| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: 085CS | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Document Number: 28300

For technical questions contact: aluminumcaps1@vishay.com

www.vishay.com

Revision: 22-Sep-03

1

085 CS

Vishay BCcomponents

Aluminum Capacitors

SMD (Chip) Standard

FEATURES

∑

Polarized aluminum electrolytic capacitors,

non-solid electrolyte, self healing

∑

SMD-version, rectangular case, insulated

∑

Miniaturized, high CV per unit volume, low height

∑

Flexible terminals, reflow and wave solderable

∑

Charge and discharge proof

∑

Supplied in blister tape on reel.

APPLICATIONS

∑

SMD technology, boards with restricted mounting height

∑

General applications, consumer electronics, low profile

and lightweight equipment

∑

Decoupling, smoothing, filtering and buffering.

MARKING

The capacitors are marked (where possible) with the

following information:

∑

Rated capacitance (in µF).

∑

Rated voltage code (see Table 1), the U

R

code letter

indicates the position of the decimal point in the

capacitance value.

∑

Name of manufacturer.

∑

`-' sign indicating the cathode. The anode is identified by

bevelled edges.

Examples

for C

R

; U

R

marking:

H22 represents 0.22µF; 63 V

2G2 represents 2.2 µF; 40 V

22C represents 22 µF; 6.3 V.

Table 1

RATED VOLTAGE MARKING CODE

U

R

(V)

6.3

10

16

25

40

63

Code letter

C

D

E

F

G

H

QUICK REFERENCE DATA

DESCRIPTION

VALUE

Nominal case sizes

(L

◊

W

◊

H in mm)

8.8

◊

3.7

◊

3.9 and

11.9

◊

3.7

◊

3.9

Rated capacitance range, C

R

0.47 to 22

µ

F

Tolerance on C

R

10 to +50% or

±

20%

Rated voltage range, U

R

6.3 to 63 V

Category temperature range

40 to +85∞C

Endurance test at 85

∞

C

1000 hours

Useful life at 85 ∞C

1500 hours

Useful life at 40 ∞C;

1.4

◊

l

R

applied

40000 hours

Shelf life at 0 V, 85 ∞C

500 hours

Resistance to soldering

heat test

immersion in solder:

