Product Data Sheet

VC-800

Voltage Controlled Crystal Oscillator

Features

∑ Worlds Smallest VCXO, 5.0 x 3.2 x 1.5 mm

∑ High Frequencies to 51.84 MHz

∑ 5 or 3.3 V operation

∑ Linearity

10%

∑ Tri-State Output

∑ Low jitter < 6ps rms

∑ VCXO with CMOS outputs

∑ 0/70 or ≠40/85∞C temperature range

∑ Hermetically sealed ceramic SMD package

Applications

∑ SONET/SDH

∑ DWDM

∑ xDSL/PCMCIA cards

∑ Digital Video

Description

Vectron's VC-800 Voltage Controlled Crystal Oscillator

(VCXO) is a quartz stabilized square wave generator

with a CMOS output and is tested at CMOS and TTL

(5 volt operation) logic levels.

The VC-800 is the smallest available VCXO making it

ideally suitable for PCMCIA applications as well as any

other where size is limited but performance is required.

VC-800 Voltage Controlled Crystal Oscillator

Performance Characteristics

Electrical Performance

Vectron International ∑

267 Lowell Road, Hudson, NH 03051

∑ Tel: 1-88-VECTRON-1 ∑ Fax: 1-888-FAX-VECTRON

2

.

Figure 1. Output Waveform

Conditions (25±5∞C)

Figure 2. Typical Output Test

1. A 0.01uF and a 0.1uF capacitor should be located as close to the supply as possible (to ground) is recommended.

2. Figure 1 defines these parameters. Figure 2 illustrates the equivalent five gate TTL load and operating conditions under

which these parameters are tested and specified.

3. Symmetry is defined as (ON TIME/PERIOD with Vs = 1.4 V for TTL and Vs=2.5 V for CMOS, 5 volt operation, and

Vs=1.65V for 3.3 Volt operation.

4. Load Capacitor will depend on frequency.

Frequency

f

O

1.544

51.84

MHz

Supply Voltage

1

(+3.3 V)

V

DD

2.97

3.3

3.63

V

(+5.0 V)

4.5

5.0

5.5

Supply Current

I

DD

12

25

mA

Output Logic Levels

Output Logic High

2

V

OH

0.9*V

DD

V

Output Logic Low

2

V

OL

0.1V

DD

Transition Times

Rise Time

2

t

R

5

ns

Fall Time

2

t

F

5

ns

Symmetry or Duty Cycle

3

SYM

40

50

60

%

Operating temperature (ordering option)

0/70 or ≠40/85

∞C

Test Conditions for APR (+5V option)

V

C

0.5

4.5

V

Test Conditions for APR (+3.3V option)

V

C

0.3

3.0

V

Absolute Pull Range (ordering option)

APR

+/-50

ppm

+/- 80

Gain Transfer (See Figure 3)

Positive

Control Voltage Leakage Current

I

VCXO

±1

uA

Control Voltage Bandwidth (-3dB)

