| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: TB6581H | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

TB6581H/HG

2004-03-01

1

TOSHIBA Bi-CMOS Power Integrated Circuit Multi-Chip Package (MCP)

TB6581H/HG

3-Phase Full-Wave Sine-Wave PWM Brushless Motor Controller

The TB6581H/HG is a high-voltage PWM BLDC motor driver.

The product integrates the TB6551F/FG sine-wave controller and

the TPD4103AK high-voltage driver in a single package ("2-in-1").

It is designed to change the speed of a BLDC directly motor by

using a speed control signal (analog) from a microcontroller.

Features

∑

A sine wave PWM drive controller and a high-voltage driver

integrated in a single package.

∑

IGBTs arranged in three half-bridge units

∑

Triangle wave generator (carrier frequency = f

osc

/254 (Hz))

∑

Dead-time insertion (1.9 µs)

∑

High-side bootstrap supply

∑

Bootstrap diode

∑

Overcurrent protection, thermal shutdown, and undervoltage lockout

∑

On-chip regulator (V

reg

= 7 V (typ.), 30 mA (max),

Vrefout = 5 V (typ.), 30 mA (max))

∑

Operating power supply voltage range: V

CC

= 13.5~16.5 V

∑

Motor power supply operating voltage range: VB = 50~400 V

Weight:

HZIP25-P-1.00K: 7.7 g (typ.)

TB6581HG:

TB6581HG is a Pb-free product.

The following conditions apply to solderability:

*Solderability

1.

Use of Sn-63Pb solder bath

*solder bath temperature = 230∞C

*dipping time = 5 seconds

*number of times = once

*use of R-type flux

2.

Use of Sn-3.0Ag-0.5Cu solder bath

*solder bath temperature = 245∞C

*dipping time = 5 seconds

*the number of times = once

*use of R-type flux

TB6581H/HG

2004-03-01

2

Pin Description

Pin No.

Symbol

Description

Function

1

PGND

Grounding pin

Power ground

2

VREG

Reference voltage output Connected to pin 5. 7 V (typ.), 30 mA (max)

3

IS

IGBT emitter pin

For connecting a current sensing resistor to ground.

4

NC

Not connected

This pin is left open and can be used as a jumper on a PCB.

5 V

CC7

Signal control power

supply pin

Connected to pin 2. The control stage operating voltage: V

CC

=

6 to 10 V

6 V

refout

Reference

voltage

output 5 V (typ.), 30 mA (max)

For connecting a bypass capacitor for internal V

DD

.

7

Idc

Current limit input

DC link input

Reference potential of 0.5 V. This pin has a filter (

-

1

µ

s).

8

SGND

Grounding pin

Signal ground

9 X

in

Clock

input

10 X

out

Clock

output

These pins have a feedback resistor. For connecting to a crystal oscillator.

11

Ve

Voltage command input

This pin has a pull-down resistor.

12 HU

U-phase position sensing

input

13 HV

V-phase position sensing

input

14 HW

W-phase position

sensing input

If the position sensing inputs are all HIGH or LOW, the outputs are turned off.

This pin has a pull-up resistor.

15

LA

Lead angle control input

0 to 58∞ in 32 steps

16

FG

FG signal output

This pin drives three pulses per rotation.

17

REV

Reverse rotation signal

For reverse rotation detection.

18 BSU

Bootstrap supply

(phase U)

For connecting a bootstrap capacitor to the U-phase output.

19 U

U-phase

output

pin

20 BSV

Bootstrap supply

(phase V)

For connecting a bootstrap capacitor to the V-phase output.

21 V

V-phase

output

pin

22 BSW

Bootstrap supply

(phase W)

For connecting a bootstrap capacitor to the W-phase output.

23

W

W-phase output pin

24 VB

High-voltage power

supply pin

Power supply pin for driving a motor.

