| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: TSOP5700 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

VISHAY

TSOP5700

Document Number 82166

Rev. 5, 14-Aug-03

Vishay Semiconductors

www.vishay.com

1

16797

1

2

3

4

IR Receiver for High Data Rate PCM at 455 kHz

Description

The TSOP5700 is a miniaturized SMD IR receiver for

infrared remote control and IR data transmission. PIN

diode and preamplifier are assembled on lead frame,

the epoxy package is designed as IR filter.

The demodulated output signal can directly be

decoded by a microprocessor. The main benefit is the

operation with high data rates and long distances.

Features

∑ Photo detector and preamplifier in one package

∑ Internal Bandfilter for PCM frequency

∑ Internal shielding against electrical field

disturbance

∑ TTL and CMOS compatibility

∑ Output active low

∑ Small size package

Special Features

∑ Data rate 20 kbit/s

∑ Supply voltage 2.7 - 5.5 V

∑ Short settling time after power on

∑ High envelope duty cycle can be received

∑ Enhanced immunity against disturbance from

energy saving lamps

∑ Taping available for topview and sideview

assembly

Mechanical Data

Pinning:

1 = GND, 2 = NC, 3 = OUT, 4 = V

S

Block Diagram

Application Circuit

10 k

3

1

V

S

OUT

Demo-

GND

Pass

AGC

Input

PIN

Band

dulator

Control Circuit

4

16840

C

1

=

4.7 µF

TSOPxxxx

OUT

GND

Circuit

µC

R

1

= 47

+V

S

GND

Transmitter

with

TSHFxxxx

V

S

R

1

+ C

1

recommended to suppress power supply

disturbances.

V

O

R

2

>=

1 k

R

2

optional for improved pulse forming.

16843

www.vishay.com

2

Document Number 82166

Rev. 5, 14-Aug-03

VISHAY

TSOP5700

Vishay Semiconductors

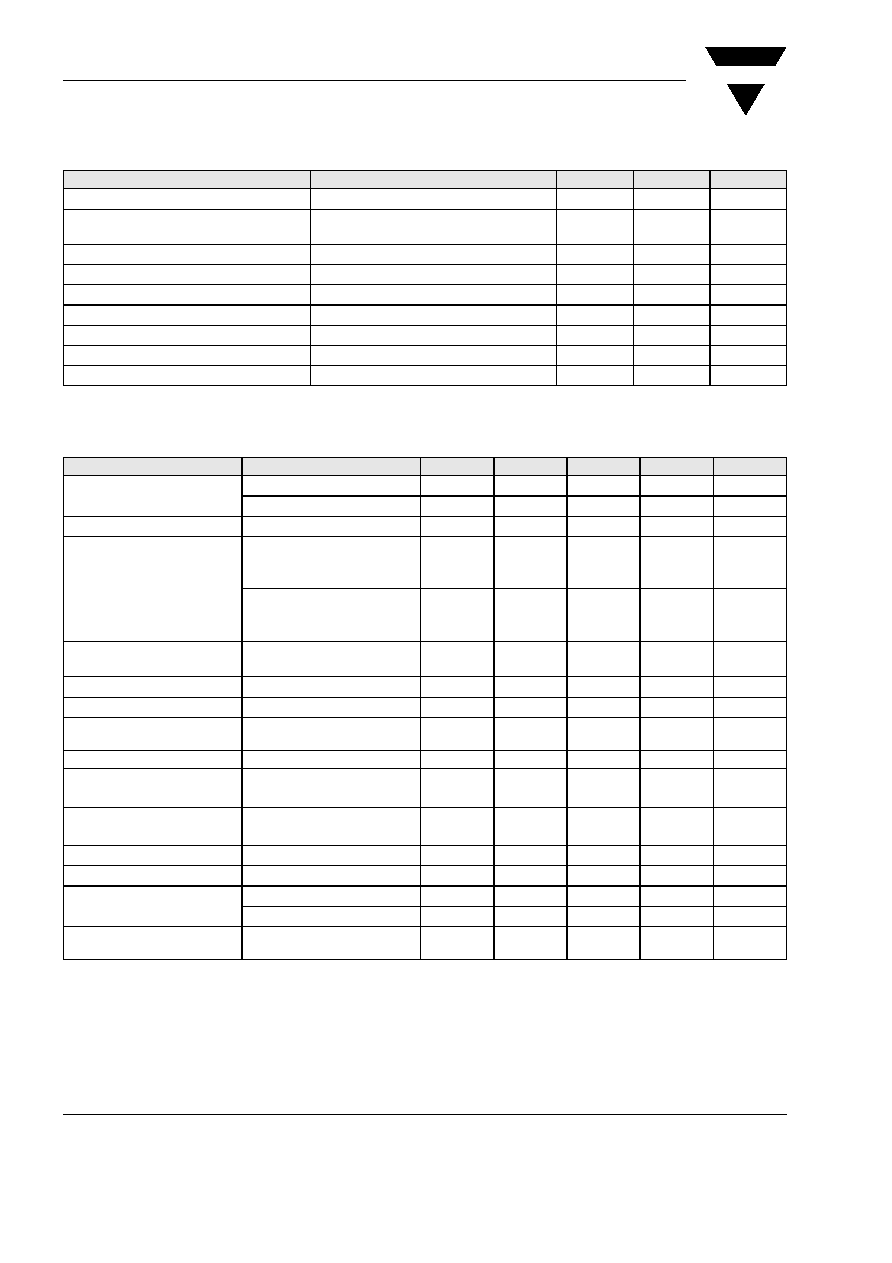

Absolute Maximum Ratings

T

amb

= 25 ∞C, unless otherwise specified

Electrical and Optical Characteristics

T

amb

= 25 ∞C, unless otherwise specified

Parameter

Test condition

Symbol

Value

Unit

Supply Voltage

Pin 4

V

S

- 0.3 to + 6.0

V

Voltage at output to supply

Pin 3

V

S

- V

O

- 0.3 to

(V

S

+ 0.3)

V

Supply Current

Pin 4

I

S

5

mA

Output Voltage

Pin 3

V

O

- 0.3 to + 6.0

V

Output Current

Pin 3

I

O

15

mA

Junction Temperature

T

j

100

∞C

Storage Temperature Range

T

stg

- 40 to + 85

∞C

Operating Temperature Range

T

amb

- 25 to + 85

∞C

Power Consumption

T

amb

85 ∞C

P

tot

50

mW

Parameter

Test condition

Symbol

Min

Typ.