10 s at 260 ∞C or 20 s at 215 ∞C

Based on sectional

specification

IEC 60384-18/CECC 32300

Climatic category IEC 60068

40/085/56

085 CS

longer

life

139 CLL

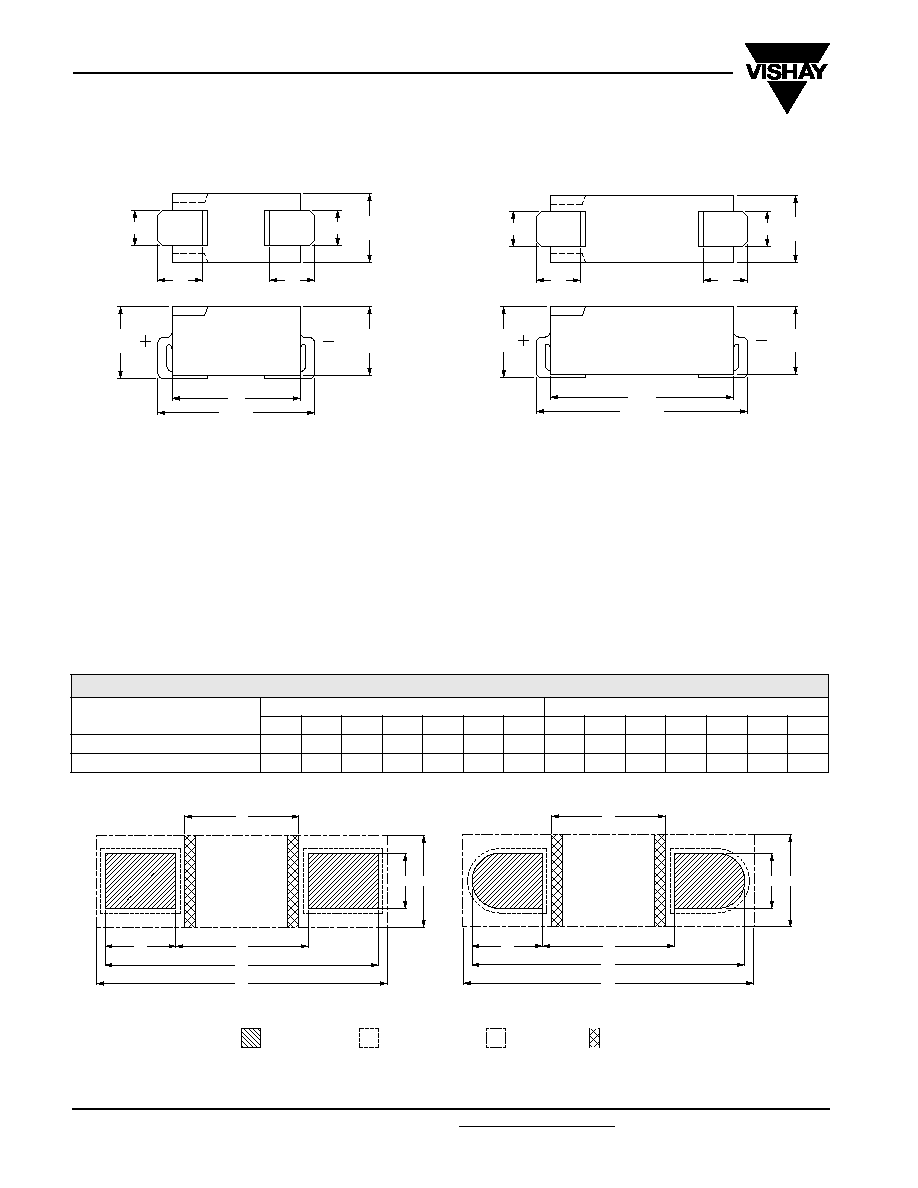

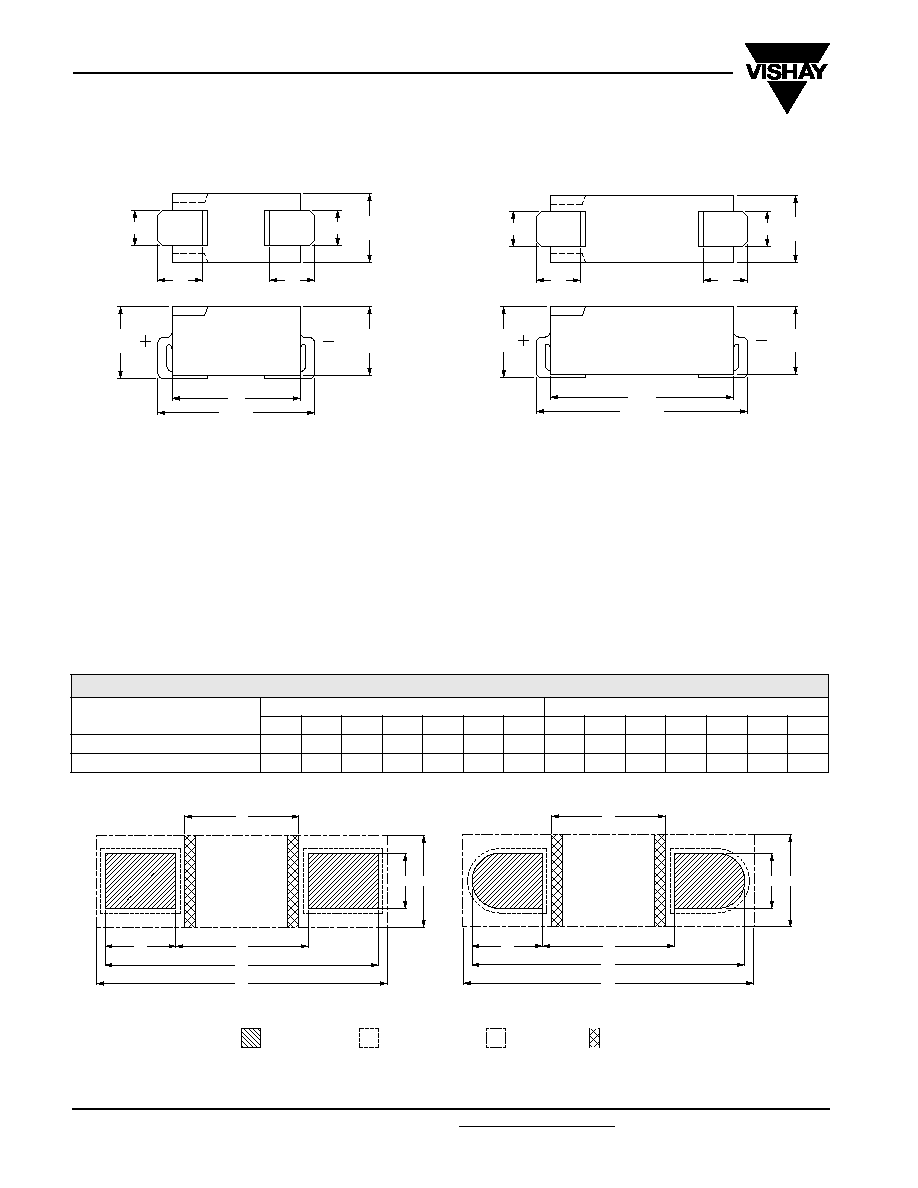

Fig.1 Component outlines

SELECTION CHART FOR C

R

, U

R

AND RELEVANT NOMINAL CASE SIZES

(L x W x H in mm)

C

R

(µF)

U

R

(V)

6.3

10

16

25

40

63

0.47

-

-

-

-

-

8.8

◊

3.7

◊

3.9

1.0

-

-

-

-

-

8.8

◊

3.7

◊

3.9

2.2

-

-

-

-

8.8

◊

3.7

◊

3.9

11.9

◊

3.7

◊

3.9

3.3

-

-

-

8.8

◊

3.7

◊

3.9

-

11.9

◊

3.7

◊

3.9

4.7

-

-

8.8

◊

3.7

◊

3.9

-

11.9

◊

3.7

◊

3.9

-

6.8

-

8.8

◊

3.7

◊

3.9

-

11.9

◊

3.7

◊

3.9

-

-

10

8.8

◊

3.7

◊

3.9

-

11.9

◊

3.7

◊

3.9

-

-

-

15

-

11.9

◊

3.7

◊

3.9

-

-

-

-

22

11.9

◊

3.7

◊

3.9

-

-

-

-

-

www.vishay.com

For technical questions contact: aluminumcaps1@vishay.com

Document Number: 28300

2

Revision: 22-Sep-03

085 CS

Vishay BCcomponents

Aluminum Capacitors

SMD (Chip) Standard

DIMENSIONS

in millimeters

7.5

9 max

2.7

max

2 max

3.9

max

4.1

max

2 max

3.9

max

2.7

max

Fig.2 Dimensional outlines.

a. Case size 8.8 ◊ 3.7 ◊ 3.9 mm.

10.8

12.2 max

2.7

max

2 max

3.9

max

4.1

max

2 max

3.9

max

2.7

max

a.

b.

b. Case size 11.9 x 3.7 x 3.9 mm.

