+Vo

PFM

Isolation

Ref.Amp

+Vin

-Vin

-Vo

On/Off

Block Diagram

Wide Range

2:1

Low Profile

Low Cost

$

Remote on/off

I/O Isolation

Low Noise

MCW1000-Series power modules are low-profile

dc-dc converters that operate over input voltage ranges of

4.5-9VDC, 9-18VDC, 18-36VDC and 36-75VDC and provide

precisely regulated output voltages of 3.3V, 5V, 12V.

The -40] to +65] operating temperature range makes it ideal

for data communication equipments, mobile battery driven

equipments, distributed power systems, telecommunication

equipments, mixed analog/digital subsystems, process/machine

control equipments, computer peripheral systems and industrial robot

systems.

The modules have a maximum power rating of 2W and a typical

full-load efficiency of 80%, continuous short circuit, 60mV output

ripple, built-in filtering for both input and output minimizes the need

for external filtering.

Low Ripple and Noise

External ON/OFF-Control

MTBF > 1,000,000 Hours

Short Circuit Protection

SMT Technology

Industry Standard Pinout

I/O Isolation 1000VDC

2:1 Input Range

High Efficiency up to 80%

Key Features

Single Outputs

2 Watts 2 :1 Wide Input Range DC/DC Converters

TOTAL POWER INT'L MCW1000 Series

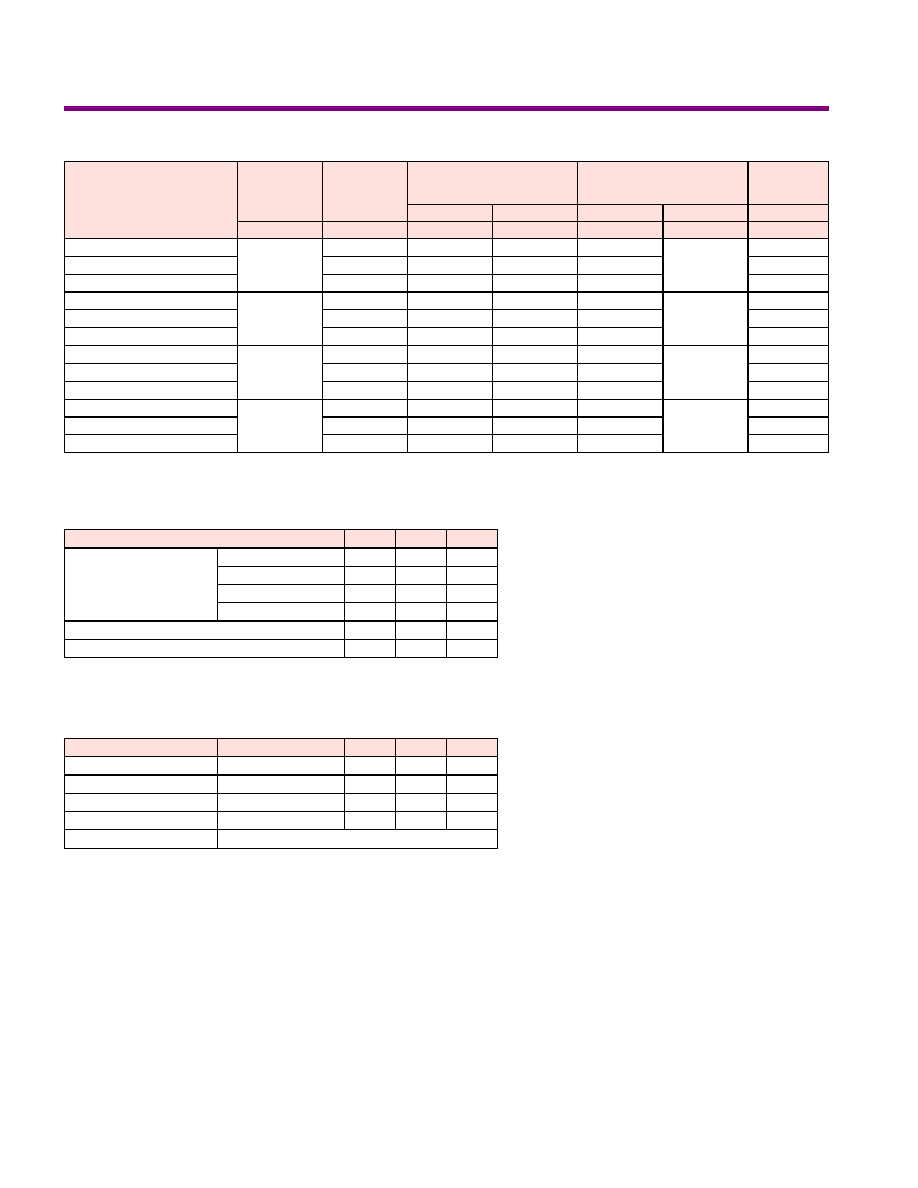

79

53

42

167

12

MCW1043

73

57

100

400

5

MCW1042

71

8

49

125

500

3.3

48

( 36 ~ 75 )

