100,

V

NFN

=

V

NFM

◊

100

V

NF

L

V

NF

H

Pin 6

(V NF) waveform

TA1317AN

2002-09-06

30

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

10 Vertical

linearity

correction

(V linearity) change amount

OFF

B

ON

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Set VD (sub-address: 00) to AC-Coupling mode (data: 81).

(3) Set V INTEGRAL CORRECTION (sub-address: 08) to center (data: 88).

(4) Set V S CORRECTION (sub-address: 09) to center (data: A0).

(5) Set V SHIFT (sub-address: 01) data to 82.

(6) Set V LINEARITY (sub-address: 02) to minimum (data: 00) and measure V

1

(00)

and V

2

(00) as shown in the figure below.

(7) Set V LINEARITY (sub-address: 02) to center (data: 80) and measure V

1

(80) and

V

2

(80) as shown in the figure below.

(8) Set V LINEARITY (sub-address: 02) to maximum (data: F8) and measure V

1

(F8)

and V

2

(F8) as shown in the figure below.

(9) Calculate maximum correction V

LIN

from measured result using the following

formula.

V

1

(00)

-

V

1

(F8)

+

V

2

(F8)

-

V

2

(00)

V

LIN

=

2

◊

[V

1

(80)

+

V

2

(80)]

◊

100

V

1

(

**

)

V

2

(

**

)

10 ms

Pin 6

(V NF) waveform

10 ms

TA1317AN

2002-09-06

31

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

11 Vertical

symmetry

(V symmetry) change amount

OFF

B

ON

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Set VD (sub-address: 00) to AC-Coupling mode (data: 81).

(3) Set V INTEGRAL CORRECTION (sub-address: 08) to center (data: 88).

(4) Set V S CORRECTION (sub-address: 09) to center (data: A0).

(5) Set V SHIFT (sub-address: 01) data to 82.

(6) Set V SYMMETRY (sub-address: 11) to minimum (data: 00) and measure Pin 6 (V

NF) voltage V

VT

(00).

(7) Set V SYMMETRY (sub-address: 11) to maximum (data: FF) and measure Pin 6 (V

NF) voltage V

VT

(FF).

(8) Calculate change amount V

VT

using the following formula.

V

VT

=

V

VT

(FF)

-

V

VT

(00)

V

VT

(00)

V

VT

(FF)

10 ms

Pin 6

(V NF) waveform

10 ms

TA1317AN

2002-09-06

32

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

12

Vertical S correction (V S

correction) change amount

OFF

B

ON

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Set VD (sub-address: 00) to AC-Coupling mode (data: 81).

(3) Set V INTEGRAL CORRECTION (sub-address: 08) to center (data: 88).

(4) Set V SHIFT (sub-address: 01) to 82.

(5) Set V S CORRECTION (sub-address: 09) to minimum (data: 80) and measure V

S

(80) as shown in the figure below.

(6) Set V S CORRECTION (sub-address: 09) to maximum (data: BF) and measure V

S

(BF) as shown in the figure below.

(7) Calculate maximum correction V

S

using measured result and the following formula.

V

S

(80)

-

V

S

(8F)

V

S

=

V

S

(80)

+

V

S

(8F)

◊

100

V

S

(80)

V

S

(B

F

)

Pin 6

(V NF) waveform

TA1317AN

2002-09-06

33

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

13 Vertical

integral

correction

(V

correction) change

amount

OFF

B

ON

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Set VD (sub-address: 00) to AC-Coupling mode (data: 81).

(3) Set V S CORRECTION (sub-address: 09) to center (data: A0).

(4) Set V SHIFT (sub-address: 01) to 82.

(5) Set V INTEGRAL CORRECTION (sub-address: 08) to minimum (data: 80) and

measure V

(80) as shown in the figure below.

(6) Set V INTEGRAL CORRECTION (sub-address: 08) to maximum (data: 8F) and

measure V

(8F) as shown in the figure below.

(7) Calculate maximum correction V

from measured result using the following

formula.

