| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: TA8409SG | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

TA8409S/SG, F/FG

2003-08-12

1

TOSHIBA Bipolar Linear Integrated Circuit Silicon Monolithic

TA8409S/SG, TA8409F/FG

Bridge Driver

The TA8409S/SG and TA8409F/FG are bridge drivers with

output voltage control.

Features

Modes available (CW/CCW/STOP/BRAKE)

Output current up to 0.4 A (AVE) and 1.0 A (PEAK)

Wide range of operating voltages

V

CC

(opr.) = 4.5 to 20 V

V

S

(opr.) = 0 to 20 V

V

ref

(opr.) = 0 to 20 V (V

ref

V

S

)

Built-in thermal shutdown

Standby mode available (STOP MODE)

Hysteresis for all inputs.

TA8409S/SG

TA8409F/FG

Weight

SIP9-P-2.54A: 0.92 g (typ.)

SSOP10-P-225-1.00: 0.09 g (typ.)

TA8409FG/SG:

The TA8409FG/SG is a Pb-free product.

The following conditions apply to solderability:

*Solderability

1. Use of Sn-63Pb solder bath

*solder bath temperature = 230∞C

*dipping time = 5 seconds

*number of times = once

*use of R-type flux

2. Use of Sn-3.0 Ag-0.5 Cu solder bath

*solder bath temperature = 245∞C

*dipping time = 5 seconds

*the number of times = once

*use of R-type flux

TA8409S/SG, F/FG

2003-08-12

2

Block Diagram

TA8409S/SG, TA8409F/FG

TA8409S/SG PIN : Non-connection

TA8409F/FG PIN, : Non-connection

TA8409S/SG, F/FG

2003-08-12

3

Pin Function

TA8409S/SG

Pin No.

Symbol

Functional Description

1 IN2

Input

terminal

2 V

CC

Supply voltage terminal for logic

3 OUT2

Output

terminal

4 NC

Non-connection

5 GND

GND

terminal

6 V

S

Supply voltage terminal for motor driver

7 OUT1

Output

terminal

8 V

ref

Reference voltage terminal for control circuit

9 IN1

Input

terminal

TA8409F/FG

Pin No.

Symbol

Functional Description

1 IN2

Input

terminal

2 V

CC

Supply voltage terminal for logic

3 OUT2

Output

terminal

4 NC

Non-connection

5 GND

GND

terminal

6 NC

Non-connection

7 V

S

Supply voltage terminal for motor driver

8 OUT1

Output

terminal

9 V

ref

Reference voltage terminal for control circuit.

10 IN1

Input

terminal

Function

Input Output

Mode

IN 1

IN 2

OUT1

OUT2

MB

0 0

STOP

1 0 H L

CW/CCW

0 1 L H

CCW/CW

1 1 L L

BRAKE

: High

impedance

Note: Inputs are all high active type.

