Document Number: 40017

Revision 11-Nov-04

www.vishay.com

24

550D

Vishay Sprague

For technical questions, contact tantalum@vishay.com

ORDERING INFORMATION

550D

MODEL

This is expressed in picofarads. The

first two digits are the significant figures.

The third is the number of zeros to

follow. Standard capacitance ratings

are in accordance with EIA preferred

number series wherever possible.

157

CAPACITANCE

X0 =

±

20%

X9 =

±

10%

X5 =

±

5%

Special Order.

X0

CAPACITANCE

TOLERANCE

This is expressed in

volts. To complete the

three-digit block, zeros

precede the voltage

rating.

006

DC VOLTAGE

RATING AT + 85

∞

C

See Ratings

and Case

Codes Table.

R

CASE

CODE

2

STYLE NUMBER

2 = Insulated

sleeve.

T = Tape and Reel

T

PACKAGING

*When a shrink-fitted insulation is used, it shall lap over the ends of the capacitor body.

PERFORMANCE CHARACTERISTICS

Operating Temperature: - 55

∞

C to + 85

∞

C. (To + 125

∞

C

with voltage derating.)

Capacitance Tolerance: At 120 Hz, + 25

∞

C.

±

20% and

±

10% standard.

±

5% available as a special.

Dissipation Factor: At 120 Hz, + 25

∞

C. Dissipation factor,

as determined from the expression 2

fRC, shall not exceed

the values listed in the Standard Ratings Tables.

DC Leakage Current (DCL Max.):

At + 25

∞

C: Leakage current shall not exceed the values

listed in the Standard Ratings Tables.