25 V

CC15

Power supply pin for the

power stage

Power stage operating range: V

CC

=

15 V

TB6581H/HG

2004-03-01

3

Pin Assignment

Maximum Ratings

(Ta

=

25∞C)

Characteristics Symbol

Rating

Unit

V

CC7

12

V

CC15

18

Power supply voltage

VB 500

V

V

in (1)

-

0.3 to V

CC1

(Note 1)

Input voltage

V

in (2)

-

0.3 to 5.5

(Note 2)

V

PWM output current

I

OUT

2

(Note 3)

A

Power dissipation

P

D

40

(Note 4)

W

Operating temperature

T

opr

-

30 to 115

(Note 5)

∞C

Storage temperature

T

stg

-

50 to 150

∞C

Note 1: V

in (1)

pin: V

e

, LA

Note 2: V

in (2)

pin: I

dc

, HU, HV, HW

Note 3: Apply pulse

Note 4: Package thermal resistance (

j-c

=

1∞C/W) with an infinite heat sink at Ta

=

25∞C

Note 5: The operating temperature range is determined according to the P

D

MAX

-

Ta characteristics.

V

CC7

1

PGND

VREG

IS

Vrefout Xout

Xin

BSU

U

BSV

V

BSW

W

VB

V

CC15

SGND FG

HU

NC

HV

HW

Ve

LA

REV

2 3 4 5 6

7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

Idc

TB6581H/HG

2004-03-01

4

Recommended operating conditions

(Ta

=

25∞C)

Characteristics Symbol

Min

Typ.

Max

Unit

V

CC7

6 7

10

Power supply voltage

V

CC15

13.5

15 16.5

V

Crystal oscillator frequency

X

in

2 4 5

MHz

Motor power supply voltage

VB

50

280

400

V

Output current

Iout

1 2 A

P

D

Max ≠ Ta

Ambient temperature Ta (∞C)

Pow

e

r

dis

s

ip

at

io

n

P

D

ma

x

(

W

)

(1)

(2)

(3)

25

0

150

0

80

75

40

100

20

60

50

125

(1) INFINITE HEAT SINK

R

j-c

=

1∞C/W

(2) HEAT SINK (R

HS

=

3.5∞C/W)

R

j-c

+

R

HS

=

4.5∞C/W

(3) NO HEAT SINK

R

j-a

=

39∞C/W

TB6581H/HG

2004-03-01

5

Electrical Characteristics

(Ta

=

25∞C)

Characteristics Symbol Test

Condition Min

Typ.

Max

Unit

I

B

V

B

=

400 V

0.1 0.5

I

CC15

V

reg

=

OPEN, V

CC

=

15 V

1.1 3

I

CC7

V

refout

=

OPEN, V

CC

=

7 V

3 6

mA

I

BS (ON)

V

BS

=

15 V, high-side ON

260 410

Current dissipation

I

BS (OFF)

V

BS

=

15 V, high-side OFF

230 370

µ

A

I

in

(LA)

Vin

=

5 V, LA

25 50

I

in

(V

e

) Vin

=

5 V, V

e

35 70

Input current

I

in

(Hall)

Vin

=

0 V, HU, HV, HW

-

50

-

25

µ

A

HIGH

V

refout

-

1

V

refout

V

in

(Hall)

LOW

HU, HV, HW

0.8

HIGH PWM

Duty

100%

5.1 5.4 5.7

Middle Refresh

Start motor operation

1.8

2.1

2.4

Input voltage

V

in

(V

e

)

LOW Turned-off

Refresh

0.7 1.0 1.3

V

Input hysteresis voltage

V

H

HU, HV, HW

(Note 6)

0.3

V

V

DT

HU, HV, HW

X

in

=

4.19 MHz

4.0

Input delay time

V

DC

Idc

X

in

=

4.19 MHz

4.0

µ

s

V

CEsat

H V

CC

=

15 V, IC

=

0.5 A

2.4 3

Output saturation voltage

V

CEsat

L V

CC

=

15 V, IC

=

0.5 A

2.4 3

V

V

FG (H)

I

OUT

=

1 mA

FG

V

refout

-

1.0

V

refout

-

0.2

V

FG (L)

