NTC Thermistors, Special Long Lead Sensors

2322 641 2/3/4....

Vishay BCcomponents

Document Number: 29060

For technical questions contact: nlr.europe@vishay.com

www.vishay.com

Revision: 10-Oct-03

117

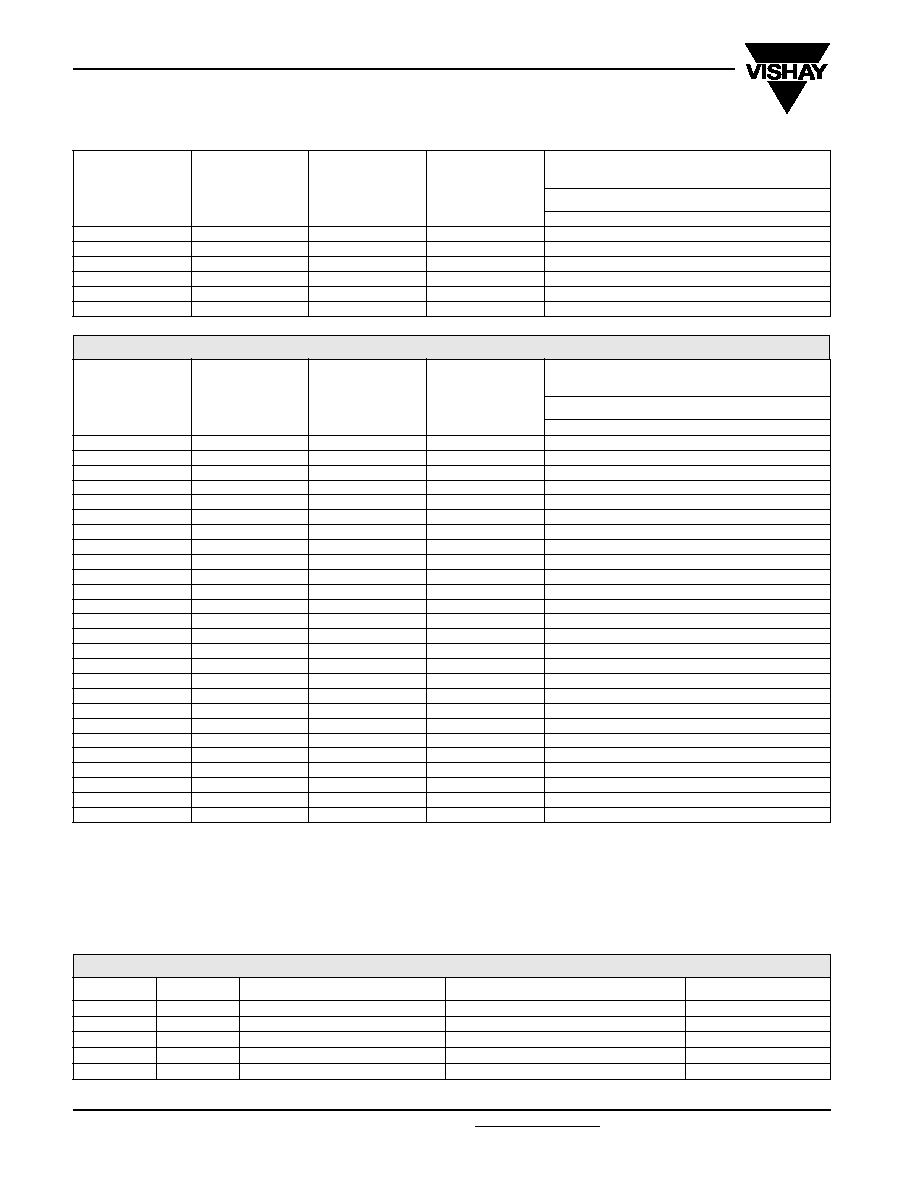

QUICK REFERENCE DATA

Notes

1. Response time in silicone oil MS 200/50. This is the time needed

for the sensor to reach 63.2% of the total temperature difference

when subjected to a temperature change from 25

∞

C in air to

85

∞

C in oil.

2. Wire length and wire type are optional on request. The products

can be provided with a connector on request.

3. Tighter tolerances on R

25

are available upon request.

PARAMETER

VALUE

UNIT

Resistance value at 25

∞

C (R

25

)

2.2 to 100

k

Tolerance on R

25

-value

±

3

%

Tolerance on B

25/85

-value

±

1.5 or

±

0.75

%

Maximum dissipation

250

mW

Dissipation factor:

2322 641 2....

