| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: ZMD31050 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Copyright © 2005, ZMD AG, Rev. 0.95, 2005-09-16

1/20

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior

written consent of the copyright owner. The Information furnished in this publication is preliminary and subject to changes without notice.

ZMD31050

Advanced Differential Sensor Signal Conditioner

Datasheet

PRELIMINARY

Features

∑

Digital compensation of sensor offset, sensitivity,

temperature drift and non-linearity

∑

Accommodates nearly all bridge sensor types

(signal spans from 1 up to 275mV/V processable)

∑

Digital one-shot calibration: quick and precise

∑

Selectable compensation temperature T1 source:

bridge, thermistor, internal diode or external diode

∑

Output options: voltage (0...5V), current

(4...20mA), PWM, I

2

C, SPI, ZACwire

TM

(one-wire-

interface), alarm

∑

Adjustable output resolution (up to 15 bits) versus

sampling rate (up to 3.9kHz)

∑

Selectable bridge excitation: ratiometric voltage,

constant voltage or constant current

∑

Input channel for separate temperature sensor

∑

Sensor connection and common mode check

(Sensor aging detection)

∑

operation temperature, depending on product

version, up to -40...+125∞C (-40...+150∞C derated)

∑

Supply voltage +2.7V...+5.5V

∑

Available in SSOP16 or as die

Benefits

∑

No external trimming components required

∑

PC-controlled configuration and calibration via

digital bus interface - simple, low cost

∑

High accuracy (±0.1% FSO @ -25...85∞C; ±0.25%

FSO @ -40...125∞C)

Brief Description

ZMD31050 is a CMOS integrated circuit for highly-

accurate amplification and sensor-specific correction

of bridge sensor signals. The device provides digital

compensation of sensor offset, sensitivity, temperature

drift and non-linearity by a 16-bit RISC micro controller

running

a

correction

algorithm

with correction

coefficients stored in non-volatile EEPROM.

The ZMD31050 accommodates virtually any bridge

sensor (e.g. piezo-resistive, ceramic-thickfilm or steel

membrane based). In addition, the IC can interface a

separate temperature sensor.

The

bi-directional

digital

interfaces

(I

2

C,

SPI,

ZACwire

TM

) can be used for a simple PC-controlled

one-shot calibration procedure, in order to program a

set of calibration coefficients into an on-chip

EEPROM. Thus a specific sensor and a ZMD31050

are mated digitally: fast, precise and without the cost

overhead

associated

with

laser

trimming,

or

mechanical potentiometer methods.

ß

Application kit available (SSOP16 samples,

calibration PCB, calibration software, technical

documentation)