BW

10

kHz

Package Size

5.0 x 3.2 x 1.5

mm

Parameter

Symbol

Minimum

Typical

Maximum

Units

VC-800 Voltage Controlled Crystal Oscillator

Vectron International ∑

267 Lowell Road, Hudson, NH 03051

∑ Tel: 1-88-VECTRON-1 ∑ Fax: 1-888-FAX-VECTRON

3

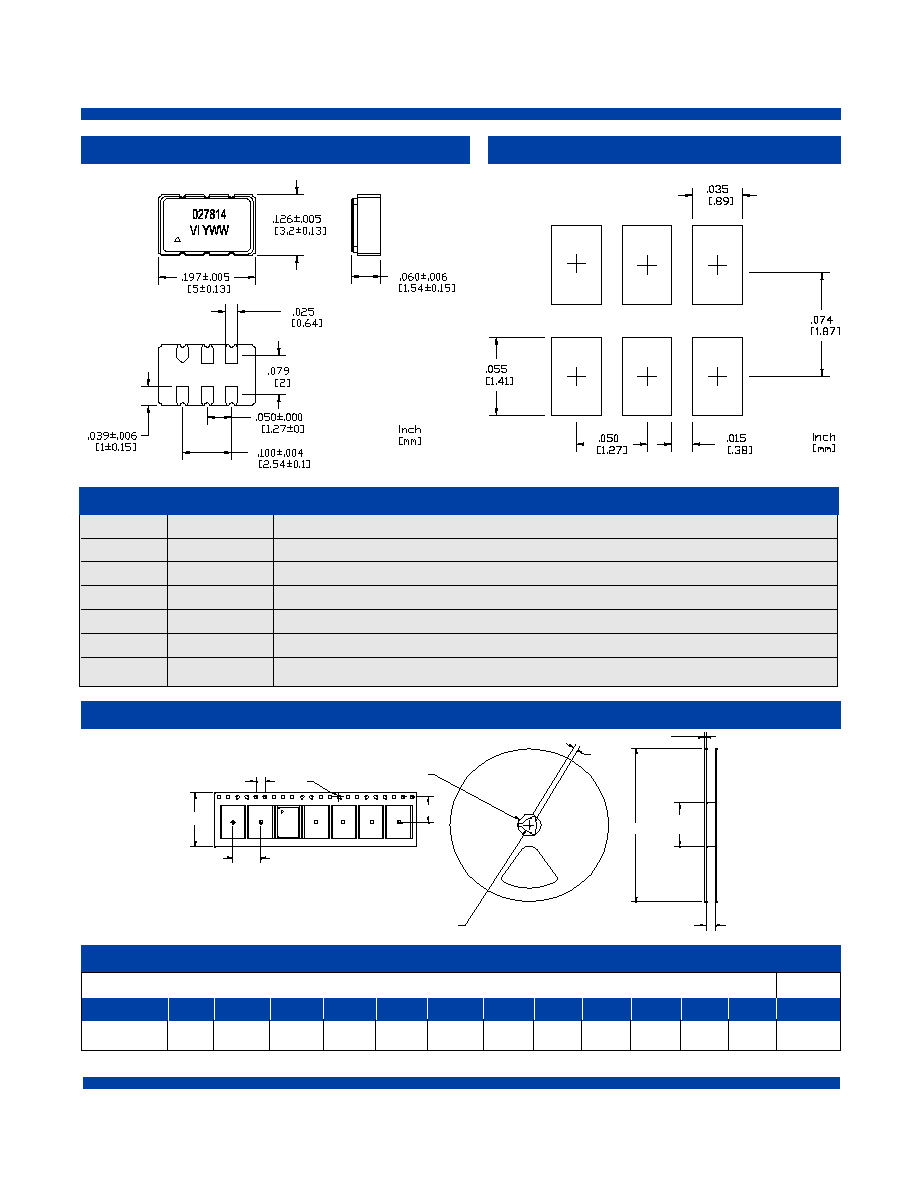

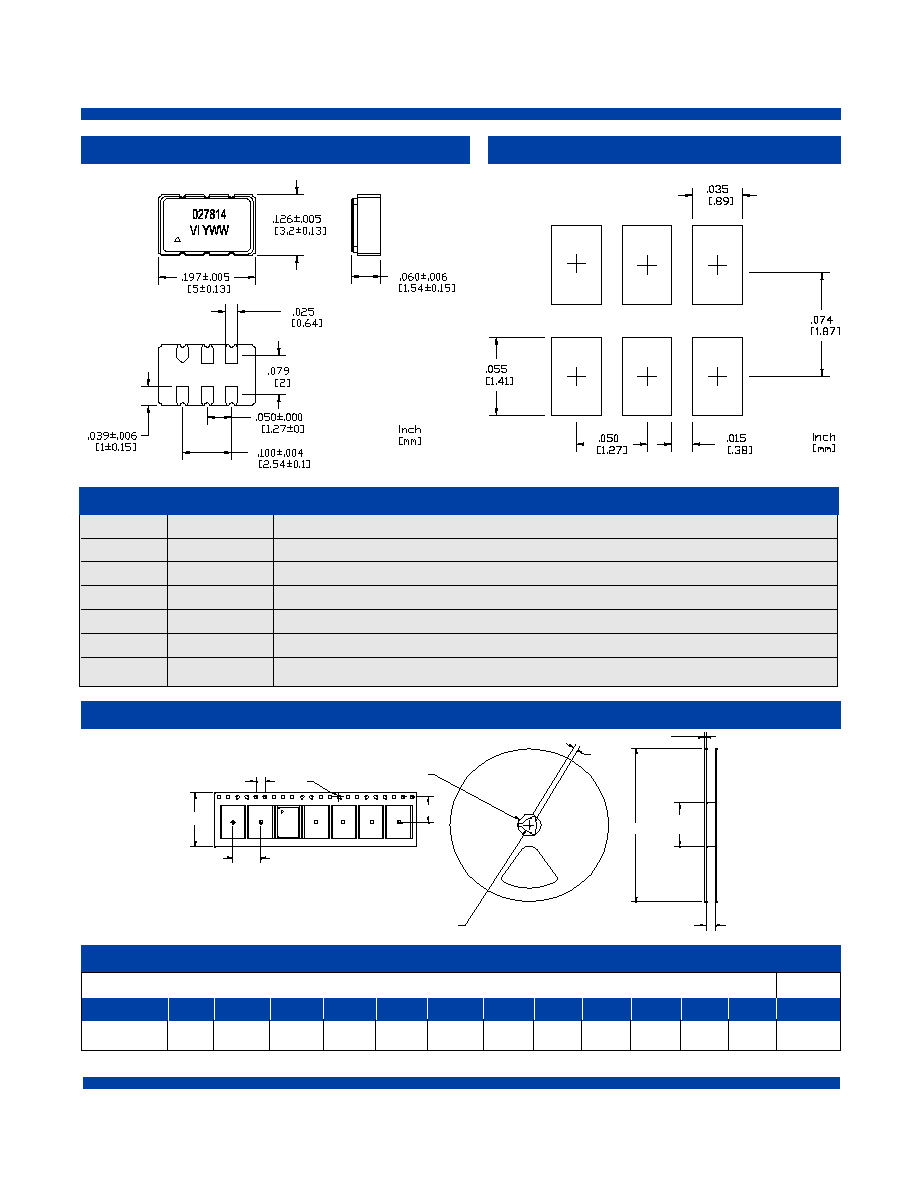

Outline Diagram

Pad Layout

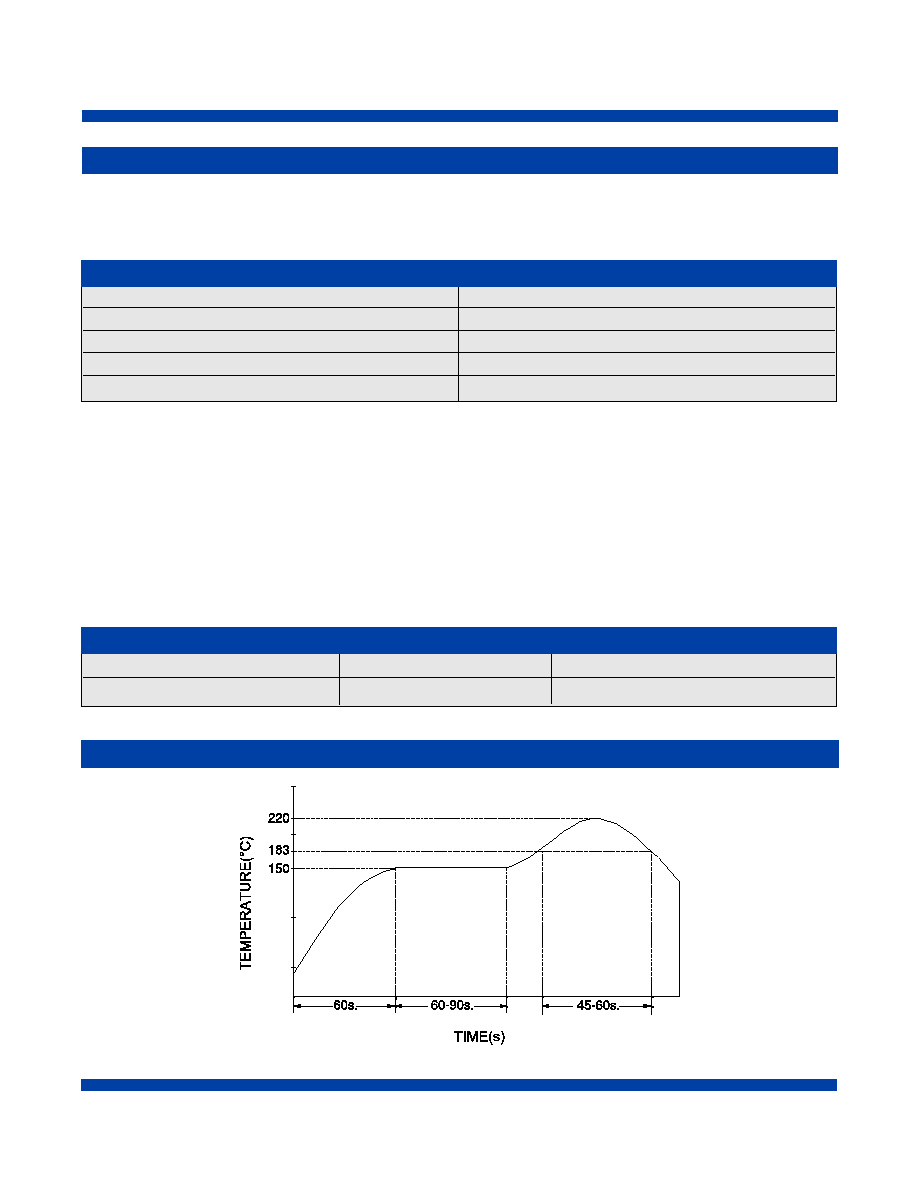

Tape and Reel

A

E

C

D

B

G

F

J

L

I

K

H

Tape Dimensions

Reel Dimensions

# Per Reel

Product A B C D E

F

G

H

I

J

K

L

VC-800

12 5.5 1.5

4

8

1.78

20.6

13 55 6 12.4

178

500

Tape and Reel Dimensions (mm)

1

2

3

4

5

6

Pin #

Symbol

Function

1

VC

Control Voltage

2

Tri-state

Logic low disables output. Logic high or N/C enables output waveform.

3

GND

Ground

4

f

O

Output Frequency

5

CMOS/TTL

Logic low for CMOS optimized symmetry. Logic high or N/C for TTL optimized symmetry.

6

V

DD

Supply Voltage