Max

Unit

Supply Current (Pin 4)

Dark ambient

I

SD

2.0

2.7

mA

E

v

= 40 klx, sunlight

I

SH

2.3

mA

Supply Voltage (Pin 4)

V

S

2.7

5

5.5

V

Transmission Distance

p

= 870 nm,

IR Diode TSHF5400,

I

F

= 300 mA

d

max

15

m

p

= 950 nm,

IR Diode TSAL6400,

I

F

= 300 mA

d

max

9

m

Threshold Irradiance

p

= 870 nm,

optical test signal of Fig.1

E

e min

1.5

2.5

mW/m

2

Maximum Irradiance

Optical test signal of Fig.1

E

e max

30

W/m

2

Output Voltage Low (Pin 3)

1 k

external pull up resistor

V

QL

100

mV

Output Voltage High (Pin 3)

No external pull-up resistor,

test signal see fig. 1

V

QH

V

S

- 0.25

V

Bandpass filter quality

Q

10

Out-Pulse width tolerance

Optical test signal of Fig.1,

2.5 mW/m

2

E

e

30 W/m

2

tpo

- 15

+ 5

+ 15

µs

Delay time of output pulse

Optical test signal of Fig.1,

E

e

> 2.5 mW/m

2

t

don

15

36

µs

Receiver start up time

Valid data after power on

t

V

50

µs

Falling time

Leading edge of output pulse

t

f

0.4

µs

Rise time

No external pull up resistor

t

r

12

µs

1 k

external pull up resistor

t

r

1.2

µs

Directivity

Angle of half transmission

distance

1/2

± 50

deg

VISHAY

TSOP5700

Document Number 82166

Rev. 5, 14-Aug-03

Vishay Semiconductors

