High Precision Wraparound

Thin Film Chip Resistors

P

Vishay Sfernice

www.vishay.com

For technical questions, contact: sfer@vishay.com

Document Number: 53017

2

Revision: 18-Jul-06

For low noise and precision applications, superior stability,

low temperature coefficient of resistance, and low voltage

coefficient, VISHAY SFERNICE's proven precision thin film

wraparound resistors exceed requirements of

MIL-PRF-55342G characteristics Y (± 10 ppm/∞C).

FEATURES

∑ Load Life Stability at ± 70 ∞C for 2000 hours:

0.1 % under Pn/0.05 % under Pd

∑ Low Temperature Coefficient down to ± 10 ppm/∞C

∑ Very Low Noise < 35 dB a

nd Voltage Coefficient

< 0.01 ppm/V

∑

Resistance Range: 10

to 3 M depending on size

∑

Extended Ohmic Value Range (see table)

∑

Tolerances to ± 0.01 %

∑

In Lot Tracking

5 ppm/∞C

∑

Termination: Thin Film Technology

∑ Gold Plated or Pre-tinned Terminations over Nickel Barrier

∑

Short Circuits (Jumpers) r < 50 mR, I < 2 A

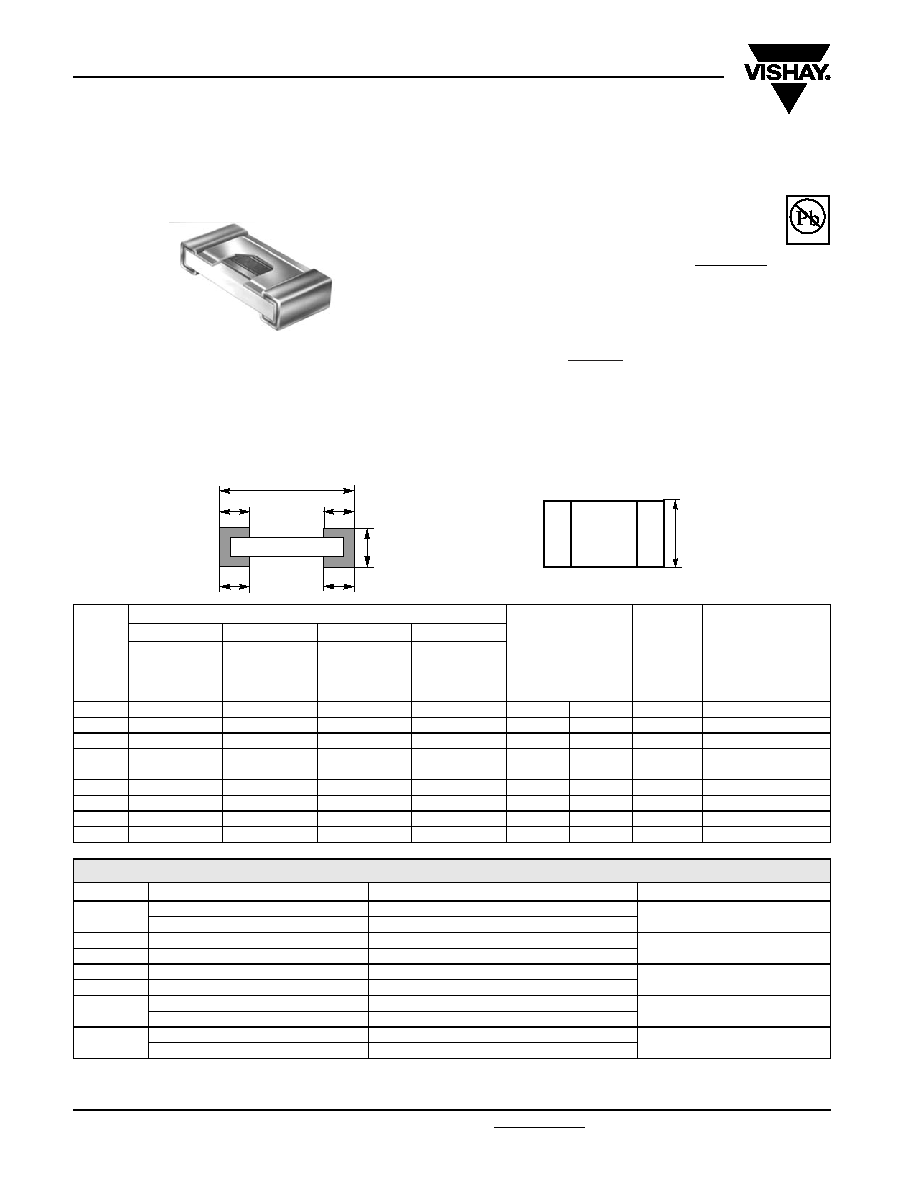

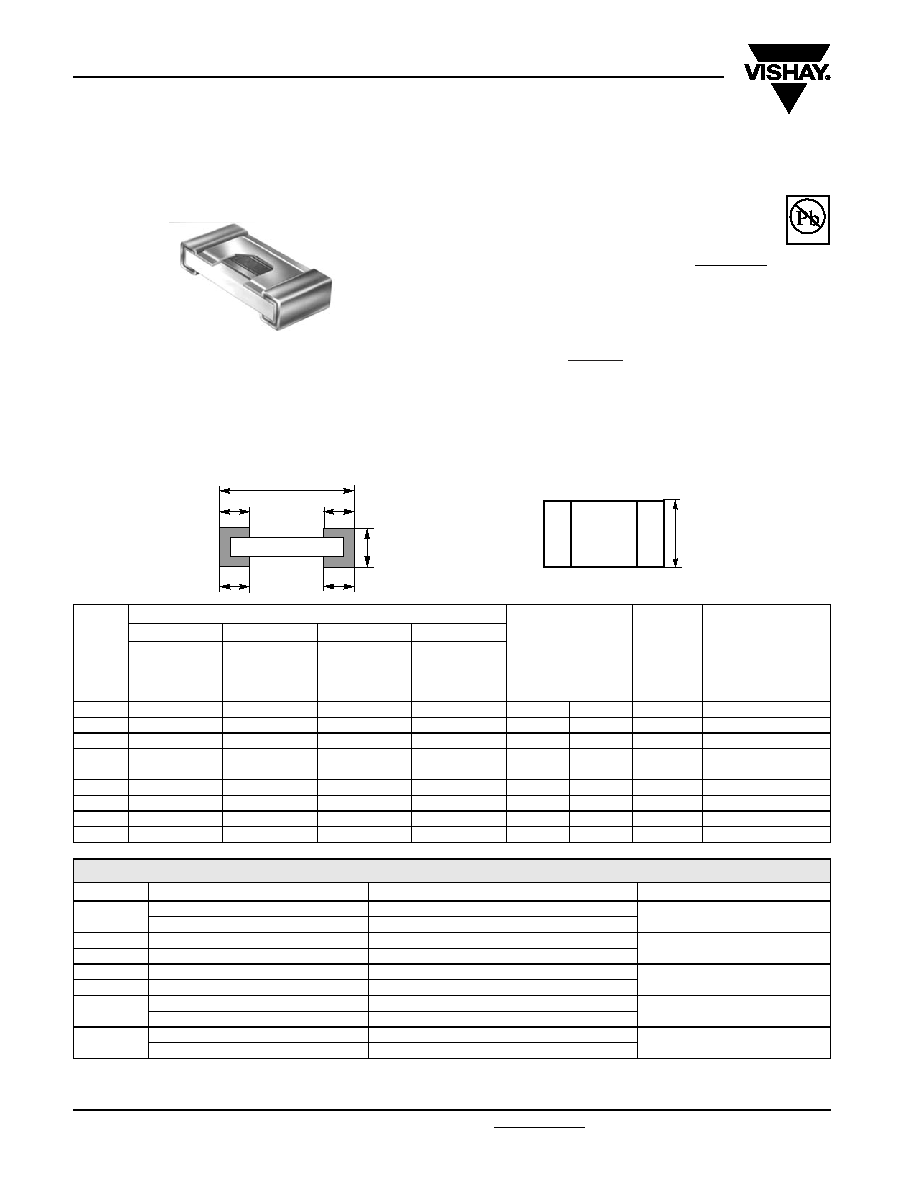

DIMENSIONS in millimeters (inches)

Using special NiCr and CrSi alloys we are able to extend the ohmic value range as indicated above.

* Pb containing terminations are not RoHS compliant, exemptions may apply

Available

Pb-free

RoHS*

COMPLIANT

A

D

D

E

E

C

B

CASE

SIZE

DIMENSION

POWER RATING

mW

LIMITING

ELEMENT

VOLTAGE

RESISTANCE

RANGE (SEE

BELOW FOR

EXTENDED

RANGE)

A

B

C

D/E

MAX. TOL.

