For technical questions in the Americas, contact foilsupport1@vishay.com

For technical questions in Asia/Japan/Europe/Africa/Israel, contact foilsupport2@vishay.com

Document Number: 63061

Revision 17-Aug-04

www.vishay.com

22

VSM0805

Vishay Foil Resistors

SURF

ACE MOUNT

∑ ISRAEL: foilsales.israel@vishay.com ∑ FRANCE/SWITZERLAND/SOUTHERN EUROPE: foilsales.eusouth@vishay.com ∑ AMERICAS: foilsales.usa@vishay.com

∑ ASIA/JAPAN: foilsales.asia@vishay.com ∑ UK/HOLLAND/SCANDANAVIA: foilsales.eunorth@vishay.com ∑ GERMANY/CZECH REPUBLIC/AUSTRIA: foilsales.eucentral@vishay.com

SALES

Bulk Metal

Æ

Foil Technology

Discrete Surface Mount Chip Resistors

MIL-PRF-55342G

VSM

TEST

CHARACTERISTIC. E

MAXIMUM

R LIMITS

R LIMITS*

Thermal Shock

± 0.10%

± 0.02%

Low Temperature Operation

± 0.10%

± 0.02%

Short Time Overload

± 0.10%

± 0.02%

High Temperature Exposure

± 0.10%

± 0.05%

Resistance to Bonding

± 0.20%

± 0.05%

Moisture Resistance

± 0.20%

± 0.10%

Life 2000 hours @ + 70

∞

C

± 0.50%

± 0.025%

The VSM0805 represents the latest addition and smallest size

to the Precision Bulk Metal

Æ

Foil (BMF) technology surface

mount chip resistor series. The VSM0805 has a conventional

full wrap around termination.

The BMF technology offers designers the lowest and most

predictable absolute Temperature Coefficient Resistance

available. The TCR is a process capability not a selection

process and for the most part is independent of ohmic value

and lot related variations.

The availability of tight absolute tolerance provides a good cost

solution for the variability of other components when compiling

the total error budget. BMF offers the best stability available;

and is an order of magnitude better than thin film technology.

The noise generated by the resistor is non measurable and its

design and construction make it well suited for high frequency

applications. The BMF is the ultimate resistor component for

analog applications.

VALUE

TIGHTEST

(

)

TOLERANCE (%)*

250 to 12K

± 0.01

100 to < 250

± 0.02

50 to < 100

± 0.05

25 to < 50

± 0.1

10 to < 25

± 0.25

5.5 to <10

± 0.5

FEATURES

∑ Nominal TCR: + 0.6ppm/∞C (0 to 25∞C)

- 0.6ppm/C∞ (+ 25∞C to + 60∞C)

+ 2.2ppm/∞C (- 55∞C to + 25∞C)

- 1.8ppm/∞C (+ 25∞C to + 125∞C)

∑ Absolute Tolerance: to ± 0.01%

∑ Resistance Range: 5.5 to 12K

∑ Load Life Stability: ± 0.025% (2000 hours @ 70∞C)

∑ Shelf Life Stability: 0.005% Maximum R

∑ Voltage Coefficient: < 0.00001%/volt (< 0.1ppm/V)

∑ Current Noise: < - 40dB

∑ Non Inductive: < 0.08µH

∑ Terminal Finishes Available:

Lead (Pb)-free (Sn 99.3% Cu 0.7%)

Tin/Lead Alloy (Sn 62% Pb 36% Ag 2%)

*As shown + 0.01 Ohms to allow for measurement errors at low values.

The TCR for values < 100 are influenced by the termination

composition and result in a deviation from this curve. Contact our

application engineering department for detailed specification on low

values

TABLE 1 - TOLERANCE VERSUS RESISTANCE VALUE

*Tighter tolerances are available. Please contact Application

Engineering. Soldering temperatures used during installation may

cause resistance to shift up to 0.05%.