www.vishay.com

3

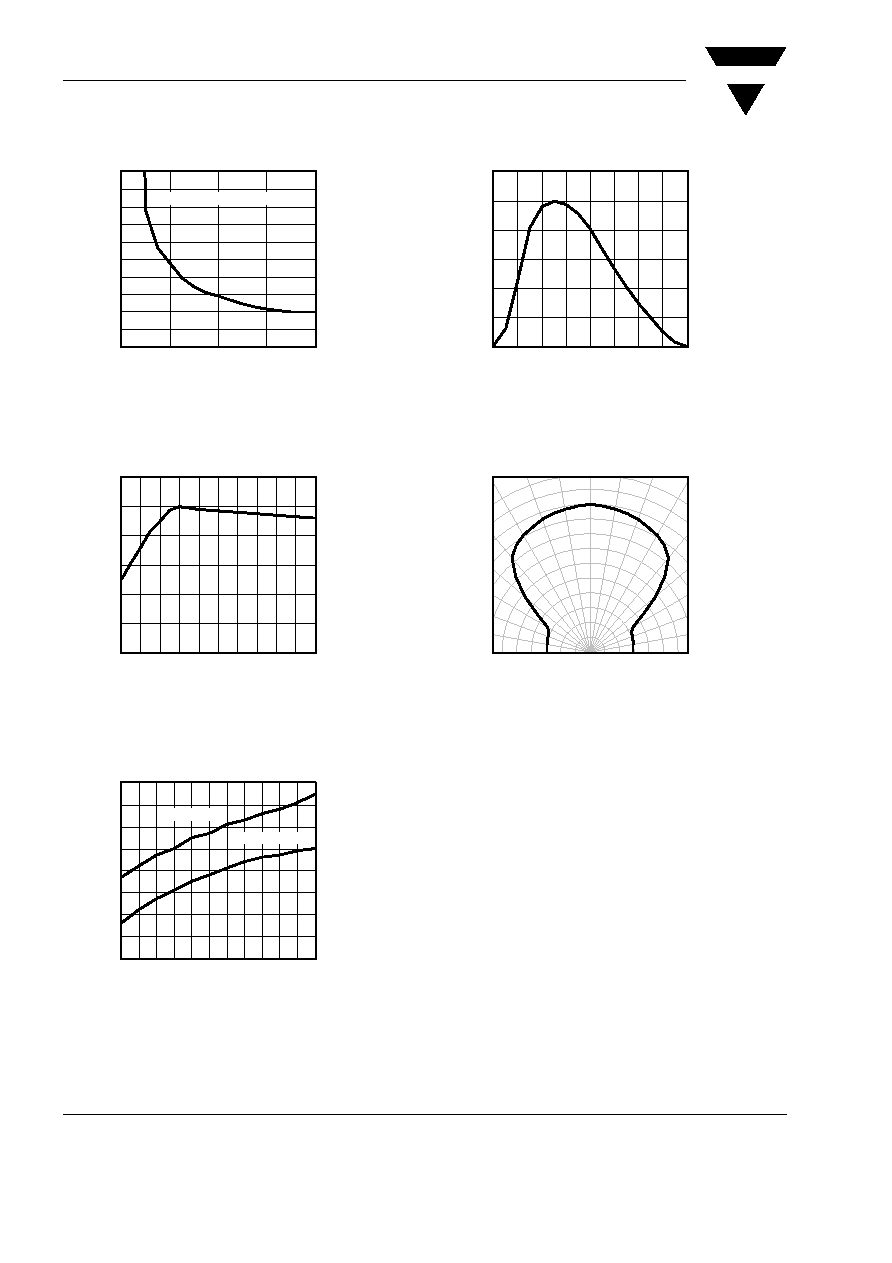

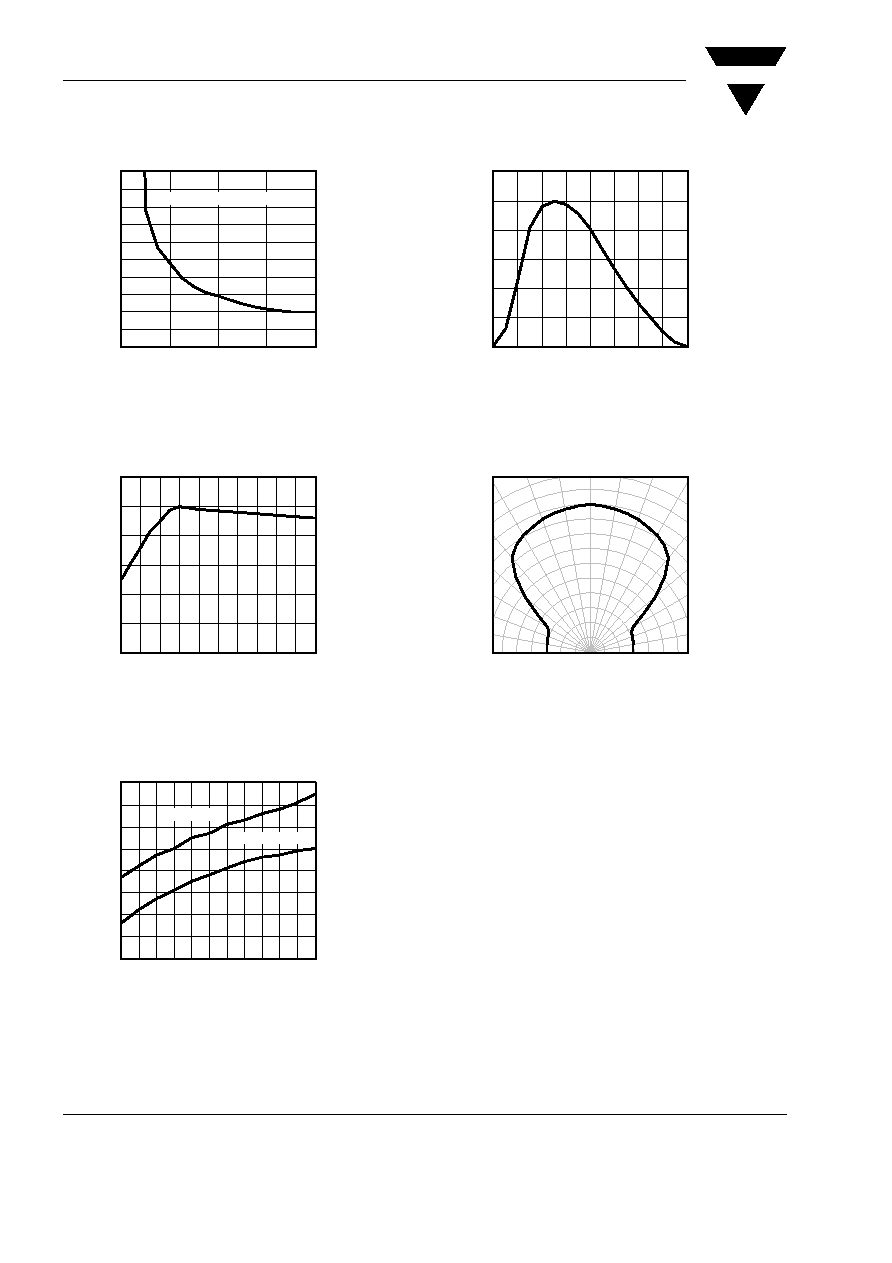

Typical Characteristics

(T

amb

= 25

∞C unless otherwise specified)

Figure 1. Output Function

Figure 2. Output Fucntion (mit Jitter)

Figure 3. Output Pulse Diagram (t

don

, t

po

)

E

e

V

Q

V

QH

V

QL

Optical Test Signal

(f=455kHz, 10 cycles/burst)

Output Signal of TSOP5700

t

pi

= 22

s

t

t

don

t

po

t

f

16563

2.2

s

t

r

50%

90%

10%

t

po

= t

pi i

15

s

> 48.6

s

(min. duty cycle)

t

E

e

V

O

V

OH

V

OL

t

Optical Test Signal

(IR diode TSHF5400,

p

870 nm, I

F

= 300 mA, f = 455 kHz, 10 cycles/burst)

Output Signal of TSOP5700

j

tdon

t

don

t

po

jitter of leading edge

jitter of output pulse width

j

tpo

16565

t

pi

= 22

s

t

0

5

10

15

20

25

30

35

0.1

1.0

10.0 100.0 1000.010000.0

100000.0

E

e

≠ Irradiance (mW/m

2

)

16790

don

t , t Output Pulse Length ( s )

Output pulse width ≠ t

po

Delay time ≠ t

don

1

10

100 1000 10000 100000

N = 10 cycles/burst

p

o

Figure 4. Jitter of Output Pulse

Figure 5. Frequency Dependence of Responsivity

Figure 6. Sensitivity in Bright Ambient

0

5

10

15

20

25

30

0.1

1.0

10.0

100.0 1000.010000.0

100000.0

E

e

≠ Irradiance (mW/m

2

)