V

(8F)

-

V

(80)

V

=

V

(80)

◊

100

Pin 6

(V NF) waveform

V

(8F)

V

(80)

TA1317AN

2002-09-06

34

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

14

Vertical EHT compensation

(V EHT compensation)

change amount

OFF

B

ON

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Set VD (sub-address: 00) to AC-Coupling mode (data: 81).

(3) Set V SHIFT (sub-address: 01) data to 82.

(4) Connect external power supply (DC voltage

=

0 V) to pin 3 (EHT IN).

(5) Set V-EHT COMPENSATION (sub-address: 02) to minimum (data: 80) and

measure Pin 6 (V NF) amplitude V

E

(80).

(6) Set V-EHT COMPENSATION (sub-address: 02) to maximum (data: 87) and

measure Pin 6 (V NF) amplitude V

E

(87).

(7) Calculate change amount V

EHT

using the following formula.

V

E

(80)

-

V

E

(87)

V

EHT

=

V

E

(87)

◊

100

TA1317AN

2002-09-06

35

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

15

EHT input dynamic range

OFF

B

ON

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Set VD (sub-address: 00) to AC-Coupling mode (data: 81).

(3) Set V SHIFT (sub-address: 01) data to 82.

(4) Connect external power supply V

3

to pin 3 (EHT IN).

(5) Set V-EHT COMPENSATION (sub-address: 02) to maximum (data: 87).

(6) Change external power supply V

3

from 1 to 7 V and monitor Pin 6 (V NF)

amplitude.

(7) When Pin 6 (V NF) amplitude changes, measure V

3

voltages V

EHL

and V

EHH

.

16 Horizontal

amplitude

adjustment (picture width)

change amount

OFF

B

ON

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Set EW PARABOLA (sub-address: 0A) to minimum (data: 00).

(3) Set PICTURE WIDTH to maximum ( (sub-address: 01, data: FC) and (sub-address:

0C, data: 81) ) and measure Pin 10 (EW FD) voltage V

EV

(FC).

(4) Set PICTURE WIDTH to minimum ( (sub-address: 01, data: 00) and (sub-address:

0C, data: 80) ) and measure Pin 10 (EW FD) voltage V

EV

(00).

(5) Calculate change amount V

EV

using the following formula.

V

EV

=

V

EV

(FC)

-

V

EV

(00)

Voltage applied to pin 3 (EHT IN) (V

3

)

P

i

n 6

(V

NF)

a

m

pl

i

t

ude

V

EHL

V

EHH

TA1317AN

2002-09-06

36

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

17 Parabola

amplitude

adjustment (EW parabola)

change amount

OFF

B

ON

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Set PICTURE WIDTH (sub-address: 01) to maximum (data: FC).

(3) Apply external power supply (DC voltage

=

7 V) to pin 3 (EHT IN).

(4) Set EW PARABOLA (sub-address: 0A) to minimum (data: 00) and measure Pin 10

(EW FD) amplitude V

PB

(00).

(5) Set EW PARABOLA (sub-address: 0A) to center (data: 20) and measure Pin 10

(EW FD) amplitude V

PB

(20).

(6) Set EW PARABOLA (sub-address: 0A) to maximum (data: 3F) and measure Pin 10

(EW FD) amplitude V

PB

(3F).

(7) Calculate change amount V

PB

using the following formula.

V

PB

=

V

PB

(3F)

-

V

PB

(00)

Pin 10 (EW FD) waveform

V

PB

(00)

V

PB

(3F

)

TA1317AN

2002-09-06

37

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

18

EW top corner correction (EW

top corner) change amount

OFF

B

ON

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Apply external power supply (DC voltage

=

7 V) to pin 3 (EHT IN).

(3) Set EW PARABOLA (sub-address: 0A) to center (data: 20).

(4) Set EW TOP CORNER (sub-address: 0C) to minimum (data: 00) and measure Pin

10 (EW FD) amplitude V

TC

(00).