Solid-Electrolyte T

ANTALEX

Æ

Capacitors

for High Frequency Power Supplies

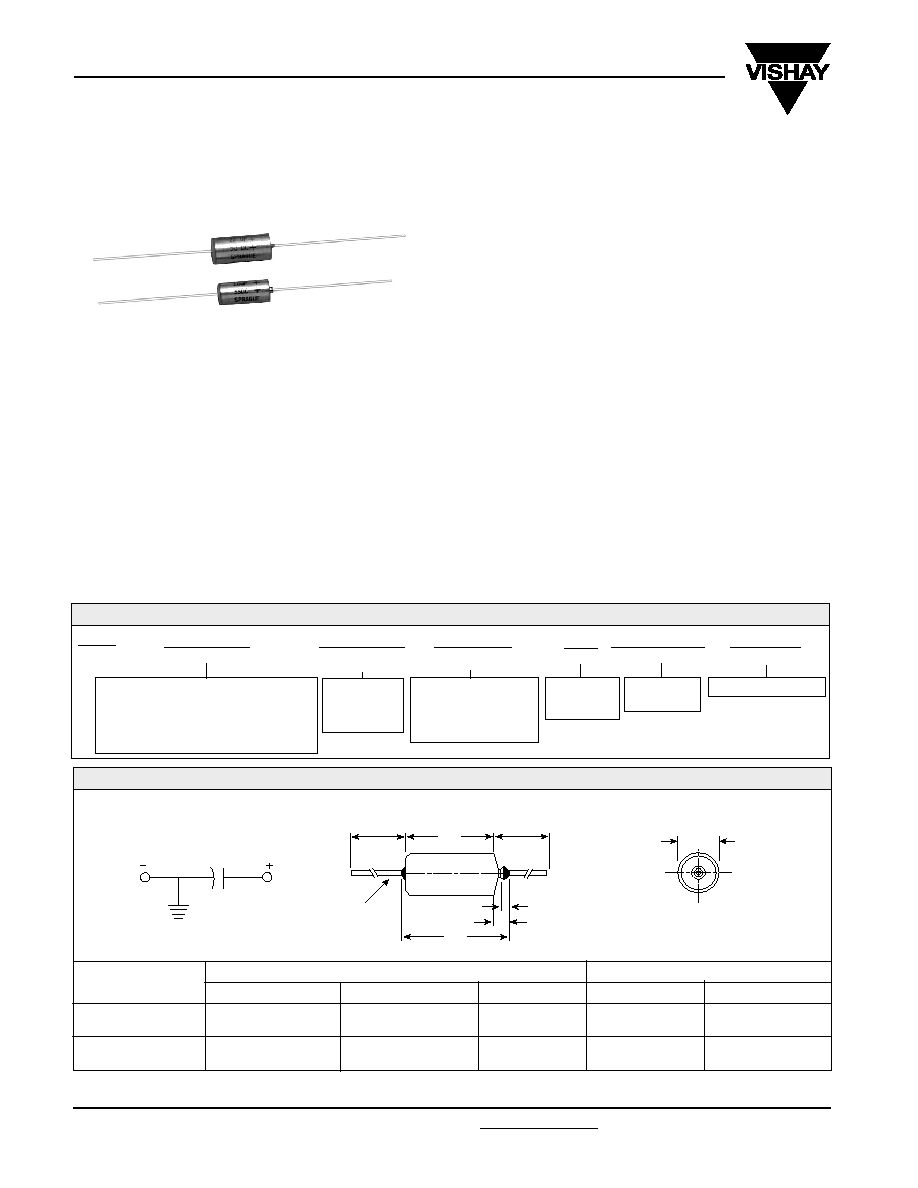

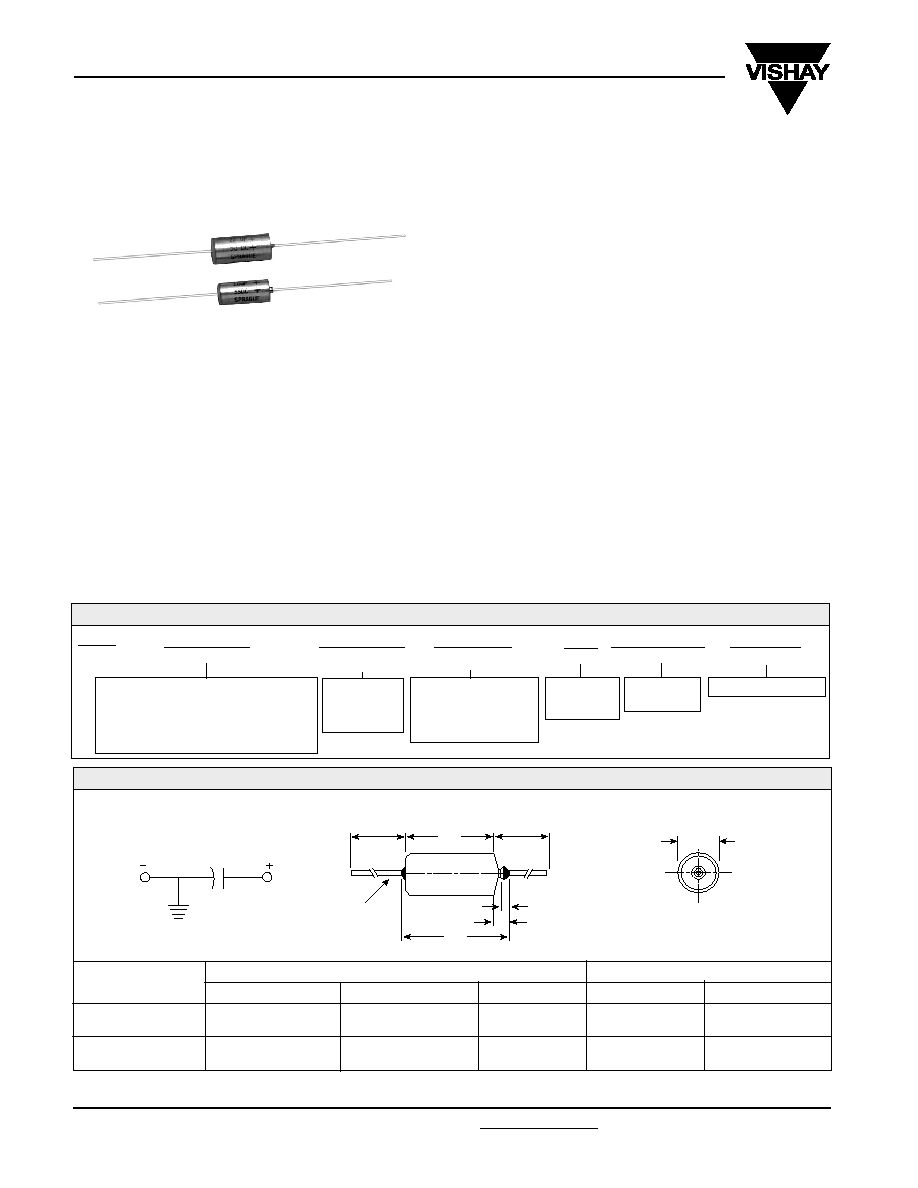

DIMENSIONS

in inches [millimeters]

D

Dia.

L

J

Max.

Solid Tinned

Leads

0.047 [1.19] Max.

0.125 [3.18] Max.

WITH INSULATING SLEEVE*

LEAD SIZE

CASE CODE

R

S

D

0.289

±

0.016

[7.34

±

0.41]

0.351

±

0.016

[8.92

±

0.41]

L

0.686

±

0.031

[17.42

±

0.79]

0.786

±

0.031

[19.96

±

0.79]

AWG NO.

22

22

J (MAX.)

0.822

[20.88]

0.922

[23.42]

NOM. DIA.

0.025

[0.64]

0.025

[0.64]

1.500

±

0.250

[38.10

±

6.35]

1.500

±

0.250

[38.10

±

6.35]

FEATURES

∑ Hermetically-sealed, axial-lead solid tantalum capacitors

∑ Small size and long life

∑ Exceptional capacitance stability and excellent resistance

to severe environmental conditions

∑ The military equivalent is the CSR21 which is qualified to

MIL-C-39003/09

APPLICATIONS

Designed for power supply filtering applications at above

100kHz

At + 85

∞

C: Leakage current shall not exceed 10 times the

values listed in the Standard Ratings Tables.

At +125

∞

C: Leakage current shall not exceed 15 times the

values listed in the Standard Ratings Tables.

Life Test: Capacitors shall withstand rated DC voltage

applied at + 85

∞

C for 2000 hours or derated DC voltage

applied at + 125

∞

C for 1000 hours.

Following the life test:

1. DCL shall not exceed 125% of the initial requirement.

2. Dissipation Factor shall meet the initial requirement.

