| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: DRTOP50 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

www.vishay.com

27

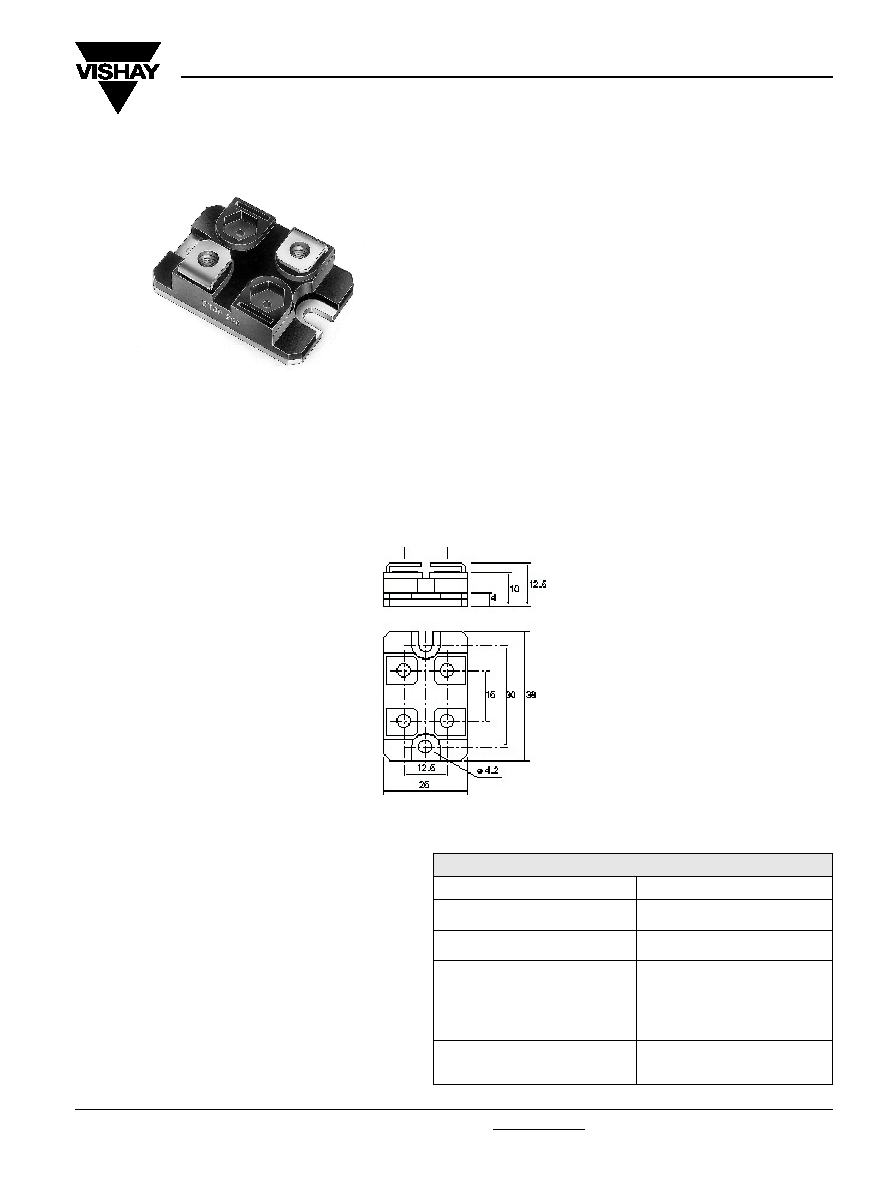

RTOP

Vishay Sfernice

Document Number: 50045

Revision 14-Jan-04

For technical questions, contact sfer@vishay.com

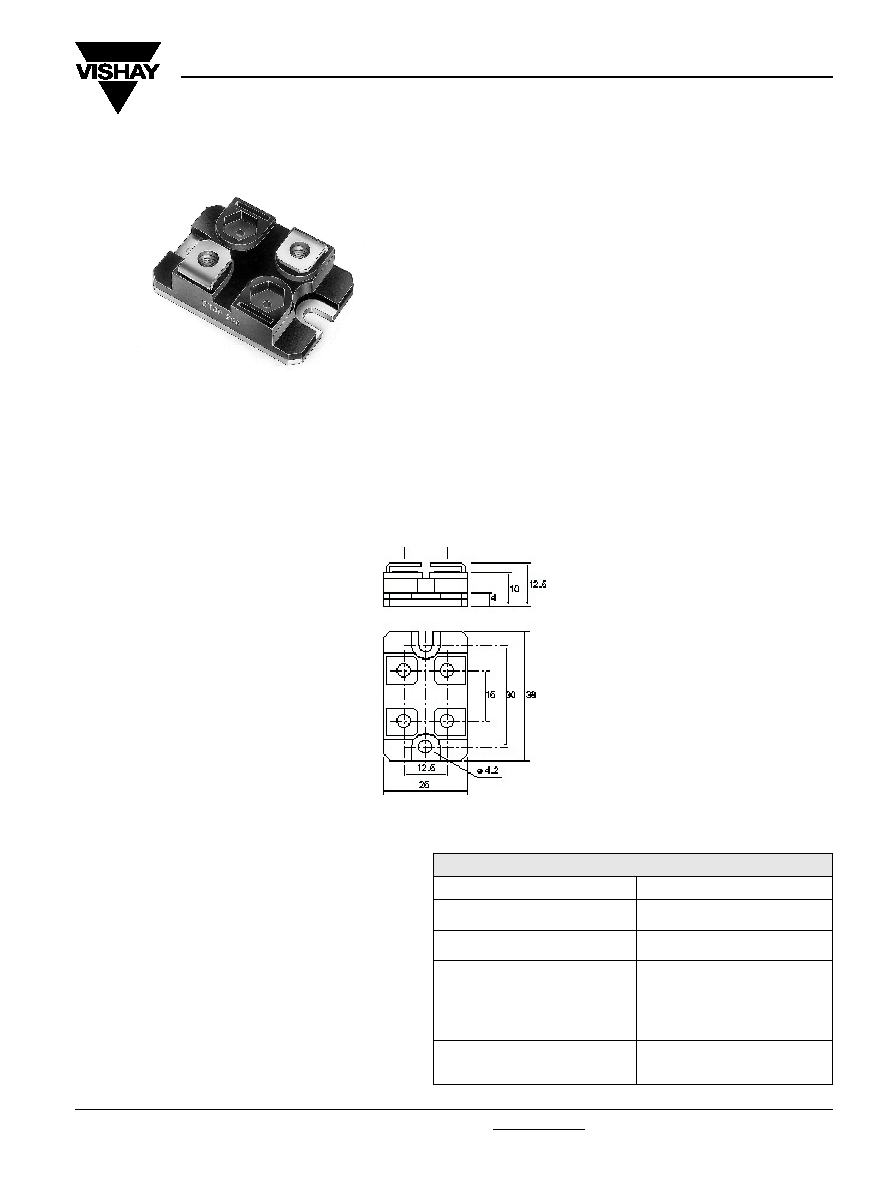

MECHANICAL SPECIFICATIONS

Mechanical Protection

Insulated case

Substrate

Alumina on insulated base

Resistive Element

Cermet

End Connection

V connections: screw M4 x 6

Tightening Torque Connections 1 Nm

Tightening Torque Heatsink 2 Nm

ENVIRONMENTAL SPECIFICATIONS

Temperature Range

- 55∞C to + 125∞C

Climatic Category

55/125/56

Power Resistors for Mounting onto a Heatsink

Thick Film Technology

FEATURES

∑ 1% tolerance available

∑ High power rating

∑ Wide ohmic value range

∑ Non inductive

∑ Easy mounting

∑ Low thermal radiation of the case

∑ Standard Isotop case (SOT 227 B)

This series of thick film power resistors include modules which can incorporate up to 2 different resistor values in the same SOT

227B package. Two types of terminations are available along with a 4 terminal device for measurement applications in the case

of the single resistor version. This product range benefits from Vishay Sfernice's experience in thick film power resistor technol-

ogy i.e high power: volume ratio, low tolerance or individual resistors and excellent overload capabilities (due to the trimming

technique).