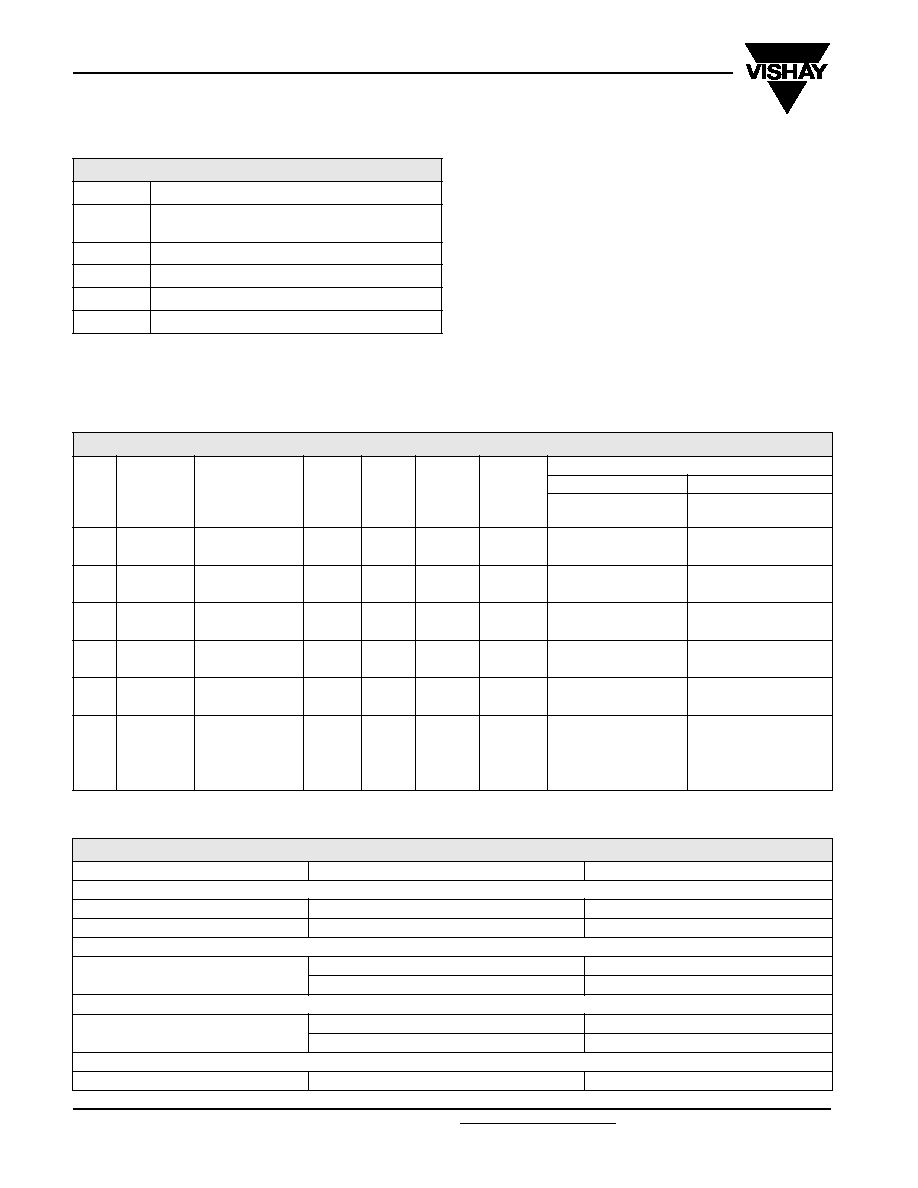

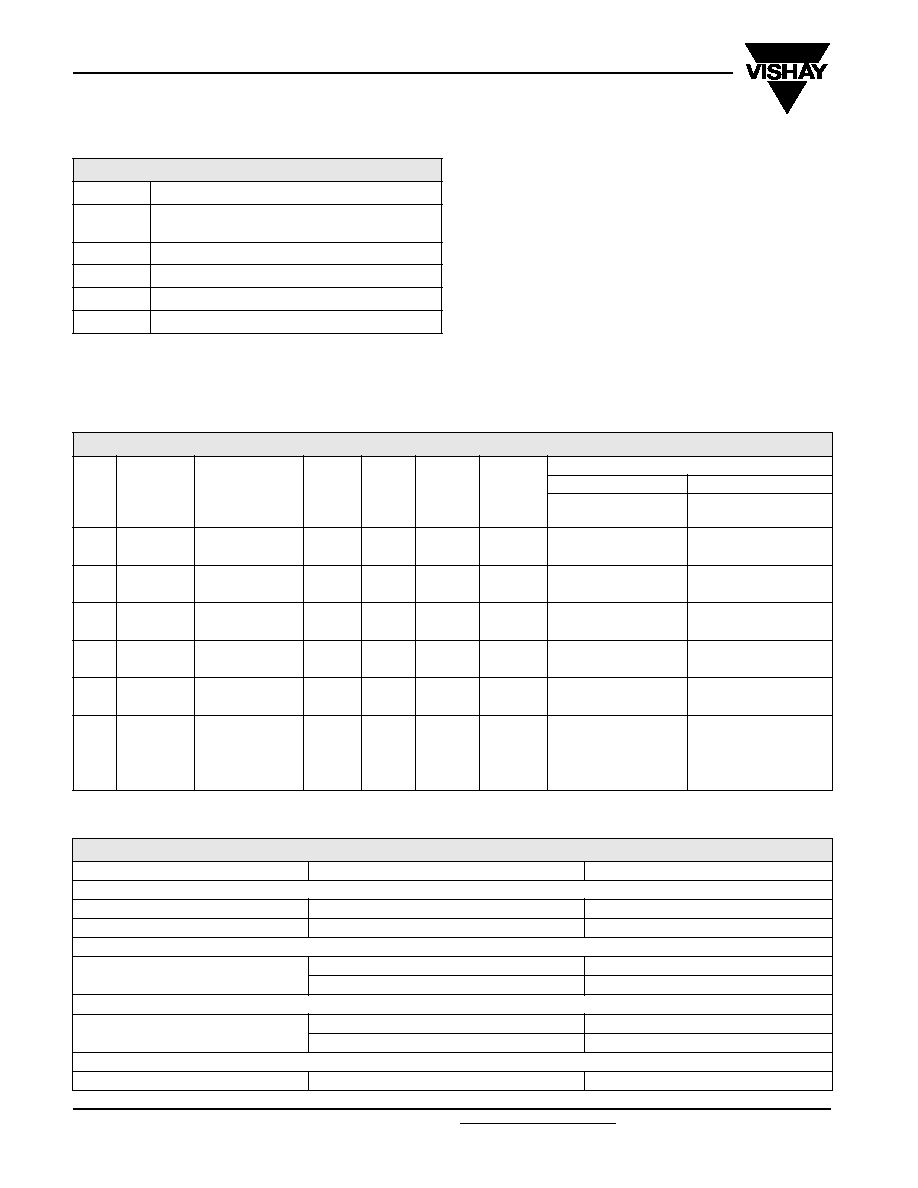

PACKAGING

Tape on reel packaging: 2000 per reel.

Detailed tape dimensions see section `PACKAGING'.

MOUNTING

The capacitors are designed for automatic placement on

printed-circuit boards or hybrid circuits.

Optimum dimensions of soldering pads depend upon

soldering method, mounting accuracy, print lay-out and/or

adjacent components.

For recommended pad dimensions, refer to Fig. 3

and Table 2.

Table 2

RECOMMENDED SOLDERING PAD DIMENSIONS

in millimeters (placement accuracy ±0.25mm)

NOMINAL CASE SIZE

L

◊

◊

◊

◊

W

◊

◊

◊

◊

H

FOR REFLOW SOLDERING

FOR WAVE SOLDERING

A

B

C

D

E

F

G

A

B

C

D

E

F

G

8.8

◊

3.7

◊

3.9

9.7

3.5

2.9

2.5

3.0

10.1

4.4

13.5

4.1

4.7

3.7

2.9

14.0

8.4

11.9

◊

3.7

◊

3.9

12.9

6.5

2.9

2.5

6.0

13.3

4.4

16.8

7.4

4.7

3.7

6.1

17.3

8.4

solder land/

solder paste

pattern

solder resist

pattern

occupied

area

tracks or

dummy tracks

E

D

G

C

B

A

F

E

D

G

C

B

A

F

reflow soldering

wave soldering

Fig.3 Recommended pad dimensions for reflow and wave soldering.