3. Change in capacitance shall not exceed

±

5%.

www.vishay.com

25

550D

Vishay Sprague

Document Number: 40017

Revision 11-Nov-04

For technical questions, contact tantalum@vishay.com

0.300

0.275

0.250

0.230

0.210

0.190

0.175

0.160

*Insert capacitance tolerance code "X5" for

±

5% units (special order).

R

R

R

R

R

R

R

S

6 WVDC @ + 85

∞

C, SURGE = 8 V . . . 4 WVDC @ + 125

∞

C, SURGE = 5 V

10 WVDC @ + 85

∞

C, SURGE = 13 V . . . 7 WVDC @ + 125

∞

C, SURGE = 9 V

82

100

120

150

180

220

15 WVDC @ + 85

∞

C, SURGE = 20 V . . . 10 WVDC @ + 125

∞

C, SURGE = 12 V

56

68

82

100

120

150

20 WVDC @ + 85

∞

C, SURGE = 26 V . . . 13 WVDC @ + 125

∞

C, SURGE = 16 V

27

33

39

47

56

68

82

100

35 WVDC @ + 85

∞

C, SURGE = 46 V . . . 23 WVDC @ + 125

∞

C, SURGE = 28 V

8.2

10

12

15

18

22

27

33

39

47

50 WVDC @ + 85

∞

C, SURGE = 65 V . . . 33 WVDC @ + 125

∞

C, SURGE = 40 V

550D825X0035R2

550D106X0035R2

550D126X0035R2

550D156X0035R2

550D186X0035R2

550D226X0035R2

550D276X0035S2

550D336X0035S2

550D396X0035S2

550D476X0035S2

550D825X9035R2

550D106X9035R2

550D126X9035R2

550D156X9035R2

550D186X9035R2

550D226X9035R2

550D276X9035S2

550D336X9035S2

550D396X9035S2

550D476X9035S2

550D566X9015R2

550D686X9015R2

550D826X9015S2

550D107X9015S2

550D127X9015S2

550D157X9015S2

8

10

12

15

18

20

CAPACITANCE

(

µ

F)

CASE

CODE

MAX. DCL

@ + 25

∞

C

(

µ

A)

MAX. ESR

@ + 25

∞

C

100kHz

(Ohms)

MAX. DF

@ + 25

∞

C

1kHz

(%)

PART NUMBER*

CAP. TOL.