MAX. TOL.

MAX. TOL.

MAX. TOL.

+ 0.152 (0.006)

+ 0.127 (0.005)

+ 0.127 (0.005)

+ 0.13 (0.005)

MIN. TOL.

MIN. TOL.

MIN. TOL.

MIN. TOL.

- 0.152 (- 0.006) - 0.127 (- 0.005) - 0.127 (- 0.005)

- 0.13 (- 0.005)

Pn

Pd

V

0402

1.00 (0.040)

0.60 (0.023)

0.5 (0.02)

0.38 (0.015)

50

37

37

10

to 50 k

0505

1.35 (0.053)

1.27 (0.050)

0.5 (0.02)

0.38 (0.015)

125

50

50

10

to 260 k

0603

1.52 (0.060)

0.75 (0.030)

0.5 (0.02)

0.38 (0.015)

125

75

50

10

to 260 k

0705

0805

1.91 (0.075)

1.27 (0.050)

0.5 (0.02)

0.38 (0.015)

200

100

50

10

to 300 k

1005

2.54 (0.100)

1.27 (0.050)

0.5 (0.02)

0.38 (0.015)

250

125

75

10

to 500 k

1206

3.06 (0.120)

1.60 (0.063)

0.5 (0.02)

0.38 (0.015)

330

150

75

10

to 1 M

1505

3.81 (0.150)

1.32 (0.054)

0.5 (0.02)

0.38 (0.015)

350

175

75

10

to 500 k

2010

5.08 (0.200)

2.54 (0.100)

0.5 (0.02)

0.38 (0.015)

1000

500

100

10

to 3 M

EXTENDED OHMIC VALUE RANGE FOR HIGH PRECISION WRAPAROUND THIN FILM CHIP RESISTORS

SIZE

TIGHTEST TOLERANCE %

EXTENDED OHMIC VALUE RANGE

BEST TCR (ppm/∞C)

0402

0.05

50 k - 100 k

25

0.1

100 k - 1 M

50

0505

0.05

250 k - 300 k

25

0603

0.1

300 k - 2 M5

50

0705

0.05

300 k - 500 k

25

0805

0.1

500 k - 5 M

50

1206

0.05

1 M - 2 M

25

0.1

2 M - 15 M

50

2010

0.05

3 M - 6 M

25

0.25

6 M - 50 M

50

P

High Precision Wraparound

Thin Film Chip Resistors

Vishay Sfernice

Document Number: 53017

For technical questions, contact: sfer@vishay.com

www.vishay.com

Revision: 18-Jul-06

3

ELECTRICAL SPECIFICATIONS

Resistance Range:

10

to 3 M

Resistance Tolerance:

± 0.1 % to ± 5 %

± 0.01 % to ± 0.05 % on Y type

Power Dissipation:

Pn: 50 mW to 1 W

Pd: 37 mW to 500 mW

on tolerance tighter than ± 0.05 %

Temperature Coefficient: see table below

MECHANICAL SPECIFICATIONS

Substrate:

Alumina

Technology:

Thin Film

Film:

Nickel Chromium with mineral

passivation or Ta

2

N

Protection:

Silicon

Terminations:

B type: SnPb over nickel barrier

for solder reflow

N type: SnAg over nickel barrier

G type: gold over nickel barrier

for other applications

CLIMATIC SPECIFICATIONS

Operating Temp. Range: - 55 ∞C to + 155 ∞C

For temperature up to 200 ∞C, please consult factory

* R > 50

on request for lower values

POWER DERARING CURVE

PACKAGING

Several types of packaging are available: tube, waffle-pack, and

tape and reel.

* 12 mm on request

* 0.05 % under Pd

TEMPERATURE COEFFICIENT

TCR

CODE

FILM

± 10 ppm/∞C*

Y

Ni Cr

± 25 ppm/∞C

E

Ni Cr

± 50 ppm/∞C

H

Ni Cr or Ta

2

N

± 100 ppm/∞C

K

Ni Cr or Ta

2

N

SIZE

NUMBER OF PIECES PER PACKAGE

TAPE

WIDTH

TUBE

WAFFLE

PACK

2" ◊ 2"

TAPE AND REEL

MIN.

MAX.