TABLE 2 - TYPICAL PERFORMANCE SPECIFICATIONS

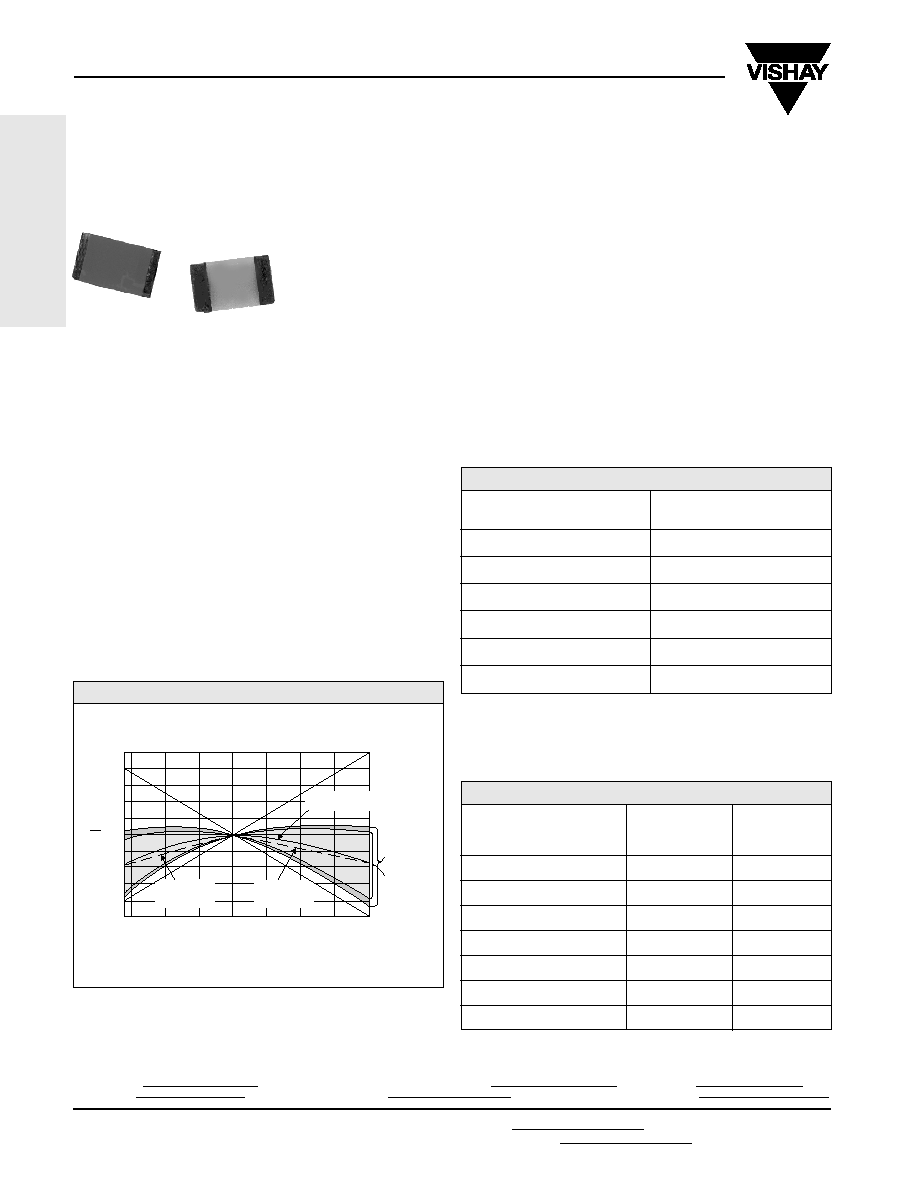

FIGURE 1 - NOMINAL TCR CURVE

Product may not

be to scale

Maximum

Spread

±2.3 ppm/∞C

+125

≠55

≠50

≠25

0

+25

+50

+75

+100

+500

+400

+300

+200

+100

0

≠100

≠200

≠300

≠400

≠500

Standard

Spread

±2.0 ppm/∞C

+2.2 ppm/∞C

Nominal Chord

Slope (TCR)

≠1.8 ppm/∞C

Nominal Chord

Slope (TCR)

≠55∞C / +25∞C / +125∞C are the test points

with +25∞C as the reference temperature

R

R

(ppm)

Nominal Resistance/

Temperature (RT) Curve

+5 ppm

-5 ppm

For technical questions in the Americas, contact foilsupport1@vishay.com

For technical questions in Asia/Japan/Europe/Africa/Israel, contact foilsupport2@vishay.com

www.vishay.com

23

VSM0805

Vishay Foil Resistors

Document Number: 63061

Revision 17-Aug-04

SURF

ACE MOUNT

∑ ISRAEL: foilsales.israel@vishay.com ∑ FRANCE/SWITZERLAND/SOUTHERN EUROPE: foilsales.eusouth@vishay.com ∑ AMERICAS: foilsales.usa@vishay.com

∑ ASIA/JAPAN: foilsales.asia@vishay.com ∑ UK/HOLLAND/SCANDANAVIA: foilsales.eunorth@vishay.com ∑ GERMANY/CZECH REPUBLIC/AUSTRIA: foilsales.eucentral@vishay.com