V Connections

RTOP

∑ Tolerances unless otherwise specified: ± 0.3mm

DIMENSIONS in millimeters

Resistance Range

0.046 to 1M

Standard Tolerance

± 1% to ± 10%

Power Rating

50W to 200W at + 25∞C

Temperature Coefficient

Standard

± 300 ppm/∞C (R < 1)

± 150 ppm/∞C (R > 1)

Insulation Resistance

> 10

6

M

ELECTRICAL SPECIFICATIONS

Document Number: 50045

Revision 14-Jan-05

www.vishay.com

28

RTOP

Vishay Sfernice

For technical questions, contact sfer@vishay.com

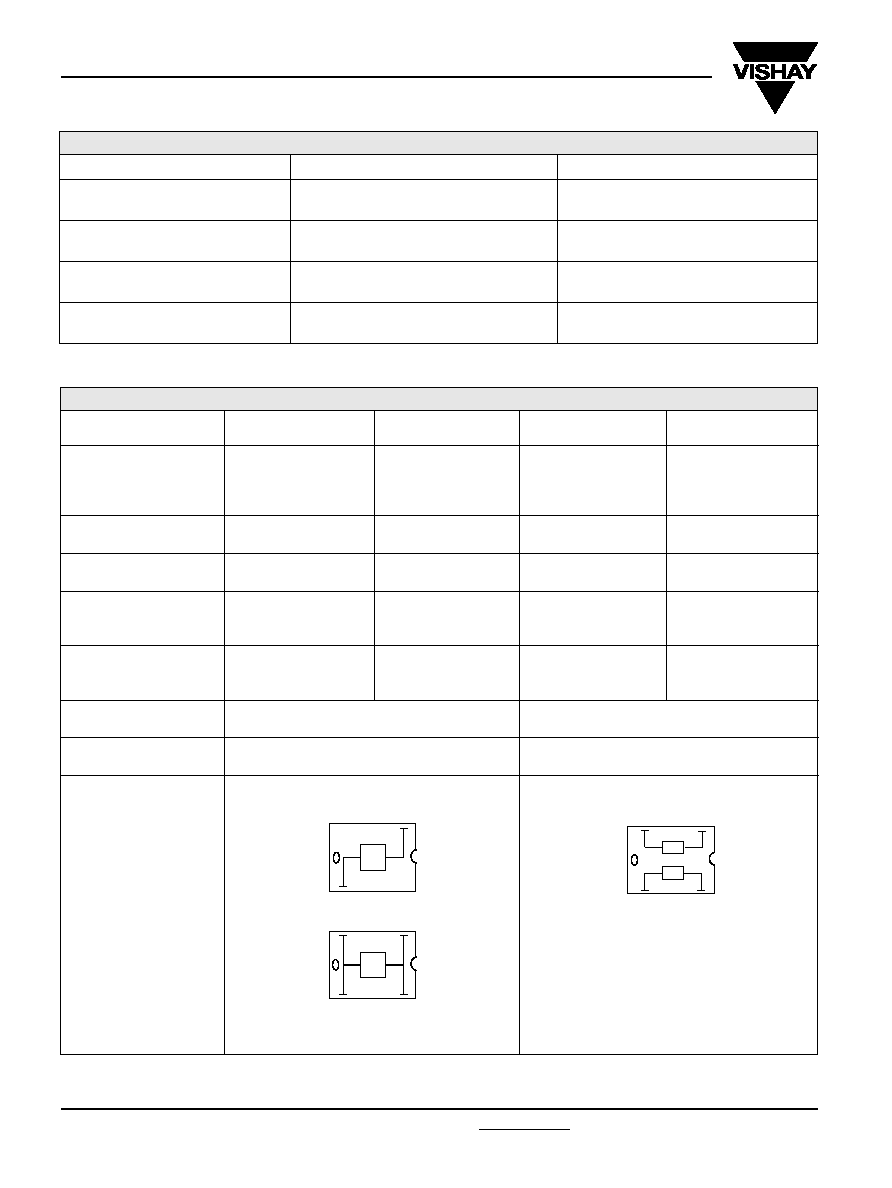

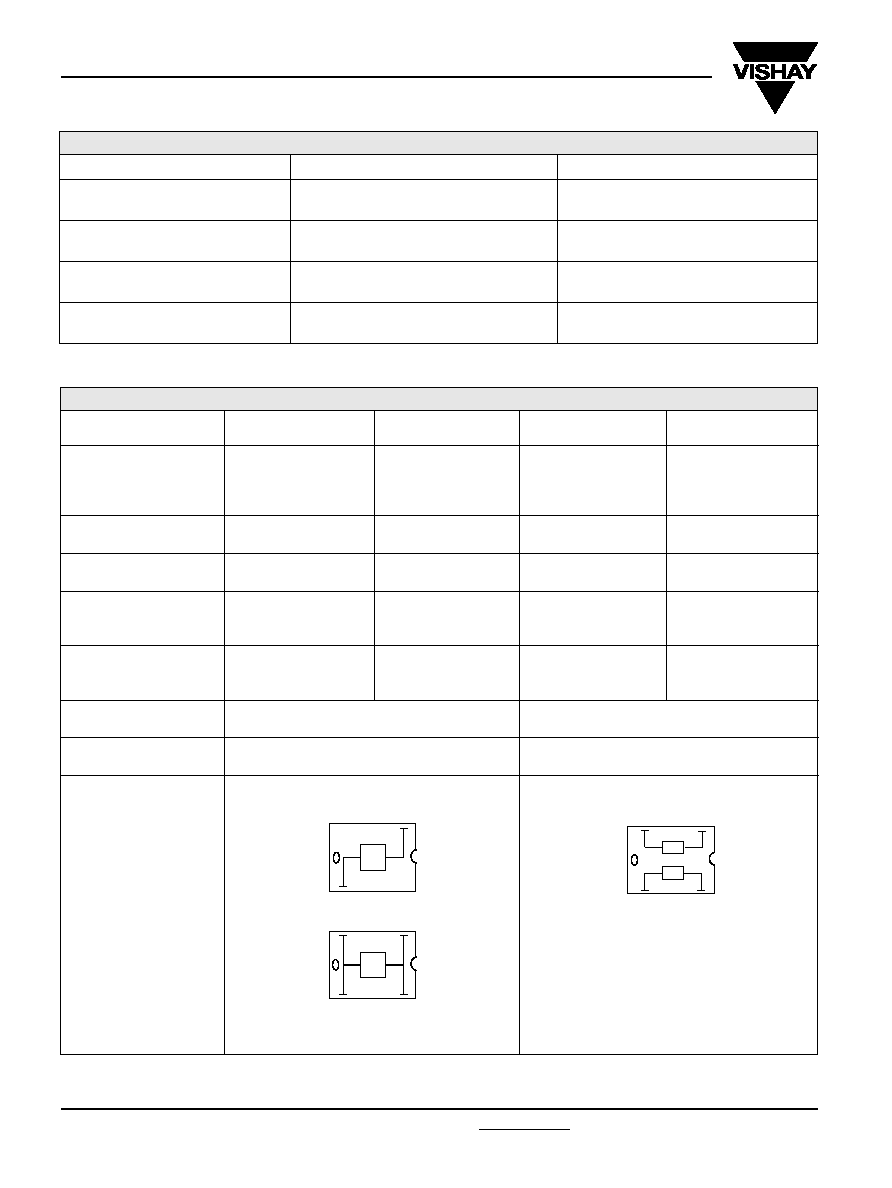

MODEL

RTOP 200

RTOP 100

DRTOP 100

DRTOP 50

Power Rating at + 25∞C

chassis mounted resistors

200W

100W

100W

50W

unmounted resistors

5W

5W

3.5W

3.5W

Thermal Resistance (per resistor)