0402

500

100

100

4000

8 mm

0505

0603

0805

0705

1005

500

140

1206

1505

60

2010

100

100

2000

8 mm*

BEST TOL. AND TCR V RESISTANCE VALUE

TIGHTEST

TOLERANCE

CODE

OHMIC VALUES

TCR

ppm/∞C

± 0.25 %

C

R > 10

± 25

± 0.10 %

B

R > 25

± 20

± 0.05 %

W

R > 50

± 10

± 0.02 %

P

R > 100

± 0.01 %

L

R > 250

R

E

W

O

P

D

E

T

A

R

%

100

80

60

40

20

0

0 20 40 60 70 80 100 120 140 155

AMBIENT TEMPERATURE IN ∞C

PERFORMANCE

TESTS

CONDITIONS

Ta

2

N

DRIFTS

Ni Cr

MIL-PRF-55342G

Requirements

Typical

Performances

MIL-PRF-55342G

Typical

Performances

Thermal Shock

MIL-PRF-55342G

MIL-STD-202 F-Method 107 F

± 0.25 %

± 0.02 %

± 0.05 %

± 0.02 %

Short Time Overload

MIL-PRF-55342G

Para 3.10.4.7.5

± 010 %

± 0.01 %

± 0.05 %

± 0.01 %

Low Temperature Operation

MIL-PRF-55342G

Para 3.9 & 4.7.4

± 0.25 %

± 0.01 %

± 0.05 %

± 0.01 %

Resistance to Solder Heat

MIL-PRF-55342G

Para 3.12, 4.7.7, 4.7.1.2

± 0.25 %

± 0.04 %

± 0.05 %

± 0.03 %

Moisture Resistance

MIL-PRF-55342G

Para 3.13 & 4.7.8

MIL-STD-202 F-Method 106 E

± 0.40 %

± 0.01 %

± 0.10 %

± 0.01 %

High Temperature

MIL-PRF-55342G

Para 3.11 & 4.7.6

± 0.20 %

± 0.075 %

± 0.05 %

± 0.05 %

Load Life

MIL-PRF-55342G

2000 hours Pn at 70 ∞C

MIL-STD-202 F-Method 108 A

± 0.50 %

± 0.15 %

± 0.5 %

± 0.10 %*

P

Vishay Sfernice

www.vishay.com

For technical questions, contact: sfer@vishay.com

Document Number: 53017

4

Revision: 18-Jul-06

Chips ready to be trimmed available. (P

trim

) - Please consult Sfernice.