ß

Support for industrial mass calibration

available

ß

Quick circuit customization possible for large

production volumes

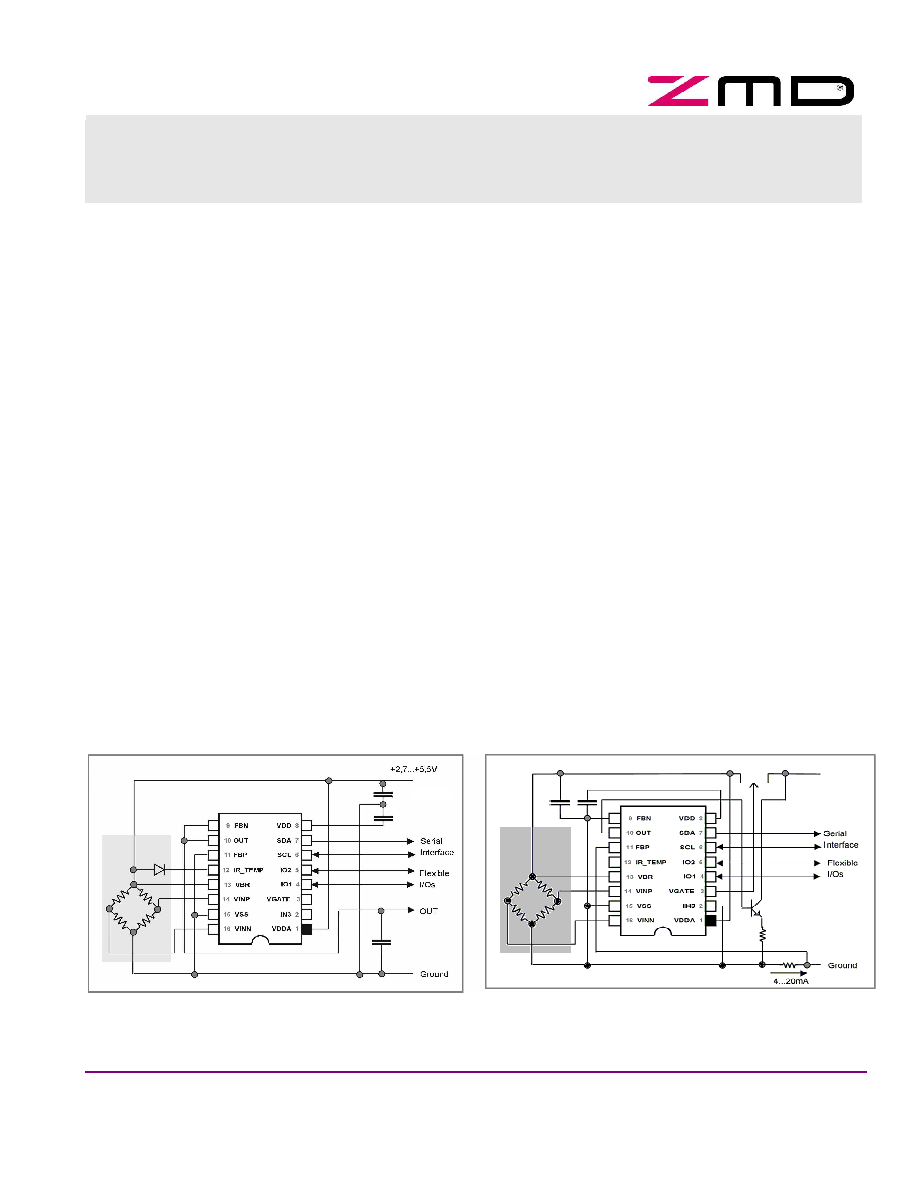

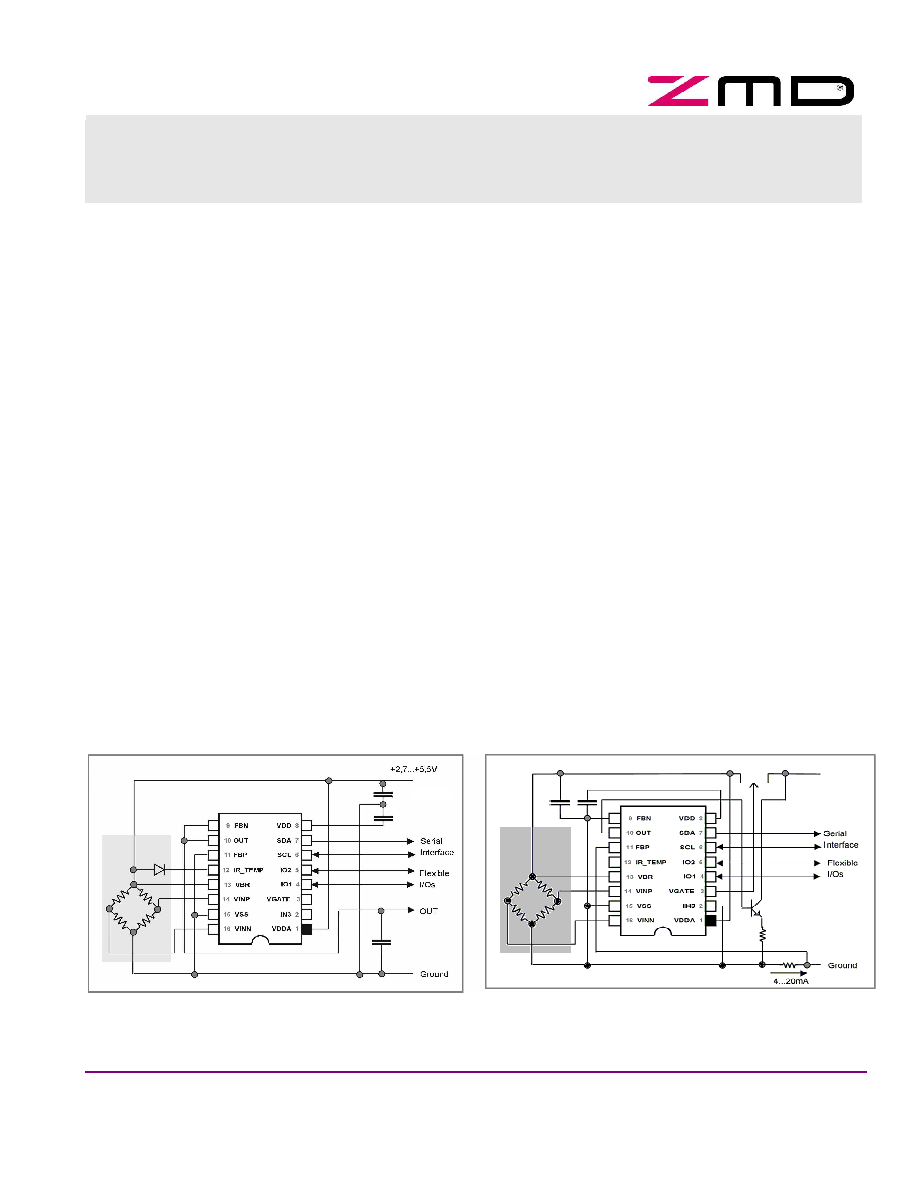

Application Circuit (Examples)

Fig.1: Ratiometric measurement with voltage output,

temperature compensation via external diode

R

e

R

sens

Refer also chapter 2 for additional application circuits and details

Fig.2: Two-wire-(4 to 20) mA configuration [(7 to 40) V],

temperature compensation via internal diode

V

SUPP

+7...+40 V

100

nF

100

nF

VDDA = 5 V

(50 )

(120 )

100 nF

100 nF

V

SUPP

15 nF

Copyright © 2005, ZMD AG, Rev. 0.95, 2005-09-16

2/20

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior

written consent of the copyright owner. The Information furnished in this publication is preliminary and subject to changes without notice.

ZMD31050

Advanced Differential Sensor Signal Conditioner

Datasheet

PRELIMINARY

Contents

1.

CIRCUIT DESCRIPTION ........................................................................................................... 3

1.1

S

IGNAL

F

LOW

........................................................................................................................... 3

1.2

A

PPLICATION

M

ODES

................................................................................................................ 4

1.3

A

NALOG

F

RONT

E

ND

(AFE)....................................................................................................... 5

1.3.1.

Programmable Gain Amplifier........................................................................................... 5

1.3.2.

Analog Sensor Offset Compensation - Analog Zero Point Shift (AZS).............................. 5

1.3.3.

Measurement Cycle realized by Multiplexer...................................................................... 6

1.3.4.

Analog-to-Digital Converter .............................................................................................. 7

1.4

S

YSTEM

C

ONTROL

.................................................................................................................... 8

1.5

O

UTPUT

S

TAGE

........................................................................................................................ 9