Pin Out

4

VC-800 Voltage Controlled Crystal Oscillator

Vectron International ∑

267 Lowell Road, Hudson, NH 03051

∑ Tel: 1-88-VECTRON-1 ∑ Fax: 1-888-FAX-VECTRON

Absolute Maximum Ratings

Power Supply

V

DD

6

Vdc

Storage Temperature

Tstorage

-55/125

∞C

Voltage Control Range

V

C

0 to V

DD

V

Stresses in excess of the absolute maximum ratings can permanently damage the device. Functional operation is

not implied at these or any other conditions in excess of conditions represented in the operational sections of this

data sheet. Exposure to absolute maximum ratings for extended periods may adversely affect device reliability.

-200.0

-150.0

-100.0

-50.0

0.0

50.0

100.0

150.0

200.0

0.30

0.60

0.90

1.20

1.50

1.80

2.10

2.40

2.70

3.00

Control Voltage (volts)

Frequency Pull (ppm)

Parameter

Symbol

Ratings

Unit

Figure 3. Typical Frequency Pull Versus Control Voltage, 35.328MHz Output, 3.3 Volt Supply

VC-800 Voltage Controlled Crystal Oscillator

5

Reliability

Environmental Compliance

ESD Ratings

The VC-800 is capable of meeting the following qualification tests.

Mechanical Shock

MIL-STD-883 Method 2002

Mechanical Vibration

MIL-STD-883 Method 2007

Solderability

MIL-STD-883 Method 2003

Gross and Fine Leak

MIL-STD-883 Method 1014

Resistance to Solvents

MIL-STD-883 Method 2016

Handling Precautions

Although ESD protection circuitry has been designed into the the VC-800, proper precautions should be

taken when handling and mounting. VI employs a Human Body Model and a Charged-Device Model

(CDM) for ESD susceptibility testing and design protection evaluation. ESD thresholds are dependent on

the circuit parameters used to define the model. Although no industry wide standard has been adopted

for the CDM, a standard HBM of resistance=1.5kohms and capacitance = 100pF is widely used and

therefore can be used for comparison purposes.