±

20%

PART NUMBER*

CAP. TOL.

±

10%

R

R

R

S

S

S

550D826X0010R2

550D107X0010R2

550D127X0010R2

550D157X0010S2

550D187X0010S2

550D227X0010S2

550D826X9010R2

550D107X9010R2

550D127X9010R2

550D157X9010S2

550D187X9010S2

550D227X9010S2

8

10

12

15

18

20

8

8

8

8

8

10

0.085

0.075

0.070

0.065

0.060

0.055

150

180

220

270

330

R

R

S

S

S

550D157X0006R2

550D187X0006R2

550D227X0006S2

550D277X0006S2

550D337X0006S2

550D157X9006R2

550D187X9006R2

550D227X9006S2

550D277X9006S2

550D337X9006S2

9

11

12

13

15

10

10

10

10

12

0.065

0.060

0.055

0.050

0.045

0.100

0.095

0.085

0.075

0.070

0.065

6

6

6

8

8

8

550D566X0015R2

550D686X0015R2

550D826X0015S2

550D107X0015S2

550D127X0015S2

550D157X0015S2

R

R

S

S

S

S

R

R

R

R

S

S

S

S

550D276X0020R2

550D336X0020R2

550D396X0020R2

550D476X0020R2

550D566X0020S2

550D686X0020S2

550D826X0020S2

550D107X0020S2

550D276X9020R2

550D336X9020R2

550D396X9020R2

550D476X9020R2

550D566X9020S2

550D686X9020S2

550D826X9020S2

550D107X9020S2

5

7

8

9

11

14

16

20

5

5

5

6

6

6

6

8

0.145

0.130

0.120

0.110

0.100

0.095

0.085

0.075

0.250