6.0

mW/K

2322 641 3....

8.0

mW/K

2322 641 4....

6.0

mW/K

Response time; note 1:

2322 641 2....

7

s

2322 641 3....

15

s

2322 641 4....

10

s

Operating temperature range:

at zero dissipation

-

40 to +85

∞

C

at maximum dissipation

0 to +50

∞

C

Climatic category

40/085/56

Lead wire; note 2

UL-2468.AWG24 wire

Mass:

2322 641 2....

4

g

2322 641 3....

6

g

2322 641 4....

6

g

FEATURES

∑

Accurate over wide temperature range

∑

High stability

∑

Excellent price/performance ratio

∑

High adhesive strength between PVC wire and the

encapsulating laquer

APPLICATIONS

Temperature sensing and control

These thermistors have a negative temperature coefficient.

The epoxy-coated type (2322 641 2....) consists of a chip

with UL wire and is lacquered and insulated with black

epoxy.

The sleeved type (2322 641 3....) and the brass-pipe type

(2322

641

4....) are suitable for application in various

environmental conditions.

MARKING

UL mark on wire, no mark on body.

PACKAGING

The thermistors are packed in cardboard boxes; each box

containing 500 pcs.

ELECTRICAL DATA AND ORDERING INFORMATION

Notes

1. Other values based on the 2322 640 0.... series are available on request.

2. The specified catalog numbers refer to products with L = 400 mm, without connector and adopt UL-2468.AWG24 wire.

R

25

(k

)

B

25/85

-VALUE

CATALOG NUMBER 2322 641 .....

(2)

EPOXY-COATED TYPE

SLEEVED

TYPE

BRASS-PIPE

TYPE

2.2

3977 K

±

0.75%

26222

36222

46222

5

3977 K

±

0.75%

26502

36502

-

10

3977 K

±

0.75%

26103

36103

46103

47

4090 K

±

1.5%

26473

36473

-

100

4190 K

±

1.5%

26104

36104

46104

2322 641 2/3/4....

Vishay BCcomponents

NTC Thermistors, Special Long Lead Sensors

www.vishay.com

For technical questions contact: nlr.europe@vishay.com

Document Number: 29060

118

Revision: 10-Oct-03

DIMENSIONS

in millimeters

Epoxy-coated type 2322 641 2....

L = 400 mm +15/-0. Other wire lengths available on request.

L

6 max

3

17 +

-

2

5

L = 400 mm +15/-0. Other wire lengths available on request.

L

8 max

25 5

15 max

2

5

Sleeved type 2322 641 3....

L = 400 mm +15/-0. Other wire lengths available on request.

6

0.1

25 0.5

L

2

5

Brass-pipe type 2322 641 4....

DERATING

Power derating curve.

0

55

40

85

125

T ( C)

o

100

0

P

(%)

amb

2322 641 2/3/4....