TA8409S/SG, F/FG

2003-08-12

4

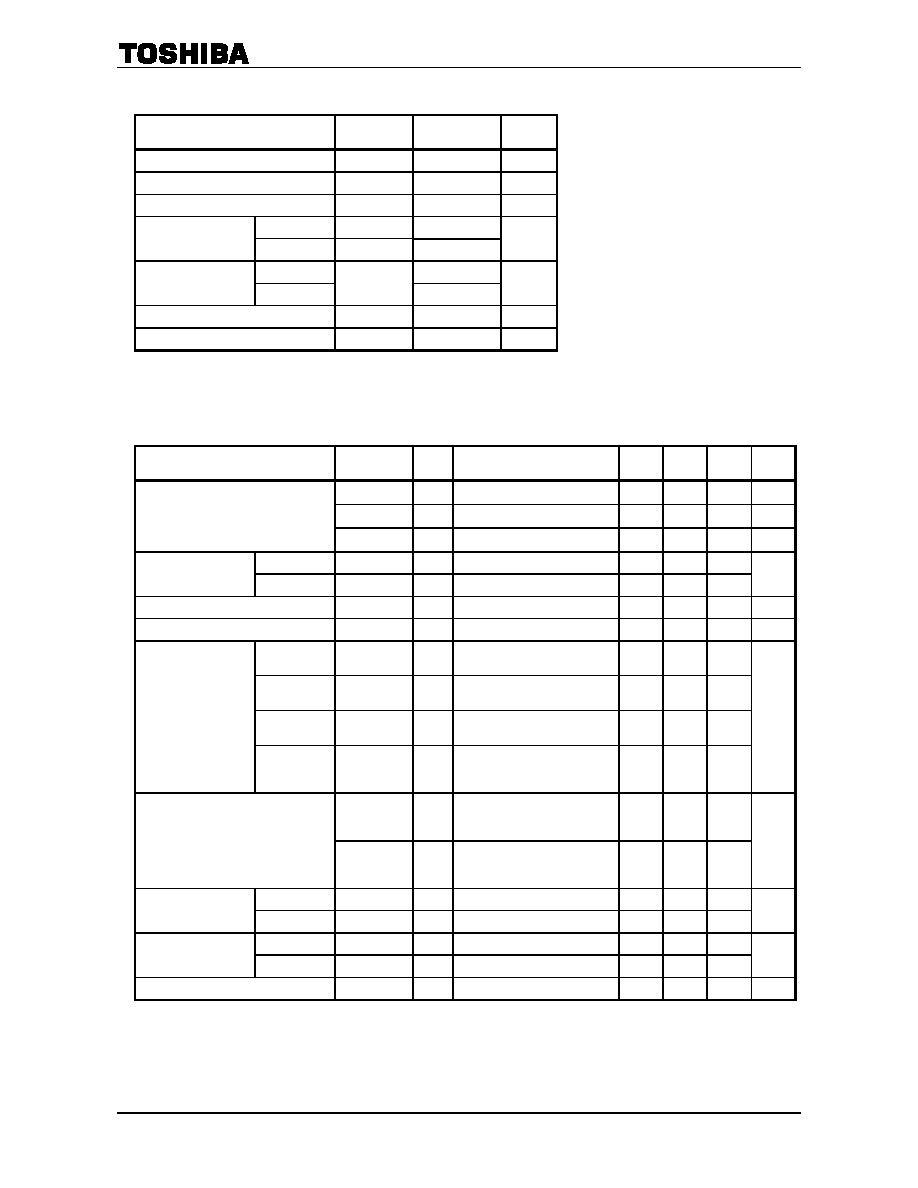

Maximum Ratings

(Ta = 25∞C)

Characteristics Symbol

Rating

Unit

Supply voltage

V

CC

25 V

Motor drive voltage

V

S

25 V

Reference voltage

V

ref

25 V

PEAK I

O

(PEAK)

1.0

Output current

AVE. I

O

(AVE.)

0.4

A

TA8409F/FG 0.735

(Note)

Power dissipation

TA8409S/SG

P

D

0.95

W

Operating temperature

T

opr

-30 to 75

∞C

Storage temperature

T

stg

-55 to 150

∞C

Note: This rating is obtained when the device is mounted on a 50 ◊ 50 ◊ 1.6 mm PCB with a Cu area of 30% or

more.