MCW1041

81

103

42

167

12

MCW1033

77

109

100

400

5

MCW1032

72

10

96

125

500

3.3

24

( 18 ~ 36 )

MCW1031

80

209

42

167

12

MCW1023

77

217

100

400

5

MCW1022

73

20

184

125

500

3.3

12

( 9 ~ 18 )

MCW1021

75

534

42

167

12

MCW1013

73

548

100

400

5

MCW1012

70

40

471

125

500

3.3

5

( 4.5 ~ 9 )

MCW1011

% (Typ.)

mA (Typ.)

mA (Typ.)

mA

mA

VDC

VDC

@Max. Load

@No Load

@Max. Load

Min.

Max.

Efficiency

Input Current

Output Current

Output

Voltage

Input

Voltage

Model

Number

Model Selection Guide

Free-Air Convection

Cooling

%

95

---

Humidity

]

+105

-55

Storage Temperature

]

+90

-40

Case

Operating Temperature

]

+65

-40

Ambient

Operating Temperature

Unit

Max.

Min.

Conditions

Parameter

Environmental Specifications

Exceeding these values can damage the module. These are not continuous

operating ratings.

mW

1,800

---

Internal Power Dissipation

]

260

---

Lead Temperature (1.5mm from case for 10 Sec.)

VDC

100

-0.7

48VDC Input Models

VDC

50

-0.7

24VDC Input Models

VDC

25

-0.7

12VDC Input Models

VDC

15

-0.7

5VDC Input Models

Input Surge Voltage

( 1000 mS )

Unit

Max.

Min.

Parameter

Note :

1. Specifications typical at Ta=+25], resistive load,

nominal input voltage, rated output current unless

otherwise noted.

2. Transient recovery time is measured to within 1%

error band for a step change in output load of 50%

to 100%.

3. Ripple & Noise measurement bandwidth is 0-20

MHz.

4. These power converters require a minimum

output loading to maintain specified regulation.

5. Operation under no-load conditions will not

damage these devices; however they may not

meet all listed specifications.

6. All DC/DC converters should be externally fused at

the front end for protection.

7. Other input and output voltage may be available,

please contact factory.

8. Specifications subject to change without notice.

Absolute Maximum Ratings

MCW1000 Series

K Hours

---

---

1000

MIL-HDBK-217F @ 25], Ground Benign

MTBF

KHz

650

300

100

Switching Frequency

pF

120

65

---

100KHz,1V

Isolation Capacitance

M[

---

---

1000

500VDC

Isolation Resistance

VDC

---

---

1100

Flash Tested for 1 Second

Isolation Test Voltage

VDC

---

---

1000

60 Seconds

Isolation Voltage

Unit

Max.

Typ.

Min.

Conditions

Parameter

General Specifications

Continuous

Output Short Circuit

%/]

{0.02

{0.01

---

Temperature Coefficient

%

{5

{3

---

Transient Response Deviation

uS

300

100

---

25% Load Step Change

Transient Recovery Time

%

---

---

120

Over Power Protection

mV rms.

15

---

---

Ripple & Noise (20MHz)

mV P-P

75

---

---

Over Line,Load & Temp

Ripple & Noise (20MHz)

mV P-P

50

30

---

Ripple & Noise (20MHz)

%

{0.75

{0.5

---

Io=25% to 100%

Load Regulation

%

{0.5

{0.3

---

Vin=Min. to Max.

Line Regulation

%

{2

{1

---

Output Voltage Accuracy

Unit

Max.

Typ.

Min.

Conditions

Parameter

Output Specifications

Capacitor type

Input Filter

mW

1500

---

---

Short Circuit Input Power

A

1

---

---

All Models

Reverse Polarity Input Current

34

22

---

48V Input Models

17

11

---

24V Input Models

8.5

6.5

---

12V Input Models

4

3.5

---

5V Input Models

Under Voltage Shortdown

36

24

16

48V Input Models

18

12

8

24V Input Models

9

7

4.5

12V Input Models

VDC

4.5

4

3.5

5V Input Models

Start Voltage

Unit

Max.

Typ.

Min.