I

OUT

=

-

1 mA

FG

0.2 1.0

V

refout

I

OUT

=

30 mA

V

refout

4.5 5.0 5.5

Output voltage

V

reg

I

OUT

=

30 mA

6.5

7

7.5

V

V

F

H IF

=

0.5 A, high-side

1.3 2.0

FRD forward voltage

V

F

L IF

=

0.5 A, low-side

1.3 2.0

V

BSD forward voltage

V

F (BSD)

IF

=

500

µ

A

0.9 1.2 V

Current detection

V

dc

I

dc

0.47

0.5

0.53

V

TSD

150 165 200

Thermal shutdown protection

TSDhys

(Note 7)

20

∞C

V

CC15

(H)

Undervoltage positive-going threshold

10.5

11.5

12.5

V

CC15

undervoltage protection for

driver

V

CC15

(L)

Undervoltage negative-going threshold

10

11

12

V

VBS (H)

Undervoltage positive-going threshold

8.5

9.5

10.5

VBS undervoltage protection for driver

VBS (L)

Undervoltage negative-going threshold

8

9

10

V

V

CC7

(H)

Undervoltage positive-going threshold

4.2

4.5

4.8

V

CC7

undervoltage protection for

controller

V

CC7

(L)

Undervoltage negative-going threshold

3.7

4.0

4.3

V

t

on

V

BB

=

280 V, V

CC

=

15 V, IC

=

0.5 A

1.5 3

Output turn-on/-off delay time

t

off

V

BB

=

280 V, V

CC

=

15 V, IC

=

0.5 A

1.2 3

µ

s

Dead time

tdead

X

in

=

4.19 MHz

1.5

1.8

µ

s

FRD reverse recovery time

t

rr

V

BB

=

280 V, V

CC

=

15 V, IC

=

0.5 A

200

ns

Note 6 and Note 7: Toshiba does not implement testing before shipping.

TB6581H/HG

2004-03-01

6

Functional Description

1. Basic

operation

The motor is driven by the square-wave turn-on signal based on a positional signal. When the positional

signal reaches number of rotations f

= 5 Hz or higher, the rotor position is estimated according to the

positional signal and a modulation wave is generated. The modulation wave and the triangular wave are

compared; then the sine-wave PWM signal is generated and the motor is driven.

From start to 5 Hz: When driven by square wave (120∞ turn-on) f

= f

osc

/(2

12

◊ 32 ◊ 6)

5 Hz~: When driven by sine-wave PWM (180∞ turn-on); when f

osc

= 4 MHz, approx. 5 Hz

2. V

e

voltage command input and bootstrap power supply

(1)

Voltage command input: When V

e

<

= 1.0 V

U, V and W signals are stopped to protect IGBTs

(2)

Voltage command input: When 1.0 V

< V

e

<

= 2.1 V

The low-side IGBTs are turned on at a fixed frequency (carrier frequency) (duty cycle: 8%).

(3)

Voltage command input: When V

e

> 2.1 V

The U, V and W signals are driven out during sine wave drive.

The low-side IGBTs are forced to on at fixed frequency (carrier frequency) during square-wave drive

(duty cycle: 8%).

Note 1: At startup, the low-side IGBTs must be turned on for a fixed period at 1.0 V

<

V

e

<

=

2.1 V to charge the

high-side IGBT power supply.

3. Dead time function: upper/lower transistor output off-time

When the motor is driven by sine-wave PWM, dead time is digitally generated inside the IC to prevent

short circuit caused by the simultaneously turning on of upper and lower external power devices. When a

square wave is generated in full-duty cycle mode, the dead time function is turned on to prevent a short

circuit.

Internal Counter

T

OFF

8/f

osc

1.9

µ

s

T

OFF

values above are obtained when fosc = 4.19 MHz.

f

osc

= reference clock (crystal oscillation)

4. Correcting the lead angle

The lead angle can be corrected in the turn-on signal range from 0 to 58∞ in relation to the induced

voltage.