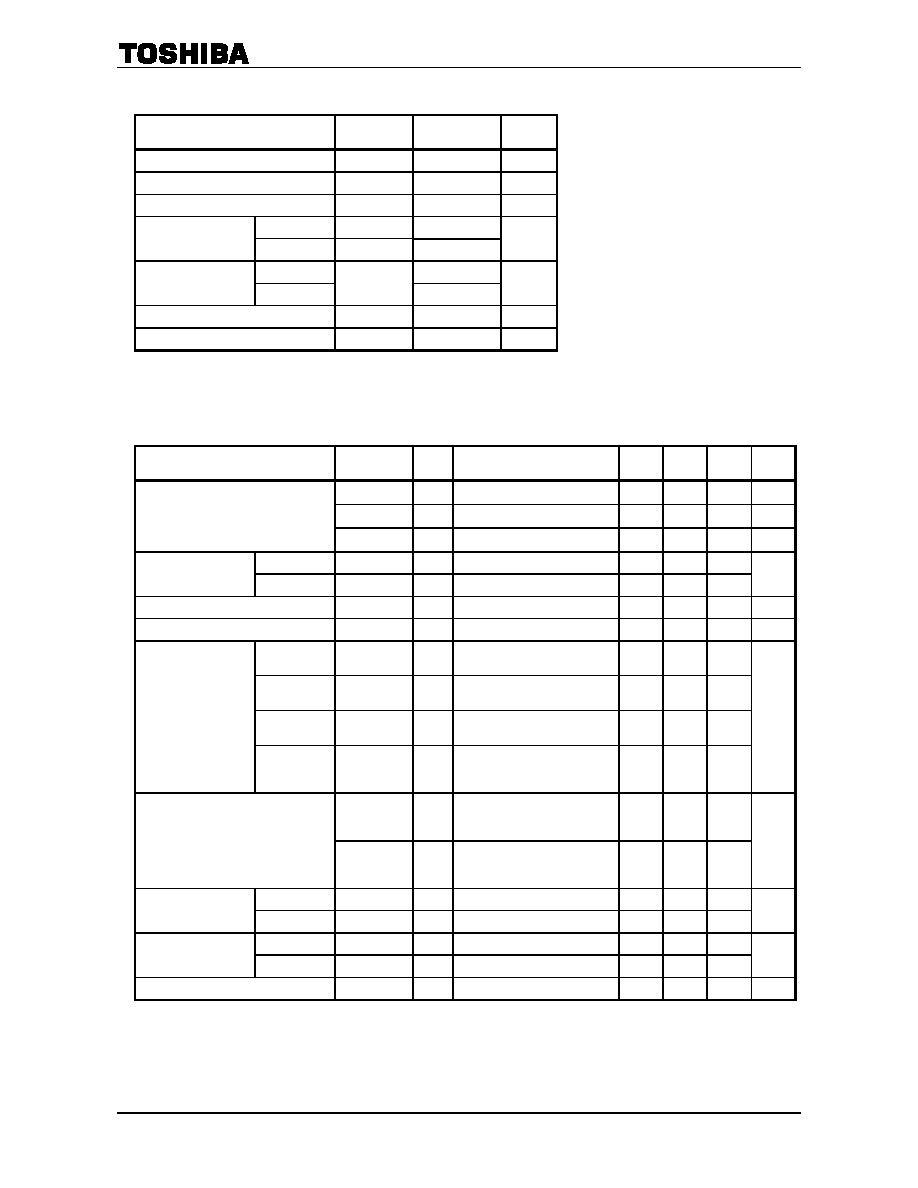

Electrical Characteristics

(Ta = 25∞C, V

CC

= 12 V, V

S

= 18 V)

Characteristics Symbol

Test

Circuit

Test Condition

Min

Typ.

Max

Unit

I

CC1

1

Output OFF, CW/CCW mode

10.0 15.0 mA

I

CC2

1

Output OFF, STOP mode

0 50 µA

Supply current

I

CC3

1

Output OFF, BREAK mode

6.5 10.0 mA

1 (High)

V

IN

1

2 T

j

= 25∞C IN1, 2

3.5

5.5

Input operating

voltage

2 (Low)

V

IN

2

2 T

j

= 25∞C IN1, 2

GND

0.8

V

Input current

I

IN

2 Sink

mode,

V

IN

= 3.5 V

3 10 µA

Input hysteresis voltage

V

T

2

0.7 V

Upper side

V

SAT

U-1

3

V

ref

= V

S

, V

OUT

-V

S

measure

I

O

= 0.2 A, CW/CCW mode

0.9 1.2

Lower side

V

SAT

L-1

3

V

ref

= V

S

, V

OUT

-GND measure

I

O

= 0.2 A, CW/CCW mode

0.8 1.2

Upper side

V

SAT

U-2

3

V

ref

= V

S

, V

OUT

-V

S

measure

I

O

= 0.4 A, CW/CCW mode

1.0 1.35

Saturation voltage

Lower side

V

SAT

L-2

3

V

ref

= V

S

, V

OUT

-GND

measure

I

O

= 0.4 A, CW/CCW mode

0.9 1.35

V

V

SAT

U-1'