1.5.1.

Analog Output ................................................................................................................ 10

1.5.2.

Comparator Module (ALARM Output)............................................................................. 10

1.5.3.

Serial Digital Interface .................................................................................................... 10

1.6

V

OLTAGE

R

EGULATOR

............................................................................................................ 11

1.7

W

ATCHDOG AND

E

RROR

D

ETECTION

....................................................................................... 11

2.

APPLICATION CIRCUIT EXAMPLES ..................................................................................... 12

3.

ESD/LATCH-UP-PROTECTION .............................................................................................. 13

4.

PIN CONFIGURATION AND PACKAGE ................................................................................. 13

5.

IC CHARACTERISTICS........................................................................................................... 14

5.1

A

BSOLUTE

M

AXIMUM

R

ATINGS

................................................................................................. 14

5.2

O

PERATING

C

ONDITIONS

(V

OLTAGES RELATED TO

VSS) ....................................................... 14

5.3

B

UILD

I

N

C

HARACTERISTICS

.................................................................................................... 15

5.4

E

LECTRICAL

P

ARAMETERS

(V

OLTAGES RELATED TO

VSS) .................................................... 17

5.5

I

NTERFACE

C

HARACTERISTICS

................................................................................................. 18

6.

TEST........................................................................................................................................ 19

7.

RELIABILITY ........................................................................................................................... 19

8.

CUSTOMIZATION ................................................................................................................... 19

9.