Analog input from LA pin (0 V to 5 V divided by 32)

0 V

= 0∞

5 V

= 58∞ (when more than 5 V is input, 58∞)

(1)

(2) (3)

100%

2.1 V

1.0 V

5.4 V

Ve

PWM duty cycle

(1) 0 to 1.0 V: Reset state (All outputs are off.)

(2) Ve

=

1.0 to 2.1 V: Startup operation

(duty cycle of 8% for the low-side IGBTs)

(3) Ve

=

2.1 to 5.4 V: Running state

(5.4 V or higher: PWM duty cycle = 100%)

TB6581H/HG

2004-03-01

7

5. Setting the carrier frequency

This function sets the triangular wave cycle (carrier cycle) necessary for generating the PWM signal.

(The triangular wave is used for forcibly turning on the lower transistor when the motor is driven by

square wave.)

Carrier cycle

= f

osc

/252 (Hz) f

osc

= reference clock (crystal oscillation)

6. Outputting the reverse rotation detection signal

This function detects the motor rotation direction every electrical angle of 360∞. This function judges

whether the actual direction of a rotating motor coincides with that of the internal reference voltage.

Actual Motor Rotating Direction

REV Pin

Drive Mode

CW (forward)

HIGH

Square waveform (120∞ turn-on mode)

CCW (reverse)

LOW

Sine-wave waveform (180∞ turn-on mode)

*:

CW or CCW of the motor is determined by the direction of the Hall signal, which is specified in the timing

chart on page 9.

*:

When the REV pin is set to LOW, and the Hall signal is higher than 5 Hz, sine-wave drive mode is turned

on.

7. Protecting

input

pin

(1)

Overcurrent protection (Pin I

dc

)

When the DC-link-current exceeds the internal reference voltage, gate block protection is performed.

Overcurrent protection is released for each carrier frequency.

Reference voltage

= 0.5 V (typ.)

(2)

Positional signal abnormality protection

Output is turned off when the positional signal is HHH or LLL; otherwise, it is restarted.

(3)

Monitor protection for V

CC7

/ V

CC15

low supply voltage

For power supply on/off outside the operating voltage range, the U, V and W drive outputs are

turned off and the motor is stopped when there is a power supply fault.

< V

CC7

>

< V

CC15

>

Turn-off drive output

Turn-off drive output

Turn-on drive output

Power supply voltage 4.5 V (typ.)

4.0 V (typ.)

GND

V

B

V

CC7

Output

Turn-off drive output

Turn-on drive output

Power supply voltage 11.5 V (typ.)

11.0 V (typ.)

GND

V

B

V

CC15

Turn-off drive output

Output

TB6581H/HG

2004-03-01

8

(4)

Monitor protection for V

BS

Bootstrap power supply

When V

BS

power supply is lowered, the high-side IGBT is turned off.

(5)

Overheat protection

The overheat protection circuit will operate and all IGBTs will be turned off if the chip temperature

becomes abnormally high due to internal or external heat generation.

T

SD

= 165∞C (typ.)

T

SDhys

= 20∞C (typ.)

After the overheat protection circuit is turned on, the return temperature is 145∞C (typ.).

Turn-off high-side IGBT

Turn-off high-side IGBT

High-side IGBT

V

BS

(Output -BS)

9.5 V (typ.)

9.0 V (typ.)

Output

TB6581H/HG

2004-03-01

9

Timing Chart

∑

CW (forward) mode (CW mode means that the Hall signal is input in the order shown below.)

∑

CCW (reverse) mode (CCW mode means that the Hall signal is input in the order shown below.)