3

V

ref

= 10 V, V

OUT

-GND

measure

I

O

= 0.2 A

10.4 11.2 12.2

Output voltage

V

SAT

U-2'

3

V

ref

= 10 V, V

OUT

-GND

measure

I

O

= 0.4 A

10.9

V

Upper side

I

LU

4 V

L

= 25 V

50

Output transistor

leakage current

Lower side

I

LL

4 V

L

= 25 V

50

µA

Upper side

V

F

U-1

5 I

F

= 0.4 A

1.5

Diode forward voltage

Lower side

V

F

L-1

5 I

F

= 0.4 A

0.9

V

Reference current

I

ref

2 V

ref

= 10 V, source mode

20 40 µA

TA8409S/SG, F/FG

2003-08-12

5

Test Circuit 1

I

CC1

,

I

CC2

,

I

CC3

Test Circuit 2

V

IN1

, V

IN2

, I

IN

,

V

T

, I

ref

TA8409S/SG, F/FG

TA8409S/SG, F/FG

TA8409S/SG, TA8409F/FG

TA8409S/SG, F/FG

2003-08-12

6

Test Circuit 3

V

SAT U-1, 2

,

V

SAT L-1, 2

,

V

SAT U-1', 2'

Note: Calibrate

I

OUT

to 0.2

/

0.4 A by R

L

.

Test Circuit 4

I

L U, L

Test Circuit 5

V

F U-1, 2

,

V

F L-1, 2

TA8409S/SG, F/FG

TA8409S/SG, F/FG

TA8409S/SG, F/FG

TA8409S/SG, TA8409F/FG

TA8409S/SG, TA8409F/FG

TA8409S/SG, F/FG

2003-08-12

7

TA8409F/FG

TA8409F/FG

TA8409S/SG,

TA8409S/SG,

TA8409S/SG

TA8409S/SG

TA8409S/SG, F/FG

2003-08-12

8

Application Circuit

Note 1: Attach a bypass capacitor to the Vs pin as required.

Note 2: Utmost care is necessary in the design of the output line, V

S

, V

CC

and GND line since the IC may be

destroyed by short-circuits between outputs, by supply faults, or by ground faults. Bear in mind also that

mounting the IC in the reverse orientation may also cause a breakdown.

Note 3: Switching the inputs may allow a pass-through current to flow. Keep the IC device in STOP mode (for at

least 100

µs) during the switching. Alternatively, insert a current-limiting resistor R.

Note 4: Use a current-limiting resistor R or fuse for overcurrent protection.

Note 5: When turning on the power for the IC device, apply VS after V

CC

(or V

CC

and V

S

simultaneously).

When shutting off the power, drop V

S

before V

CC

(or Vs and V

CC

simultaneously).

When turning on the power (V

CC

), keep both inputs (IN1 and IN2) on a low level.

TA8409S/SG, TA8409F/FG

7/8

GND

IN2

TA8409S/SG,F/FG

V

CC

V

S

IN1

R

M

10

µ

F

3/3

8/9

6/7

5/5

2/2

9/10

1/1

V

CC

V

S

V

ref

(Note)

OUT1

OUT2

TA8409S/SG, F/FG

2003-08-12

9

Package Dimensions

Weight: 0.92 g (typ.)

TA8409S/SG, F/FG

2003-08-12

10

Package Dimensions

Weight: 0.09 g (typ.)

TA8409S/SG, F/FG

2003-08-12

11

Notes on Contents

1. Block Diagrams

Some of the functional blocks, circuits, or constants in the block diagrams may be omitted or simplified for

explanatory purposes

.

2. Equivalent Circuits

The equivalent circuit diagrams may be simplified or some parts of them may be omitted for purposes.

3. Timing Charts

Timing charts may be simplified for explanatory purposes

.