16791

j

N=10 cycles/burst

Jitter ≠ t

don

Jitter ≠ t

po

1

10

100 1000 10000 100000

tdon,

tpo

j

≠

Jitter of Output Pulse ( s )

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

300

350

400

450

500

550

600

f ≠ Frequency ( kHz )

16751

/

E

e min

e

rel

E ≠ Responsitivity

0

2

4

6

8

10

12

14

0.1

1.0

10

100

E - DC Irradiance (W/m

2

)

16558

e

min

E

-

Threshold

Irradiance

(

mW/m

)

2

i

Ambient,

= 950 nm

i

i

Correlation with ambient light sources:

10W/m

2

1.4klx (Std.illum.A,T= 2855 K)

10W/m

8.2klx (Daylight,T = 5900 K)

2

www.vishay.com

4

Document Number 82166

Rev. 5, 14-Aug-03

VISHAY

TSOP5700

Vishay Semiconductors

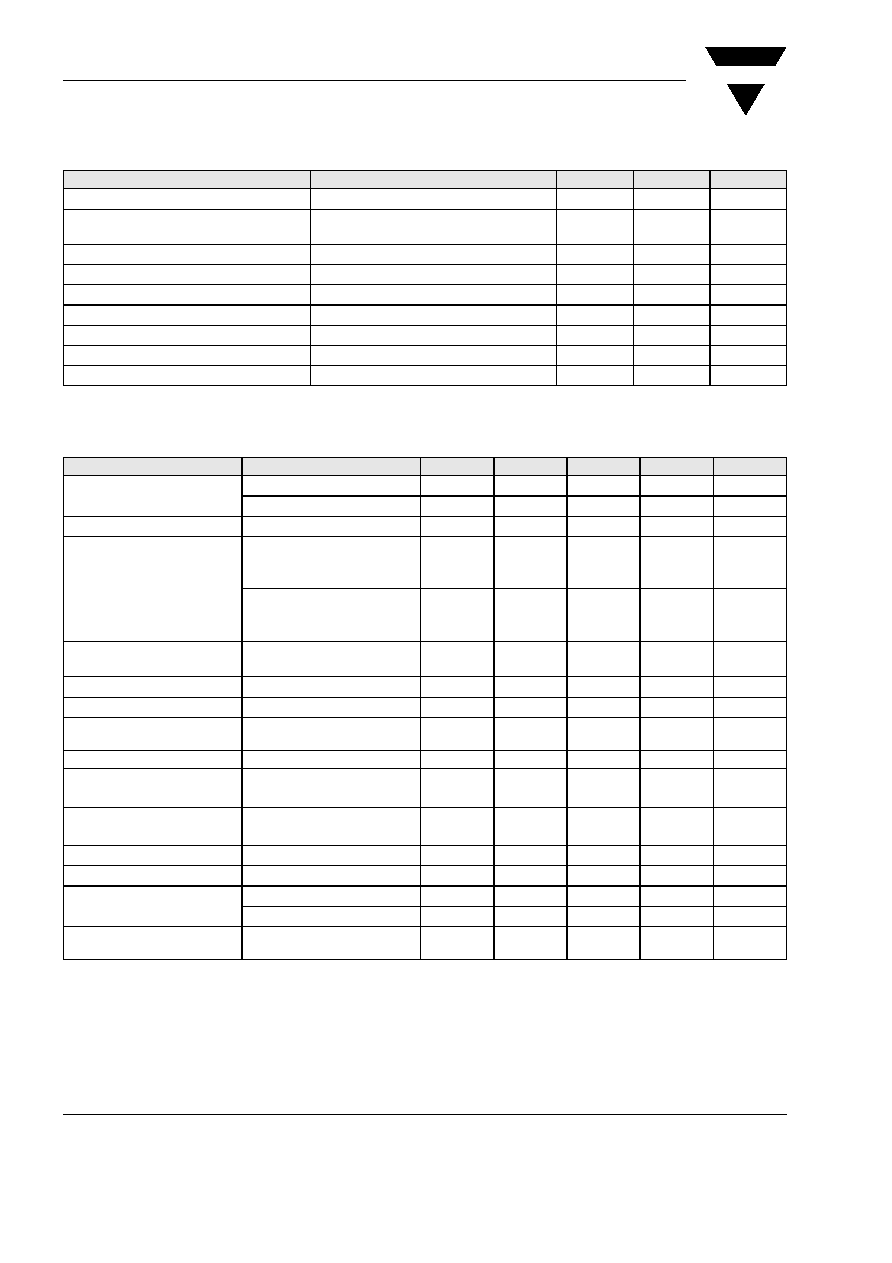

Figure 7. Sensitivity vs. Supply Voltage

Figure 8. Rel. Sensitivity vs. Burstlength

Figure 9. Supply Current vs. Ambient Temperature

1.0

1.2

1.4

1.6

1.8

2.0

2.2

2.4

2.6

2.8

3.0

2

3

4

5

6

V

S

- Supply Voltage ( V )

16559

Sensitivity in dark ambient

e

min

E

Threshold

Irradiance

(

mW/m

)

2

0.5

0.6

0.7

0.8

0.9

1.0

1.1

N - Burstlength ( carriercycles/burst )

16788

e

min

E

-

Relative

Sensitivity

26

22

18

14

28

24

20

16

12

10

8

1.5

1.6

1.7

1.8

1.9

2.0

2.1

2.2

2.3

5 15 25 35 45 55 65 75 85

T

amb

- Ambient Temperature ( ∞C )