Document Number: 28300

For technical questions contact: aluminumcaps1@vishay.com

www.vishay.com

Revision: 22-Sep-03

3

085 CS

Aluminum Capacitors

SMD (Chip) Standard

Vishay BCcomponents

b

a

d

+

+

++

c

flow-direction of solder

Fig.4 Minimum distances between 085 CS capacitors on a printed-circuit board for wave soldering.

For dimensions a, b, c and d, refer to Table 3 .

Flow direction of solder preferably onto side-walls or plus-side of the capacitors.

SOLDERING

Soldering conditions are defined by the curve, temperature

versus time. The temperature is that measured on the

soldering pad during processing.

For maximum conditions of different soldering methods see

Figs 5, 6 and 7.

Any temperature/time curve which does not exceed the

specified maximum curves may be applied.

AS A GENERAL PRINCIPLE, TEMPERATURE AND

DURATION SHALL BE THE

MINIMUM

NECESSARY

REQUIRED TO ENSURE GOOD SOLDERING

CONNECTIONS.

Table 3

MINIMUM DISTANCES BETWEEN

CAPACITORS

in millimeters

NOMINAL CASE

SIZE

L

◊

◊

◊

◊

W

◊

◊

◊

◊

H

CASE

CODE

a

min

b

min

c

min

d

min

8.8

◊

3.7

◊

3.9

1a

12

12

6.8

6.8

11.9

◊

3.7

◊

3.9

1

15

15

6.8

6.8

Table 4

CURING CONDITIONS FOR SMD-GLUE

MAX. T

amb

(

∞

∞

∞

∞

C)

MAX. EXPOSURE TIME

(minutes)

125

10

140

3

150

1

160

0.5

250

280

80

0

50

200

180

150

100

200

220

240

260

160

140

120

100

T

PAD

( C)

o

t (s)

Fig.5

Maximum temperature load

during infrared reflow soldering.

250

280

80

0

50

200

180

150

100

200

220

240

260

160

140

120

100

T

PAD

( C)

o

t (s)

Fig.6

Maximum temperature load during

vapour phase reflow soldering.

250

280

80

0

50

200

180

150

100

200

220

240

260

160

140

120

100

T

PAD

( C)

o

t (s)

Fig.7

Maximum temperature load during

(double-) wave soldering.

www.vishay.com

For technical questions contact: aluminumcaps1@vishay.com

Document Number: 28300

4

Revision: 22-Sep-03

085 CS

Vishay BCcomponents

Aluminum Capacitors

SMD (Chip) Standard

Note

1. Unless otherwise specified, all electrical values in Table 5 apply at

T

amb

= 20

∞

C, P = 86 to 106 kPa, RH = 45 to 75%

.

ORDERING EXAMPLE

Electrolytic capacitor 085 series

10 µF/16 V; -10/+50%

Nominal case size: 11.9 ◊ 3.7 ◊ 3.9 mm; Form BR

Catalog number: 2222 085 25109.

ELECTRICAL DATA

SYMBOL

DESCRIPTION

C

R

rated capacitance at 100 Hz

(tolerance -10 to +50% or ±20%)

I

R

rated RMS ripple current at 100 Hz, 85 ∞C

I

L5

max. leakage current after 5 minutes at U

R

Tan

max. dissipation factor at 100 Hz

Z

max. impedance at 10 kHz

Table 5

ELECTRICAL DATA AND ORDERING INFORMATION

U

R

(V)

C

R

100 Hz

(µ

µ

µ

µF)

NOMINAL

CASE SIZE

L ◊

◊

◊

◊ W ◊

◊

◊

◊ H

(mm)

I

R

100 Hz

85 ∞∞∞∞C

(mA)

I

L5

5 min

(µ

µ

µ

µA)

Tan

100 Hz

Z

10 kHz

(

)

CATALOG NUMBER 2222 085 .....