RELATED DOCUMENTS......................................................................................................... 19

Copyright © 2005, ZMD AG, Rev. 0.95, 2005-09-16

3/20

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior

written consent of the copyright owner. The Information furnished in this publication is preliminary and subject to changes without notice.

ZMD31050

Advanced Differential Sensor Signal Conditioner

Datasheet

PRELIMINARY

1.

CIRCUIT DESCRIPTION

1.1

Signal Flow

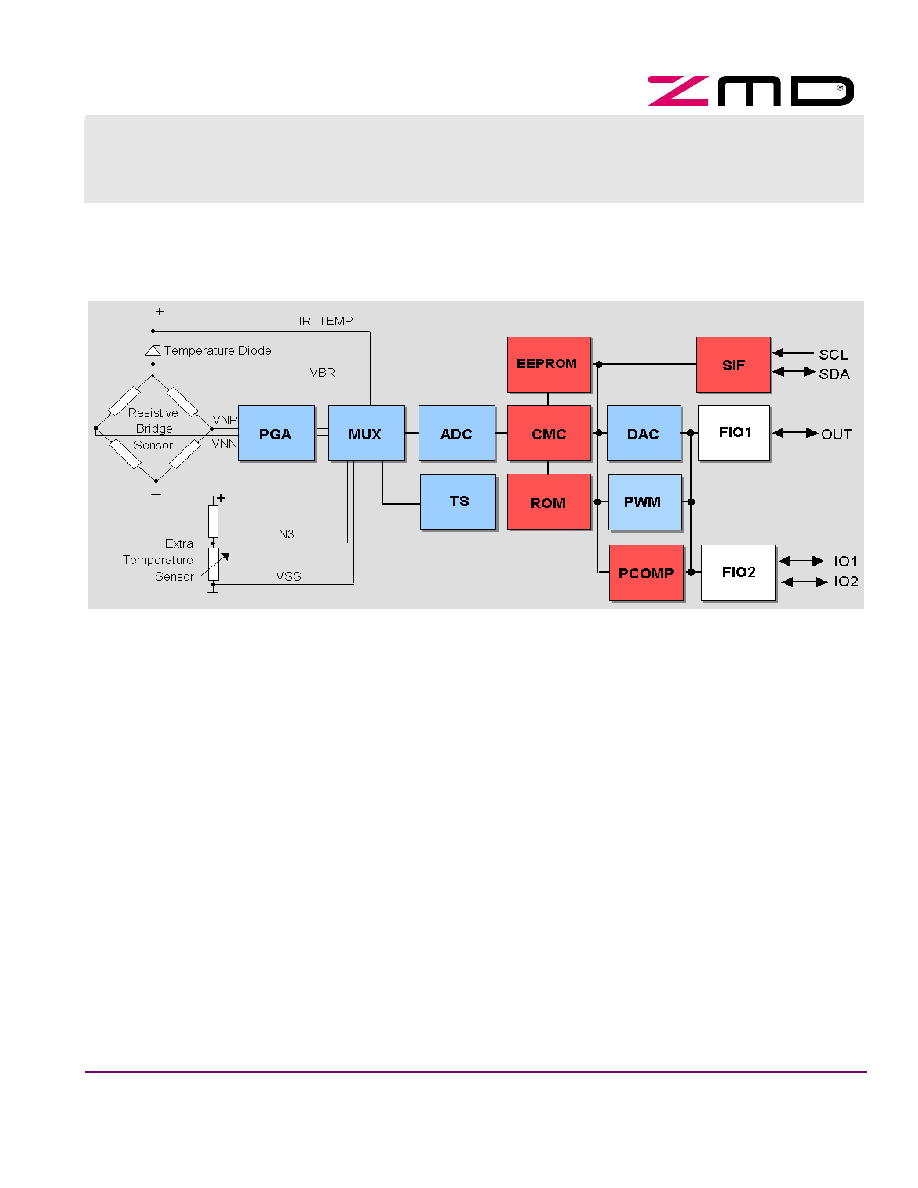

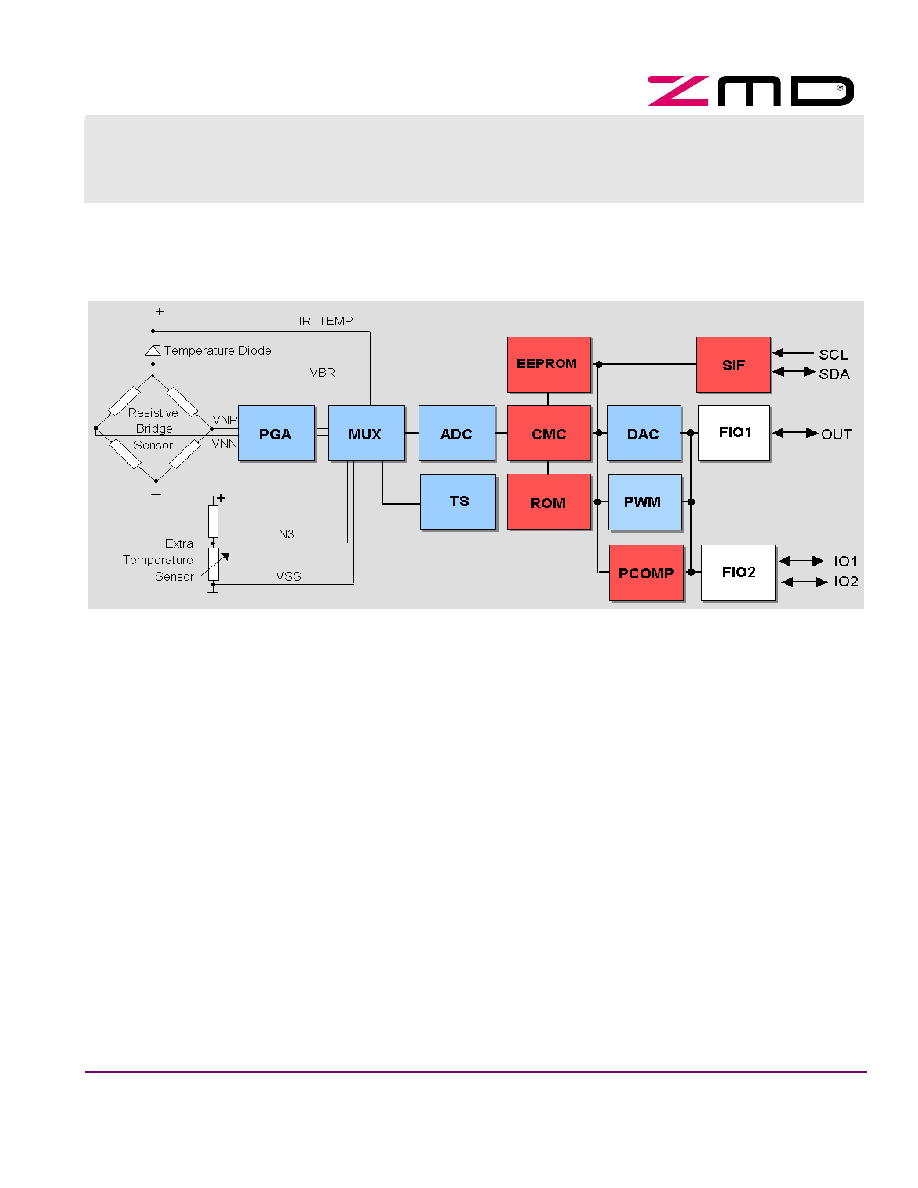

Fig.3: Block diagram of ZMD31050

PGA

programmable gain amplifier

MUX

multiplexer

ADC

analog-to-digital converter

CMC

calibration microcontroller

DAC

digital-to-analog converter

FIO1

flexible I/O 1: analog out (voltage/current), PWM2,

ZACwire

TM

(one-wire-interface)

FIO2

flexible I/O 2: PWM1, SPI data out, SPI slave select, Alarm1, Alarm2SIF

serial interface: I2C data I/O, SPI data in, clock

PCOMP

programmable comparator

EEPROM

for calibration parameters and configuration

TS

on-chip temperature sensor (pn-junction)

ROM

for correction formula and ≠algorithm

PWM

PWM module

The ZMD31050's signal path is partly analog (blue) and partly digital (red). The analog part is realized

differential ≠ this means internal is the differential bridge sensor signal also handled via two signal

lines, which are rejected symmetrically around a common mode potential (analog ground = VDDA/2).