0.230

0.210

0.190

0.175

0.160

0.145

0.130

0.120

0.110

4

4

4

4

4

4

4

5

5

5

3

4

4

5

6

8

9

11

14

16

R

R

R

R

R

R

S

S

S

S

5.6

6.8

8.2

10.0

12.0

15.0

18.0

22.0

550D565X0050R2

550D685X0050R2

550D825X0050R2

550D106X0050R2

550D126X0050R2

550D156X0050R2

550D186X0050R2

550D226X0050S2

550D565X9050R2

550D685X9050R2

550D825X9050R2

550D106X9050R2

550D126X9050R2

550D156X9050R2

550D186X9050R2

550D226X9050S2

4

4

5

5

6

8

9

11

3

3

3

3

3

3

4

4

STANDARD RATINGS

Solid-Electrolyte T

ANTALEX

Æ

Capacitors

for High Frequency Power Supplies

Document Number: 40017

Revision 11-Nov-04

www.vishay.com

26

550D

Vishay Sprague

For technical questions, contact tantalum@vishay.com

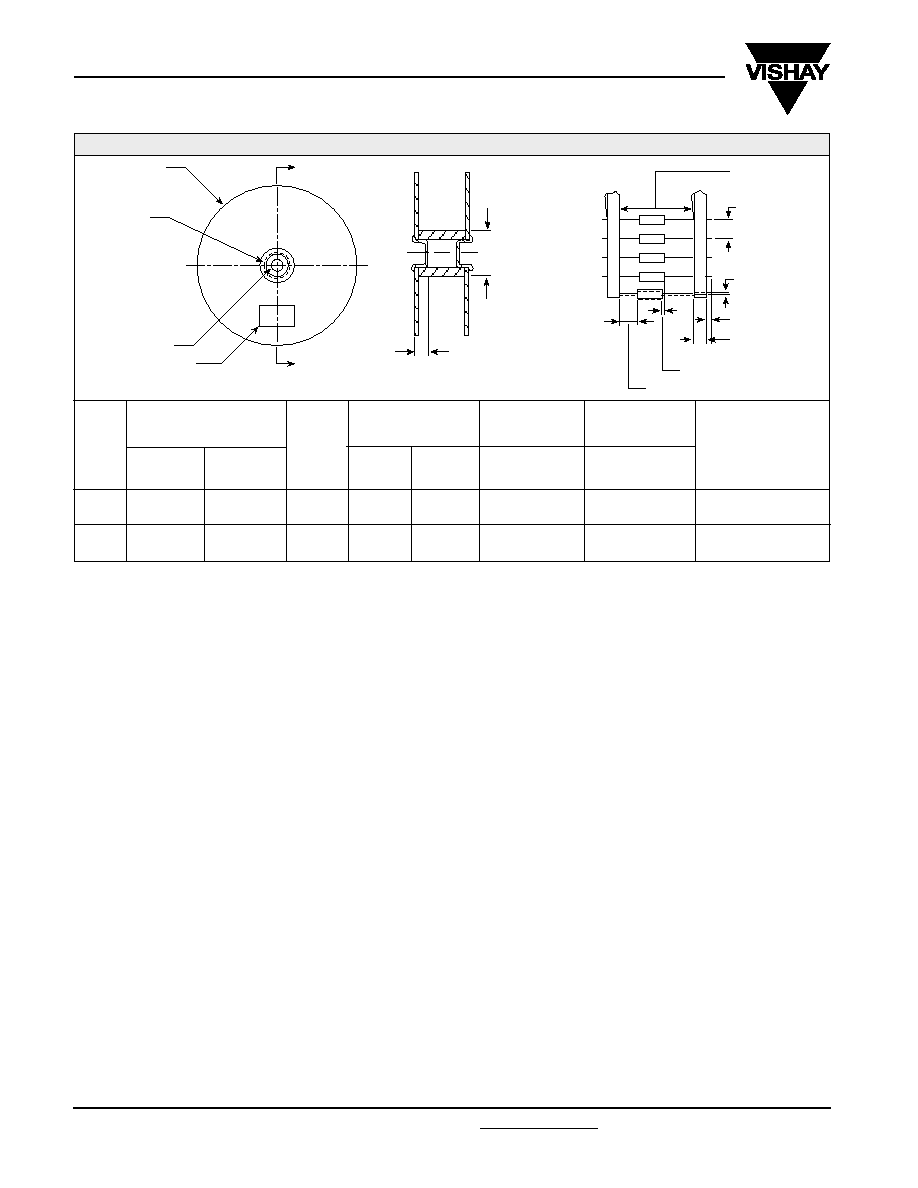

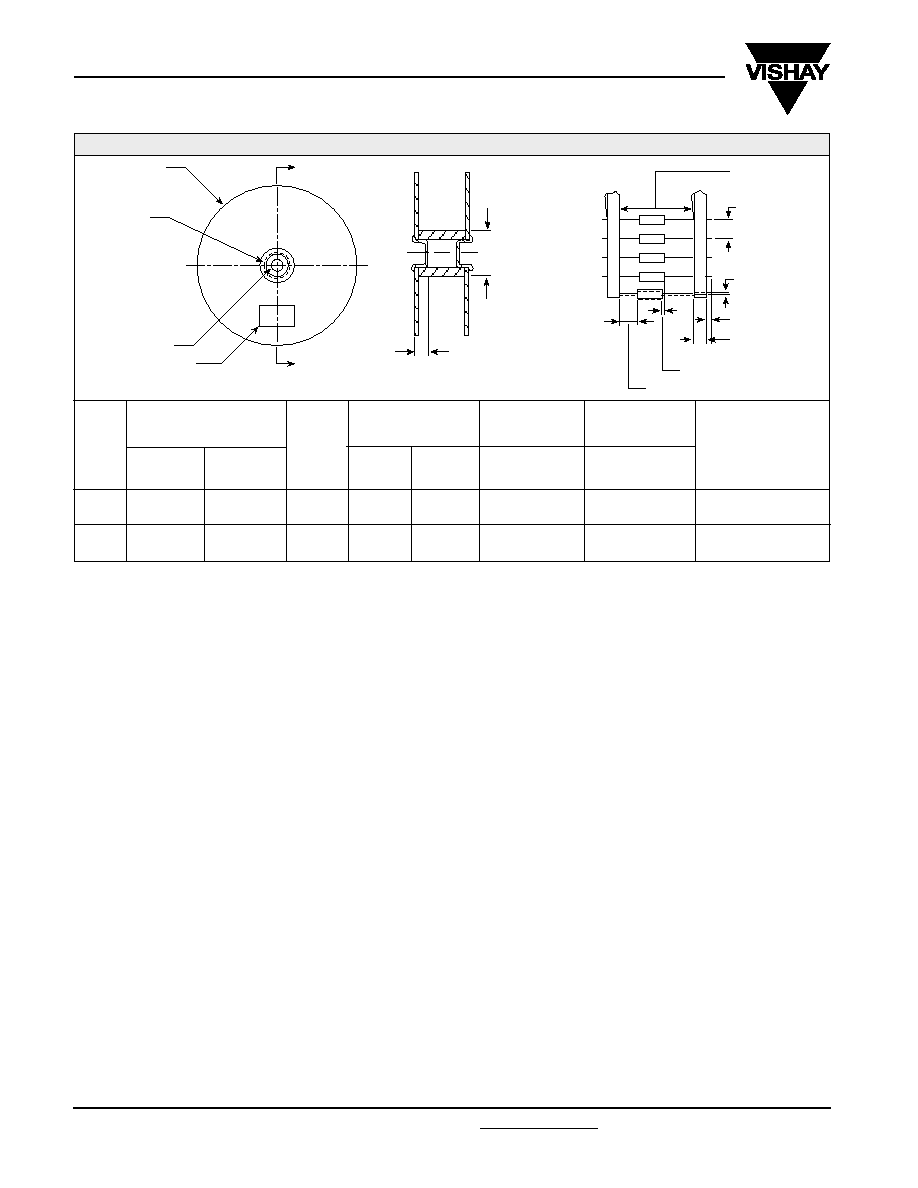

LEAD SIZE

TYPE 550D UNITS WITH

INSULATING SLEEVE

CASE

CODE

R

S

1.374 to 3.626

[34.9 to 92.1]

0.750 [19.05]

SECTION "A" - "A"

TAPE AND REEL PACKAGING

in inches [millimeters]

13 [330.2]

STANDARD REEL

"A"

"A"

1.126 to 3.07

[28.6 to 78.0]

I.D. REEL HUB

LABEL (4.a)

UNITS PER REEL

B

2.875

±

0.062

[73.03

±

1.57]

2.875

±