-

-

-

-10/+50%

±

±

±

±20%

BLISTER TAPE

ON REEL FORM BR

BLISTER TAPE

ON REEL FORM BR

6.3

10.0

8.8 ◊ 3.7 ◊ 3.9

11

3.1

0.30

20

23109

63109

22

11.9 ◊ 3.7 ◊ 3.9

20

3.3

0.30

9

23229

63229

10

6.8

8.8 ◊ 3.7 ◊ 3.9

10

3.1

0.25

24

24688

64688

15

11.9 ◊ 3.7 ◊ 3.9

18

3.3

0.25

11

24159

64159

16

4.7

8.8 ◊ 3.7 ◊ 3.9

9

3.2

0.20

26

25478

65478

10

11.9 ◊ 3.7 ◊ 3.9

16

3.3

0.20

12

25109

65109

25

3.3

8.8 ◊ 3.7 ◊ 3.9

8

3.2

0.18

27

26338

66338

6.8

11.9 ◊ 3.7 ◊ 3.9

14

3.3

0.18

13

26688

66688

40

2.2

8.8 ◊ 3.7 ◊ 3.9

7

3.2

0.16

32

27228

67228

4.7

11.9 ◊ 3.7 ◊ 3.9

13

3.4

0.16

15

27478

67478

63

0.47

8.8 ◊ 3.7 ◊ 3.9

4

3.1

0.10

120

28477

68477

1.0

8.8 ◊ 3.7 ◊ 3.9

6

3.1

0.12

55

28108

68108

2.2

11.9 ◊ 3.7 ◊ 3.9

11

3.3

0.14

25

28228

68228

3.3

11.9 ◊ 3.7 ◊ 3.9

13

3.4

0.14

17

28338

68338

ADDITIONAL ELECTRICAL DATA

PARAMETER

CONDITIONS

VALUE

Voltage

Surge voltage for short periods

U

s

1.15 ◊ U

R

Reverse voltage

U

rev

1 V

Current

Leakage current

after 1 minute at U

R

I

L1

0.02 C

R

◊ U

R

+ 3 µA

after 5 minutes at U

R

I

L5

0.002 C

R

◊ U

R

+ 3 µA

Inductance

Equivalent series inductance (ESL)

nominal case size 8.8 ◊ 3.7 ◊ 3.9 mm

typ. 11 nH

nominal case size 11.9 ◊ 3.7 ◊ 3.9 mm

typ. 13 nH

Resistance

Equivalent series resistance (ESR)

calculated from tan

max

and C

R

(see Table 5)

ESR = tan / 2fC

R

Document Number: 28300

For technical questions contact: aluminumcaps1@vishay.com

www.vishay.com

Revision: 22-Sep-03

5

085 CS

Aluminum Capacitors

SMD (Chip) Standard

Vishay BCcomponents

CAPACITANCE (C)

0

20

40

20

40

60

80

0.4

0.6

0.8

1.0

100

1.2

T amb ( C)

o

C

0

C

1

2

3

1

2

3

Fig.8 Typical multiplier of capacitance as a function of ambient

temperature.

Curve 1: 6.3 V.

Curve 2: 25 V.

Curve 3: 63 V.

C

0

= capacitance at 20 ∞C, 100 Hz.

10

4

10

3

10

2

10

f (Hz)

0.6

0.7

0.8

0.9

1.0

1.1

C

0

C

1

2

3

1

2

3

Fig.9 Typical multiplier of capacitance as a function of frequency.

Curve 1: 6.3 V.

Curve 2: 25 V.

Curve 3: 63 V.

C

0

= capacitance at 20 ∞C, 100 Hz.

T

amb

= 20 ∞C.

RIPPLE CURRENT AND USEFUL LIFE

3.3

3.2

3.0

2.8

2.6

2.4

2.2

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.5

0.0

3.1

40

50

60

70

80

90

100

T

amb

(∞C)

lifetime multiplier

(1)

70

50

4.0

6 .0

2.0

1.5

30

15

10

3.0

20

1.0

I

A

I

R

CCC205

Fig.10 Multiplier of useful life as a function of ambient temperature and ripple current load.

I

A

= actual ripple current at 100 Hz.

I

R

= rated ripple current at 100 Hz, 85 ∞C.

(1) Useful life at 85 ∞C and I

R

applied: 1500 hours.