(5) Set EW TOP CORNER (sub-address: 0C) to maximum (data: F8) and measure Pin

10 (EW FD) amplitude V

TC

(F8).

(6) Calculate change amounts V

TCP

and V

TCN

using the following formulas.

V

TC

(00)

-

V

PB

(20)

V

TCP

=

V

PB

(20)

◊

100

V

TC

(F8)

-

V

PB

(20)

V

TCN

=

V

PB

(20)

◊

100

VT

C(

F8

VT

C(

00

Pin 10 (EW FD) waveform

V

TC

(F

8)

V

TC

(00)

TA1317AN

2002-09-06

38

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

19

EW bottom corner correction

(EW bottom corner) change

amount

OFF

B

ON

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Apply external power supply (DC voltage

=

7 V) to pin 3 (EHT IN).

(3) Set EW PARABOLA (sub-address: 0A) to center (data: 20).

(4) Set EW BTM CORNER (sub-address: 0D) to minimum (data: 00) and measure Pin

10 (EW FD) amplitude V

BC

(00).

(5) Set EW BTM CORNER (sub-address: 0D) to maximum (data: F8) and measure Pin

10 (EW FD) amplitude V

BC

(F8).

(6) Calculate change amounts V

BCP

and V

BCN

using the following formulas.

V

BC

(00)

-

V

PB

(20)

V

BCP

=

V

PB

(20)

◊

100

V

BC

(F8)

-

V

PB

(20)

V

BCN

=

V

PB

(20)

◊

100

VT

C(

F8

VT

C(

00

Pin 10 (EW FD) waveform

V

BC

(F

8)

V

BC

(00)

TA1317AN

2002-09-06

39

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

20

EW corner correction change

amount

OFF

B

ON

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Apply external power supply (DC voltage

=

7 V) to pin 3 (EHT IN).

(3) Set EW PARABOLA (sub-address: 0A) to center (data: 20).

(4) Set EW CORNER (sub-address: 0F) to minimum (data: 00) and measure Pin 10

(EW FD) amplitude V

M

(00).

(5) Set EW CORNER (sub-address: 0F) to maximum (data: F8) and measure Pin 10

(EW FD) amplitude V

M

(F8).

(6) Calculate change amounts V

MP

and V

MN

using the following formulas.

V

M

(00)

-

V

PB

(20)

V

MP

=

V

PB

(20)

◊

100

V

M

(F8)

-

V

PB

(20)

V

MN

=

V

PB

(20)

◊

100

Pin 10 (EW FD) waveform

V

M

(F

8)

V

M

(00)

TA1317AN

2002-09-06

40

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

21

EW S correction change

amount

OFF

B

ON

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Apply external power supply (DC voltage

=

7 V) to pin 3 (EHT IN).

(3) Set EW PARABOLA (sub-address: 0A) to center (data: 20).

(4) Set S CORRECTION (sub-address: 0E) to minimum (data: 00) and measure Pin 10

(EW FD) amplitude V

S

(00).

(5) Set S CORRECTION (sub-address: 0E) to maximum (data: F8) and measure Pin

10 (EW FD) amplitude V

S

(F8).

(6) Calculate change amounts V

SP

and V

SN

using the following formulas.

V

S

(00)

-

V

PB

(20)

V

SP

=

V

PB

(20)

◊

100

V

S

(F8)

-

V

PB

(20)

V

SN

=

V

PB

(20)

◊

100

Pin 10 (EW FD) waveform

V

S

(F

8)

V

S

(00)

TA1317AN

2002-09-06

41

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

22

EW trapezium correction

change amount

OFF

B

ON

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Apply external power supply (DC voltage

=

7 V) to pin 3 (EHT IN).

(3) Set EW PARABOLA (sub-address: 0A) to maximum (data: 3F).

(4) Set EW TRAPEZIUM (sub-address: 0B) to minimum (data: 00) and measure Pin 10

(EW FD) phase V

ET

(00).

(5) Set EW TRAPEZIUM (sub-address: 0B) to maximum (data: FE) and measure Pin

10 (EW FD) phase V

ET

(FE).