0.062

[73.03

±

1.57]

COMPONENT

SPACING

A

0.400

±

0.015

[10.16

±

0.38]

0.400

±

0.015

[10.16

±

0.38]

NOM. DIA.

0.025

[0.64]

0.025

[0.64]

AWG NO.

22

22

J (MAX.)

0.822

[20.88]

0.922

[23.42]

L

0.686

±

0.031

[17.42

±

0.79]

0.786

±

0.031

[19.96

±

0.79]

D

0.289

±

0.016

[7.34

±

0.41]

0.351

±

0.016

[8.92

±

0.41]

TAPE

SPACING

500

500

0.625

±

0.062

[15.88

±

1.57]

DIA. THRU HOLE

0.125 [3.18] MAX.

B

TAPE SPACING

COMPONENT

SPACING

A

0.031 [0.79] (3.f)

(BOTH SIDES) ( 3.f)

0.250 [6.35] (3.b)

0.047 [1.19] MAX.

OFF CENTER

(1.a)

Solid-Electrolyte T

ANTALEX

Æ

Capacitors

for High Frequency Power Supplies

STANDARD REEL PACKAGING INFORMATION

1. Component Leads:

a. Component leads shall not be bent beyond 0.047"

[1.19mm] maximum from their nominal position when

measured from the leading edge of the component lead

at the inside tape edge and at the lead egress from the

component.

b. The 'C' dimension shall be governed by the overall length

of the reel packaged component. The distance between

flanges shall be 0.125" to 0.250" [3.18mm to 6.35mm]

greater than the overall component length.