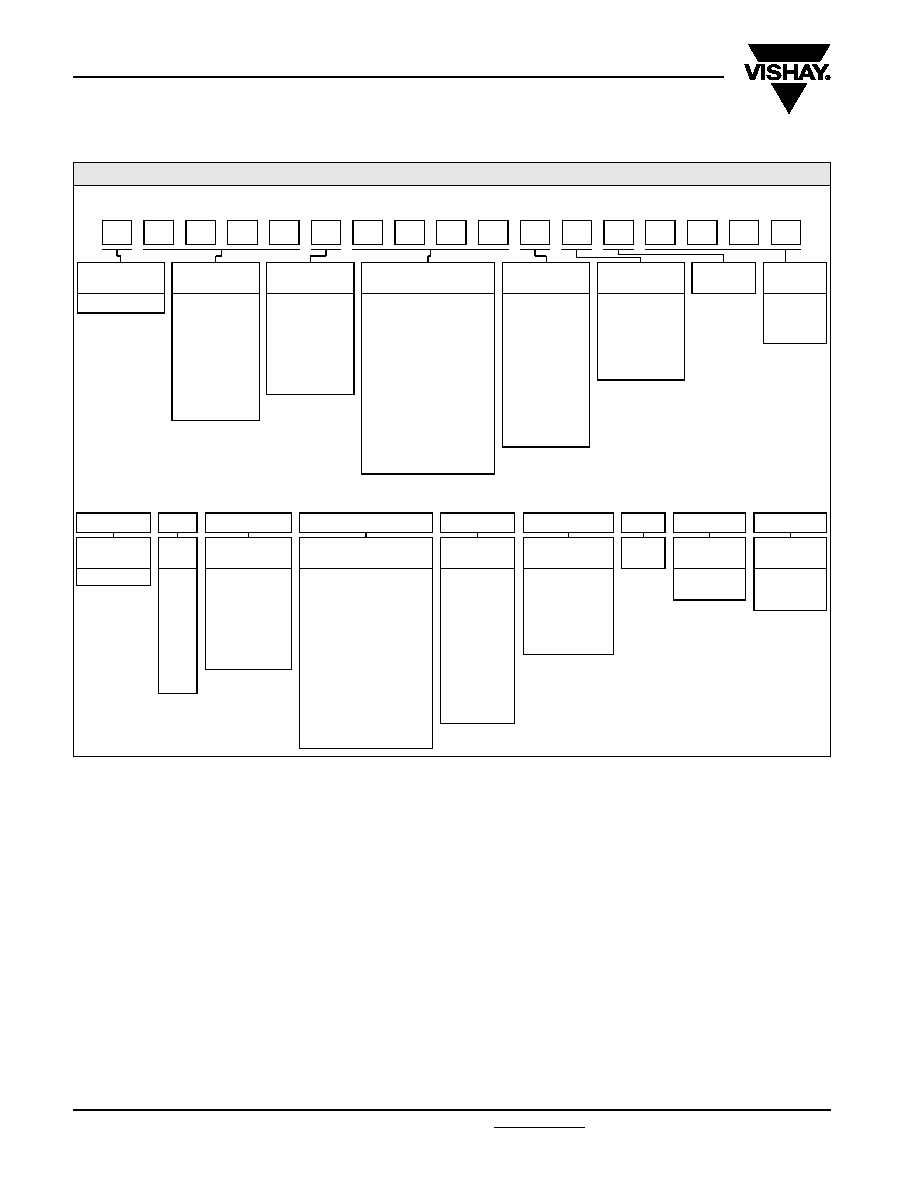

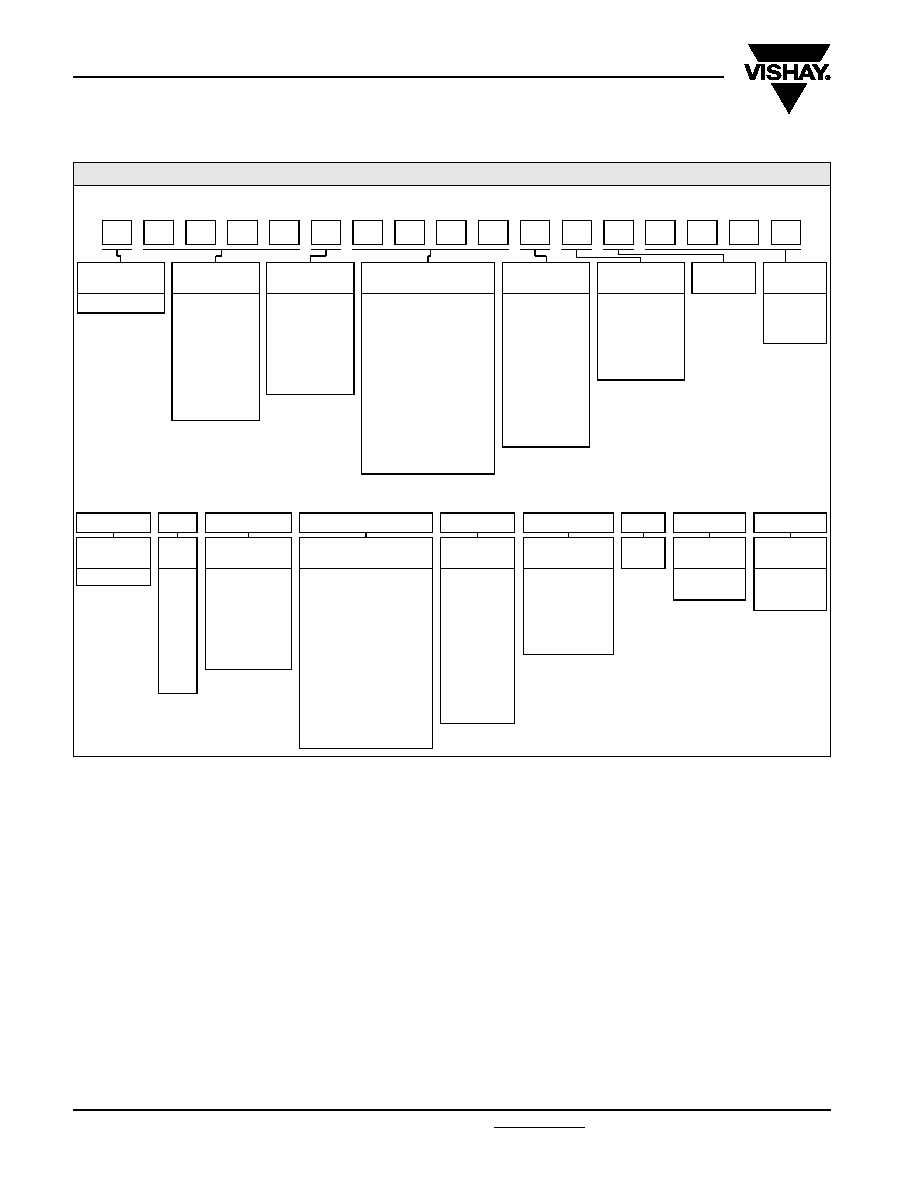

GLOBAL PART NUMBER INFORMATION

New Global Part Numbering: P0505Y1003BBT0933

GLOBAL

MODEL

SIZE

TCR

VALUE

TOLERANCE

TERMINATION

TAPE

OPTION

P

0402

0505

0603

0705

0805

1005

1206

1505

2010

K = ± 100 ppm/∞C

H = ± 50 ppm/∞C

E = ± 25 ppm/∞C

Y = ± 10 ppm/∞C

X = Jumper

Z = ± 5 ppm

(0.70 ∞C)

The first three digits (2

digits are enough for

tolerance G and J) are

significant figures and

the last digit specifies

the number of zeros to

follow, R designates

decimal point

10R0 = 10

3901 = 3900

1004 = 1 M

0R00 = Jumper

L = ± 0.01 %

P = ± 0.02 %

W = ± 0.05 %

B = ± 0.1 %

C = ± 0.25 %

D = ± 0.5 %

F = ± 1 %

G = ± 2 %

J = ± 5 %

S = Special

X = Jumper

B: SnPb over

nickel barrier

N: SnAg over

nickel barrier

G: Gold over

nickel barrier

Leave

blank if no

option

B: Lead bearing version

N and G: Lead

(Pb)-free/RoHS version

Historical Part Number example: P 0505 Y 1003 B B TR R0933 e2

P

0505

Y

1003

B

B

TR

R0933

e2

HISTORICAL

MODEL

SIZE

TCR

VALUE

TOLERANCE

TERMINATION

TAPE

OPTION

RoHS

P

0402

0505

0603

0705

0805

1005

1206

1505

2010

K = ± 100 ppm/∞C

H = ± 50 ppm/∞C

E = ± 25 ppm/∞C

Y = ± 10 ppm/∞C

X = Jumper

Z = ± 5 ppm

(0.70 ∞C)

The first three digits (2

digits are enough for

tolerance G and J) are

significant figures and

the last digit specifies

the number of zeros to

follow, R designates

decimal point

10R0 = 10

3901 = 3900

1004 = 1 M

0R00 = Jumper

L = ± 0.01 %

P = ± 0.02 %

W = ± 0.05 %