Motor drive

output

waveform

(line voltage)

Hall signal

(input)

H

u

H

v

H

w

FG signal

(output)

FG

Turn-on signal

when driven

by square wave

(inside the IC)

U

V

W

X

Y

Z

REV signal

(output)

REV

(HIGH

)

V

uv

V

vw

V

wu

* The waveform of actual

operation is the PWM

Motor drive

output

waveform

(line voltage)

H

u

H

v

H

w

FG signal

(output)

FG

REV

(LO

W)

Modulation

waveform when

driven by sine

wave

(inside of IC)

S

u

S

v

S

w

Hall signal

(input)

REV signal

(output)

V

uv

V

vw

V

wu

* The waveform of actual

operation is the PWM

TB6581H/HG

2004-03-01

10

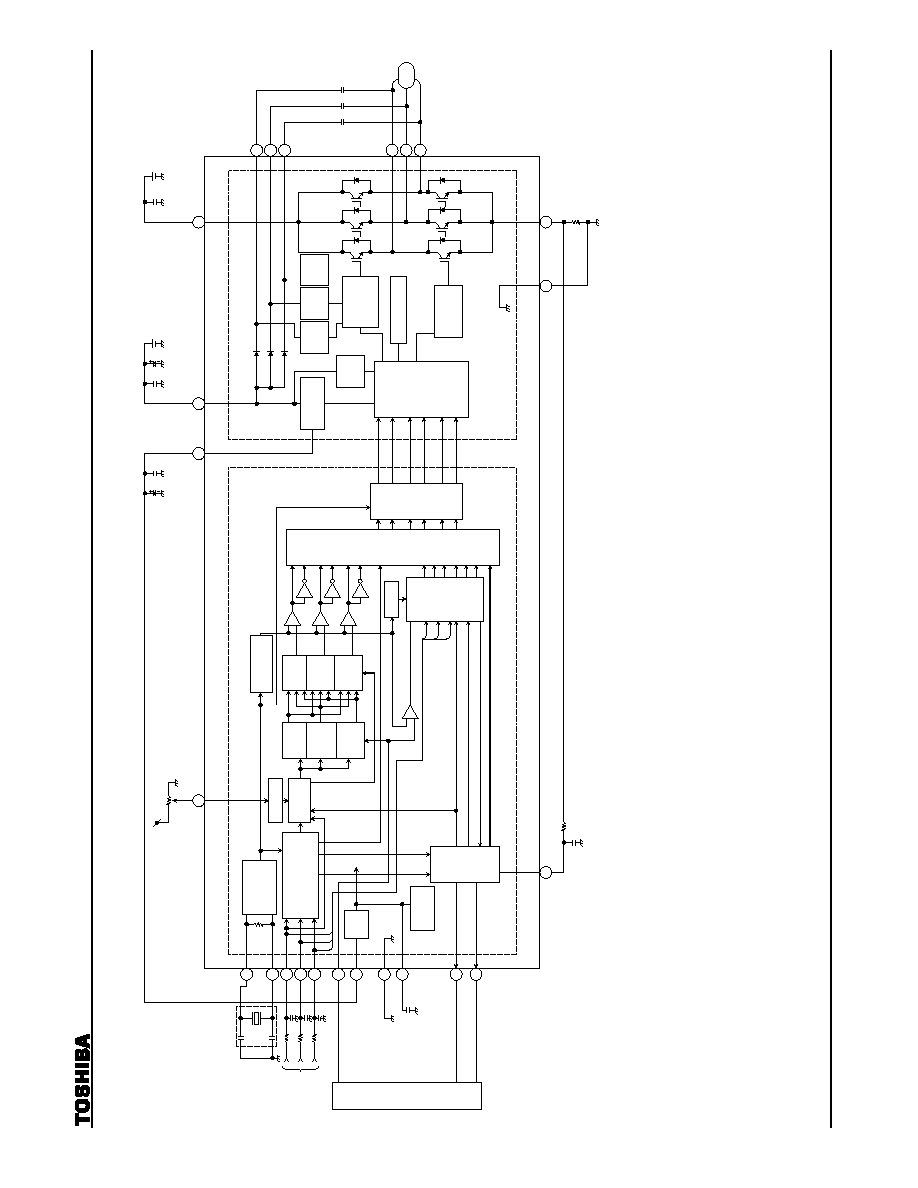