2. Orientation:

a. All polarized components must be oriented to one

direction. The cathode lead tape shall be a color and the

anode lead tape shall be white.

3. Reeling:

a. Components on any reel shall not represent more t h a n

two date codes when date code identification is

required.

b. Component leads shall be positioned between pairs of

0.250" [6.35mm] tape.

c. The disposable reels have hubs with corrugated fiber

board flanges and core or equivalent.

d. A minimum of 12" [304.8mm] leader of tape shall be

provided before the first and after the last component on

the reel.

e. 50 or 60 lb. Kraft paper must be wound between layer of

components as far as necessary for component protection.

Width of paper to be 0.062" to 0.250" [1.57mm to 6.35mm]

less than the 'C' dimension of the reel.

f. A row of components must be centered between tapes

±

0.047" [1.19mm]. In addition, individual components

may deviate from center of component row

±

0.031"

[0.79mm].

g. Staples shall not be used for splicing. Not more than 4

layers of tape shall be used in any splice area and no

tape shall be offset from another by more than 0.031"

[0.79mm] non-cumulative. Tape splices shall overlap at

least 6" [152.4mm] for butt joints and at least 3" [76.2mm]

for lap joints and shall not be weaker than unspliced tape.

Universal splicing clips may also be used.

h. Quantity per reel shall be controlled so that tape

components and cover shall not extend beyond the

smallest dimension of the flange (either across flats or

diameter). Once the quantity per reel for each part number

has been established, future orders for that part number

shall be packaged in that quantity. When order or release

quantity is less than the established quantity, a standard

commercial pack is to be used.

i. A maximum of 0.25% of the components per reel quantity

may be missing without consecutive missing components.

j. Adequate protection must be provided to prevent physical

damage to both reel and components during shipment

and storage.

4. Marking:

a. Minimum reel and carton marking shall consist of the

following: Customer Part Number, Purchase Order No.,

Quantity, Package Date, Manufacturer's name, Electrical

Value, Date Code, Vishay Sprague Part Number and

Country of Origin.

www.vishay.com

27

550D

Vishay Sprague

Document Number: 40017

Revision 11-Nov-04

For technical questions, contact tantalum@vishay.com

TYPICAL CURVES @ + 25∞C, IMPEDANCE AND ESR VS FREQUENCY

1

0.1

.01

FREQUENCY IN HERTZ

100 1K 10K 100K 1M 10M

10

180

µ

F, 6 V

180

µ

F, 6 V

IMPEDANCE

ESR

330

µ

F, 6 V

330

µ

F, 6 V

1

0.1

.01

FREQUENCY IN HERTZ

100 1K 10K 100K 1M 10M

10

IMPEDANCE

ESR

120

µ

F, 10 V

220

µ

F, 10 V

120

µ

F, 10 V

220

µ

F, 10 V

1

0.1

.01

FREQUENCY IN HERTZ

100 1K 10K 100K 1M 10M

10

IMPEDANCE

ESR

150

µ

F, 15 V

68

µ

F, 15 V

150

µ

F, 15 V

68

µ

F, 15 V

1

0.1

.01

FREQUENCY IN HERTZ

100 1K 10K 100K 1M 10M

10

IMPEDANCE

ESR

100

µ

F, 20 V

47

µ

F, 20 V

47

µ

F, 20 V

100

µ

F, 20 V

1

0.1

.01

FREQUENCY IN HERTZ

100 1K 10K 100K 1M 10M

10

IMPEDANCE

ESR

47

µ

F, 35 V

22

µ

F, 35 V

22

µ

F, 35 V

47

µ

F, 35 V

1

0.1

.01

FREQUENCY IN HERTZ

100 1K 10K 100K 1M 10M

10

IMPEDANCE

ESR

22

µ

F, 50 V

18

µ

F, 50 V

22

µ

F, 50 V

18

µ

F, 50 V

OHMS

OHMS

OHMS

OHMS

OHMS

OHMS

Document Number: 40017

Revision 11-Nov-04

www.vishay.com

28

550D

Vishay Sprague

For technical questions, contact tantalum@vishay.com

PERFORMANCE CHARACTERISTICS

1.