Model

Parameter

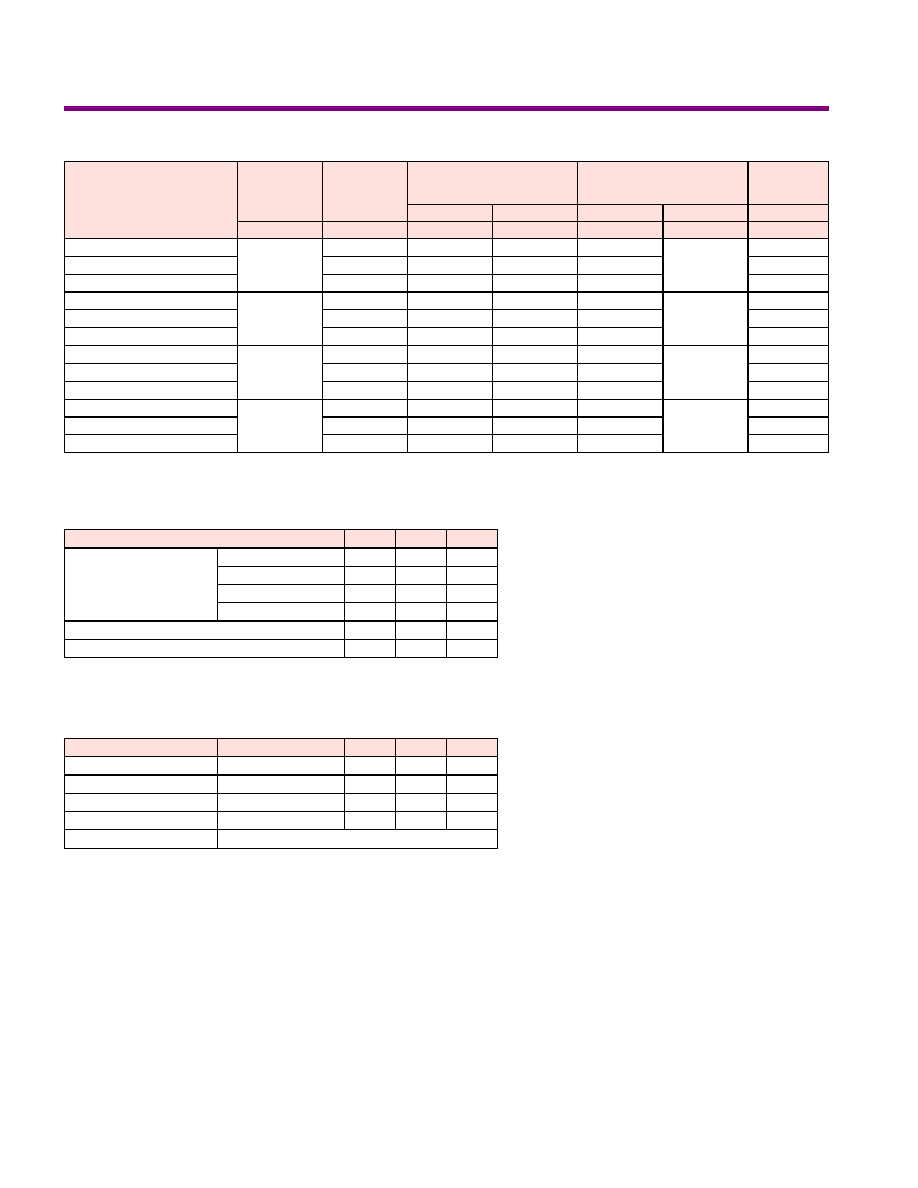

Input Specifications

Referenced to Negative Input

Control Common

mA

1

---

---

Control Input Current ( off )

mA

-0.4

---

---

Control Input Current ( on )

mA

0.2

0.1

---

Device Standby Input Current

VDC

15

---

2.7

Supply Off

under 1VDC or open circuit

Supply On

Unit

Max.

Typ.

Min.

Conditions

Parameter

Remote On/Off Control

MCW1000 Series

Note: # For each output .

uF

170

170

1000

2200

Maximum Capacitive Load

Unit

12V

5V

3.3V

Models by Vout

Capacitive Load

135mA Slow - Blow Type

350mA Slow - Blow Type

700mA Slow - Blow Type

1500mA Slow - Blow Type

48V Input Models

24V Input Models

12V Input Models

5V Input Models

Input Fuse Selection Guide

Input Voltage Transient Rating

MCW1000 Series

Derating Curve

]

Ambient Temperature

Output Power (%)

0

20

40

60

80

100

-40

50

60

80

100

110

90

70

400LFM

200LFM

100LFM

Natural

convection

Efficiency vs Output Load ( Single Output )

Efficiency vs Input Voltage ( Single Output )

Load Current (%)

Efficiency(%)

20

30

40

50

60

70

80

90

10

20

40

60

80

100

Input Voltage (V)

Efficiency(%)

Low

High

Nom

20

30

40

50

60

70

80

90

MCW1000 Series

Test Configurations

Input Reflected-Ripple Current Test Setup

Input reflected-ripple current is measured with a inductor

Lin (4.7uH) and Cin (220uF, ESR < 1.0[ at 100 KHz) to

simulate source impedance.