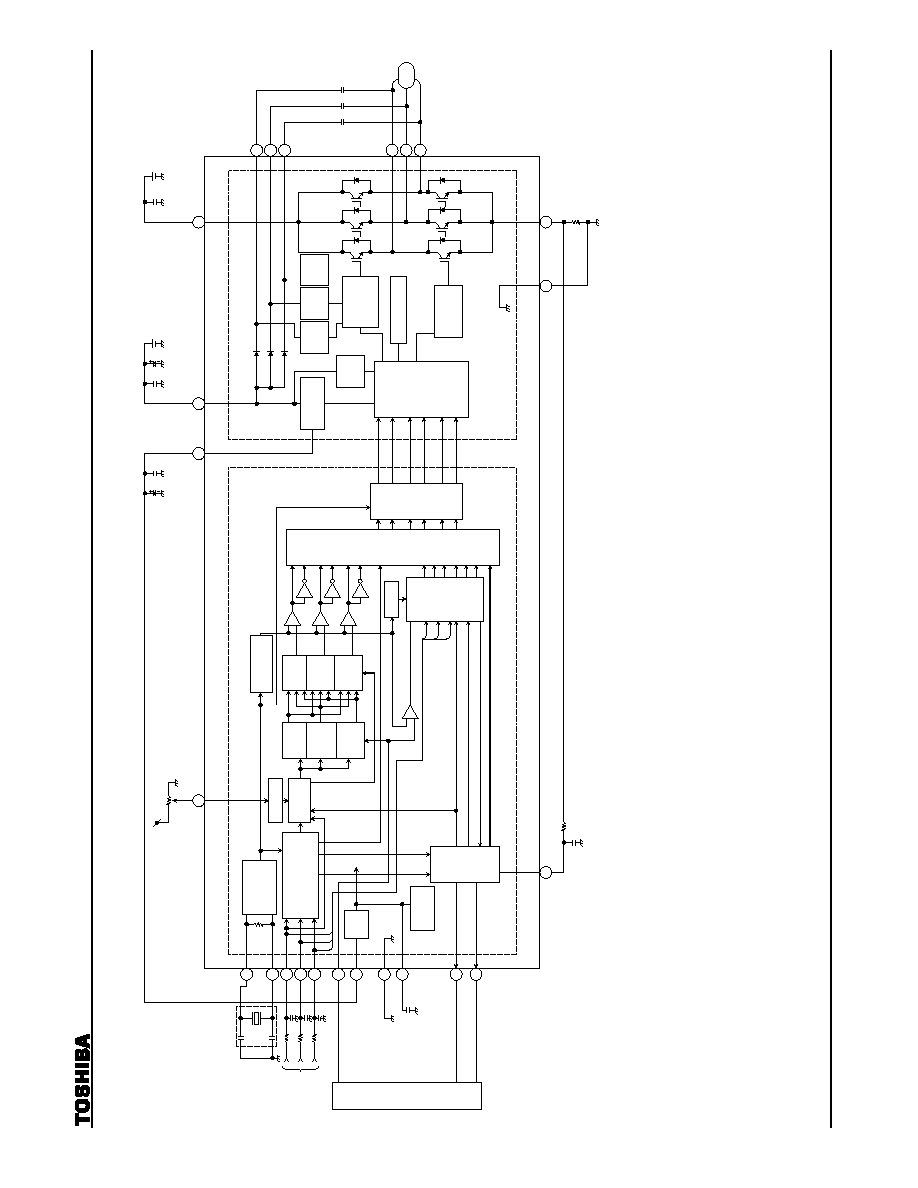

Example of Application Circuit

System clock

generator

Position detector

Counter

5-bit AD

Triangular wave

generator 6-bit

Output

waveform

generator

Selecting

data

Switching

120∞/180∞

&

gate

block

protection

on/off

Setting

dead time

Charger

120∞-

turn-on

matrix

Power-on

reset

Protection

&

reset

15

9

10

12

13

14

11

5

8

6

16

17

Phase

matchin

4 bit

FG

Rotating

direction

ST/SP

ERR

GB

Comparator

Comparator

PWM

HU

HV

HW

120∞/180∞

Phase

U

X

in

X

out

HU

HV

HW

V

e

V

CC7

S-GND

V

refout

FG

REV

LA

U

X

V

Y

W

Z

BRK (CHG)