Operating Temperature: Capacitors are designed

to operate over the temperature range of - 55

∞

C to

+85

∞

C with no derating.

1.1

Capacitors may be operated up to + 125

∞

C with voltage

derating to two-thirds the + 85

∞

C rating.

2.

DC Working Voltage: The DC working voltage is the

maximum operating voltage for continuous duty at the

rated temperature.

3.

Surge Voltage: The surge DC rating is the maximum

voltage to which the capacitors may be subjected

under any conditions, including transients and peak

ripple at the highest line voltage.

3.1

Surge Voltage Test: Capacitors shall withstand the

surge voltage applied in series with a 33 ohm

±

5%

resistor at the rate of one-half minute on, one-half

minute off, at + 85

∞

C, for 1000 successive test cycles.

3.2

Following the surge voltage test, the dissipation factor

and the leakage current shall meet the initial

requirements; the capacitance shall not have changed

more than

±

10%.

4.

Capacitance Tolerance: The capacitance of all

capacitors shall be within the specified tolerance limits

of the nominal rating.

4.1

Capacitance measurements shall be made by means

of polarized capacitance bridge. The polarizing

voltage shall be of such magnitude that there shall be

no reversal of polarity due to the AC component. The

maximum voltage applied to capacitors during

measurement shall be 2 volts rms at 1000Hz at + 25

∞

C.

If the AC voltage applied is less than one-half volt rms,

no DC bias is required. Measurement accuracy of the

bridge shall be within

±

2%.

5.

Capacitance Change With Temperature: The

capacitance change with temperature shall not

exceed the following percentage of the capacitance

measured at + 25%

6.

Dissipation Factor: The dissipation factor,

determined from the expression 2

fRC, shall not

exceed values listed in the Standard Ratings Table.

6.1

Measurements shall be made by the bridge method

at, or referred to, a frequency of 1000Hz and a

temperature of + 25

∞

C.

7.

Leakage Current: Capacitors shall be stabilized at

the rated temperature for 30 minutes. Rated voltage

shall be applied to capacitors for 5 minutes using a

steady source of power (such as a regulated power

supply) with 1000 ohm resistor connected in series with

the capacitor under test to limit the charging current.

Leakage current shall then be measured.

Note that the leakage current varies with applied voltage. See graph

below for the appropriate adjustment factor.

7.1

At + 25

∞

C, the leakage current shall not exceed the

value listed in the Standard Ratings Table.

7.2

At + 85

∞

C, the leakage current shall not exceed 10

times the value listed in the Standard Ratings Table.

7.3

At + 125

∞

C, the leakage current shall not exceed 15

times the value listed in the Standard Ratings Table.

8.

Life Test: Capacitors shall withstand rated DC voltage

applied at + 85

∞

C for 2000 hours or rated DC voltage

applied at + 125

∞

C for 1000 hours.

8.1

Following the life test, the dissipation factor shall meet

the initial requirement; the capacitance change shall

not exceed

±

2%; the leakage current shall not exceed

125% of the original requirement.

- 55

∞

C

- 10%

+ 85

∞

C

+ 8%

+ 125

∞

C

+ 12%

WORKING

SURGE

WORKING

SURGE

VOLTAGE

VOLTAGE

VOLTAGE

VOLTAGE

(V)

(V)

(V)

(V)

6

8

4

5

10

13

7

9

15

20

10

12

20

26

13

16

35

46

23

28

50

65

33

40

+ 85

∞

C Rating

+ 125

∞

C Rating

TYPICAL LEAKAGE CURRENT FACTOR RANGE

1.0

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.08

0.07

0.06

0.05

0.04

0.03

0.02

0.01

0.008

0.007

0.006

0.005

0.004

0.003

0.002

0.001

LEAKAGE CURRENT F

ACT

OR

0

PERCENT OF RATED VOLTAGE

10

30

20

90

40

50

60

70

80

100

At

+ 25

∞

C