Human Body Model

1500

MIL-STD-883 Method 3115

Charged Device Model

1000

JESD 22-C101

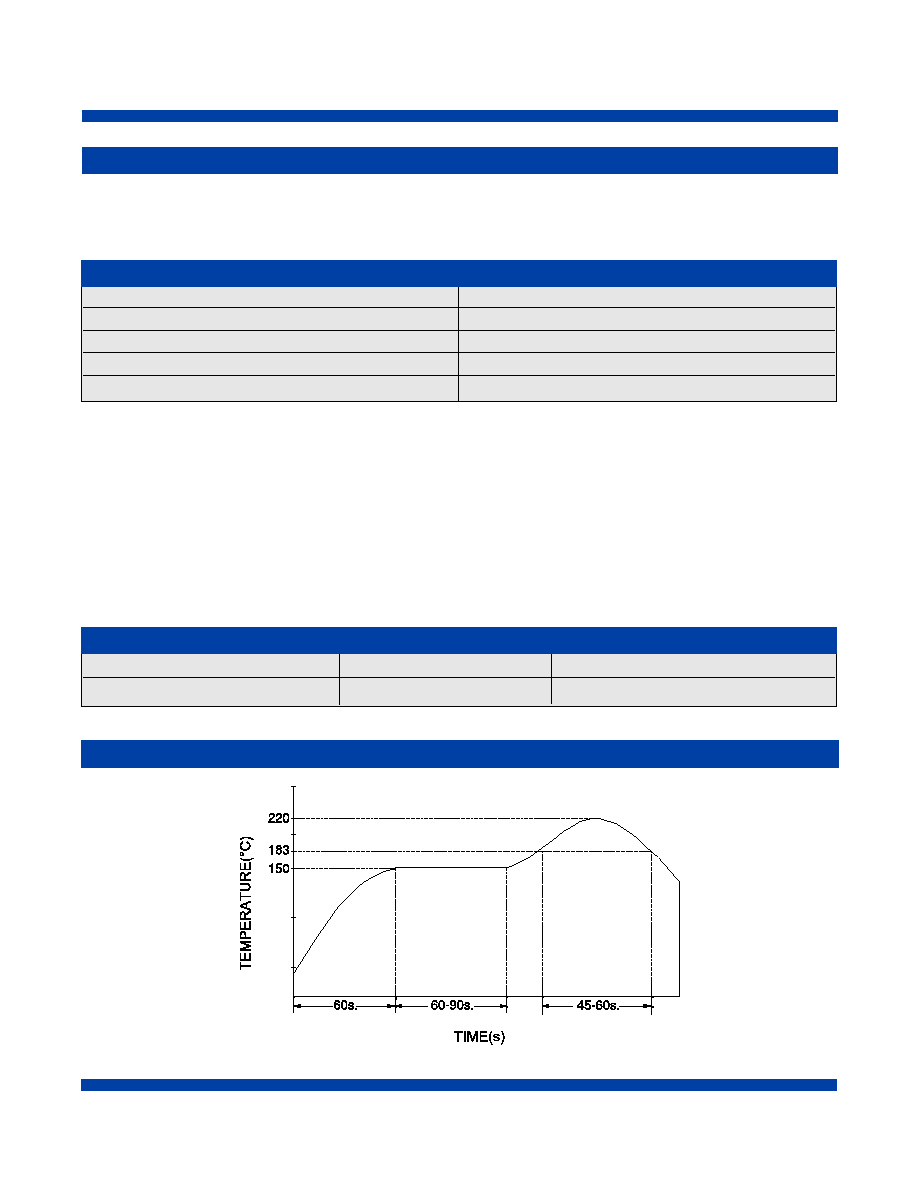

Recommended Solder Reflow Profile

Vectron International ∑

267 Lowell Road, Hudson, NH 03051

∑ Tel: 1-88-VECTRON-1 ∑ Fax: 1-888-FAX-VECTRON

Model

Minimum

Conditions

Parameter

Conditions