V

refout

MCU

Regula

tor

Internal

reference

voltage

Low-side

driver

V

REG

Input control

BSV

BSU

V

B

BSW

U

V

W

High-side

level shift

driver

2

HU

HV

HW

LU

LV

LW

18

20

22

19

21

23

Under-

voltage

protection

7-V

Regulator

C

10

C

11

C

12

C

3

C

2

C

1

R

1

R

2

R

3

Hall IC

input

X

1

C

4

7 Idc

1

24

3

V

CC15

25

P-GND

IS

R

5

C

5

R

4

C

9

C

8

15 V

Power supply

for motor

C

7

C

6

Motor

(Controller) (Driver)

Phase

V

Phase

W

Comparator

Comparator

Under-

voltage

protection

Under-

voltage

protection

Under-

voltage

protection

Thermal shutdown

TB6581H/HG

03/12/25

11

External Parts

Symbol Purpose

Recommended

value

Note

X

1

Internal clock generation

4.19 MHz

(Note 1)

C

1

, C

2

, C

3

10

V/1000

pF

R

1

, R

2

, R

3

Noise absorber

10 k

(Note 2)

C

4

V

refout

oscillation protection

10 V/0.1

µ

F~1.0

µ

F (Note

3)

C

5

10

V/1000pF

R

4

Noise absorber

5.1 k

(Note 2)

R

5

Overcurrent

detection

0.62

±

1% (1 W)

(Note 4)

C

6

16

V/1.0

µ

F~10

µ

F

C

7

V

REG

power supply stability

10 V/1000 pF

(Note 3)

C

8

25

V/0.1

µ

F

C

9

V

CC15

power supply stability

25 V/10

µ

F

(Note 3)

C

10

, C

11

, C

12

Bootstrap

capacitor

25

V/2.2

µ

F (Note

5)

Note 1: For carrier frequency and dead time, connect a 4.19 MHz ceramic resonator.

Note 2: These parts are used as a low-pass filter for noise absorption. Test to confirm noise filtering, then set the

filter time-constant.

Note 3: This part is used as a capacitor for power supply stability. Adjust the part to the application environment as

required. When mounting, place it as close as possible to the base of the leads of this product to improve

the noise elimination.

Note 4: This part is used to set the value for overcurrent detection. I

out (max)

=

V

dc

˜

R

5

(V

dc

=

0.5 V (typ.))

Note 5: The required bootstrap capacitance value varies according to the motor drive conditions. The voltage stress

for the capacitor is the value of V

CC15

.

Other Precautions

A short circuit between the outputs, or between output and supply or ground may damage the device. Peripheral

parts may also be damaged by overvoltage and overcurrent. Design the output lines, V

CC

and GND lines so that

short circuits do not occur.

Also be careful not to insert the IC in the wrong direction because this could destroy the IC.

In turning on the power, first supply Vcc15 and confirm its stability; then apply Vcc7 and the driving input signal.

Vcc15 and VB may be turned on in either order. In turning off the power, take care not to cut off the VB line by

relay while the motor is spinning. Doing so may cause the IC to break down by cutting the current-producing route

for VB.

The TB6581H/HG is sensitive to electrostatic discharge. Handle with care.

The product should be mounted by the solder-flow method. The preheating time is from 60 to 120 seconds at

150∞C. The maximum heat is 260∞C, to be applied within 10 seconds and as far as the lead stopper.

TB6581H/HG

03/12/25

12

Package Dimensions

Weight: 7.7 g (typ.)

TB6581H/HG

03/12/25

13

Notes on contents

1. Block Diagrams

Some functional blocks, circuits, or constants may be omitted or simplified in the block diagram for explanatory

purposes.

2. Equivalent Circuits

The equivalent circuit diagrams may be simplified or some parts of them may be omitted for explanatory

purposes.

3. Timing Charts

Timing charts may be simplified for explanatory purposes.