16754

I

-

Supply

Current

(

m

A

)

s

V

S

= 5.5 V

V

S

= 2.7 V

-5

-15

-25

Figure 10. Relative Spectral Sensitivity vs. Wavelength

Figure 11. Directivity

0.0

0.2

0.4

0.6

0.8

1.0

1.2

750 800 850 900 950 1000 10501100 1150

- Wavelength ( nm )

16789

S

(

)

-

Relative

Spectral

Sensitivity

rel

16801

0.4

0.2

0

0.2

0.4

0.6

0.6

0.9

0∞

30∞

10∞

20∞

40∞

50∞

60∞

70∞

80∞

1.0

0.8

0.7

d

rel

- Relative Transmission Distance

VISHAY

TSOP5700

Document Number 82166

Rev. 5, 14-Aug-03

Vishay Semiconductors

www.vishay.com

5

Recommendation for Suitable Data

Formats

The circuit of the TSOP5700 is designed in that way

that disturbance signals are identified and unwated

output pulses due to noise or disturbances are

avoided. A bandpass filter, an automatic gain control

and an integrator stage is used to suppress such dis-

turbances. The distinguishing marks between data

signal and disturbance are carrier frequency, burst

length and the envelope duty cycle.

The data signal should fulfill the following conditions:

∑ The carrier frequency should be close to 455 kHz.

∑ The burstlength should be at least 22

µs (10 cycles

of the carrier signal) and shorter than 500

µs.

∑ The separation time between two consecutive

bursts should be at least 26

µs.

∑ If the data bursts are longer than 500

µs then the

envelope duty cycle is limited to 25 %

∑ The duty cycle of the carrier signal (455 kHz) may be

between 50 % (1.1

µs pulses) and 10 % (0.2 µs

pulses). The lower duty cycle may help to save bat-

tery power.