Capacitor Cin, offsets possible battery impedance.

Current ripple is measured at the input terminals of the

module, measurement bandwidth is 0-500 KHz.

Peak-to-Peak Output Noise Measurement Test

Use a Cout 0.47uF ceramic capacitor.

Scope measurement should be made by using a BNC

socket, measurement bandwidth is 0-20 MHz. Position the

load between 50 mm and 75 mm from the DC/DC Converter.

Design & Feature Considerations

Maximum Capacitive Load

The MCW1000 series has limitation of maximum

connected capacitance at the output.

The power module may be operated in current limiting

mode during start-up, affecting the ramp-up and the startup

time.

The maximum capacitance can be found in the data.

Overcurrent Protection

To provide protection in a fault (output overload) condition,

the unit is equipped with internal current limiting circuitry and

can endure current limiting for an unlimited duration. At the

point of current-limit inception, the unit shifts from voltage

control to current control. The unit operates normally once the

output current is brought back into its specified range.

Input Source Impedance

The power module should be connected to a low

ac-impedance input source. Highly inductive source

impedances can affect the stability of the power module.

In applications where power is supplied over long lines and

output loading is high, it may be necessary to use a capacitor

at the input to ensure startup.

Capacitor mounted close to the power module helps

ensure stability of the unit, it is recommended to use a good

quality low Equivalent Series Resistance (ESR < 1.0[ at 100

KHz) capacitor of a 8.2uF for the 5V input devices, a 3.3uF for

the 12V input devices and a 1.5uF for the 24V and 48V

devices.

Output Ripple Reduction

A good quality low ESR capacitor placed as close as

practicable across the load will give the best ripple and noise

performance.

To reduce output ripple, it is recommended to use 3.3uF

capacitors at the output.

MCW1000 Series

+Out

-Out

+Vin

-Vin

DC / DC

Converter

Load

Battery

+

Lin

+

Cin

To Oscilloscope

Current

Probe

+Out

-Out

+Vin

-Vin

Single Output

DC / DC

Converter

Resistive

Load

Scope

Copper Strip

Cout

+

+Out

-Out

+Vin

-Vin

DC / DC

Converter

Load

DC Power

Source

+

-

Cin

+Out

-Out

+Vin

-Vin

Load

DC Power

Source

+

-

Cout

Single Output

DC / DC

Converter

Thermal Considerations

Many conditions affect the thermal performance of the

power module, such as orientation, airflow over the module

and board spacing. To avoid exceeding the maximum

temperature rating of the components inside the power

module, the case temperature must be kept below 90�C.

The derating curves are determined from measurements

obtained in an experimental apparatus.

MCW1000 Series

DUT

Position of air velocity

probe and thermocouple

50mm / 2in

Air Flow

15mm / 0.6in

Units are encapsulated in a low thermal resistance molding compound which has excellent chemical resistance and electrical

properties in high humidity environment and over a wide operating temperature range.

The encapsulant and outer shell of the unit have UL94V-0 ratings. The leads are tin plated for better soldering.

NC: No Connection

UL94V-0

:

Flammability

No function

8

-Vout

7

4.8g

:

Weight

+Vout

6

No function

5

Non-Conductive Black Plastic

:

Case Material

Remote ON/OFF

3

+Vin(VCC)

2

0.86*0.37*0.44inches

-Vin(GND)

1

21.8*9.3*11.1mm

:

Case Size

Single Output

Pin

Physical Characteristics

Pin Connections

{0.002

{0.05

Pin

.XXX{0.01

.XX{0.25

.XX{0.01

.X{0.25

Inches

Millimeters

Tolerance

Single Output

0.01

(0.25)

0.12 (3.0)

0.36

(9.2)

1

2

3

6

7

8

0.86 (21.8)

0.02

(0.5)

0.02

(0.5)

0.10

(2.54)

0.08

(2.0)

0.44

(11.2)

0.13

(3.2)

0.20

(5.08)

5

Bottom

Connecting Pin Patterns

Top View ( 2.54 mm / 0.1 inch grids )

Mechanical Data

MCW1000 Series