4. Maximum Ratings

The absolute maximum ratings of a semiconductor device are a set of specified parameter values that must not

be exceeded during operation, even for an instant.

If any of these ratings are exceeded during operation, the electrical characteristics of the device may be

irreparably altered, in which case the reliability and lifetime of the device can no longer be guaranteed.

Moreover, any exceeding of the ratings during operation may cause breakdown, damage and/or degradation in

other equipment. Applications using the device should be designed so that no maximum rating will ever be

exceeded under any operating conditions.

Before using, creating and/or producing designs, refer to and comply with the precautions and conditions set

forth in this document.

5. Application Circuits

The application circuits shown in this document are provided for reference purposes only. Thorough evaluation

is required in the mass production design phase.

In furnishing these examples of application circuits, Toshiba does not grant the use of any industrial property

rights.

6. Test Circuits

Components in test circuits are used only to obtain and confirm device characteristics. These components and

circuits are not guaranteed to prevent malfunction or failure in application equipment.

Handling of the IC

Ensure that the product is installed correctly to prevent breakdown, damage and/or degradation in the product

or equipment.

Over-current protection and heat protection circuits

These protection functions are intended only as a temporary means of preventing output short circuits or other

abnormal conditions and are not guaranteed to prevent damage to the IC.

If the guaranteed operating ranges of this product are exceeded, these protection features may not operate

and some output short circuits may result in the IC being damaged.

The over-current protection feature is intended to protect the IC from temporary short circuits only.

Short circuits persisting over long periods may cause excessive stress and damage the IC. Systems should

be configured so that any over-current condition will be eliminated as soon as possible.

Counter-electromotive force

When the motor reverses or stops, the effect of counter-electromotive force may cause the current to flow to the

power source.

If the power supply is not equipped with sink capability, the power and output pins may exceed the maximum

rating.

The counter-electromotive force of the motor will vary depending on the conditions of use and the features of

the motor. Therefore make sure there will be no damage to or operational problem in the IC, and no damage to

or operational errors in peripheral circuits caused by counter-electromotive force.

TB6581H/HG

03/12/25

14

∑

The information contained herein is subject to change without notice.

∑

The information contained herein is presented only as a guide for the applications of our products. No

responsibility is assumed by TOSHIBA for any infringements of patents or other rights of the third parties which

may result from its use. No license is granted by implication or otherwise under any patent or patent rights of

TOSHIBA or others.

∑

TOSHIBA is continually working to improve the quality and reliability of its products. Nevertheless, semiconductor

devices in general can malfunction or fail due to their inherent electrical sensitivity and vulnerability to physical

stress. It is the responsibility of the buyer, when utilizing TOSHIBA products, to comply with the standards of

safety in making a safe design for the entire system, and to avoid situations in which a malfunction or failure of

such TOSHIBA products could cause loss of human life, bodily injury or damage to property.

In developing your designs, please ensure that TOSHIBA products are used within specified operating ranges as

set forth in the most recent TOSHIBA products specifications. Also, please keep in mind the precautions and

conditions set forth in the "Handling Guide for Semiconductor Devices," or "TOSHIBA Semiconductor Reliability

Handbook" etc..

∑

The TOSHIBA products listed in this document are intended for usage in general electronics applications

(computer, personal equipment, office equipment, measuring equipment, industrial robotics, domestic appliances,

etc.). These TOSHIBA products are neither intended nor warranted for usage in equipment that requires

extraordinarily high quality and/or reliability or a malfunction or failure of which may cause loss of human life or

bodily injury ("Unintended Usage"). Unintended Usage include atomic energy control instruments, airplane or

spaceship instruments, transportation instruments, traffic signal instruments, combustion control instruments,

medical instruments, all types of safety devices, etc.. Unintended Usage of TOSHIBA products listed in this

document shall be made at the customer's own risk.

∑

The products described in this document are subject to the foreign exchange and foreign trade laws.

∑

TOSHIBA products should not be embedded to the downstream products which are prohibited to be produced

and sold, under any law and regulations.

030619EBA

RESTRICTIONS ON PRODUCT USE