www.vishay.com

6

Document Number 82166

Rev. 5, 14-Aug-03

VISHAY

TSOP5700

Vishay Semiconductors

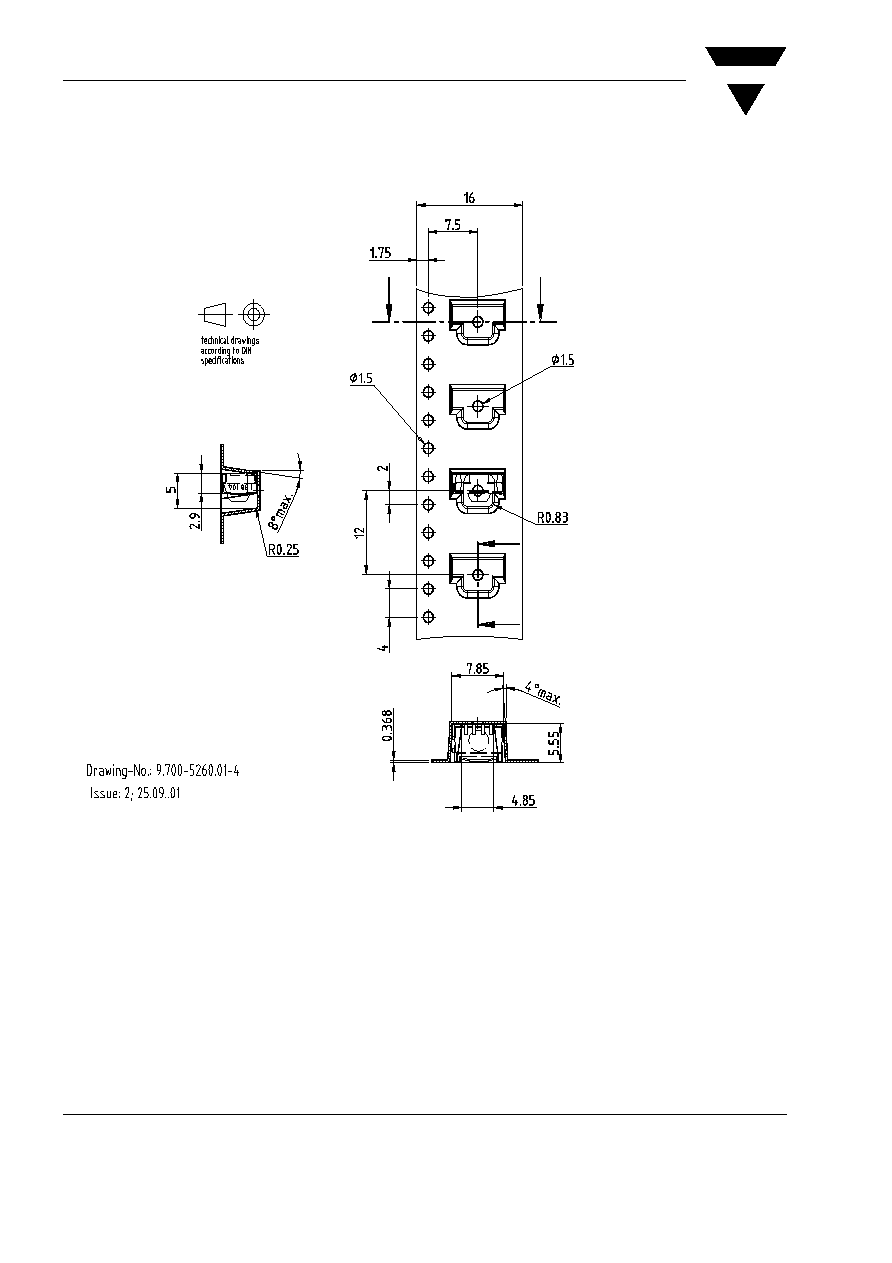

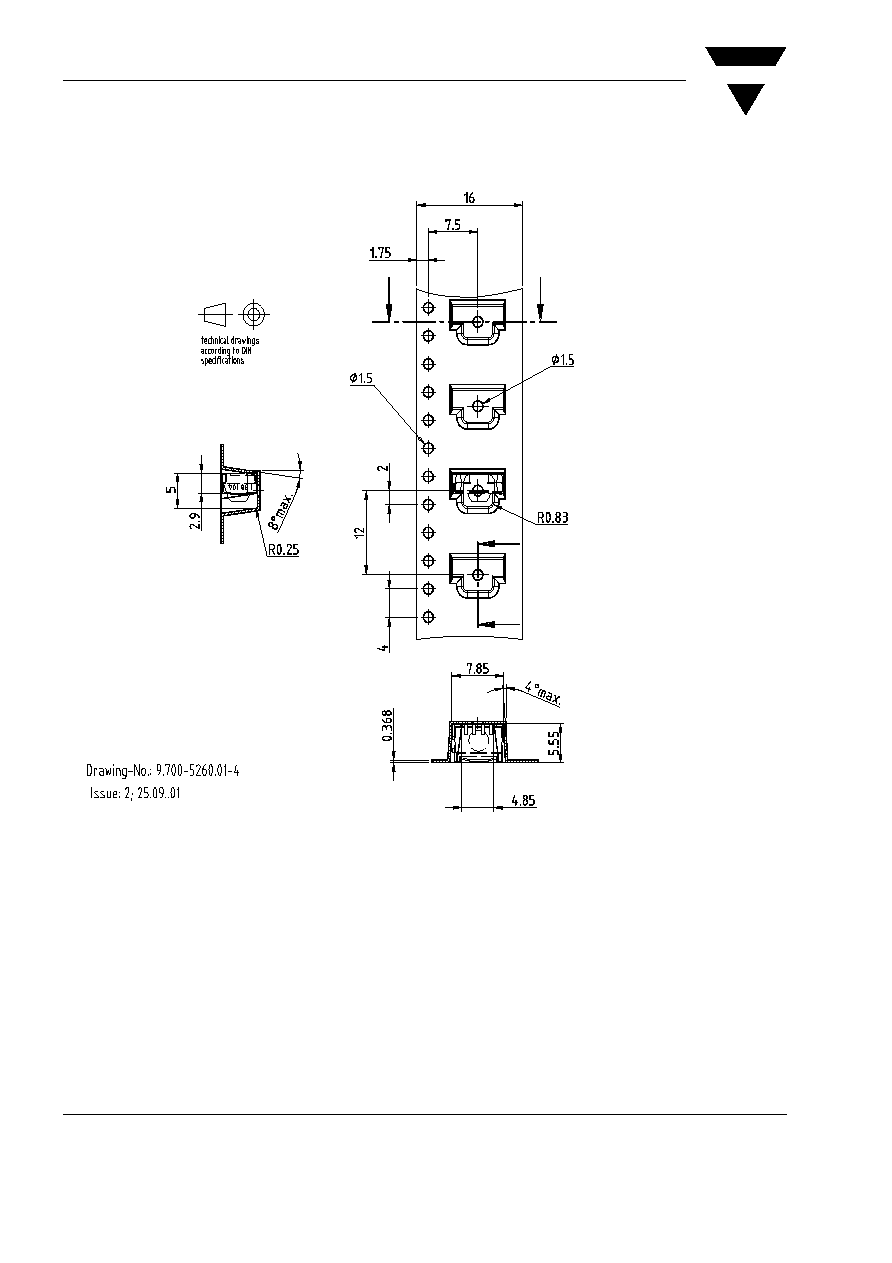

Package Dimensions in mm

16776

VISHAY

TSOP5700

Document Number 82166

Rev. 5, 14-Aug-03

Vishay Semiconductors

www.vishay.com

7

Taping Version TSOP5700..TT

16584

www.vishay.com

8

Document Number 82166

Rev. 5, 14-Aug-03

VISHAY

TSOP5700

Vishay Semiconductors

Taping Version TSOP5700..TR

16585

VISHAY

TSOP5700

Document Number 82166

Rev. 5, 14-Aug-03

Vishay Semiconductors

www.vishay.com

9

Reel Dimensions

16734

www.vishay.com

10

Document Number 82166

Rev. 5, 14-Aug-03

VISHAY

TSOP5700

Vishay Semiconductors

Leader and Trailer

Cover Tape Peel Strength

According to DIN EN 60286-3

0.1 to 1.3 N

300 ± 10 mm/min

165 ∞ - 180 ∞ peel angle

Label

Standard bar code labels for finished goods

The standard bar code labels are product labels and

used for identification of goods. The finished goods

are packed in final packing area. The standard pack-

ing units are labeled with standard bar code labels

before transported as finished goods to warehouses.

The labels are on each packing unit and contain

Vishay Semiconductor GmbH specific data.

Trailer

Leader

no devices

no devices

min. 200

min. 400

Start

End

devices

96 11818

VISHAY

TSOP5700

Document Number 82166

Rev. 5, 14-Aug-03

Vishay Semiconductors

www.vishay.com

11

Dry Packing

The reel is packed in an anti-humidity bag to protect

the devices from absorbing moisture during transpor-

tation and storage.

Final Packing

The sealed reel is packed into a cardboard box. A

secondary cardboard box is used for shipping pur-

poses.