(6) Calculate change amounts V

ETP

and V

ETN

using the following formulas.

V

ET

(FE)

V

ETP

=

20

◊

100

V

ET

(00)

V

ETN

=

20

◊

100

Pin 10 (EW FD) waveform

V

ET

(00)

V

ET

(FE)

TA1317AN

2002-09-06

42

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

23

Horizontal EHT compensation

(H-EHT compensation) DC

change amount

OFF

B

ON

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Apply external power supply (DC voltage

=

1 V) to pin 3 (EHT IN).

(3) Set H-EHT COMPENSATION (sub-address: 03) to minimum (data: 80) and

measure Pin 10 (EW FD) amplitude V

HC

(80).

(4) Set H-EHT COMPENSATION (sub-address: 03) to maximum (data: 87) and

measure Pin 10 (EW FD) amplitude V

HC

(87).

(5) Calculate change amount V

HC

using the following formula.

V

HC

=

V

HC

(87)

-

V

HC

(80)

Pin 10 (EW FD) waveform

V

HC

(80)

V

HC

(87)

TA1317AN

2002-09-06

43

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

24 Parabola

amplitude

EHT

compensation

OFF

B

ON

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Apply external power supply V

3

to pin 3 (EHT IN).

(3) Set EW PARABOLA (sub-address: 0A) to center (data: 20).

(4) Set external power supply V

3

to 7 V and measure Pin 10 (EW FD) amplitude EHT

(7).

(5) Set external power supply V

3

to 1 V and measure Pin 10 (EW FD) amplitude EHT

(1).

(6) Calculate change amount EHT using the following formula.

EHT (7)

-

EHT (1)

EHT

=

EHT (7)

◊

100

25

AGC operating current

OFF

B

ON

OFF

B

ON

A

B

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) When V AGC (sub-address: 09) is switched, set data to 00, 40, 80, and C0 and

measure the following.

(3) Connect external power supply 2 V through 2 k

to pin 24 (AGC FILTER).

(4) Monitor pin 24 (AGC FILTER) and measure pulse levels V

X

(00), V

X

(40), V

X

(80),

and V

X

(C0) as shown in the figure below.

(5) Calculate output currents (I

X

(00), I

X

(40), I

X

(80), I

X

(C0) using the following

formula.

V

X

(**)

I

X

(**)

=

2 k

Pin 24 (AGC FILTER) waveform

V

X

TA1317AN

2002-09-06

44

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

26 Sawtooth

correction

(cent saw) maximum

amplitude

OFF

B

ON

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Set CENTER SAW (sub-address: 10) to maximum (data: 8F) and measure pin 19

(CENT OUT) amplitude V

N

(8F).

(3) Set CENTER SAW (sub-address: 10) to minimum (data: 80) and measure pin 19

(CENT OUT) amplitude V

N

(80).

27

Parabola correction (cent par)

maximum amplitude

OFF

B

ON

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Set CENTER PARABOLA (sub-address: 10) to maximum (data: F8) and measure

pin 19 (CENT OUT) amplitude V

P

(F8).

(3) Set CENTER PARABOLA (sub-address: 10) to minimum (data: 08) and measure

pin 19 (CENT OUT) amplitude V

P

(08).