NTC Thermistors, Special Long Lead Sensors

Vishay BCcomponents

Document Number: 29060

For technical questions contact: nlr.europe@vishay.com

www.vishay.com

Revision: 10-Oct-03

119

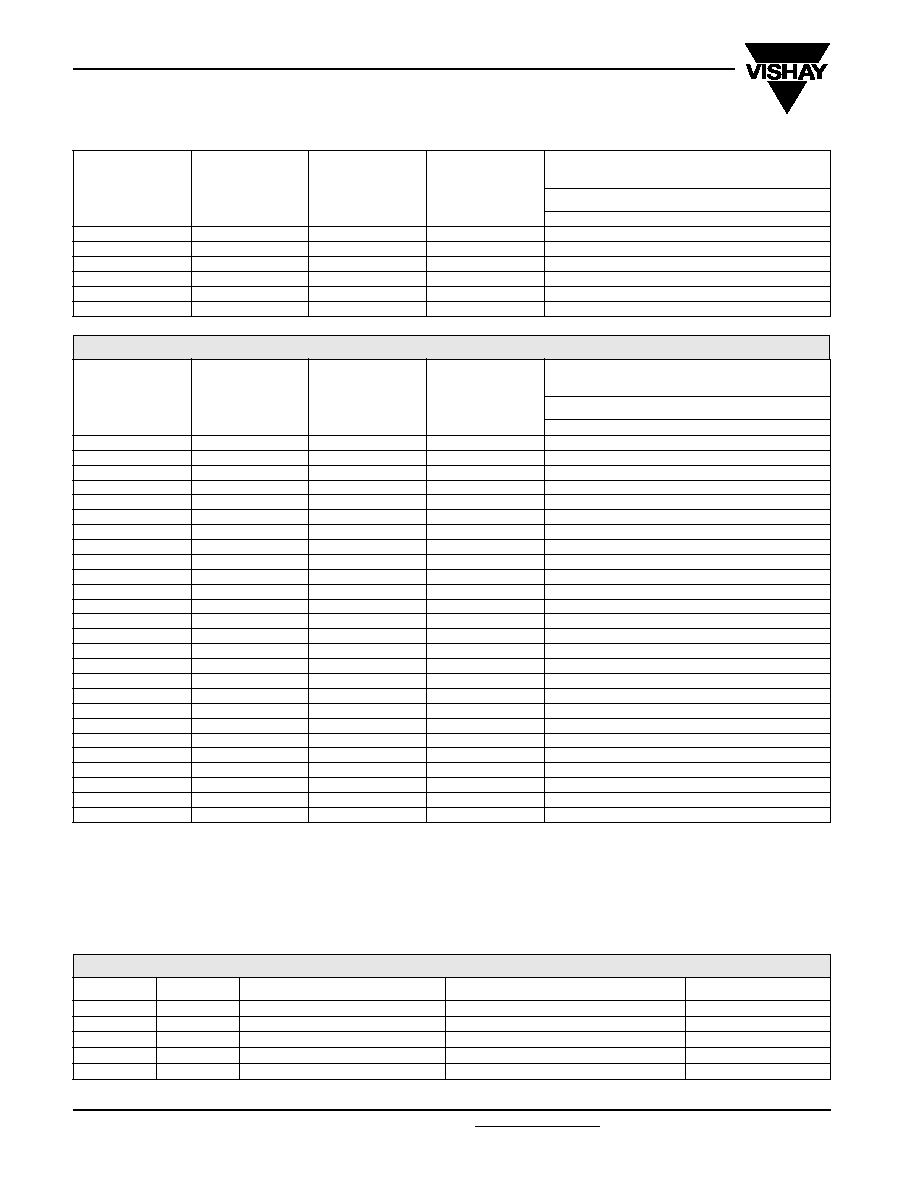

R-T CHARACTERISTICS

RESISTANCE VALUES AT INTERMEDIATE TEMPERATURES

T

amb

(

∞

∞

∞

∞

C)

R

T

/R

25

R DUE TO

B-TOLERANCE

(%)

TC

(%/K)

R

25

(k

)

2322 641 2/3/4 .....;

see note 1

at end of tables

.6222

.6502

.6103

-

40

33.21

2.66

6.57

73.06

166.1

332.1

-

35

23.99

2.41

6.36

52.78

120.0

240.0

-

30

17.52

2.17

6.15

38.55

87.60

175.2

-

25

12.93

1.94

5.95

28.44

64.65

129.3

-

20

9.636

1.71

5.76

21.20

48.18

96.36

-

15

7.250

1.50

5.58

15.95

36.25

72.50

-

10

5.505

1.29

5.40

12.11

27.52

55.05

-

5

4.216

1.08

5.24

9.275

21.08

42.16

0

3.255

0.89

5.08

7.162

16.28

32.56

5

2.534

0.70

4.92

5.575

12.67

25.34

10

1.987

0.52

4.78

4.372

9.936

19.87

15

1.570

0.34

4.64

3.454

7.849

15.70

20

1.249

0.17

4.50

2.747

6.244

12.49

25

1.000

0.00

4.37

2.200

5.000

10.00

30

0.8059

0.16

4.25

1.773

4.030

8.059

35

0.6535

0.32

4.13

1.438

3.267

6.535

40

0.5330

0.47

4.02

1.173

2.665

5.330

45

0.4372

0.62

3.91

0.9618

2.186

4.372

50

0.3605

0.77

3.80

0.7932

1.803

3.606

55

0.2989

0.91

3.70

0.6575

1.494

2.989

60

0.2490

1.05

3.60

0.5478

1.245

2.490

65

0.2084

1.18

3.51

0.4586

1.042

2.084

70

0.1753

1.31

3.42

0.3857

0.8765

1.753

75

0.1481

1.44

3.33

0.3258

0.7405

1.481

80

0.1256

1.57

3.25

0.2764

0.6282

1.256

85

0.1070

1.69

3.16

0.2355

0.5352

1.070

RESISTANCE VALUES AT INTERMEDIATE TEMPERATURES

T

amb

(

∞

∞

∞

∞

C)