0.5∞C/W

1∞C/W

0.5∞C/W

1∞C/W

Limiting Voltage

1500V

1500V

500V

500V

Dielectric Strength*

2500V, 1 Minute

2500V, 1 Minute

2500V, 1 Minute

2500V, 1 Minute

connections/chassis

10mA Max

10mA Max

10mA Max

10mA Max

Dielectric Strength*

-

-

2500V, 1 Minute

2500V, 1 Minute

connections/resistors

10mA Max

10mA Max

Ohmic Value Range

0.046 to 1M

0.092 to 1M

Tolerance

± 1% to ± 10%

± 1% to ± 10%

Electrical Diagrams

R

R

R2

R1

SPECIAL FEATURES

Shunt Version

TESTS

CONDITIONS

TYPICAL DRIFTS

Momentary Overload

NF EN 140000 CEI 115_1

< ± (0.25% + 0.05)

2.5Pn/5 seconds

Rapid Temperature Change

NF EN 140000 CEI 68214 Test Na

< ± (0.25% + 0.05)

5 cycles - 55∞C +125∞C

Load Life

NF EN 140000 CEI 115_1

< ± (0.5% + 0.05)

Pn at 25∞C 1000 hours

Humidity (steady state)

MIL STD 202 Method 103 B Test D

< ± (0.5% + 0.05)

56 days 95% R.H.

PERFORMANCE

Power Resistors for Mounting onto a Heatsink

Thick Film Technology

*MIL STD 202 Method 301

www.vishay.com

29

RTOP

Vishay Sfernice

Document Number: 50045

Revision 14-Jan-04

For technical questions, contact sfer@vishay.com

CHOICE OF HEATSINK

The user must choose the heatsink according to the working conditions of the component (power, room temperature).

Maximum working temperature must not exceed 125∞C. The dissipated power is simply calculated by the following ratio:

P =

P:

expressed in W

T: difference between maximum working temperature and room temperature.

R

TH:

(j-c): thermal resistance value measured between resistive layer and outer side of the resistor. It is the thermal

resistance of the component (see Table Special Features).

R

TH:

(c-a): thermal resistance value measured between outer side of the resistor and room temperature. It is the

thermal resistance of the heatsink depending on the heatsink itself (type, shape) and the quality of the fastening

device.

Example:

R

TH:

(c-a) for RTOP 200 power rating 130W at ambient temperature + 30∞C.

Thermal resistance (see table 1) R

TH

(j-c): 0.5∞C/W

T 125∞C - 30∞C - 95∞C

RTH

(

j-c) + RTH

(

c-a) = = = 0.73∞C/W

RTH

(

j-c) 0.5∞C/W

RTH

(c-a)

0.73∞C/W - 0.5∞C/W 0.23∞C/W

T

[R

TH

(j-c) + R

TH

(c-a)]

(1)

RECOMMENDATIONS FOR MOUNTING ONTO A HEATSINK

Surfaces in contact must be carefully cleaned.

The heatsink must have an acceptable flatness: from 0.05mm to 0.1mm/100mm.

Roughness of the heater must be around 6.3µm.

In order to improve thermal conductivity, surfaces in contact (alumina, heatsink) are laid on with a silicone grease (type SI 340

from RhÙne-Poulenc or Dow 340 from Dow Corning).

Tightening torque on heater: 2 Nm

For the electrical connections, it is recommended to use M4 x 6 screws and if necessary a washer of 1mm thickness. The

recommended screw tightening torque is 1 Nm.