Consequently it is possible to amplify positive and negative input signals, which are located in the

common mode range of the signal input.

The differential signal from the bridge sensor is pre-amplified by the programmable gain amplifier

(PGA). The Multiplexer (MUX) transmits the signals from bridge sensor, external diode or separate

temperature sensor to the ADC in a certain sequence (instead of the temperature diode the internal

pn-junction (TS) can be used optionally). Afterwards the ADC converts these signals into digital values.

Copyright © 2005, ZMD AG, Rev. 0.95, 2005-09-16

4/20

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior

written consent of the copyright owner. The Information furnished in this publication is preliminary and subject to changes without notice.

ZMD31050

Advanced Differential Sensor Signal Conditioner

Datasheet

PRELIMINARY

The digital signal correction takes place in the calibration micro-controller (CMC). It is based on a

special correction formula located in the ROM and on sensor-specific coefficients (stored into the

EEPROM during calibration). Dependent on the programmed output configuration the corrected sensor

signal is output as analog value, as PWM signal or in digital format (SPI, I

2

C,

ZACwire

TM

). The output

signal is provided at 2 flexible I/O modules (FIO) and at the serial interface (SIF). The configuration

data and the correction parameters can be programmed into the EEPROM via the digital interfaces.

The modular circuit concept enables fast custom designs varying these blocks and, as a result,

functionality and die size.

1.2

Application Modes

For each application a configuration set has to be established (generally prior to calibration) by

programming the on-chip EEPROM regarding to the following modes:

ß

Sensor channel

-

Sensor mode: ratiometric voltage or current supply mode.

-

Input range: The gain of the analog front end has to be chosen with respect to the maximum

sensor signal span and to this has also adjusted the zero point of the ADC

-

Additional offset compensation: The extended analog offset compensation has to be enabled if

required, e.g. if the sensor offset voltage is near to or larger than the sensor span.

-

Resolution/response time: The A/D converter has to be configured for resolution and converting

scheme (first or second order). These settings influence the sampling rate, signal integration time

and this way the noise immunity. The Sample Order influences the response time too.

-

Ability to invert the sensor bridge inputs

ß

Analog output

-

Choice of output method (voltage value, current loop, PWM) for output register 1.

-

Optional choice of additional output register 2: PWM via IO1 or alarm out module via IO1/2.

ß

Digital communication: The preferred protocol and its parameter have to be set.

ß

Temperature

-

The temperature measure source for the temperature correction has to be chosen.

-

The temperature measure source T1 sensor type

for the temperature correction has to be chosen

(only T1 is usable

for correction!!!)

-

Optional: the temperature measure channel as the second output has to be chosen.

ß

Supply voltage : For non-ratiometric output the voltage regulation has to be configured.

Note: Not all possible combinations of settings are allowed (see section 1.5).

The calibration procedure must include

-

the set of coefficients of calibration calculation

and, depending on configuration,

-

the adjustment of the extended offset compensation,

-

the zero compensation of temperature measurement,

-

the adjustment of the bridge current

and, if necessary,

-

the set of thresholds and delays for the alarms and the reference voltage.

Copyright © 2005, ZMD AG, Rev. 0.95, 2005-09-16

5/20

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior

written consent of the copyright owner. The Information furnished in this publication is preliminary and subject to changes without notice.

ZMD31050

Advanced Differential Sensor Signal Conditioner

Datasheet

PRELIMINARY

1.3

Analog Front End (AFE)

The analog front end consists of the programmable gain amplifier (PGA), the multiplexer (MUX) and

the analog-to-digital converter (ADC).

1.3.1.