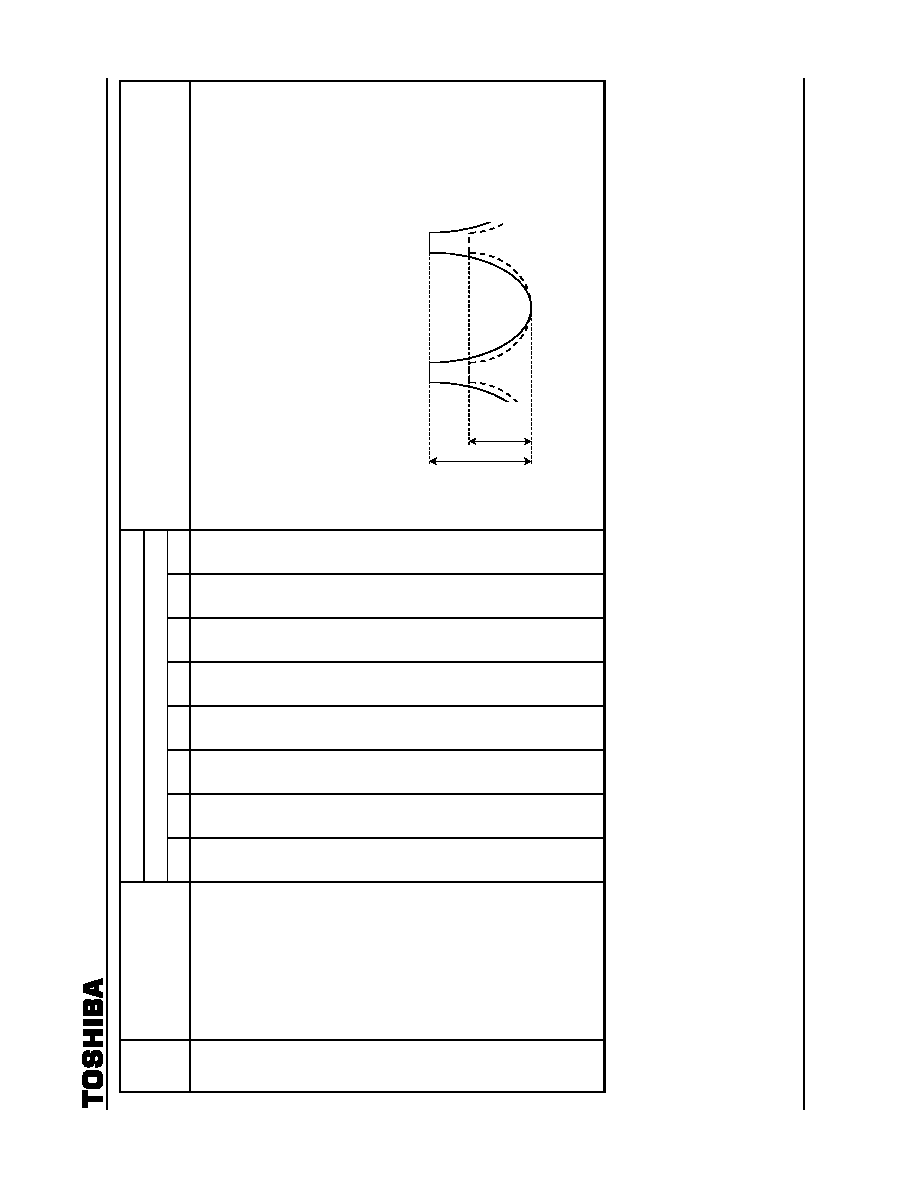

Pin 19 (CENT OUT) waveform

V

N

(8F)

Pin 19 (CENT OUT) waveform

V

N

(80)

Pin 19 (CENT OUT) waveform

Pin 19 (CENT OUT) waveform

V

P

(F8)

V

P

(08)

TA1317AN

2002-09-06

45

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

28 Horizontal

DF

amplitude

adjustment (H DF amp)

OFF

B

ON

OFF

B

ON

A

A

(1) Input horizontal trigger pulse (figure below) to pin 12 (FBP IN).

Pulse

level

(HT)

=

4.0 V

(2) Set H-DF CURVE (sub-address: 08) to maximum (data: F0).

(3) Set H-DF AMPLITUDE (sub-address: 07) to minimum (data: 80) and measure pin

16 (H-DF OUT) amplitude V

HD

(80).

(4) Set H-DF AMPLITUDE (sub-address: 07) to center (data: 88) and measure pin 16

(H-DF OUT) amplitude V

HD

(88).

(5) Set H-DF AMPLITUDE (sub-address: 07) to maximum (data: 8F) and measure pin

16 (H-DF OUT) amplitude V

HD

(8F).