130

T

P

95

Power Resistors for Mounting onto a Heatsink

Thick Film Technology

Document Number: 50045

Revision 14-Jan-05

www.vishay.com

30

RTOP

Vishay Sfernice

For technical questions, contact sfer@vishay.com

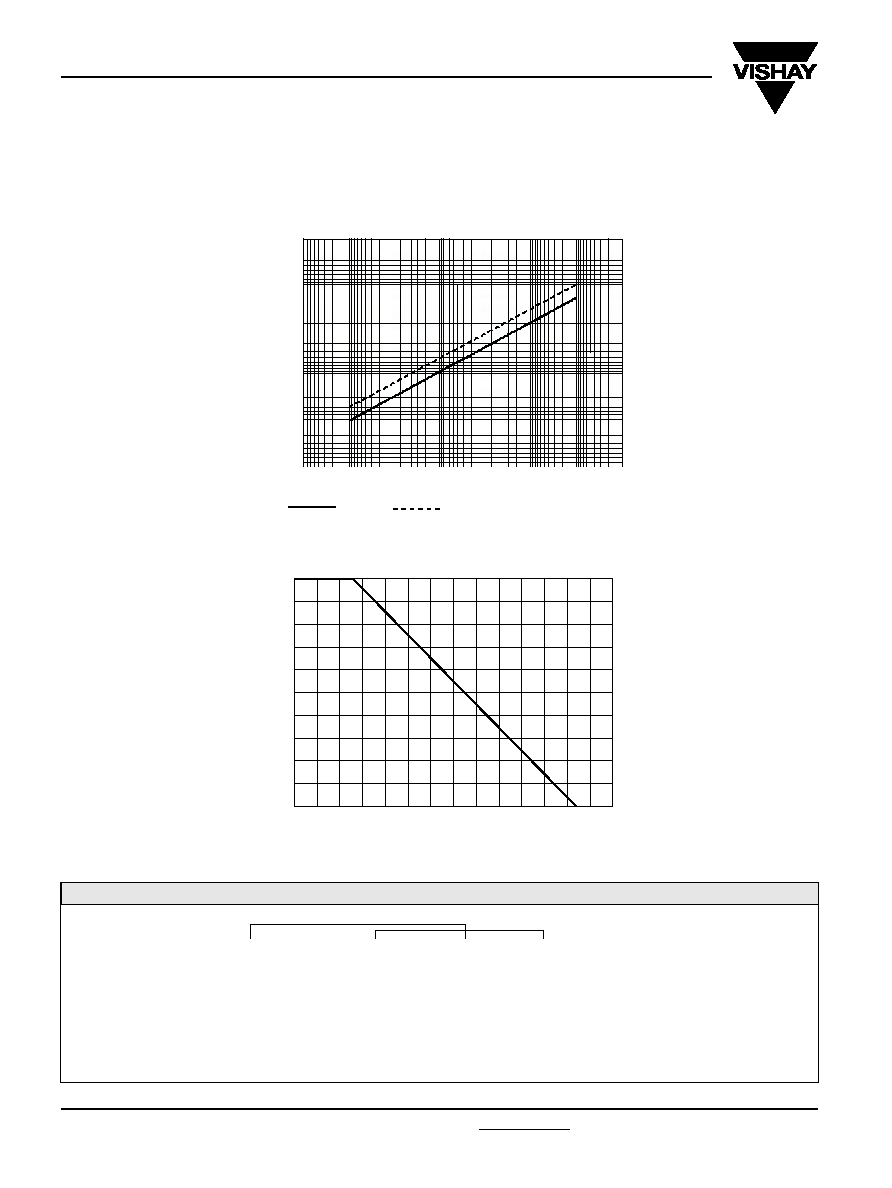

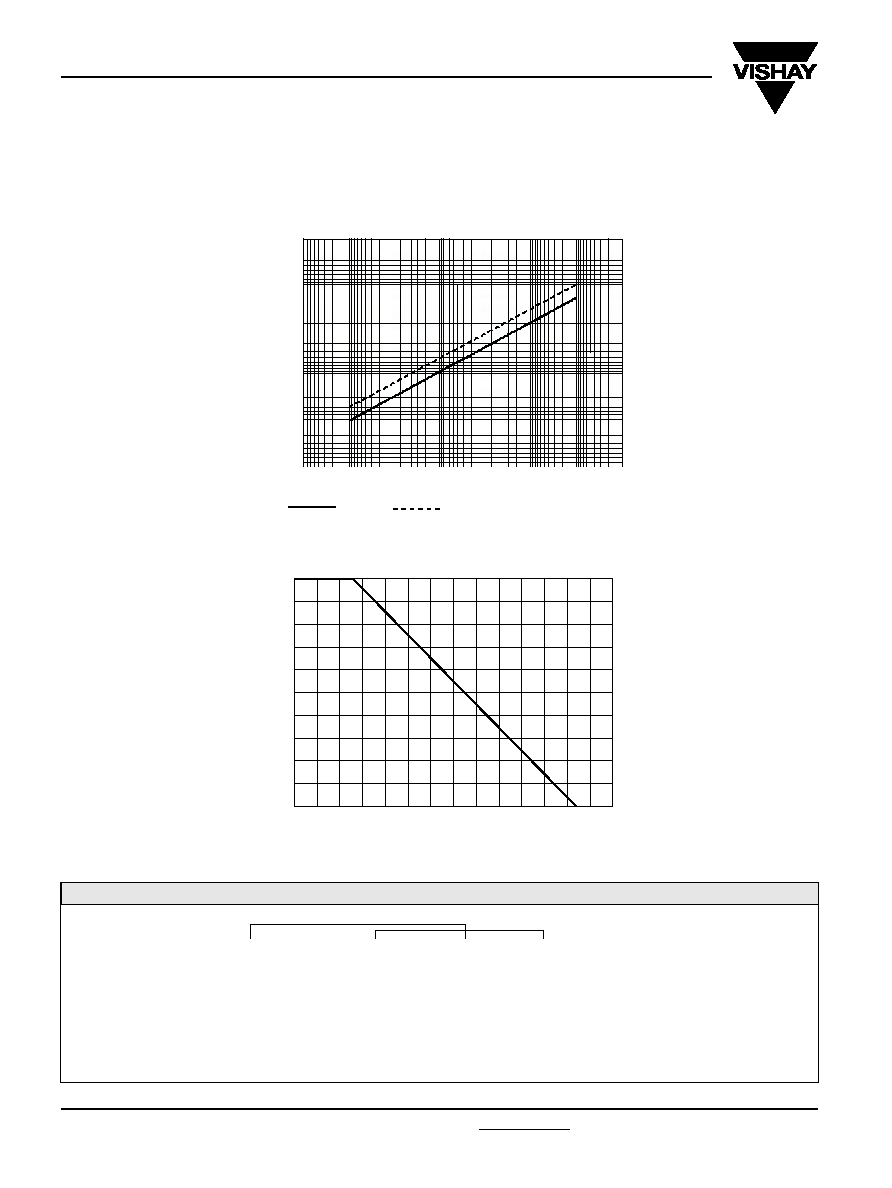

OVERLOADS

The applied power is 2.5 x rated power for 5 s with a max voltage of 2 x nominal voltage.

Accidental overload: The values indicated in the graph below are applicable to resistors in air or mounted onto a heatsink.

In case of multi-resistor devices, (DRTOP, TROP and QROP) the results apply to each resistor value in the device.

POWER RATING CHART

The temperature of the heater should be maintained in the limit specified. To improve the thermal conductivity, surfaces in

contact should be laid on with a silicon grease and the torque applied on the screw for tightening should be around 2 Nm.

MARKING

Series, style, ohmic value (in ), tolerance (in %), manufacturing date, VISHAY trade mark.

% RA

TED PO

WER

0

20

40

60

80

100

120

140

HEATSINK TEMPERATURE IN DEGREES CELSIUS

ENERGY CURVE

ORDERING INFORMATION

RTOP

200

3.2

± 1%

± %

V

R1

T1

R2

MODEL

STYLE

OHMIC VALUE

CONNECTIONS

CUSTOM DESIGN

RTOP

100

Optional

To be precise

V: Screw

Optional

DRTOP

50

± 1%

for each

VS: RTOP Shunt

± 2%

resistor

± 5 %

± 10 %

ABSOLUTE TOLERANCE PER RESISTOR

Power Resistors for Mounting onto a Heatsink

Thick Film Technology

OVERLOAD DURATION IN SECONDS

ENERGY IN JOULES

1.10

-7

1.10

-6

1.10

-5

1.10

-4

1.10

-3

1.10

-2

1.10

-1

1

RTOP

DRTOP

0.01

0.1

1

10

100

1000

0

20

40

60

80

100