R

T

/R

25

R DUE TO

B-TOLERANCE

(%)

TC

(%/K)

R

25

(k

)

2322 641 2/3/4 ....;

see note 1

at end of tables

.6473

-

40

33.81

5.55

6.55

1589

-

35

24.50

5.02

6.34

1151

-

30

17.93

4.52

6.15

842.8

-

25

13.25

4.03

5.96

622.6

-

20

9.875

3.56

5.78

464.1

-

15

7.425

3.10

5.61

349.0

-

10

5.630

2.67

5.45

264.6

-

5

4.304

2.24

5.29

202.3

0

3.315

1.84

5.14

155.8

5

2.573

1.44

4.99

120.9

10

2.011

1.07

4.85

94.53

15

1.583

0.70

4.72

74.40

20

1.254

0.34

4.59

58.95

25

1.000

0.00

4.46

47.00

30

0.8024

0.33

4.34

37.71

35

0.6474

0.66

4.23

30.43

40

0.5255

0.98

4.12

24.70

45

0.4288

1.28

4.01

20.15

50

0.3518

1.59

3.91

16.53

55

0.2901

1.88

3.81

13.63

2322 641 2/3/4....

Vishay BCcomponents

NTC Thermistors, Special Long Lead Sensors

www.vishay.com

For technical questions contact: nlr.europe@vishay.com

Document Number: 29060

120

Revision: 10-Oct-03

60

0.2403

2.17

3.71

11.30

65

0.2001

2.45

3.62

9.404

70

0.1674

2.72

3.53

7.865

75

0.1406

2.99

3.44

6.607

80

0.1186

3.25

3.36

5.573

85

0.1004

3.51

3.28

4.721

T

amb

(

∞

∞

∞

∞

C)

R

T

/R

25

R DUE TO

B-TOLERANCE

(%)

TC

(%/K)

R

25

(k

)

2322 641 2/3/4 ....;

see note 1

at end of tables

.6473

RESISTANCE VALUES AT INTERMEDIATE TEMPERATURES

Note

1. Replace dot in last 5 digits of catalog number by a number according to the following details:

a) 2 for epoxy-coated type

b) 3 for water-resistant type

c) 4 for brass-pipe type.

TESTS AND REQUIREMENTS

T

amb

(

∞

∞

∞

∞

C)

R

T

/R

25

R DUE TO

B-TOLERANCE

(%)

TC

(%/K)

R

25

(k

)

2322 641 2/3/4 ....;

see note 1

.6104

-

40

36.66

5.69

6.70

3666

-

35

26.38

5.15

6.49

2638

-

30

19.17

4.63

6.29

1917

-

25

14.06

4.13

6.10

1406

-

20

10.41

3.65

5.92

1041

-

15

7.779

3.18

5.74

777.9

-

10

5.861

2.73

5.57

586.1

-

5

4.453

2.30

5.41

445.3

0

3.409

1.88

5.26

340.9

5

2.631

1.48

5.11

263.1

10

2.044

1.09

4.97

204.4

15

1.600

0.72

4.83

160.0

20

1.261

0.35

4.70

126.1

25

1.000

0.00

4.57

100.0

30

0.7981

0.34

4.45

79.81

35

0.6408

0.67

4.35

64.08

40

0.5175

1.00

4.22

51.74

45

0.4202

1.32

4.11

42.02

50

0.3431

1.63

4.00

34.31

55

0.2816

1.93

3.90

28.16

60

0.2322

2.22

3.80

23.22

65

0.1925

2.51

3.71

19.25

70

0.1602

2.79

3.62

16.03

75

0.1340

3.06

3.53

13.40

80

0.1126

3.33

3.45

11.26

85

0.09496

3.59

3.36

9.496

STABILITY TESTS

IEC

CECC

TEST

PROCEDURE

DRIFT REQUIREMENT

D3; 4.20.1

endurance

85

∞

C; 1000 hours

R/R < 5%

68-2-1

endurance

-

40

∞

C; 1000 hours

R/R < 5%

539

endurance

250 mW; 55 ∞C; 1000 hours

R/R < 5%

68-2-3

D1; 4.19

damp heat, steady state

56 days at 40 ∞C; 90 to 95% RH

R/R < 7%

68-2-14

C2; 4.14

rapid change of temperature

-40 to +85 ∞C; 50 cycles

R/R < 5%