B = ± 0.1 %

C = ± 0.25 %

D = ± 0.5 %

F = ± 1 %

G = ± 2 %

J = ± 5 %

S = Special

X = Jumper

B: SnPb over

nickel barrier

N: SnAg over

nickel barrier

G: Gold over

nickel barrier

Leave blank

if no option

e2: tin/silver

e4: gold

blank: SnPb

B: Lead bearing version

N and G: Lead

(Pb)-free/RoHS version

0

5

0

5

Y

1

0

0

3

P

B

B

T

0

9

3

3

Legal Disclaimer Notice

Vishay

Document Number: 91000

www.vishay.com

Revision: 08-Apr-05

1

Notice

Specifications of the products displayed herein are subject to change without notice. Vishay Intertechnology, Inc.,

or anyone on its behalf, assumes no responsibility or liability for any errors or inaccuracies.

Information contained herein is intended to provide a product description only. No license, express or implied, by

estoppel or otherwise, to any intellectual property rights is granted by this document. Except as provided in Vishay's

terms and conditions of sale for such products, Vishay assumes no liability whatsoever, and disclaims any express

or implied warranty, relating to sale and/or use of Vishay products including liability or warranties relating to fitness

for a particular purpose, merchantability, or infringement of any patent, copyright, or other intellectual property right.

The products shown herein are not designed for use in medical, life-saving, or life-sustaining applications.

Customers using or selling these products for use in such applications do so at their own risk and agree to fully

indemnify Vishay for any damages resulting from such improper use or sale.