Programmable Gain Amplifier

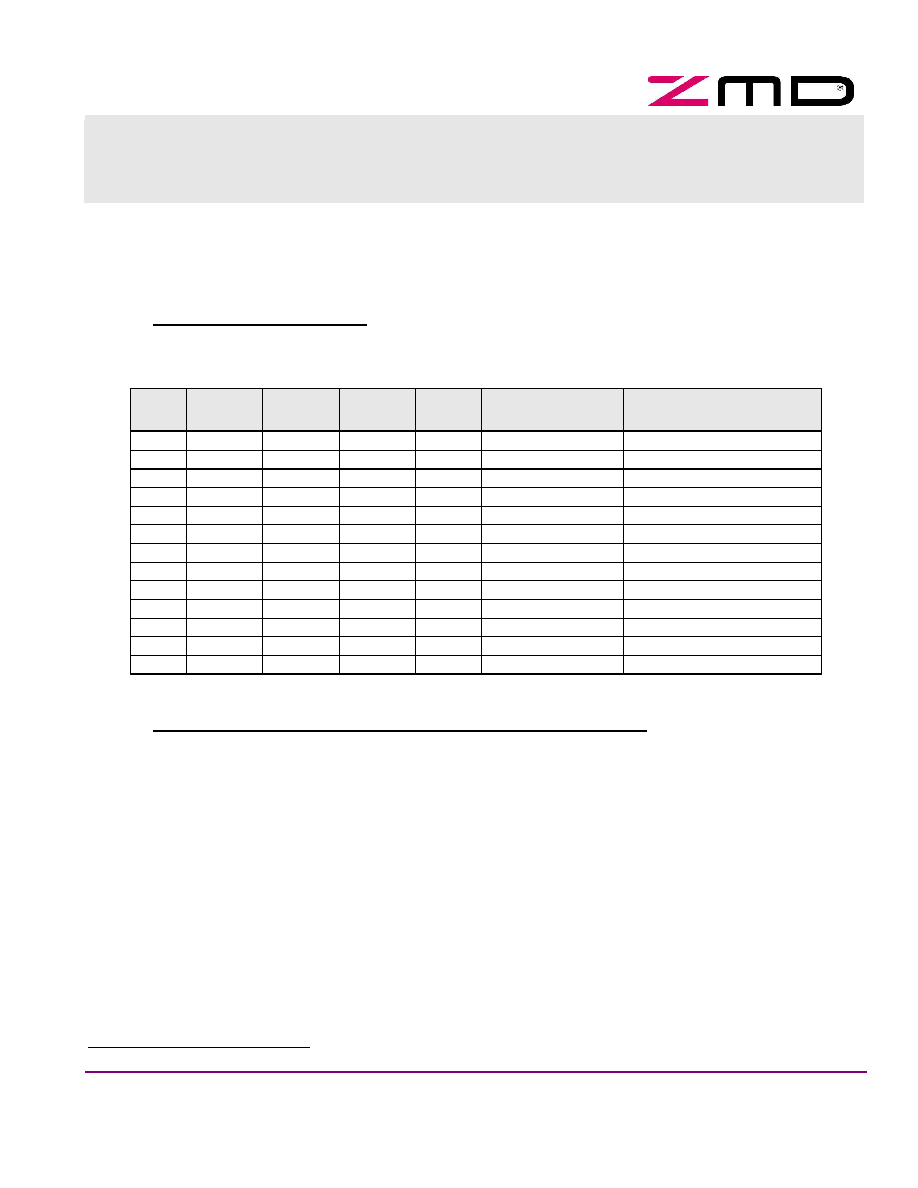

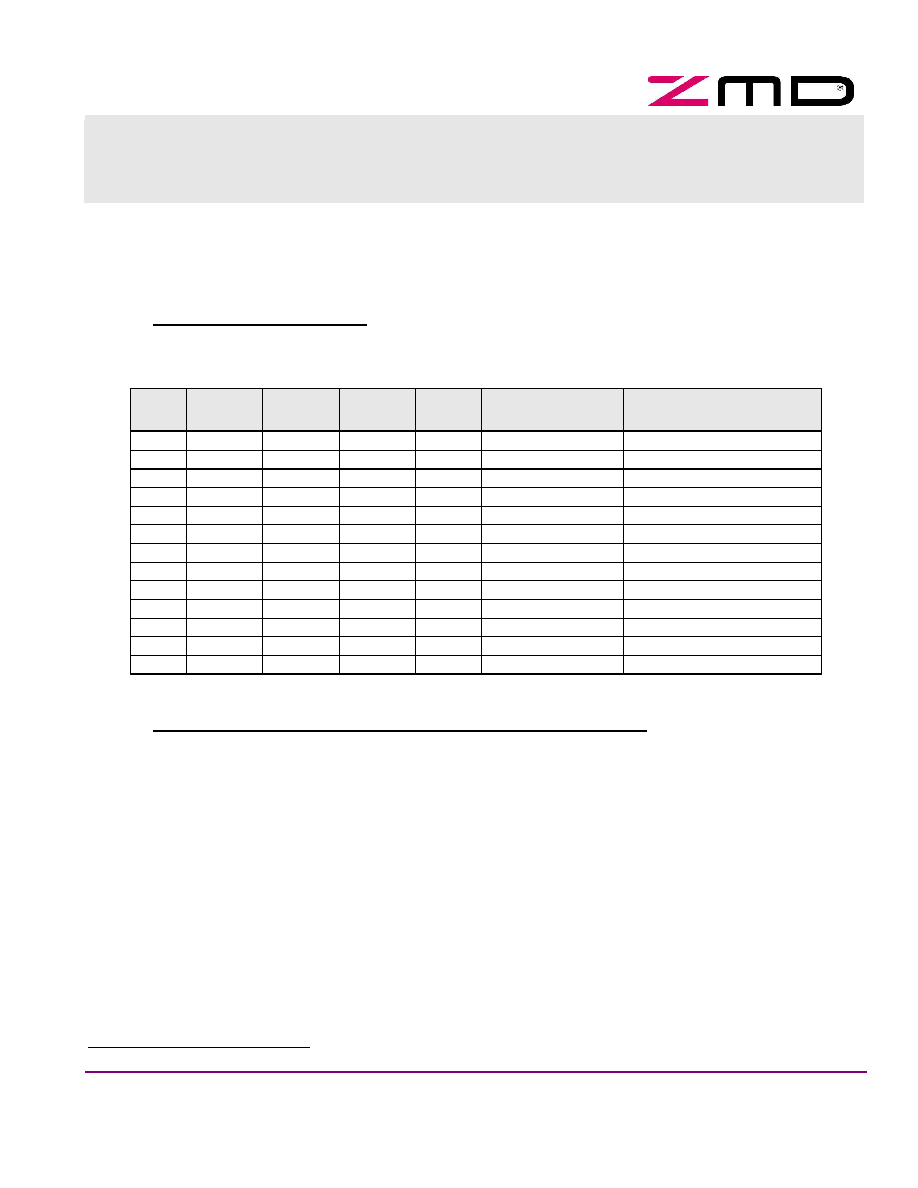

The following tables show the adjustable gains, the processable sensor signal spans and the allowed

common mode range.

No.

PGA

Gain a

IN

Gain

Amp1

Gain

Amp2

Gain

Amp3

Max. span

V

IN_SP

in mV/V

Input range

V

IN_CM

in % VDDA

1

420

30

7

2

2

43 - 57

2

280

30

4,66

2

3

40 - 59

3

210

15

7

2

4

43 - 57

4

140

15

4,66

2

6

40 - 59

5

105

15

3,5

2

8

38 - 62

6

70

7,5

4,66

2

12

40 - 59

7

52,5

7,5

3,5

2

16

38 - 62

8

35

3,75

4,66

2

24

40 - 59

9

26,3

3,75

3,5

2

32

38 - 62

10

14

1

7

2

50

43 - 57

11

9,3

1

4,66

2

80

40 - 59

12

7

1

3,5

2

100

38 - 62

13

2,8

1

1,4

2

280

21 - 76

Table 1: Adjustable gains, resulting sensor signal spans and common mode ranges

1.3.2.

Analog Sensor Offset Compensation - Analog Zero Point Shift (AZS)

The ZMD31050 supports two methods of sensor offset cancellation (zero shift):

∑

digital offset correction

∑

analog cancellation for large offset values (up to approx 300% of span)

Digital sensor offset correction will be processed at the digital signal correction/conditioning by the

CMC. Analog sensor offset pre-compensation will be needed for compensation of large offset values,

which would be overdrive the analog signal path by uncompensated gaining. For analog sensor offset

pre-compensation a compensation voltage will be added in the analog pre-gaining signal path (coarse

offset removal). The analog offset compensation in the AFE can be adjusted by 6 EEPROM bits. It

allows an Analog Zero Point Shift up to 300% of the processable signal span.

The zero point shift of the temperature measurements can also be adjusted by 6 EEPROM bits

(Z

AZS

= -25...+25) and is calculated by:

V

AZS

/ VDD

BR

= k * Z

AZS

/ ( 20 * a

IN

)

Bridge in voltage mode, refer "ZMD31050 Functional description" for usable input signal/common mode range at bridge in current mode