Item-Description

Item-Number

Selection-Code

LOT-/ Serial-Number

Data-Code

Plant-Code

Quantity

Accepted by:

Packed by:

Mixed Code Indicator

Origin

INO

≠

BATCH

SEL

COD

PTC

QTY

ACC

PCK

MIXED CODE

xxxxxxx

+

18

8

3

10

3 (YWW)

2

8

≠

≠

≠

Company Logo

Plain Writing

Abbreviation

Length

Item-Number

Sequence-Number

Plant-Code

Quantity

Total Length

N

8

2

3

8

21

Long Bar Code Top

Type

Length

N

X

N

≠

Selection≠Code

Batch-Number

Data-Code

Filter

Total Length

X

3

3

10

1

17

Short Bar Code Bottom

Type

Length

N

X

≠

≠

16942

Vishay Semiconductor GmbH standard bar code product label (finished goods)

Aluminium bag

Label

Reel

15973

www.vishay.com

12

Document Number 82166

Rev. 5, 14-Aug-03

VISHAY

TSOP5700

Vishay Semiconductors

Recommended Method of Storage

Dry box storage is recommended as soon as the alu-

minium bag has been opened to prevent moisture

absorption. The following conditions should be

observed, if dry boxes are not available:

∑ Storage temperature 10 ∞C to 30 ∞C

∑ Storage humidity

60 % RH max.

After more than 72 hours under these conditions

moisture content will be too high for reflow soldering.

In case of moisture absorption, the devices will

recover to the former condition by drying under the

following condition:

192 hours at 40 ∞C + 5 ∞C/ -0 ∞C and < 5 % RH (dry

air/ nitrogen) or

96 hours at 60 ∞C +5 ∞C and < 5 % RH for all device

containers or

24 hours at 125 ∞C +5 ∞C not suitable for reel or

tubes.

An EIA JEDEC Standard JESD22-A112 Level 4 label

is included on all dry bags.

Example of JESD22-A112 Level 4 label

ESD Precaution

Proper storage and handling procedures should be

followed to prevent ESD damage to the devices espe-

cially when they are removed from the Antistatic

Shielding Bag. Electro-Static Sensitive Devices warn-

ing labels are on the packaging.

Vishay Semiconductors Standard

Bar-Code Labels

The Vishay Semiconductors standard bar-code labels

are printed at final packing areas. The labels are on

each packing unit and contain Vishay Semiconduc-

tors specific data.

Operating Instructions

Reflow Soldering

∑ Reflow soldering must be done within 48 hours

stored under max. 30 ∞C, 80 % RH after opening

envelop

∑ Recommended soldering paste (composition: SN 63

%, Pb 37 %)

Melting temperature 178 ∞C to 192 ∞C

∑ Apply solder paste to the specified soldering pads,

by using a dispenser or by screen printing.

∑ Recommended thickness of metal mask is 0.2 mm

for screen printing.

∑ The recommended reflow furnace is a combination-

type with upper and lower heaters.

∑ Set the furnace temperatures for pre-heating and

heating in accordance with the reflow temperature

profile as shown below. Excercise extreme care to

keep the maximum temperature below 230 ∞C. The

following temperature profile means the tempera ture

at the device surface. Since temperature difference

occurs between the work and the surface of the circuit

board depending on the pes of circuit board or reflow

furnace, the operating conditions should be verified

prior to start of operation.

∑ Handling after reflow should be done only after the

work surface has been cooled off.

Manual Soldering

∑ Use the 6/4 solder or the solder containing silver.

∑ Use a soldering iron of 25 W or smaller. Adjust the

temperature of the soldering iron below 300 ∞C.

∑ Finish soldering within three seconds.

∑ Handle products only after the temperature is cooled

off.

Cleaning

∑ Perform cleaning after soldering strictly in conform-

ance to the following conditions:

Cleaning agent:

2-propanol (isopropyl alcohol).

Commercially available grades (industrial use) should

be used.

16943

16962

VISHAY

TSOP5700

Document Number 82166

Rev. 5, 14-Aug-03

Vishay Semiconductors

www.vishay.com

13

Demineralized or distilled water having a resistivity of

not less than 500 m

corresponding to a conductivity

of 2 mS/m.

∑ Temperature and time: 30 seconds under the tem-

perature below 50 ∞C or 3 minutes below 30 ∞C.

∑ Ultrasonic cleaning: Below 20 W.

Reflow Solder Profile

Assembly Instructions

Reflow Soldering

∑ Reflow soldering must be done within 72 hours

stored under max. 30 ∞C, 60 % RH after opening

envelop

∑ Recommended soldering paste (composition: SN 63

%, Pb 37 %) Melting temperature 178 ∞C to 192 ∞C

∑ Apply solder paste to the specified soldering pads,

by using a dispenser or by screen printing.

∑ Recommended thickness of metal mask is 0.2 mm

for screen printing.

∑ The recommended reflow furnace is a combination-

type with upper and lower heaters.

∑ Set the furnace temperatures for pre-heating and

heating in accordance with the reflow temperature

profile as shown below. Excercise extreme care to

keep the maximum temperature below 230 ∞C. The

following temperature profile means the tempera ture

at the device surface. Since temperature differ ence

occurs between the work and the surface of the circuit

board depending on the pes of circuit board or reflow

furnace, the operating conditions should be verified

prior to start of operation.

∑ Handling after reflow should be done only after the

work surface has been cooled off.

Manual Soldering

∑ Use the 6/4 solder or the solder containing silver.

∑ Use a soldering iron of 25 W or smaller. Adjust the

temperature of the soldering iron below 300 ∞C.

∑ Finish soldering within three seconds.

∑ Handle products only after the temperature is cooled

off.

Cleaning

∑ Perform cleaning after soldering strictly in conform-

ance to the following conditions:

Cleaning agent:

2-propanol (isopropyl alcohol)

Commercially available grades (industrial use) should

be used.

Demineralized or distilled water having a resistivity of

not less than 500 m

corresponding to a conductivity

of 2 mS/m.