SALES

Bulk Metal

Æ

Foil Technology

Discrete Surface Mount Chip Resistors

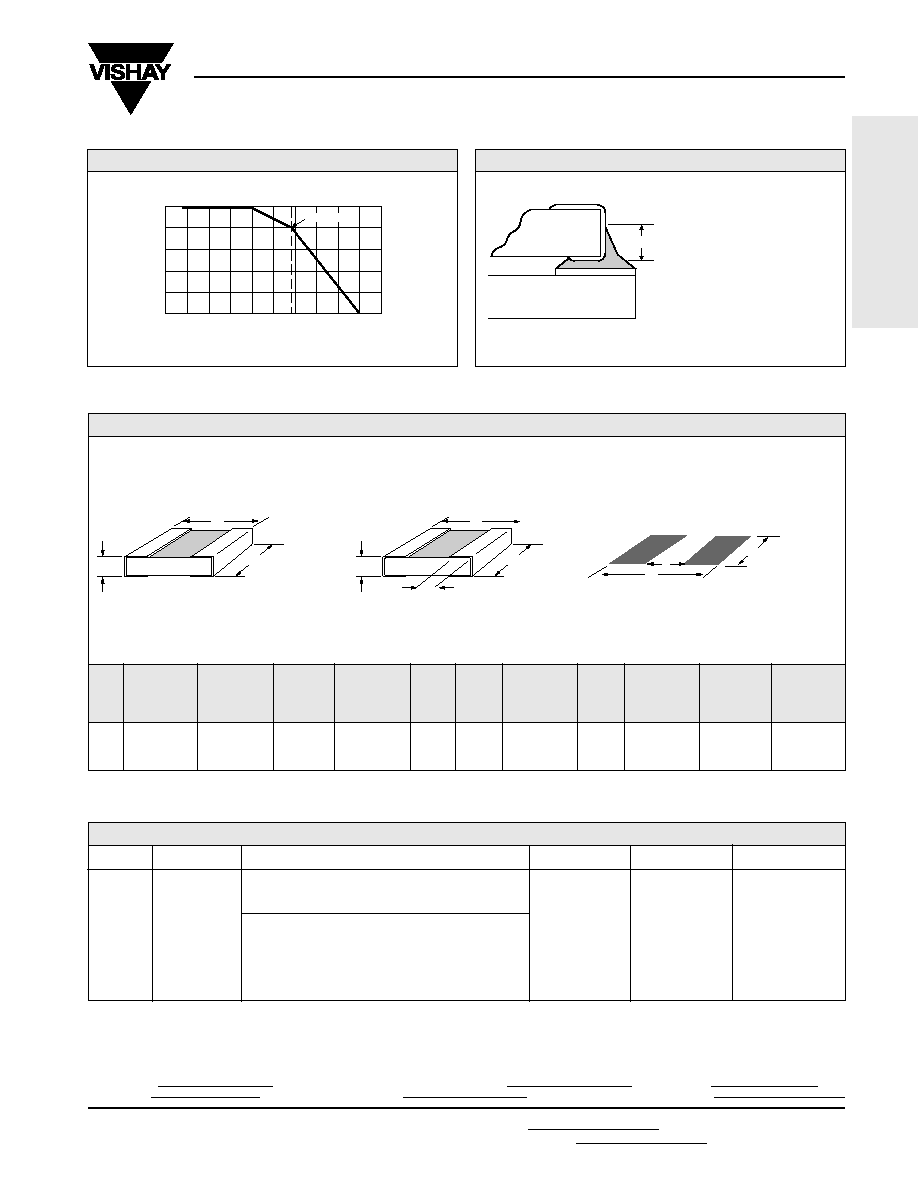

MODEL

CHIP SIZE

RESISTANCE VALUE

TOLERANCE TERMINATION

PACKAGING

VSM

0805

RESISTANCE

LETTER

MULTIPLIER

T ± 0.01%

S - Lead (Pb)-free

T = Tape and

RANGE

DESIGNATOR

FACTOR

Q ± 0.02%

B - Tin/Lead

Reel

A ± 0.05%

W = Waffle

5 to <1K

R

x 1.0

B ± 0.1%

PacK

Example: 249R00 = 249

C ± 0.25%

D ± 0.5%

F ± 1.0%

T

W

L

D

T

W

L

1K to 12K

K

x 10

3

Example: 10K000 = 10.0K

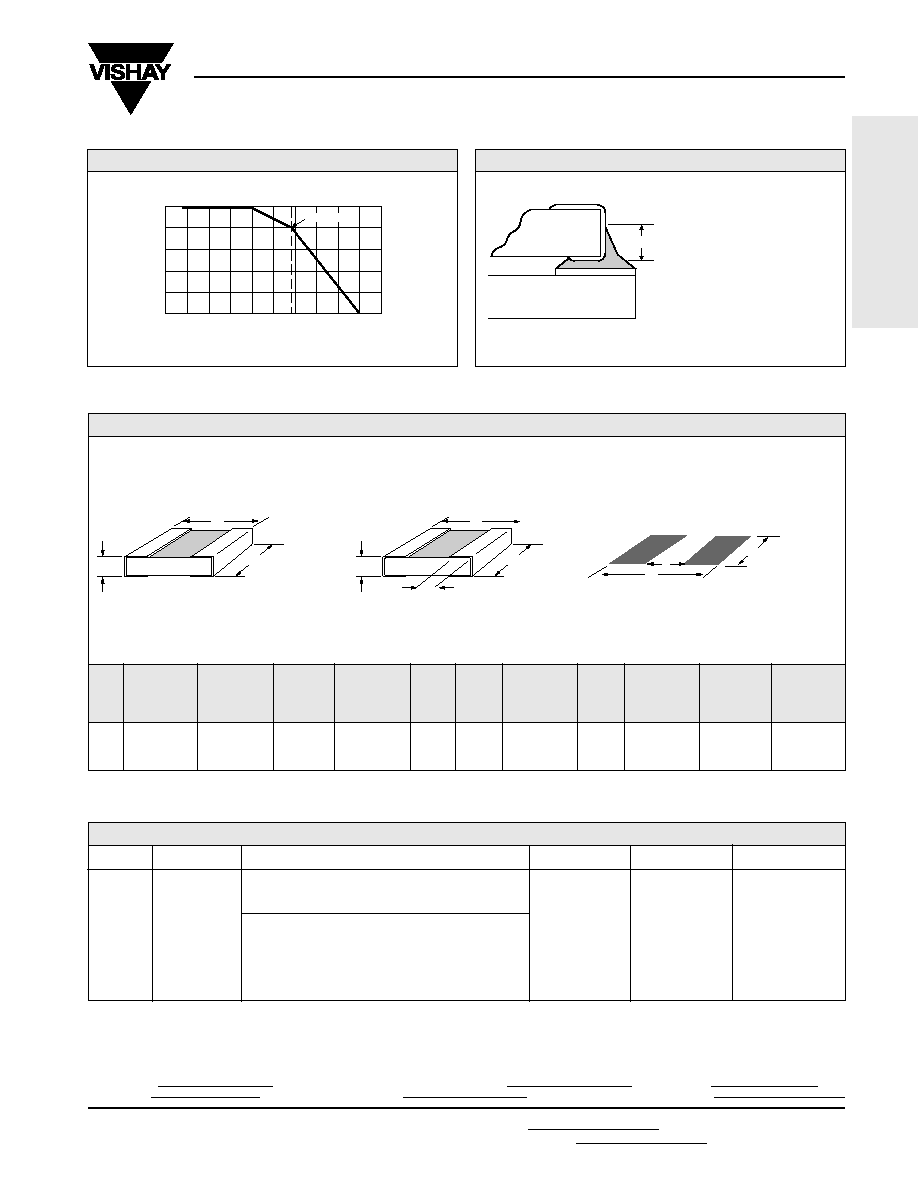

FIGURE 3 - RECOMMENDED MOUNTING

CHIP

POWER MAXIMUM RESISTANCE MAXIMUM

SIZE

L

W

T

D

+ 70

∞

C VOLTAGE

RANGE

WEIGHT

Z*

G*

X*

±

0.005 (0.13)

±

0.005 (0.13) MAXIMUM

±

0.005 (0.13) (mW)

(V)

(

)

(mG)

±

0.004 (0.10)

±

0.004 (0.10)

±

0.004 (0.10)

0805

0.080 (2.03)

0.050 (1.27) 0.025 (0.64) 0.015 (0.38)

50

22

5.5 - 12K

6

0.122 (3.10)

0.028 (0.70)

0.050 (1.27)

*Land Pattern Dimensions (Z, G, X) are per IPC-782A

TABLE 3 - CHIP SIZES AND SPECIFICATIONS in inches (millimeters)

TABLE 4 - ORDERING INFORMATION - VSM STYLE CHIP RESISTORS

FIGURE 2 - POWER DERATING CURVE

125

100

75

50

25

0

-75

≠50

≠25

0

+25

+50

+75

+100 +125 +150 +175

Ambient Temperature (∞C)

Percent of Rated Power

≠55∞C

+70∞C

Rated Power

Footprint

G

Z

X

Top View

Bottom View

Recommended Land Pattern

25% to 85% of T

A low profile solder fillet is recommended

to avoid unnecessary stresses along

top edge of metallization. IR and vapor

phase reflow are best. Avoid the use of

cleaning agents which could attack

epoxy resins, which form part of the

resistor construction.