(6) Calculate change amounts V

HDP

and V

HDN

using the following formulas.

V

HD

(8F)

-

V

HD

(88)

V

HDP

=

V

HD

(88)

◊

100

V

HD

(80)

-

V

HD

(88)

V

HDN

=

V

HD

(88)

◊

100

3

µ

s

H cycle

=

63.5

µ

s

Pulse level (HT)

Pin 16 (H-DF OUT) waveform

V

HD

(80)

V

HD

(8F

)

TA1317AN

2002-09-06

46

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

29 Horizontal

DF

phase

adjustment (H DF phase)

OFF

B

ON

OFF

B

ON

A

A

(1) Input horizontal trigger pulse (figure below) to pin 12 (FBP IN).

Pulse

level

(HT)

=

4.0 V

(2) Set H-DF CURVE (sub-address: 08) to maximum (data: F0).

(3) Set H-DF PHASE (sub-address: 07) to minimum (data: 08) and measure pin 16

(H-DF OUT) phase T

HD

(08).

(4) Set H-DF PHASE (sub-address: 07) to maximum (data: F8) and measure pin 16

(H-DF OUT) phase T

HD

(F8).

(5) Calculate change amount T

HD

using the following formula.

T

HD

=

T

HD

(08)

+

T

HD

(F8)

Pin 16 (H-DF OUT)waveform

T

HD

(F8)

T

HD

(08)

TA1317AN

2002-09-06

47

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

30 Horizontal

DF

bathtub

(H DF curve) adjustment

OFF

B

ON

OFF

B

ON

A

A

(1) Input horizontal trigger pulse (figure below) to pin 12 (FBP IN).

Pulse

level

(HT)

=

4.0 V

(2) Set H-DF AMPLITUDE (sub-address: 07) to maximum (data: 8F).

(3) Set H-DF CURVE (sub-address: 08) to minimum (data: 00) and measure pin 16

(H-DF OUT) phase T

HB

(00).

(4) Set H-DF CURVE (sub-address: 08) to maximum (data: F0) and measure pin 16

(H-DF OUT) phase T

HB

(F0).

(5) Calculate change amount T

HB

using the following formula.

T

HB

(00)

-

T

HB

(F0)

T

HB

=

2

Pin 16 (H-DF OUT) waveform

T

HB

(00)

T

HB

(F0)

1 V

TA1317AN

2002-09-06

48

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

31 Vertical

DF

amplitude

adjustment (V DF amp)

OFF

B

ON

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Set V-DF AMPLITUDE (sub-address: 06) to minimum (data: 80) and measure pin

18 (V-DF OUT) amplitude V

VD

(80).

(3) Set V-DF AMPLITUDE (sub-address: 06) to center (data: 88) and measure pin 18

(V-DF OUT) amplitude V

VD

(88).

(4) Set V-DF AMPLITUDE (sub-address: 06) to maximum (data: 8F) and measure pin

18 (V-DF OUT) amplitude V

VD

(8F).

(5) Calculate change amounts V

VDP

and V

VDN

using the following formulas.

V

VD

(80)

-

V

VD

(88)

V

VDP

=

V

VD

(88)

◊

100

V

VD

(8F)

-

V

VD

(88)

V

VDN

=

V

VD

(88)

◊

100

Pin 18 (V-DF OUT) waveform

V

VD

(80)

V

VD

(8F

)

TA1317AN

2002-09-06

49

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

32

Vertical DF phase adjustment

(V DF phase)

OFF

B

ON

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Set V-DF PHASE (sub-address: 06) to minimum (data: 08) and measure pin 18

(V-DF OUT) phase T

VD

(08).

(3) Set V-DF PHASE (sub-address: 06) to maximum (data: F8) and measure pin 18

(V-DF OUT) phase T

VD

(F8).

(4) Calculate change amount T

VD

using the following formula.

T

VD

=

T

VD

(08)

+

T

VD

(F8)

33

LVP detection voltage

OFF

B

ON

OFF

B

ON

B

A

(1) Connect external supply voltage V

7

to TP17 (LVP).