∑ Temperature and time: 30 seconds under the tem-

perature below 50 ∞C or 3 minutes below 30 ∞C.

∑ Ultrasonic cleaning: Below 20 W.

Reflow Solder Profile

0

20

40

60

80

100

120

140

160

180

200

220

240

0

50

100

150

200

250

300

350

Time ( s )

T

e

mperature

(

C

)

16735

∞

2

∞C - 4 ∞C/s

10 s max.

@ 230

∞C

90 s max

120 s - 180 s

2

∞C - 4 ∞C/s

10 s max.

@ 230 C

90 s max

0

20

40

60

80

100

120

140

160

180

200

220

240

0

50

100

150

200

250

300

350

Time ( s )

T

emperature ( C )

16944

2 C - 4 C/s

120 s - 180 s

2 C - 4 C/s

www.vishay.com

14

Document Number 82166

Rev. 5, 14-Aug-03

VISHAY

TSOP5700

Vishay Semiconductors

Taping Version TSOP..TT

VISHAY

TSOP5700

Document Number 82166

Rev. 5, 14-Aug-03

Vishay Semiconductors

www.vishay.com

15

Taping Version TSOP..TR

www.vishay.com

16

Document Number 82166

Rev. 5, 14-Aug-03

VISHAY

TSOP5700

Vishay Semiconductors

Reel Dimensions

VISHAY

TSOP5700

Document Number 82166

Rev. 5, 14-Aug-03

Vishay Semiconductors

www.vishay.com

17

Leader and Trailer

Cover Tape Peel Strength

According to DIN EN 60286-3

0.1 to 1.3 N

300 ± 10 mm/min

165 ∞ - 180 ∞ peel angle

Label

Standard bar code labels for finished goods

The standard bar code labels are product labels and

used for identification of goods. The finished goods

are packed in final packing area. The standard pack-

ing units are labeled with standard bar code labels

before transported as finished goods to warehouses.

The labels are on each packing unit and contain

Vishay Semiconductor GmbH specific data.

Dry Packing

The reel is packed in an anti-humidity bag to protect

the devices from absorbing moisture during transpor-

tation and storage.

Final Packing

The sealed reel is packed into a cardboard box. A

secondary cardboard box is used for shipping pur-

poses.

www.vishay.com

18

Document Number 82166

Rev. 5, 14-Aug-03

VISHAY

TSOP5700

Vishay Semiconductors

Recommended Method of Storage

Dry box storage is recommended as soon as the alu-

minium bag has been opened to prevent moisture

absorption. The following conditions should be

observed, if dry boxes are not available:

∑ Storage temperature 10 ∞C to 30 ∞C

∑ Storage humidity

60 % RH max.

After more than 72 hours under these conditions

moisture content will be too high for reflow soldering.

In case of moisture absorption, the devices will

recover to the former condition by drying under the

following condition:

192 hours at 40 ∞C + 5 ∞C/ -0 ∞C and < 5 % RH (dry

air/ nitrogen) or

96 hours at 60 ∞C +5 ∞C and < 5 % RH for all device

containers or

24 hours at 125 ∞C +5 ∞C not suitable for reel or

tubes.

An EIA JEDEC Standard JESD22-A112 Level 4 label

is included on all dry bags.

Example of JESD22-A112 Level 4 label

ESD Precaution

Proper storage and handling procedures should be

followed to prevent ESD damage to the devices espe-

cially when they are removed from the Antistatic

Shielding Bag. Electro-Static Sensitive Devices warn-

ing labels are on the packaging.

Vishay Semiconductors Standard

Bar-Code Labels

The Vishay Semiconductors standard bar-code labels

are printed at final packing areas. The labels are on

each packing unit and contain Vishay Telefunken

specific data.

VISHAY

TSOP5700

Document Number 82166

Rev. 5, 14-Aug-03

Vishay Semiconductors

www.vishay.com

19

Ozone Depleting Substances Policy Statement

It is the policy of Vishay Semiconductor GmbH to

1. Meet all present and future national and international statutory requirements.

2. Regularly and continuously improve the performance of our products, processes, distribution and

operatingsystems with respect to their impact on the health and safety of our employees and the public, as

well as their impact on the environment.

It is particular concern to control or eliminate releases of those substances into the atmosphere which are

known as ozone depleting substances (ODSs).

The Montreal Protocol (1987) and its London Amendments (1990) intend to severely restrict the use of ODSs

and forbid their use within the next ten years. Various national and international initiatives are pressing for an

earlier ban on these substances.

Vishay Semiconductor GmbH has been able to use its policy of continuous improvements to eliminate the

use of ODSs listed in the following documents.

1. Annex A, B and list of transitional substances of the Montreal Protocol and the London Amendments

respectively

2. Class I and II ozone depleting substances in the Clean Air Act Amendments of 1990 by the Environmental

Protection Agency (EPA) in the USA

3. Council Decision 88/540/EEC and 91/690/EEC Annex A, B and C (transitional substances) respectively.

Vishay Semiconductor GmbH can certify that our semiconductors are not manufactured with ozone depleting

substances and do not contain such substances.

We reserve the right to make changes to improve technical design

and may do so without further notice.

Parameters can vary in different applications. All operating parameters must be validated for each

customer application by the customer. Should the buyer use Vishay Semiconductors products for any

unintended or unauthorized application, the buyer shall indemnify Vishay Semiconductors against all

claims, costs, damages, and expenses, arising out of, directly or indirectly, any claim of personal

damage, injury or death associated with such unintended or unauthorized use.

Vishay Semiconductor GmbH, P.O.B. 3535, D-74025 Heilbronn, Germany

Telephone: 49 (0)7131 67 2831, Fax number: 49 (0)7131 67 2423