4. Maximum Ratings

The absolute maximum ratings of a semiconductor device are a set of specified parameter values which must

not be exceeded during operation, even for an instant.

If any of these ratings are exceeded during operation, the device electrical characteristics may be irreparably

altered and the reliability and lifetime of the device can no longer be guaranteed.

Moreover, these operations with exceeded ratings may cause breakdown, damage and/or degradation to other

equipment. Applications using the device should be designed so that each maximum rating will never be

exceeded in any operating conditions.

Before using, creating and/or producing designs, refer to and comply with the precautions and conditions set

forth in this document.

5. Application Circuits

The application circuits shown in this document are provided for reference purposes only. Thorough

evaluation is required, especially at the mass production design stage.

Toshiba does not grant any license to any industrial property rights by providing these examples of application

circuits.

6. Test Circuits

Components in the test circuits are only used to obtain and confirm the device characteristics. These

components and circuits are not guaranteed to prevent malfunction or failure from occurring in the application

equipment.

About the handling of ICs

Install the product correctly to avoid breakdown, damage and/or degradation to the product or equipment.

About over-current protection and heat protection circuits

These protection functions are intended to guard against certain output short circuits or other abnormal

conditions with only temporary effect, and are not guaranteed to prevent the IC from being damaged.

These protection features may not be effective if the product is operated outside the guaranteed operating

ranges, and some output short circuits may result in the IC being damaged.

The overcurrent protection feature is only intended to protect the IC from a temporary short circuit.

Short circuits of longer duration may damage the IC through undue stress. The systems must be configured

so that any overcurrent condition will be eliminated as soon as possible.

TA8409S/SG, F/FG

2003-08-12

12

Counter-electromotive force

When the motor reverses or stops, counter-electromotive force in the motor may influence the current to flow

to the power source. If the power source lacks sink capability, the IC power and output pins may exceed the

rating. The counter-electromotive force of the motor varies depending on the conditions of use and the features

of the motor.

Therefore ensure that there is no damage to the IC or problem in operation, and no error in or damage to

peripheral circuits resulting from counter-electromotive force.

∑ The information contained herein is subject to change without notice.

∑ The information contained herein is presented only as a guide for the applications of our products. No

responsibility is assumed by TOSHIBA for any infringements of patents or other rights of the third parties which

may result from its use. No license is granted by implication or otherwise under any patent or patent rights of

TOSHIBA or others.

∑ TOSHIBA is continually working to improve the quality and reliability of its products. Nevertheless, semiconductor

devices in general can malfunction or fail due to their inherent electrical sensitivity and vulnerability to physical

stress. It is the responsibility of the buyer, when utilizing TOSHIBA products, to comply with the standards of

safety in making a safe design for the entire system, and to avoid situations in which a malfunction or failure of

such TOSHIBA products could cause loss of human life, bodily injury or damage to property.

In developing your designs, please ensure that TOSHIBA products are used within specified operating ranges as

set forth in the most recent TOSHIBA products specifications. Also, please keep in mind the precautions and

conditions set forth in the "Handling Guide for Semiconductor Devices," or "TOSHIBA Semiconductor Reliability

Handbook" etc..

∑ The TOSHIBA products listed in this document are intended for usage in general electronics applications

(computer, personal equipment, office equipment, measuring equipment, industrial robotics, domestic appliances,

etc.). These TOSHIBA products are neither intended nor warranted for usage in equipment that requires

extraordinarily high quality and/or reliability or a malfunction or failure of which may cause loss of human life or

bodily injury ("Unintended Usage"). Unintended Usage include atomic energy control instruments, airplane or

spaceship instruments, transportation instruments, traffic signal instruments, combustion control instruments,

medical instruments, all types of safety devices, etc.. Unintended Usage of TOSHIBA products listed in this

document shall be made at the customer's own risk.

∑ The products described in this document are subject to the foreign exchange and foreign trade laws.

∑ TOSHIBA products should not be embedded to the downstream products which are prohibited to be produced

and sold, under any law and regulations.

030619EBA

RESTRICTIONS ON PRODUCT USE