(2) Decrease external supply voltage V

7

from 9 V. When D5 data in Read mode

changes from 0 to 1, measure TP17 voltage V

LVP

.

34

Vertical guard detection

voltage

OFF

C

ON

OFF

B

ON

A

A

(1) Connect external supply voltage V

6

to TP6 (V NF).

(2) Switch to VD (sub-address: 00) to AC-Coupling mode (data: 81).

(3) Increase external supply voltage V

6

from 5.5 V. When D3 data in Read mode

changes from 0 to 1, measure TP6 voltage V

VGH

.

(4) Decrease external supply voltage V

6

from 5.5 V. When D3 data in Read mode

changes from 0 to 1, measure TP6 voltage V

VGL

.

Pin 18 (V-DF OUT) waveform

T

VD

(F8)

T

VD

(08)

TA1317AN

2002-09-06

50

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

35

Vertical guard detection

output current

(BLK-OUT output current)

OFF

C

ON

OFF

B

ON

A

A

(1) Connect external supply voltage V

6

=

8 V to TP6 (V NF).

(2) Measure pin 20 (BLK OUT) voltage V

20

and calculate output current (I

20

) using the

following formula.

V

20

I

20

=

10 k

36

Vertical centering DAC output

voltage 1 (V centering)

OFF

B

ON

OFF

B

ON

A

A

(1) Set VD (sub-address: 00) to AC-Coupling mode (data: 81).

(2) Set V CENTERING (sub-address: 05) to minimum (data: 00) and measure pin 2

(CENTER DAC) voltage V

CA

(00).

(3) Set V CENTERING (sub-address: 05) to maximum (data: FE) and measure pin 2

(CENTER DAC) voltage V

CA

(FE).

37

Vertical centering DAC output

voltage 2 (V shift)

OFF A OFF

OFF B ON A A

(1)

Set

VD

(sub-address:

00)

to

DC-Coupling

mode

(data:

80).

(2) Set V SHIFT (sub-address: 01) to minimum (data: 80) and measure pin 2 (CENTER

DAC) voltage V

CD

(80).

(3) Set V SHIFT (sub-address: 01) to maximum (data: 83) and measure pin 2

(CENTER DAC) voltage V

CD

(83).

38

Vertical centering change

amount in V STOP mode

ON

A

OFF

OFF

B

ON

A

A

(1) Set VD (sub-address: 00) to DC-Coupling mode (data: 80).

(2) Set to V STOP (sub-address: 0B, data: 81).

(3) Set V CENTERING (sub-address: 05) to minimum (data: 00) and measure Pin 6 (V

NF) voltage V

Y

(00).

(4) Set V CENTERING (sub-address: 05) to center (data: 80) and measure Pin 6 (V

NF) voltage V

Y

(80).

(5) Set V CENTERING (sub-address: 05) to minimum (data: FE) and measure Pin 6 (V

NF) voltage V

Y

(FE).

TA1317AN

2002-09-06

51

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17

SW24

Test Method

(unless otherwise specified, V

CC

=

9 V, Ta

=

25

±

3∞C, data

=

preset values)

39

Vertical NF signal amplitude

at DC coupling

ON

A

OFF

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Set VD (sub-address: 00) to DC-Coupling mode (data: 80).

(3) Measure vertical Pin 6 (V NF) sawtooth width V

DFB

.

40

Vertical NF center voltage at

DC coupling

ON

A

OFF

OFF

B

ON

A

A

(1) Input vertical trigger pulse to pin V

IN

.

Pulse

level

(VT)

=

3.0 V

(2) Set VD (sub-address: 00) to DC-Coupling mode (data: 80).

(3) Measure center voltage V

C

as shown in the figure below.

Pin 6

(V NF) waveform

V

DFB

Pin 6

(V NF) waveform

10 ms

V

C

10 ms

TA1317AN

2002-09-06

52

Test Condition

SW Mode

Note

No.

Parameter

SW5 SW6 SW7 SW8 SW10

SW11

SW17